Isuzu KB P190. Manual — part 519

6A-62 ENGINE MECHANICAL (C24SE)

Installation

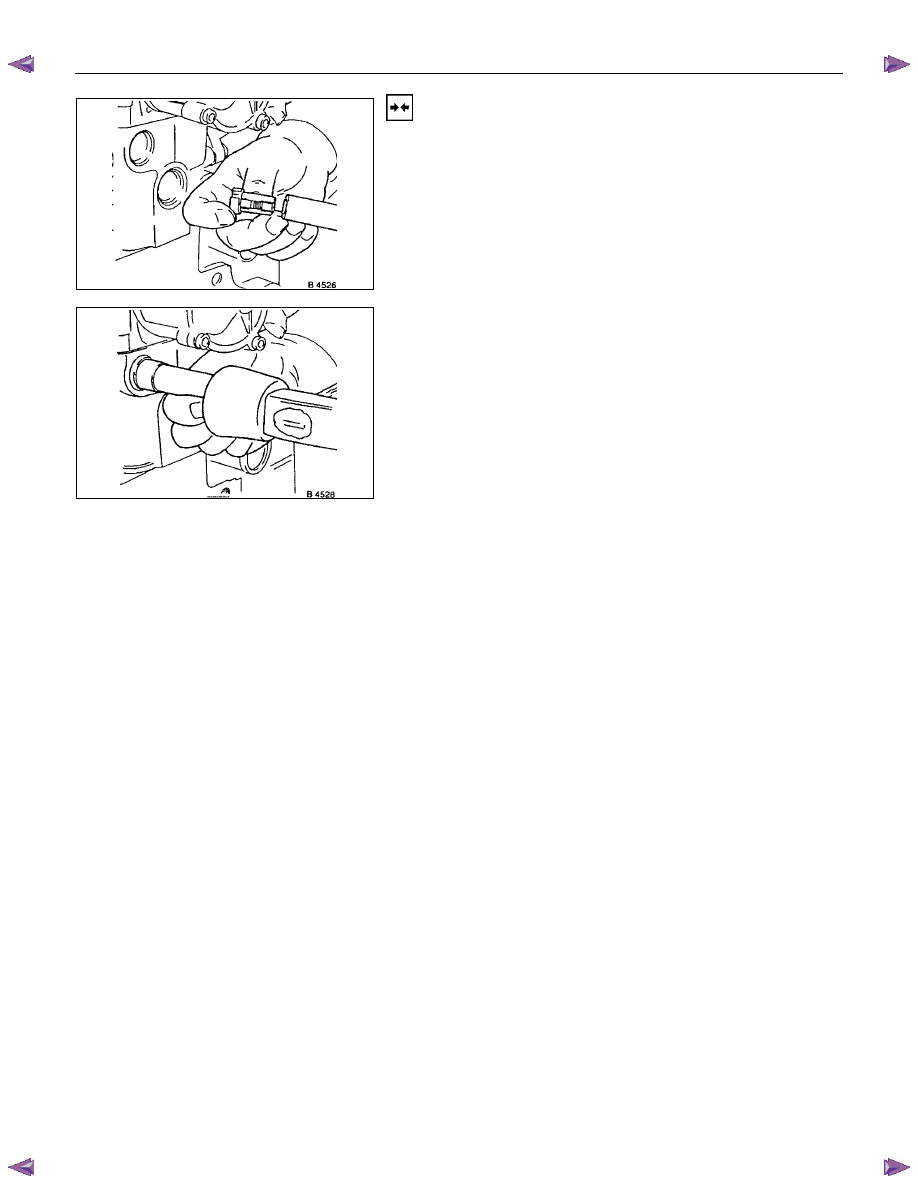

1. Install new pressure valve into cylinder head - with

suitable pipe until stop.

2. Install core hole plugs into cylinder head - with suitable

pipe to end of chamfer.

ENGINE MECHANICAL (C24SE) 6A-63

OPERATIONS ON COOLING SYSTEM

Caution!

Before working with the cooling system, be sure to confirm that

the temperature of the engine is cooled down.

Failure to observe this may cause burn.

Cooling System, Check for Leaks

Installation

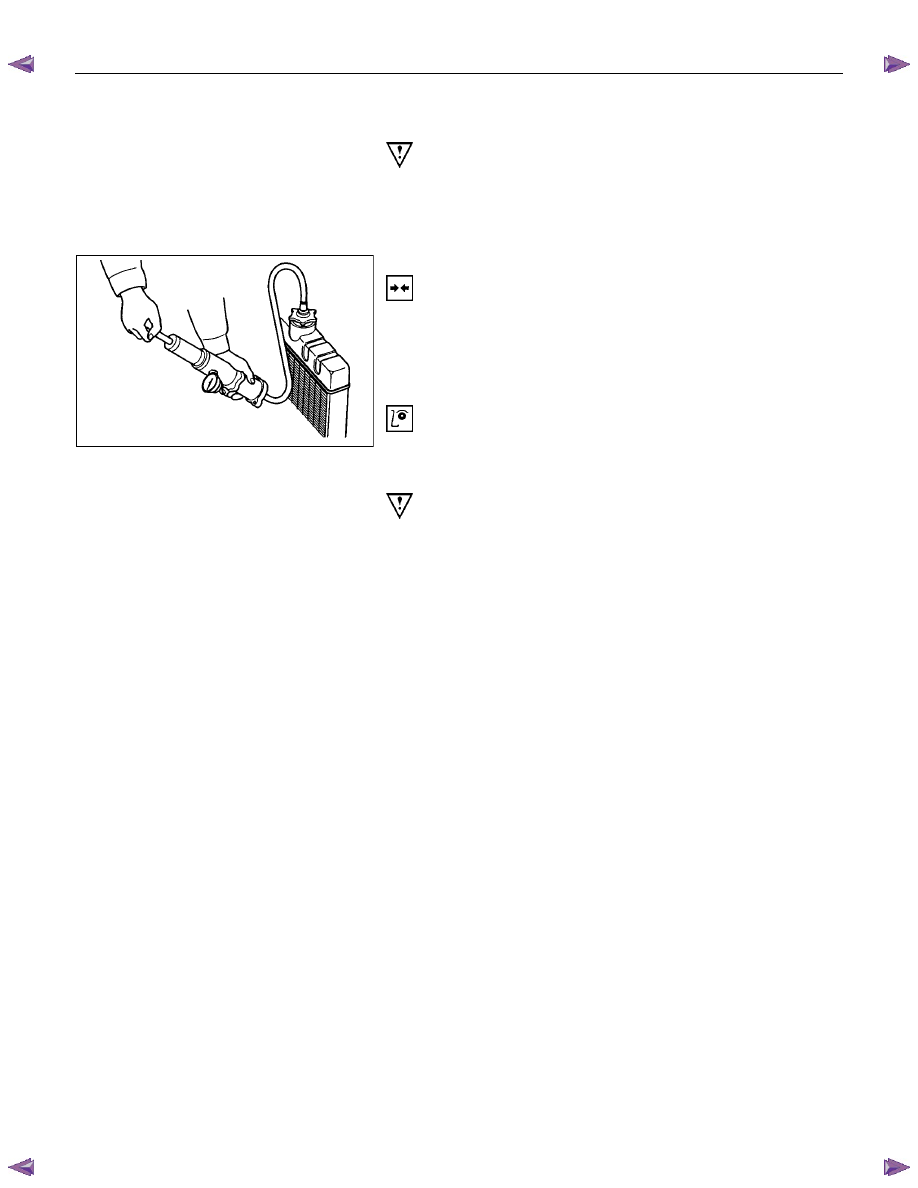

1. Install commercially available coolant checking

instrument onto compensation tank (Refer to section 6B;

Engine cooling).

2. Check coolant level.

Inspection

Use 5-8840-0277-0 tester & 5-8840-2603-0 adaptor.

Cooling System, Fill Up and Bleed

Important!

Radiator and heater core are made from alminium.

To avoid corrosion, use only anti-freeze with corrosion

protection.

Replace Coolant

1. Confirm the engine is cold enough.

2. Open the radiator cap, pour coolant to the filler neck level

and close the cap.

3. Pour coolant into the reservoir until MAX line is reached.

4. Start the engine, run 2

∼ 3 minutes at idling speed and

switch off the engine.

5. Refill coolant if the coolant level is lowered.

6A-64 ENGINE MECHANICAL (C24SE)

Important!

Do not loosen or open the radiator cap when coolant is hot.

Doing so may cause hot water or steam to splash out, resulting

in burn. When opening the radiator cap, be sure to confirm the

coolant is cold. Cover a thick cloth over the cap and loosen it

slowly to reduce pressure, then open the cap.

6. Close the radiator cap firmly and run the engine at

approx. 2000 rpm. In addition, set the heater temperature

adjuster to the max position to circulate coolant in the

heater conduit system.

7. Confirm that the temperature gauge reads half or more

of full scale and that the thermostat is activated.

Then continue idling 5 minutes more and switch off the

engine, and allow it to cool.

8. After the engine cools down, check the coolant level and

refill it if necessary. When the level is lowered extremely,

check the coolant conduit system and reservoir hose for

leak.

9. Pour coolant into the reservoir to MAX level.

Refill Coolant

Important!

After closing the cooling system, let engine run warm until

thermostat opens (coolant approx. 92

°C/197.6F)

Inspection

Coolant level

Allow engine to cool. If necessary, refill coolant.

Check that cooling system self-bleeds during engine warming-

up phase.

Ignition Timing, Check

No Adjustment

ENGINE MECHANICAL (C24SE) 6A-65

ENGINE EXTERNAL PARTS

Radiator

Removal

1. Disconnect battery ground cable.

2. Loosen a drain plug to drain EC.

3. Disconnect radiator inlet hose and outlet hose from the

engine.

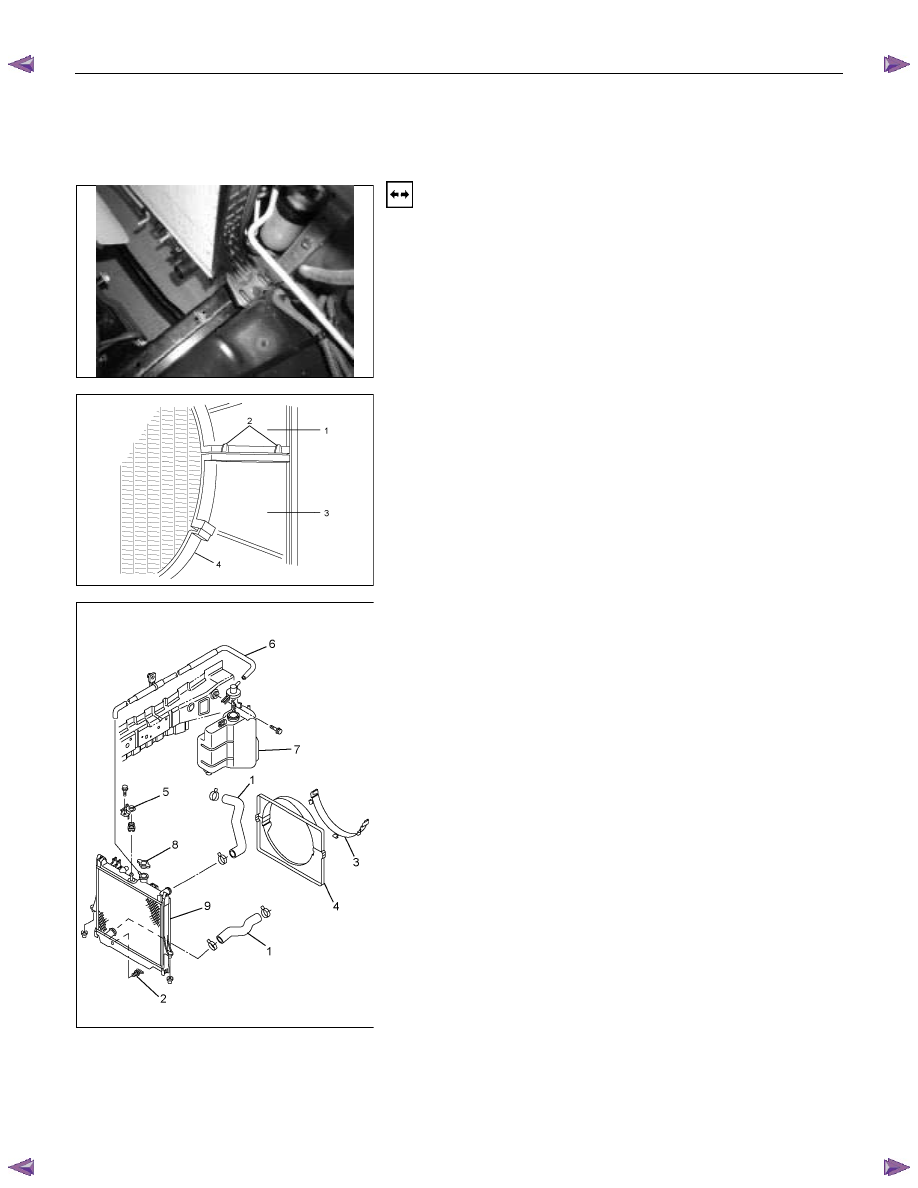

RTW46BSH000101

4. Remove fan guide(1), clips(2) on both sides and the

bottom lock, then remove lower fan guide(3) with fan

shroud(4).

5. Disconnect the reserve tank hose(6) from radiator.

RTW36BMH000101

6. Remove bracket(5).

7. Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with a fan

blade.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст