Isuzu KB P190. Manual — part 1021

7A2-118 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

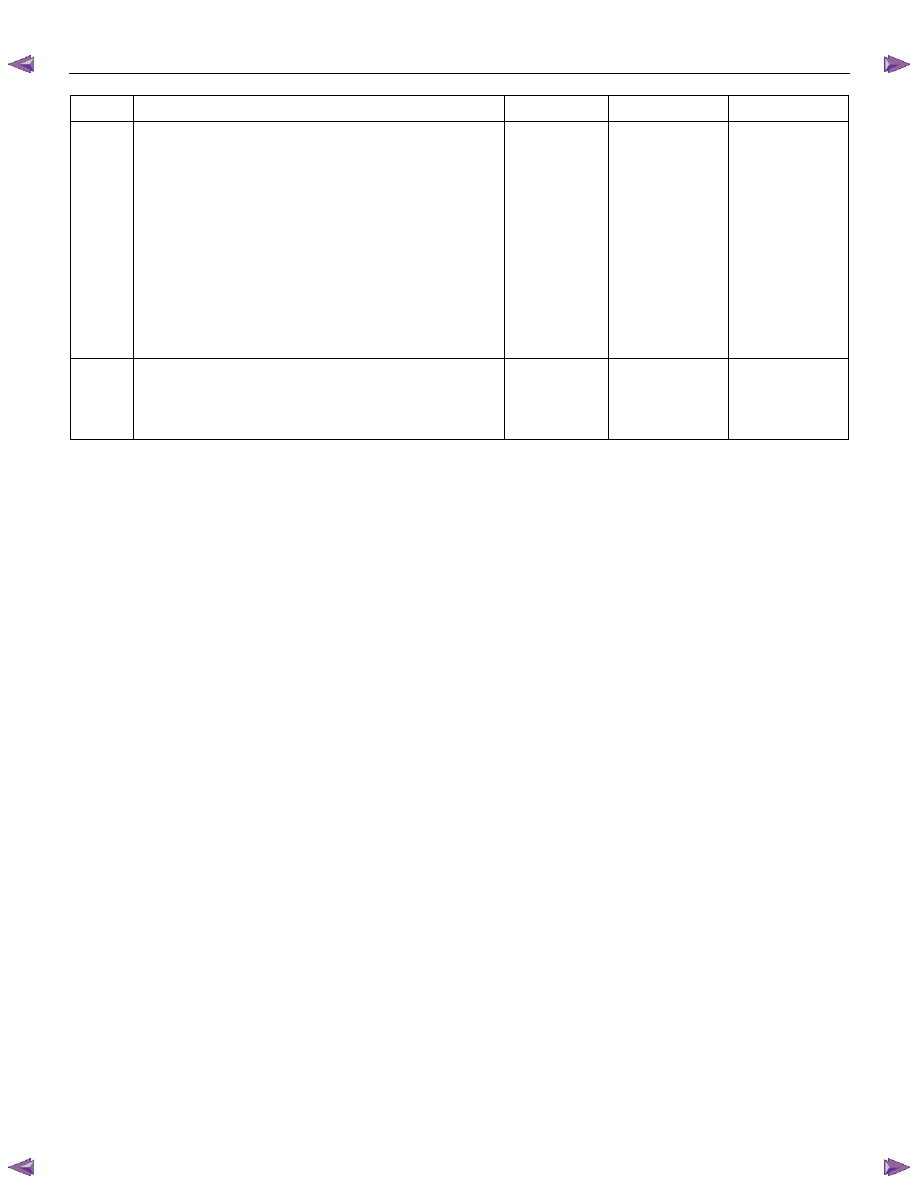

Circuit/System Testing DTC U2105

Step Action Value(s)

YES

NO

1

Was the On-Board Diagnostic (OBD) System Check

performed?

— Go

to

Step 2

Go to OBD

System Check

2

1. Install the scan tool.

2. Turn “ON” the ignition.

Does the scan tool indicate DTC U2105?

— Go

to

Step 3

Refer to

Diagnostic Aids

3

Observe the data from the ECM on a scan tool.

Was the data from the ECM fixed or did not

synchronized? (throttle opening, engine speed, etc)

— Go

to

Step 4

Refer to

Diagnostic Aids

4

Check the wire between the TCM connector and the

ECM connector by 5-8840-0285-0 DMM.

1. Turn “OFF” the ignition.

2. Disconnect the TCM connector.

3. Measure the resistance between terminal C94-7

and terminal C94-17.

Is the resistance specified value?

About 60

Ω

Go to Step 5

Go to Step 7

5

Check the resistance of the ECM.

1. Turn “OFF” the ignition.

2. Disconnect the ECM connector.

3. Measure the resistance between the ECM terminal

E66-66 and the ECM terminal E66-67.

Is the resistance specified value?

About 120

Ω

Go to Step 6

Go to Step 8

6

Replace or Repair the wire between the TCM

connector C94-7, 17 and the ECM connector E66-66,

67.

Is the action complete?

— Go

to

Step 9 —

7

Replace the TCM.

Important:

The replacement TCM must be

programmed (Refer to SPS for procedure).

Is the action complete?

— Go

to

Step 9 —

8

Replace the ECM.

Important:

The replacement ECM must be

programmed (Refer to SPS for procedure).

Is the action complete?

— Go

to

Step 9 —

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-119

Step Action Value(s)

YES

NO

9

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For

Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition?

—

Go to Step 2 Go

to

Step 10

10

Observe the stored information, Capture info with a

scan tool.

Are there any DTCs that you have not diagnosed?

—

Go to

Diagnostic

Trouble Code

(DTC) List

Verify repair

ON-VEHICLE SERVICE (AW30–40LE) 7A3-1

SECTION 7A3

ON-VEHICLE SERVICE (AW30–40LE)

TABLE OF CONTENTS

Service Precaution. . . . . . . . . . . . .. 7A3-2

Diagnosis . . . . . . . . . . . . . . . . . 7A3-3

Basic Troubleshooting . . . . . . . . . . 7A3-3

Manual Shifting Test . . . . . . . . . . ... 7A3-9

Stall Test . . . . . . . . . . . . . . . ... 7A3-9

Time Lag Test . . . . . . . . . . . . . ..7A3-10

Hydraulic Test . . . . . . . . . . . . . ..7A3-11

Road Test . . . . . . . . . . . . . . . .7A3-12

Shift Point Chart and Lock-Up Point Chart. . ..7A3-16

Shift Point Chart. . . . . . . . . . . . ...7A3-16

Lock-Up Point Chart. . . . . . . . . . . 7A3-17

Transmission Fluid Level and Condition. . . ..7A3-18

Inspection . . . . . . . . . . . . . . . .7A3-18

ATF Replacement. . . . . . . . . . . . ...7A3-19

Inspection . . . . . . . . . . . . . . . .7A3-19

Neutral Start Switch (Mode Switch). . . . . ..7A3-20

Inspection . . . . . . . . . . . . . . . .7A3-20

Removal. . . . . . . . . . . . . . . . 7A3-20

Installation. . . . . . . . . . . . . . . .7A3-20

Brake Signal . . . . . . . . . . . . . . . 7A3-21

Inspection . . . . . . . . . . . . . . . .7A3-21

Input and Output Revolution Sensor . . . . . 7A3-22

Inspection . . . . . . . . . . . . . . . .7A3-22

Power and 3rd Start switch. . . . . . . . . 7A3-22

Inspection . . . . . . . . . . . . . . . .7A3-22

Solenoid. . . . . . . . . . . . . . . . . 7A3-23

Inspection . . . . . . . . . . . . . . . .7A3-23

ATF Temperature Sensor. . . . . . . . . ..7A3-24

Inspection . . . . . . . . . . . . . . . .7A3-24

Select Lever . . . . . . . . . . . . . ...7A3-25

Remove or Disconnect . . . . . . . . . ... 7A3-26

Install or Connect . . . . . . . . . . . . 7A3-26

Shift Cable. . . . . . . . . . . . . . ..7A3-28

Remove or Disconnect . . . . . . . . . ... 7A3-28

Install or Connect . . . . . . . . . . . . 7A3-29

Torque Specifications . . . . . . . . . . . 7A3-30

Transmission Control Module (TCM). . . . ... 7A3-31

Removal . . . . . . . . . . . . . . . ... 7A3-31

Installation . . . . . . . . . . . . . . . 7A3-31

Shift Solenoid and Lock-Up Solenoid . . . . .. 7A3-32

Removal . . . . . . . . . . . . . . . ... 7A3-32

Installation . . . . . . . . . . . . . . . 7A3-33

Valve Body Assembly and Pressure

Control Solenoid. . . . . . . . . . . . . 7A3-34

Removal . . . . . . . . . . . . . . . ... 7A3-34

Installation . . . . . . . . . . . . . . . 7A3-36

Rear Oil Seal (Adapter Housing, 4

Removal . . . . . . . . . . . . . . . ... 7A3-37

Installation . . . . . . . . . . . . . . . 7A3-37

Rear Oil Seal (Extension Housing, 4

Removal . . . . . . . . . . . . . . . ... 7A3-38

Installation . . . . . . . . . . . . . . . 7A3-38

Transmission Assembly. . . . . . . . . . . 7A3-39

Transmission and Associated Parts . . . . . 7A3-39

Removal . . . . . . . . . . . . . . . ... 7A3-40

Installation . . . . . . . . . . . . . . . 7A3-44

Major Components. . . . . . . . . . . .. 7A3-49

7A3-2 ON-VEHICLE SERVICE (AW30–40LE)

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст