Freightliner Cargo Maintenance Manual — part 3

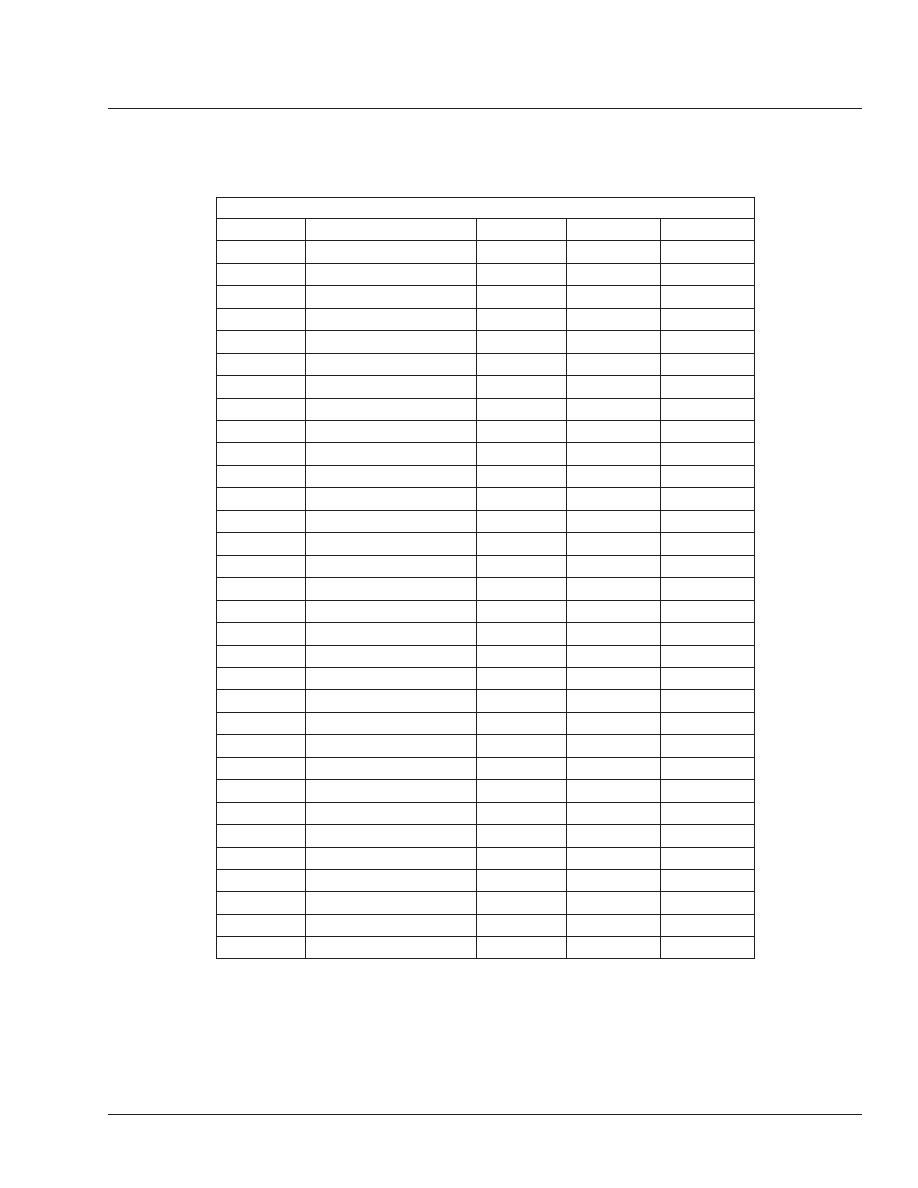

Maintenance Intervals for Schedule I

Maint. No.

Maintenance Interval

Miles

km

Hours

1

IM and M1

1000

1600

100

2

M1

2000

3200

200

3

M1

3000

4800

300

4

M1 and M2

4000

6400

400

5

M1

5000

8000

500

6

M1

6000

9600

600

7

M1

7000

11 200

700

8

M1, M2, and M3

8000

12 800

800

9

M1

9000

14 400

900

10

M1

10,000

16 000

1000

11

M1

11,000

17 600

1100

12

M1 and M2

12,000

19 200

1200

13

M1

13,000

20 800

1300

14

M1

14,000

22 400

1400

15

M1

15,000

24 000

1500

16

M1, M2, M3, and M4

16,000

25 600

1600

17

M1

17,000

27 200

1700

18

M1

18,000

28 800

1800

19

M1

19,000

30 400

1900

20

M1 and M2

20,000

32 000

2000

21

M1

21,000

33 600

2100

22

M1

22,000

35 200

2200

23

M1

23,000

36 800

2300

24

M1, M2, and M3

24,000

38 400

2400

25

M1

25,000

40 000

2500

26

M1

26,000

41 600

2600

27

M1

27,000

43 200

2700

28

M1 and M2

28,000

44 800

2800

29

M1

29,000

46 400

2900

30

M1

30,000

48 000

3000

31

M1

31,000

49 600

3100

32

M1, M2, M3, M4, and M5

32,000

51 200

3200

Table 5, Maintenance Intervals for Schedule I

General Information

00

Maintenance Interval Tables: 00–07

00/9

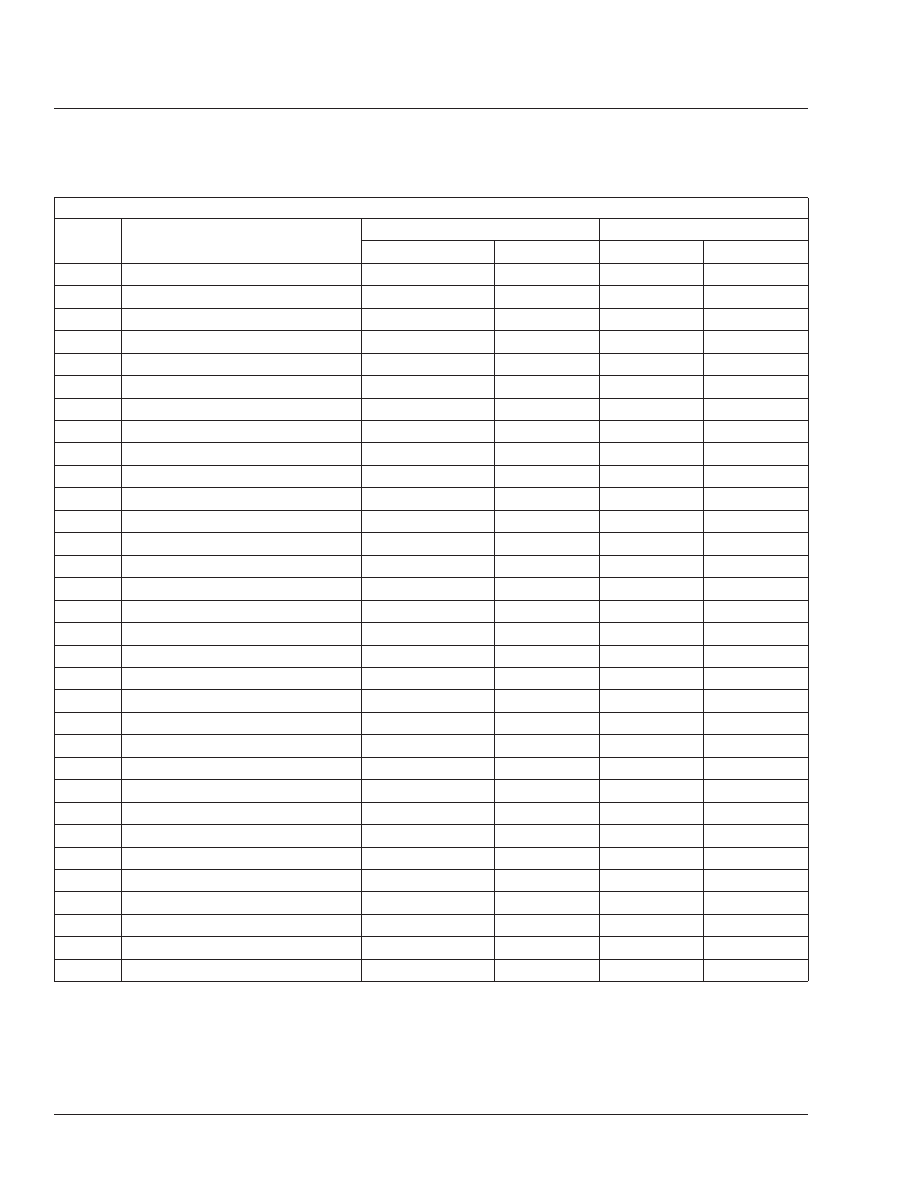

Maintenance Intervals for Schedules II and III

Maint.

No.

Maintenance Interval

Schedule II

Schedule III

Miles

km

Miles

km

1

IM and M1

8000

12 000

10,000

16 000

2

M1 and M2

16,000

24 000

20,000

32 000

3

M1

24,000

36 000

30,000

48 000

4

M1, M2, and M3

32,000

48 000

40,000

64 000

5

M1

40,000

60 000

50,000

80 000

6

M1 and M2

48,000

72 000

60,000

96 000

7

M1

56,000

84 000

70,000

112 000

8

M1, M2, M3, and M4

64,000

96 000

80,000

128 000

9

M1

72,000

108 000

90,000

144 000

10

M1 and M2

80,000

120 000

100,000

160 000

11

M1

88,000

132 000

110,000

176 000

12

M1, M2, and M3

96,000

144 000

120,000

192 000

13

M1

104,000

156 000

130,000

208 000

14

M1, and M2

112,000

168 000

140,000

224 000

15

M1

120,000

180 000

150,000

240 000

16

M1, M2, M3, M4, and M5

128,000

192 000

160,000

256 000

17

M1

136,000

204 000

170,000

272 000

18

M1 and M2

144,000

216 000

180,000

288 000

19

M1

152,000

228 000

190,000

304 000

20

M1, M2, and M3

160,000

240 000

200,000

320 000

21

M1

168,000

252 000

210,000

336 000

22

M1 and M2

176,000

264 000

220,000

352 000

23

M1

184,000

276 000

230,000

368 000

24

M1, M2, M3, and M4

192,000

288 000

240,000

384 000

25

M1

200,000

300 000

250,000

400 000

26

M1 and M2

208,000

312 000

260,000

416 000

27

M1

216,000

324 000

270,000

432 000

28

M1, M2, and M3

224,000

336,000

280,000

448 000

29

M1

232,000

348 000

290,000

464 000

30

M1 and M2

240,000

360 000

300,000

480 000

31

M1

248,000

372 000

310,000

496 000

32

M1, M2, M3, M4, and M5

256,000

384 000

320,000

512 000

Table 6, Maintenance Intervals for Schedules II and III

General Information

00

Maintenance Interval Tables: 00–07

00/10

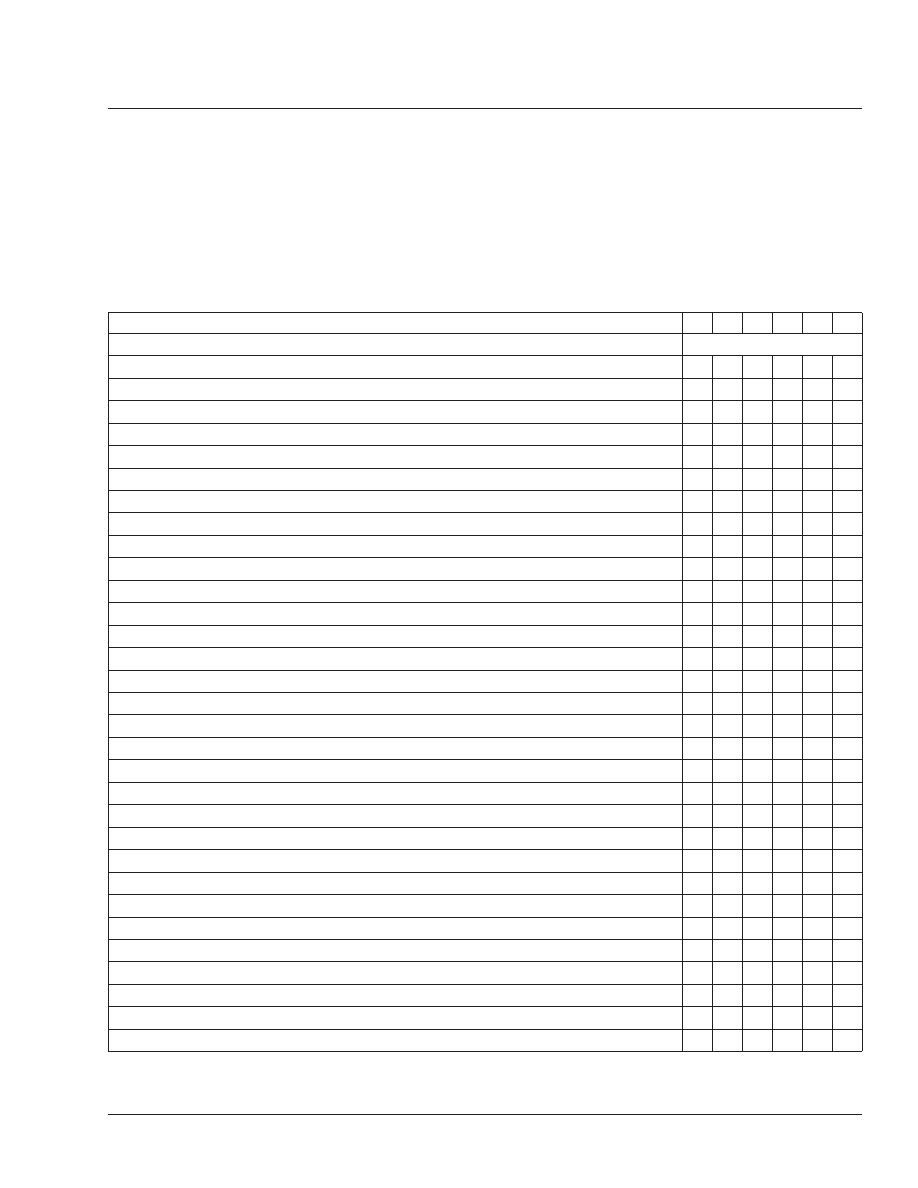

IMPORTANT: At each Maintenance Operation Set, in

addition to the maintenance operations listed in this

table, perform all daily and weekly maintenance op-

erations listed in the "Pretrip Inspection and Daily

Maintenance" chapter of the

Cargo Driver’s Manual

.

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are maintenance operation ref-

erence numbers matching those in the text of this

manual.

Maintenance Operation Sets Table

Required Maintenance Operation Set

IM

M1 M2 M3 M4 M5

Maintenance Operation Reference Number and Maintenance Operation

Lubrication and Fluid Level Check

•

•

•

•

•

Lubrication and Fluid Level Check

•

•

•

•

Engine-Support Fasteners Checking

•

•

Engine Drive Belt Inspection

•

•

•

Air Cleaner Element Inspecting and Replacing

•

•

•

Air Compressor Inspecting, Holset

•

•

•

•

Alternator and Starter Checking

•

•

•

•

Radiator Cap Checking

•

•

•

•

Radiator Pressure Flushing and Coolant Changing

•

•

Clutch Release Bearing and Release Cross-Shaft Lubricating

•

•

•

•

•

•

Clutch Inspecting and Adjusting

•

•

•

•

•

Clutch Master Cylinder Fluid Level Checking

•

•

•

•

•

•

Manual Transmission Oil Level Checking

•

•

•

•

•

Manual Transmission Oil Changing and Magnetic Plug Cleaning

•

•

•

Allison and Fuller Transmission Breather Checking

•

•

•

•

Eaton/Fuller Transmission Air Filter/Regulator Element Cleaning

•

•

•

•

Allison Transmission Fluid and Filter Changing

•

•

•

Frame Fastener Torque Checking

•

•

•

Suspension Inspecting (including cab shocks)

•

•

•

•

•

•

Suspension Lubricating

•

•

•

•

•

•

U-Bolt Torque Checking

•

•

•

•

Knuckle Pin Lubricating

•

•

•

•

•

•

Tie-Rod End Inspecting

•

•

•

•

•

•

Tie-Rod End Lubricating

•

•

•

•

•

•

All-Axle Alignment Checking

•

•

•

Axle Lubricant Level Checking

•

•

•

•

•

•

Axle Breather Checking

•

•

•

•

•

•

Axle Lubricant Changing and Magnetic Plug Cleaning

•

•

•

Wheel Nut and Rim Nut Checking

•

•

•

Driveline Inspecting

•

•

•

•

•

•

Driveline Lubricating

•

•

•

•

•

•

General Information

00

Maintenance Operation Sets Table: 00–08

00/11

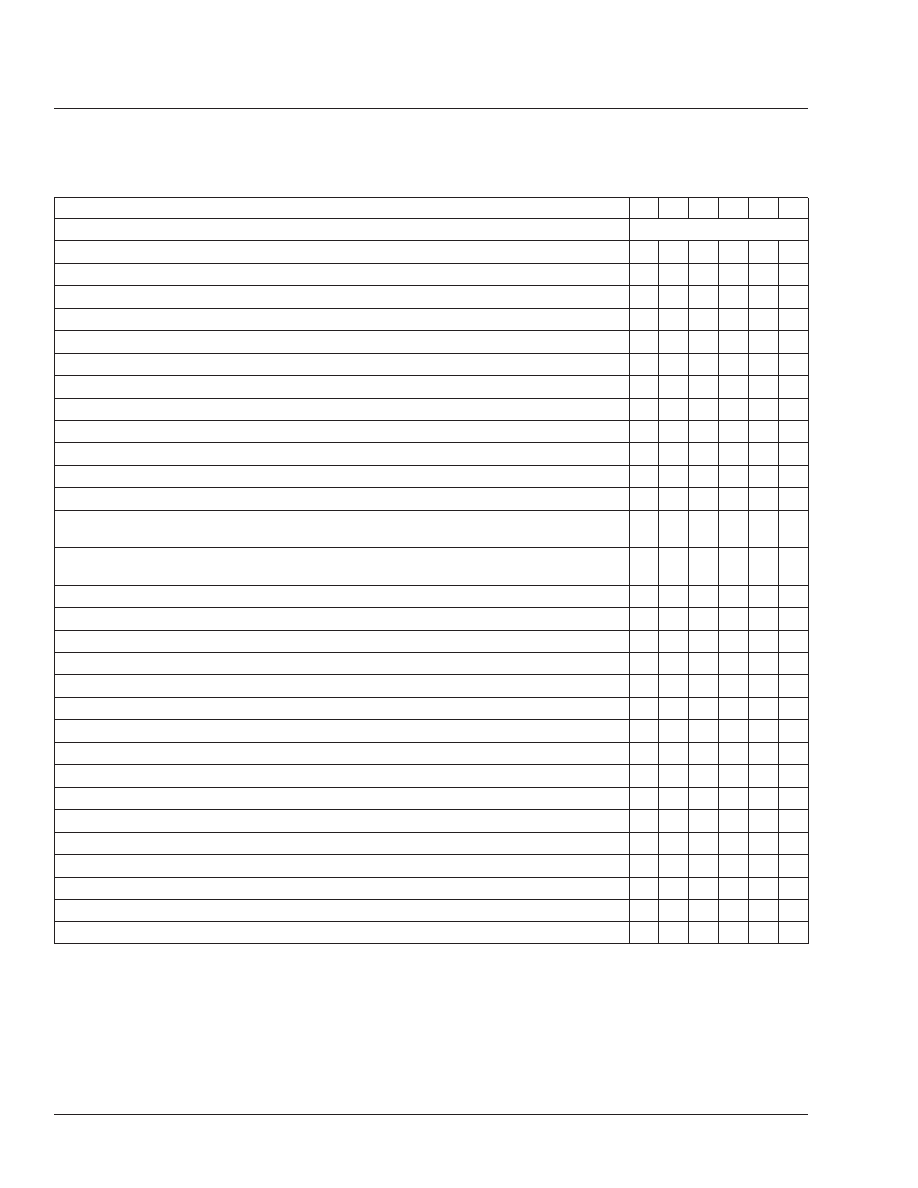

Required Maintenance Operation Set

IM

M1 M2 M3 M4 M5

Maintenance Operation Reference Number and Maintenance Operation

Air Dryer Inspecting, Bendix AD–9

•

•

•

•

•

•

Foot Brake Valve Actuator Lubricating

•

•

•

•

•

•

Air Brake Valve Operation Checking

•

•

•

•

•

•

Relay Valve Checking

•

•

•

•

•

•

Quick Release and Flipper Valves Checking

•

•

•

•

•

•

Brake Chamber Inspecting (All Models)

•

•

•

•

•

•

Camshaft Bracket Bushing Lubricating

•

•

•

•

Automatic Slack Adjuster Checking

•

•

•

•

•

•

Automatic Slack Adjuster Lubricating

•

•

•

•

•

•

Automatic Slack Adjuster Inspecting

•

•

•

•

•

•

Air Dryer Checking, Bendix AD–9

•

•

•

Air Dryer Desiccant Replacing, Bendix AD–9

•

Air Reservoir Automatic Drain Valve Disassembly, Cleaning, Inspecting, and

Lubricating, Bendix AD–9

•

•

•

•

Air Brake Valve Disassembly, Cleaning, and Inspecting, Bendix E–6, QR–1, and

ST–3

•

Steering Driveline Lubricating

•

•

•

•

Drag Link Lubricating

•

•

•

•

•

•

Power Steering Reservoir Fluid Level Checking

•

•

•

•

•

•

Power Steering Reservoir Fluid and Filter Changing

•

•

Steering Gear Lubricating (Ross TAS Series)

•

•

•

•

•

•

Fuel Tank Draining and Vent Checking

•

•

•

Exhaust System Inspecting

•

•

•

•

Electrical System Checking

•

•

•

Battery, Battery Box, and Cable Checking and Cleaning

•

•

•

•

•

•

Ground Cables Checking and Cleaning

•

•

•

•

•

•

Cab Mounting Bolts Torque Checking

•

•

•

Cab Mounts Lubricating

•

•

•

•

•

•

Cab Roof Vent Lubricating

•

•

•

•

•

•

Weatherstrip, Door Hinge, and Door Latch Lubricating

•

•

•

•

•

•

Air Conditioner Checking, R–134a Refrigerant Systems

•

•

•

•

•

•

Air Filter Replacement

*

*

Replace the HVAC air filter every three months regardless of mileage.

General Information

00

Maintenance Operation Sets Table: 00–08

00/12

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст