Isuzu KB P190. Manual — part 106

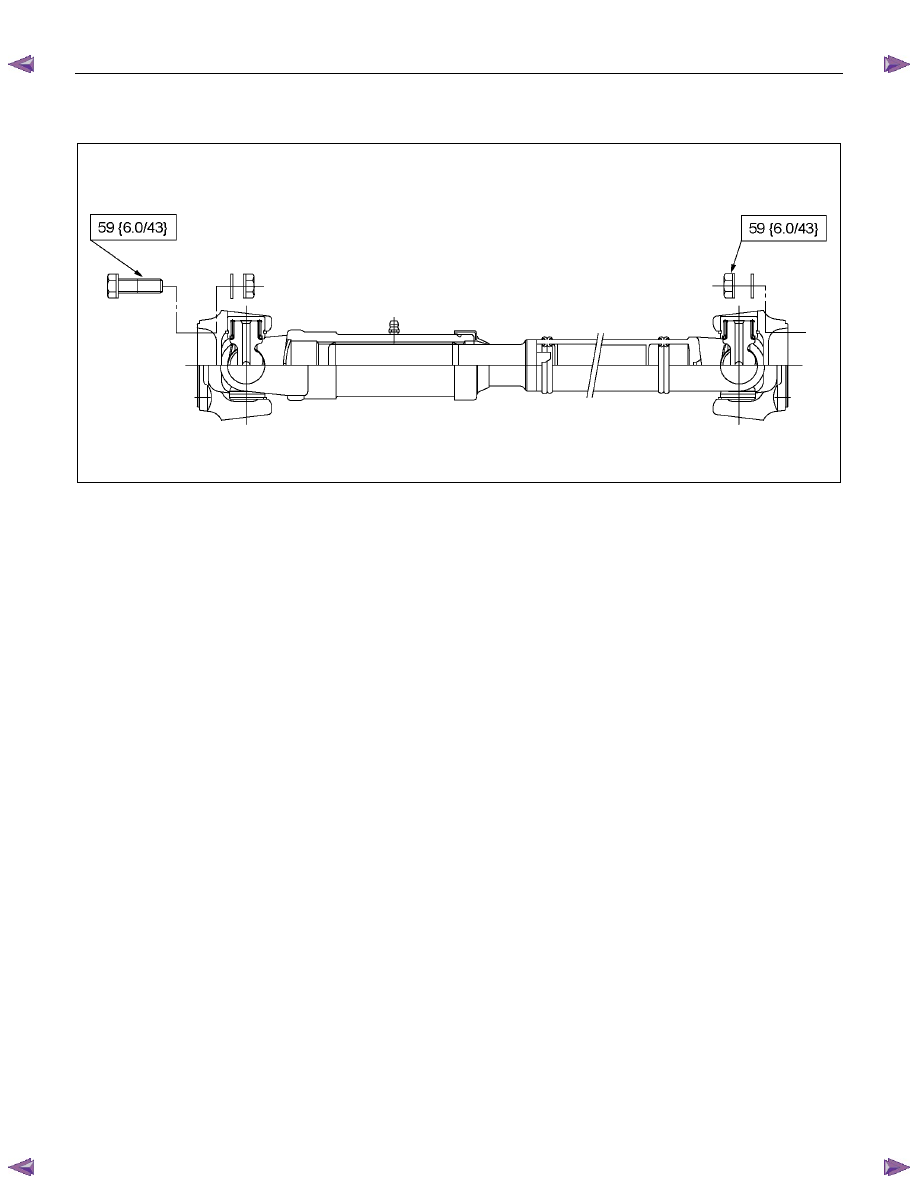

4A-8 PROPELLER SHAFT

Torque Specifications

N

⋅m (kgf⋅m/lb⋅ft)

RUW54ASF000501

PROPELLER SHAFT 4A-9

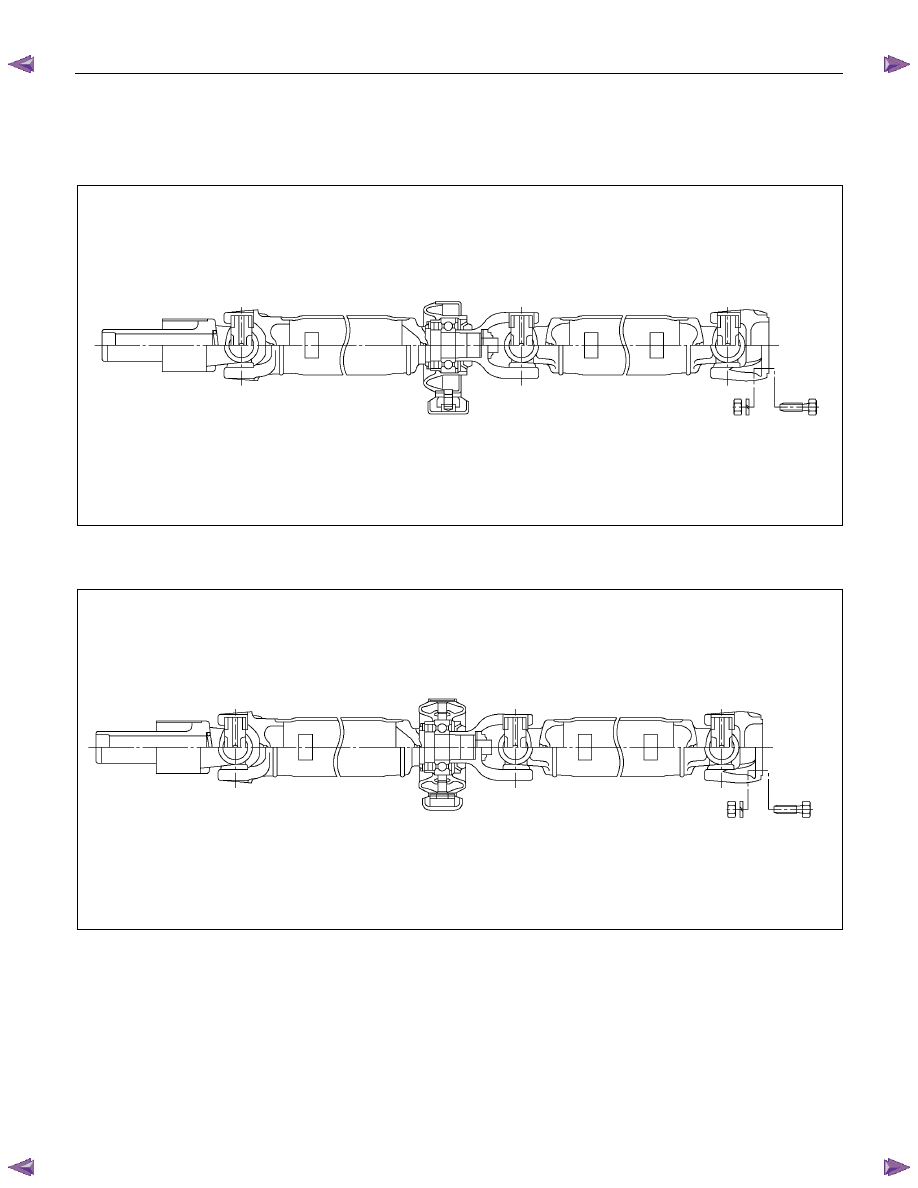

Rear Propeller Shaft

General Description

4×

×

×

×2 (Except High Ride Suspension) Model

F04R300001

4×

×

×

×2 (High Ride Suspension), 4×

×

×

×4 Model

401R300007

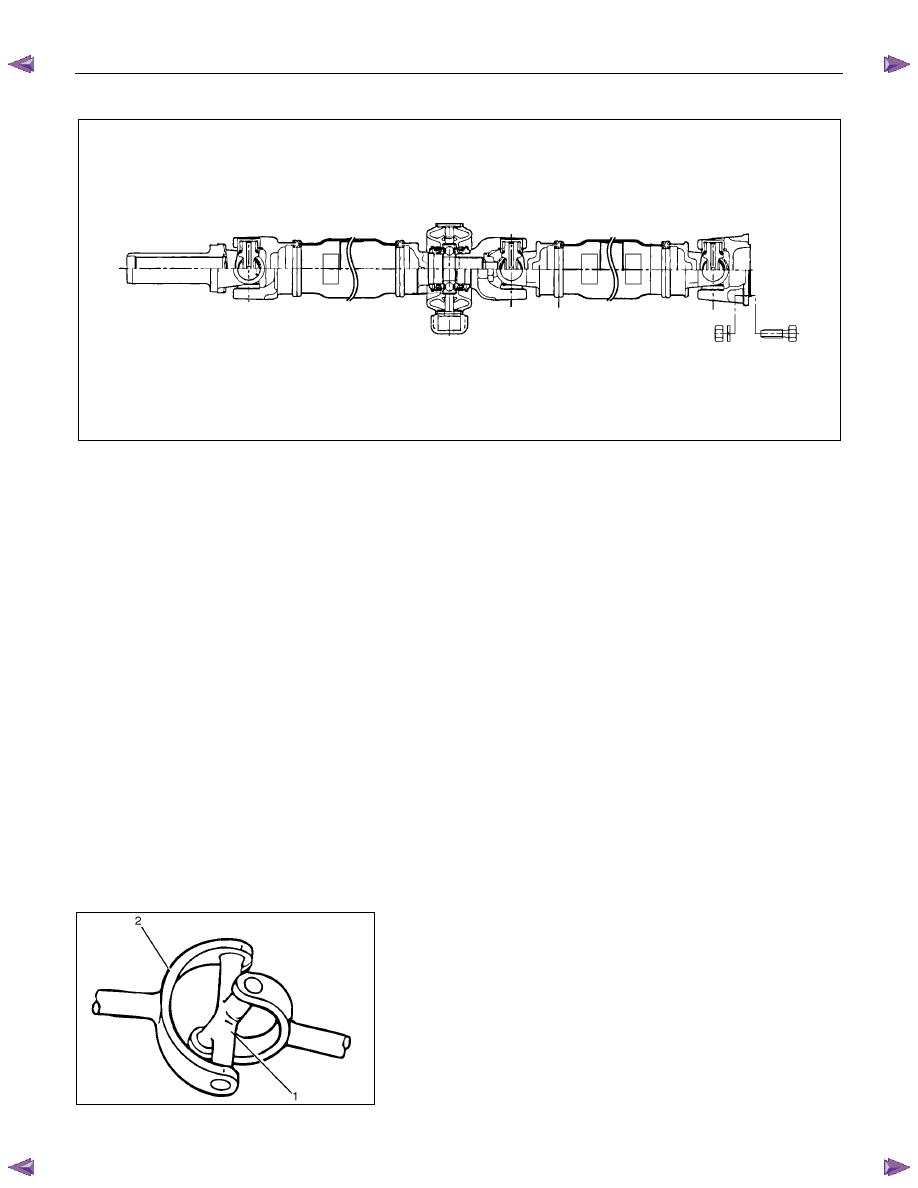

4A-10 PROPELLER SHAFT

4×

×

×

×2 M/T AR-5, 4×

×

×

×2 A/T 4L60-E Model

RTW64ASF000101

Torque is transmitted from the transmission to the

axle through propeller shaft and universal joint

assembles. All propeller shafts are the balanced

tubular type. A splined slip joint is provided in some

drivelines.

• Since the propeller shaft is total balanced carefully,

welding or any other modification are not permitted.

• Alignment marks should be applied to each

propeller shaft before removal.

• Be sure vehicle is stopped, engine is not running,

brake is secured and vehicle is secured to prevent

injury.

• Be careful not to grip the propeller shaft tube too

tightly in the bise as this will be cause deformation.

Phasing

The propeller shaft is designer and built with the yoke lugs

(ears) in line with each other. This design produces the

smoothest running shaft possible, called phasing. Vibration can

be caused by an out-of-phase propeller shaft. The propeller

shaft down each time the universal joint goes around. This

vibration would be the same as a person snapping rope and

watching the “wave” reaction flow to the end. A propeller shaft

working in phase would be similar to two persons snapping a

rope at the same time, and watching the “waves” meet and

cancel each other out. In comparison, this would be the same

as the universal joints on a propeller shaft. A total cancellation

of vibration produces a smooth flow of power in the driveline. It

is very important to apply a reference mark to the propeller

shaft before removal, to assure installation alignment.

401RW015

Universal Joint

A universal joint consists of two Y-shaped yokes (2) connected

by a crossmember called a spider (1).

The spider is shaped like a cross. Universal joints are designed

to handle the effects of various loadings and front or rear axle

windup during acceleration. Within the designed angle

variations, the universal joint will operate efficiently and safely.

When the design angle is changed or exceeded the

operational life of the joint may decrease.

The bearings used in universal joints are of the needle roller

type. The needle rollers are held in place on the trunnions by

round bearing cups. The bearing cups are held inside the

yokes by snap rings.

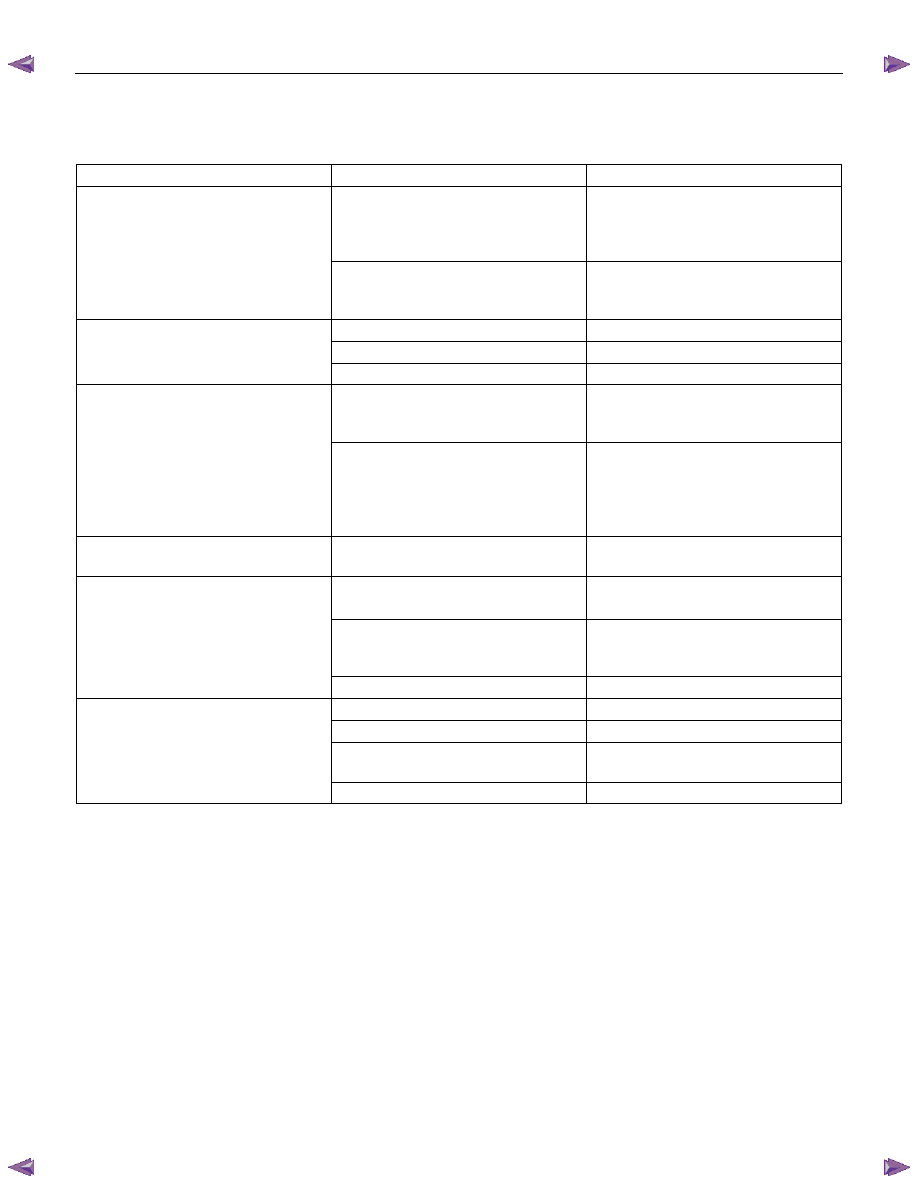

PROPELLER SHAFT 4A-11

Diagnosis of Propeller Shaft and

Universal Joint

Condition Possible

cause Correction

Rough surface on splined yoke;

burred nicked or worn.

Replace the seal. Minor burrs can

be Smoothed by careful use of

crocus cloth or fine stone honing.

Replace the yoke if badly burred.

Leak at the Front Slip Yoke (An

Occasional Drop of Lubricant

Leaking from the Splined Yoke is

Normal)

Defective transmission rear oil seal.

Replace the transmission rear oil

seal and replenish the transmission

oil.

Worn universal joint bearings.

Replace.

Improper lubrication.

Lubricate as directed.

Universal Joint Noise.

Loose flange bolts.

Tighten to specifications.

Loose bushing bolts on the rear

springs or upper and lower control

arms.

Tighten the bolts to specified

torque.

Ping, Snap, or Click in Drive Line

(Usually Heard on Initial Load after

the Transmission is in Forward or

Reverse Gear)

Loose or out-of-phase end yoke.

Remove end yoke, turn 180

degrees from its original position,

lubricate the splines and reinstall.

Tighten the bolts and pinion nut to

specified torque.

Squeak

Lack of lubricant.

Lubricate joints and splines. Also

check for worn or brinelled parts.

Loose or missing bolts at the

flanges.

Replace or tighten bolts to specified

torque.

Incorrectly set front joint angle.

Install shim under the transmission

support mount to change the front

joint angle.

Shudder on Acceleration (Low

Speed)

Worn universal joint.

Replace.

Incorrect shaft runout.

Replace.

Shaft out of balance.

Adjust.

Transmission rear housing bushing,

transfer case housing bushing worn.

Replace.

Vibration

Yoke spline jammed.

Replace.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст