Isuzu KB P190. Manual — part 362

6A-88 ENGINE MECHANICAL (4JK1/4JJ1)

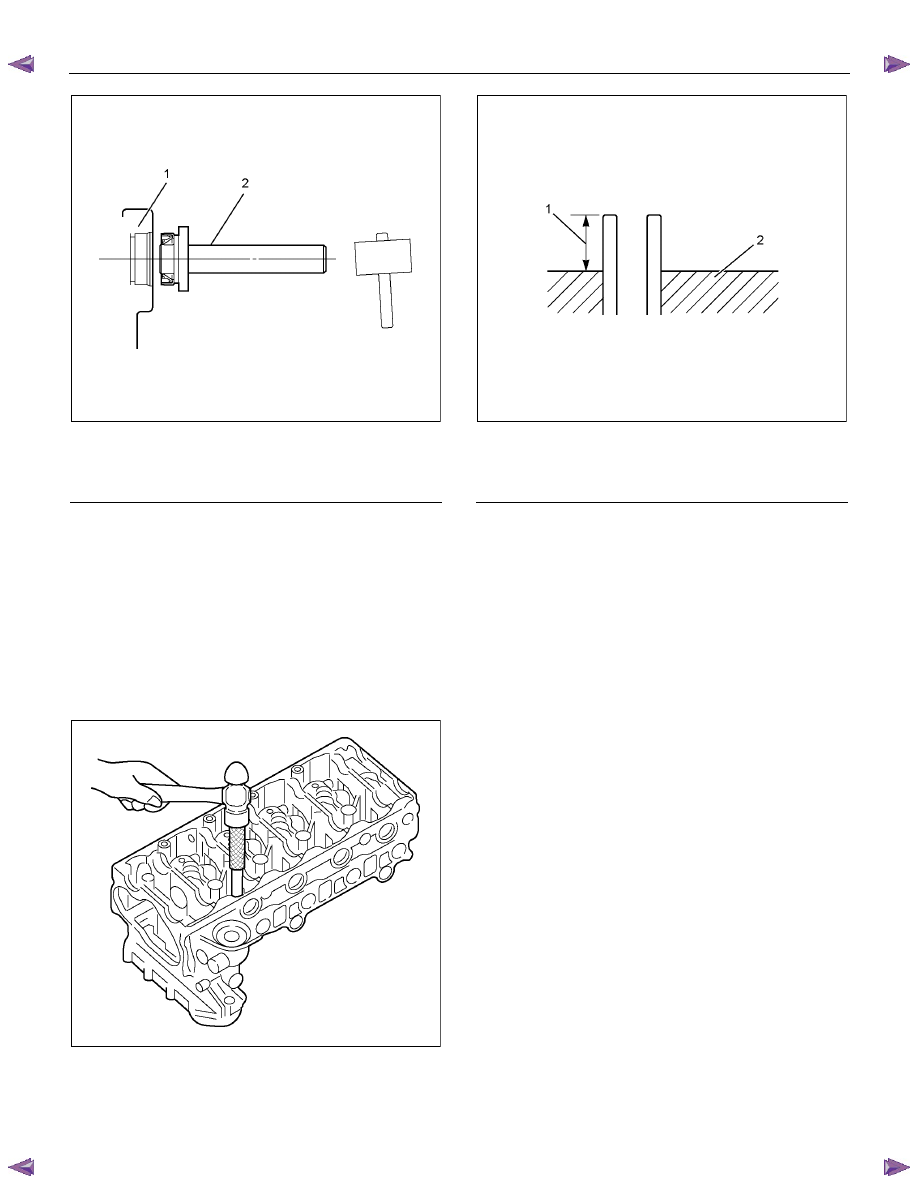

RTW56ASH009101

Legend

1. Cylinder

Head

2. Oil Seal Installer

2. Install the valve guide.

• Hammer in the valve guide from the upper

surface of the cylinder head, using the valve

guide installer.

Special

tool

Valve guide remover and installer:

5-8840-2816-0

Note:

When replacing the valve guide, it must be replaced

together with the valve.

RTW56ASH009001

• Height from the upper surface of the cylinder

head to the edge surface of the valve guide

RTW56ASH023001

Legend

1. 12.6 ± 0.1 mm (0.50 ± 0.0039 in)

2. Cylinder Head

3. Install the valve spring lower seat.

4. Install the valve stem oil seal.

• Refer to procedure for valve stem and valve in

this manual.

5. Install the intake and exhaust valve.

• Apply engine oil on the valve stem part and

install the valve.

6. Install the valve spring, the valve spring upper seat

and the split collar.

• Refer to procedure for valve stem and valve in

this manual.

7. Install the rocker arm and shaft assembly.

• Refer to procedure for valve stem and valve in

this manual.

8. Install the exhaust manifold assembly.

• Refer to procedure for Turbocharger and

Exhaust Manifold in this manual.

9. Install the turbocharger.

• Refer to procedure for Turbocharger and

Exhaust Manifold in this manual.

10. Install the intake manifold assembly.

• Refer to procedure for Intake Manifold in this

manual.

11. Install the throttle assembly.

• Refer to procedure for Intake Manifold in this

manual.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-89

Installation

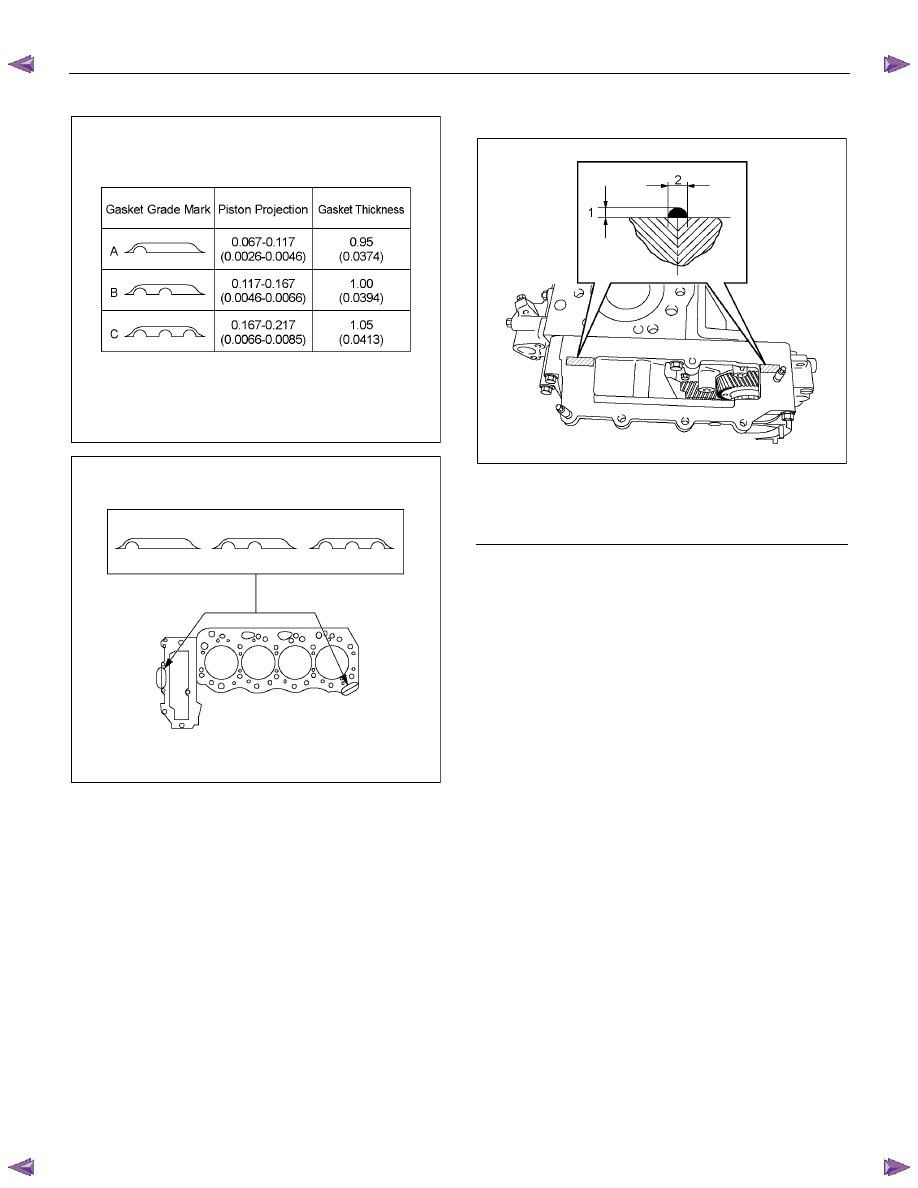

1. Select the cylinder head gasket.

Cylinder Head Gasket Selection

Cylinder head gasket is determined by the piston head

projection from the cylinder body upper surface, in order

to improve engine performance.

Three types of gasket are provided with difference of

thickness. Select the appropriate one out of three

grades of

gasket, according to the following procedure.

Before measurement, clear off carbon from the piston

head and cylinder body surface and also clean the

place where the gasket was installed.

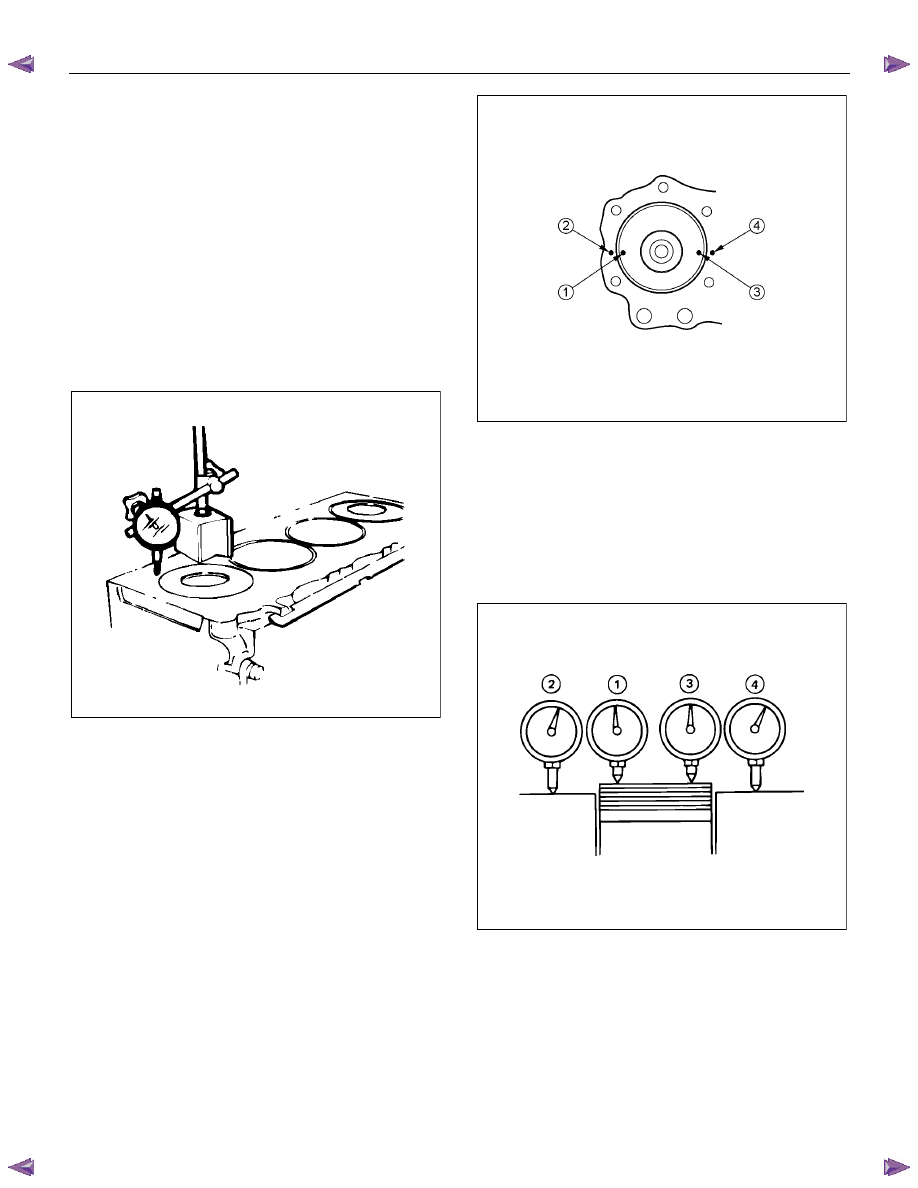

011LX011

1. Use a dial indicator to measure the piston

projection amount.

2. Refer to the illustration for the piston head

projection measuring positions. All measuring

positions should be as close as possible to the

cylinder block.

RTW36ASH001701

3. Measure the points 1, 2, 3, 4 and obtain two

differences 1-2 and 3-4 on each cylinder. Calculate

the average value of the piston head projection on

each cylinder.

4. Obtain the maximum value in the four cylinders.

5. Determine the gasket grade required to the

maximum value described above in accordance

with the following table.

011RY00027

6A-90 ENGINE MECHANICAL (4JK1/4JJ1)

Cylinder Head Gasket Combination

mm (in)

RTW76ASH000301

RTW56ASH009501

Note:

Difference of each piston projection must be equal or

within 0.05 mm (0.002 in).

7. Select the gear case gasket.

• This should be of the same grade as the

cylinder gasket.

8.

Apply liquid gasket (ThreeBond 1207B

or

equivalent) at the two locations.

RTW56ASH020901

Legend

1. 2 - 3 mm (0.079 - 0.118 in)

2. 3 - 4 mm (0.118 - 0.157 in)

9.

Install the cylinder head within 5 minutes

application of the liquid gasket.

10. Install the cylinder head.

• Wipe the cylinder head lower face.

• Install the cylinder head, adjusting the dowel of

the cylinder block.

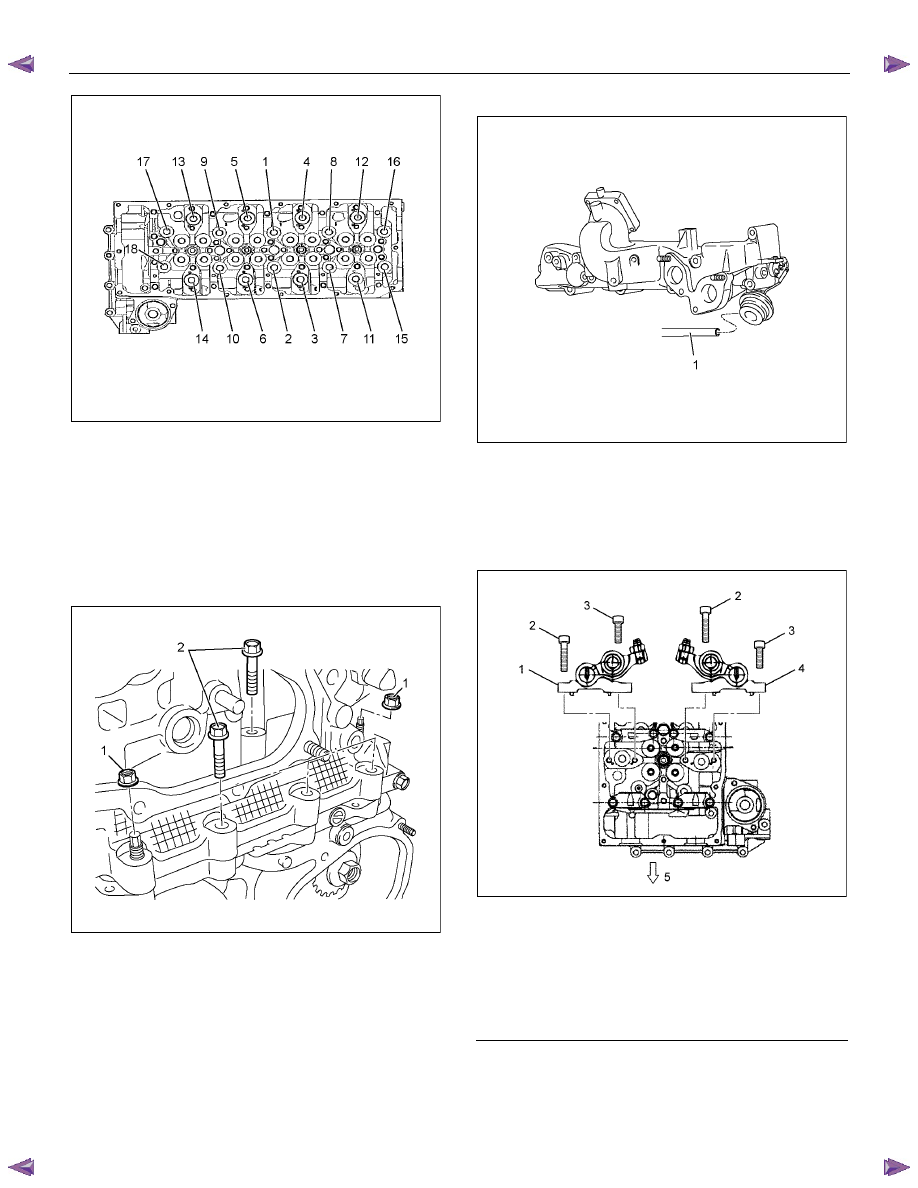

11. Install the cylinder head bolt.

• Please use new cylinder head bolt.

• Use a torque wrench and angle gauge to

tighten the head bolts in the order described in

the drawing.

Tightening torque:

1st step = 70 N

⋅⋅⋅⋅m (7.1 kg⋅⋅⋅⋅m / 51 lb ft)

2nd step = 70 N

⋅⋅⋅⋅m (7.1 kg⋅⋅⋅⋅m / 51 lb ft)

3rd step = 60° (degrees)

4th step = 60° (degrees)

ENGINE MECHANICAL (4JK1/4JJ1) 6A-91

RTW56ASH009701

Special tool

Angle gauge: 5-8840-0266-0

12. Install the cylinder head gear case bolt and nut.

• Tighten the nuts (1) and bolts (2) to the

specified torque.

Tightening torque: 25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m / 18 lb ft)

RTW56ASH020801

13. Install the water by pass pipe.

Apply soapy water to the O-ring.

Tighten the bolt to the specified torque.

Tightening torque: 25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m / 18 lb ft)

14. Install the vacuum hose (1).

RTW66ASH003101

15. Install the rocker arm shaft assembly.

• Apply the engine oil.

• Attach the rocker arm shaft assembly in

sequence from No.1 to No.4.

Tightening torque: 21 N

⋅⋅⋅⋅m (2.1 kg⋅⋅⋅⋅m / 15 lb ft)

RTW56ASH012201

Legend

1. Exhaust Rocker Arm Shaft Assembly

2. Bolt

(Long)

3. Bolt

(Short)

4. Intake Rocker Arm Shaft Assembly

5. Front

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст