Suzuki Grand Vitara JB627. Manual — part 130

2C-12 Rear Suspension:

Trailing Rod Removal and Installation

S6JB0B2306011

Removal

1) Hoist vehicle and remove rear wheels.

2) Support lower arm (1) with jack (2).

3) Remove air suction pipe bolts (1) for 5door model

only.

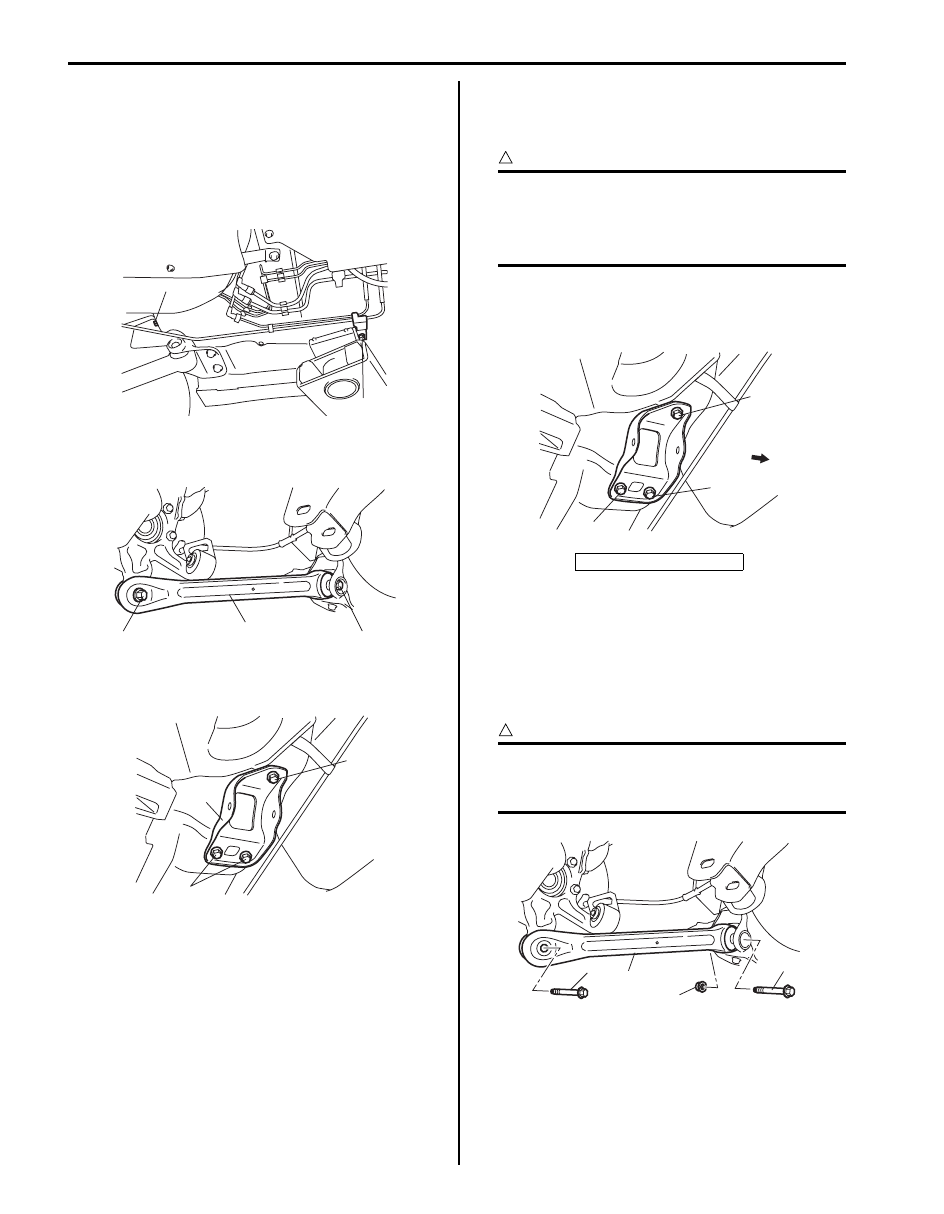

4) Remove trailing rod front bolt (1) and trailing rod rear

bolt (2) and then trailing rod (3).

5) Remove trailing rod mount bracket bolt (1) and then

trailing rod mount bracket (2).

Installation

1) Install trailing rod mount bracket and then tighten

trailing rod mount bracket bolt to specified torque.

CAUTION

!

• Tighten the bolts in order of bolt (1), (2)

and (3).

• Do not reuse removed trailing rod mount

bracket bolt.

Tightening torque

Trailing rod mount bolt (a): 105 N·m (10.5 kgf-m,

76.0 lb-ft)

2) Install trailing rod (4).

a) Install trailing rod and insert trailing rod front bolt

(1) from the body inside.

b) Insert trailing rod rear bolt (2).

c) Tighten trailing rod rear bolt (2) and trailing rod

mount nut (3) temporarily by hand.

CAUTION

!

If trailing rod mount nut and rear bolt are

reused, apply engine oil to thread, bearing

and trunk surface.

1

1

I5JB0A230026-01

2

3

1

I5JB0A230027-01

1

1

2

I5JB0A230028-02

I: Vehicle inner side

2,(a)

I

3,(a)

1,(a)

I6JB0B230003-02

2

4

3

1

I5JB0A230030-01

Rear Suspension: 2C-13

3) Tighten air suction pipe bolts (1) to specified torque

for 5door model only.

4) Remove floor jack from lower arm.

5) Install rear wheels and lower hoist.

6) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

7) Tighten trailing rod mount nut and trailing rod rear

bolt to specified torque with vehicle weight on

suspension.

CAUTION

!

It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

Tightening torque

Trailing rod mount nut: 135 N·m (13.5 kgf-m,

98.0 lb-ft)

Trailing rod rear bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

8) Check rear toe and camber adjust it as necessary.

For check and adjustment procedures, refer to “Rear

Wheel Alignment Inspection and Adjustment”.

Trailing Rod / Bushing Disassembly and

Assembly

S6JB0B2306012

Disassembly

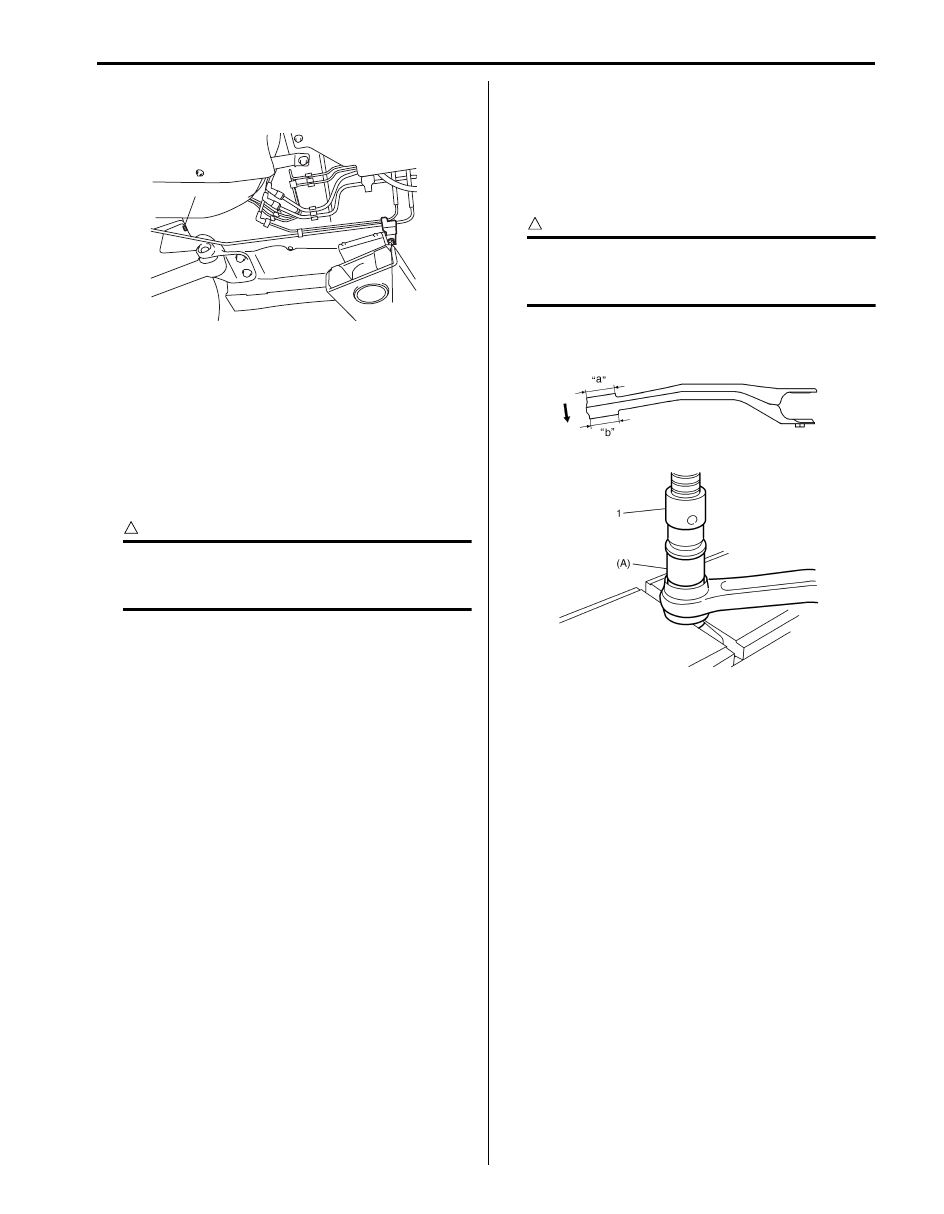

1) Push out trailing rod bushing by using hydraulic

press (1) and special tool.

CAUTION

!

Remove bushing following the direction

shown in figure since diameter “b” is bigger

than diameter “a”.

Special tool

(A): 09945–56510

1

1

I5JB0A230026-01

I5JB0A230031-03

2C-14 Rear Suspension:

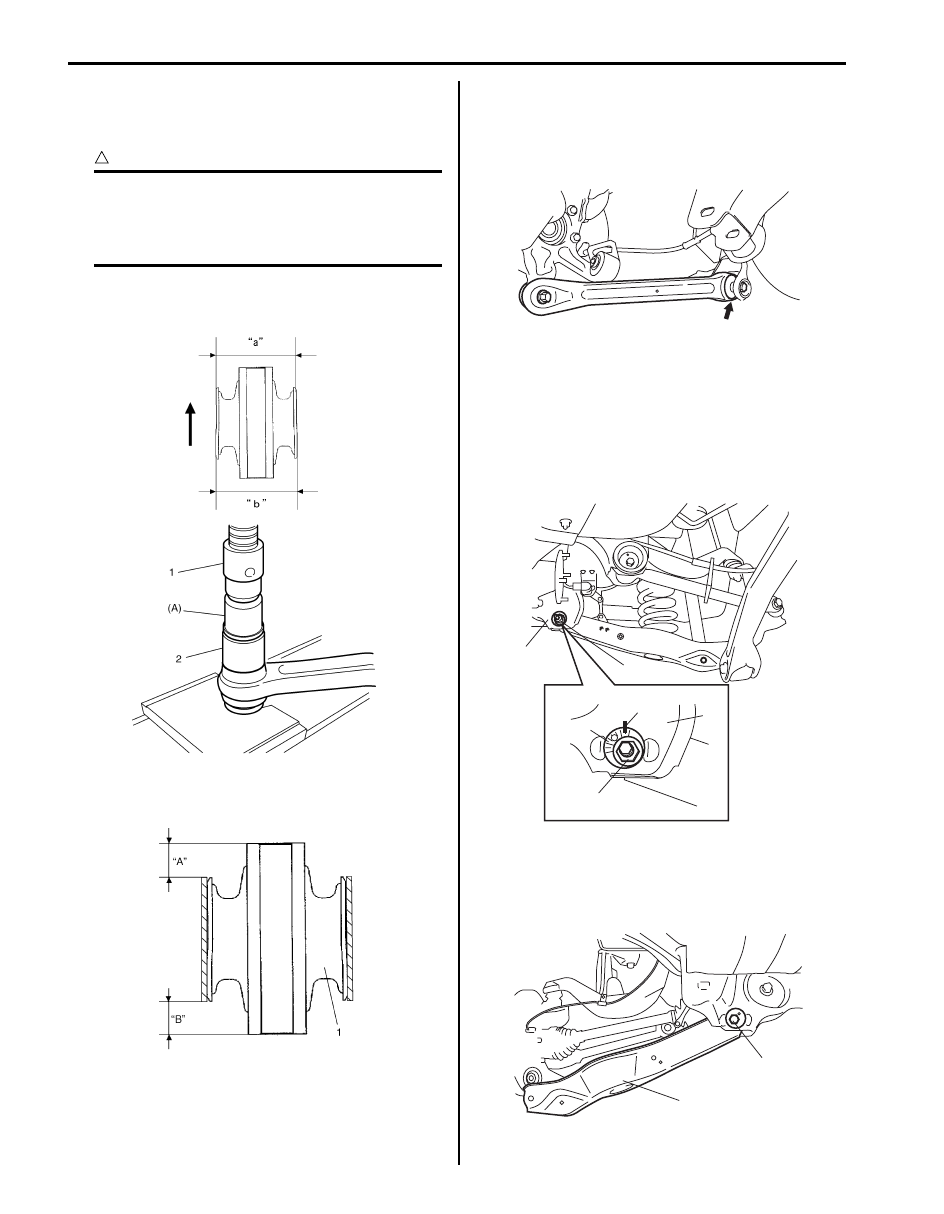

Assembly

1) Press-fit trailing rod bushing (2) by using press (1)

and special tool.

CAUTION

!

• Be sure to use new bushing.

• Install bushing following the direction

shown in figure since diameter “b” is

bigger than diameter “a”.

Special tool

(A): 09945–56510

2) Press-fit bushing (1) so that dimensions “A” and “B”

in figure become equal.

Trailing Rod Check

S6JB0B2306013

• Inspect for cracks, deformation or damage.

• Inspect bushing for wear and breakage.

If any faulty condition is found, replace.

Lower Arm Removal and Installation

S6JB0B2306014

1) Hoist vehicle and remove rear wheels.

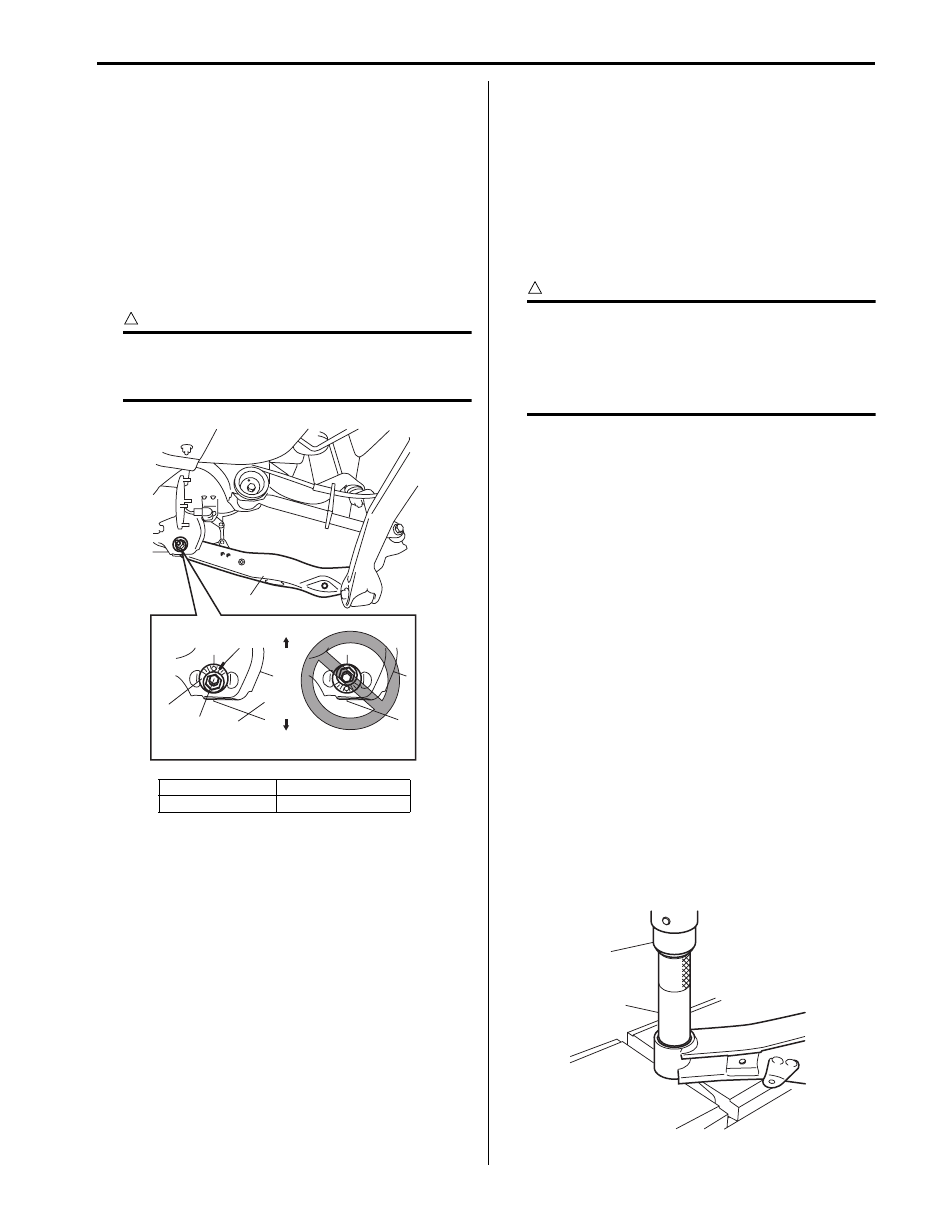

2) Put match marks (1) on lower arm washer (2) and on

suspension frame (3) to install the bolts correctly in

position.

3) Loosen lower arm mount nut (4).

4) Remove rear coil spring referring to “Rear Coil

Spring and Bump Stopper Removal and Installation”.

5) Remove suspension rod mount bolt (1) and then

lower arm (2).

I5JB0A230079-02

I5JB0A230032-02

I5JB0A230033-01

1

2

3

3

4

4

I5JB0A230010-01

2

1

I5JB0A230034-01

Rear Suspension: 2C-15

Installation

1) Install lower arm.

a) Install lower arm (1) to rear suspension frame.

b) Insert suspension lower arm inner bolt (2) from

the vehicle rearward.

c) Install lower arm washer (3) with its graduated

part facing up.

d) The marks (4) on lower arm washer (3) and rear

suspension frame marked before its removal

must be aligned and, tighten bolt and nut

temporarily by hand.

CAUTION

!

If lower arm mount nut and lower arm outer

bolt are reused, apply engine oil to thread,

bearing and trunk surface.

2) Install rear coil spring referring to “Rear Coil Spring

and Bump Stopper Removal and Installation”.

3) Install wheel with nuts and lower vehicle.

4) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

5) Tighten lower arm outer bolt and lower arm mount

nut, shock absorber bolts to specified torque with

vehicle weight on suspension.

CAUTION

!

• It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

• Tighten lower arm washer with match

marks aligned.

Tightening torque

Lower arm outer bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Lower arm mount nut: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Shock absorber upper bolt: 60 N·m (6.0 kgf-m,

43.5 lb-ft)

Shock absorber lower bolt: 90 N·m (9.0 kgf-m,

65.0 lb-ft)

6) Check rear toe and camber adjust it as necessary.

For check and adjustment procedures, refer to “Rear

Wheel Alignment Inspection and Adjustment”.

7) Adjust headlight auto leveling system, refer to

“Initialization of Auto Leveling Headlight System in

Section 9B”.

Lower Arm / Bushing Disassembly and

Assembly

S6JB0B2306015

Disassembly

1) Push out suspension lateral link bushing by using

hydraulic press (1) and special tool.

Special tool

(A): 09913–84510

[A]: Correct

U: Upper side

[B]: Wrong

L: Lower side

1

[A]

[B]

U

L

4

2

3

1

I5JB0A230035-02

1

(A)

I5JB0A230036-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст