Suzuki Grand Vitara JB627. Manual — part 122

2B-2 Front Suspension:

Front Wheel Alignment Construction

S6JB0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and

approximately the same tread wear.

• Check for loose of ball joints. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missing stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check

alignment and follow manufacturer’s instructions.

• Regardless of equipment used to check alignment,

vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S6JB0B2206001

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted

properly and wheel is free from deflection.

• Check that each suspension part is free from bend,

dent, wear or damage in any other form.

• Check that ground clearance at the right and left is

just about the same.

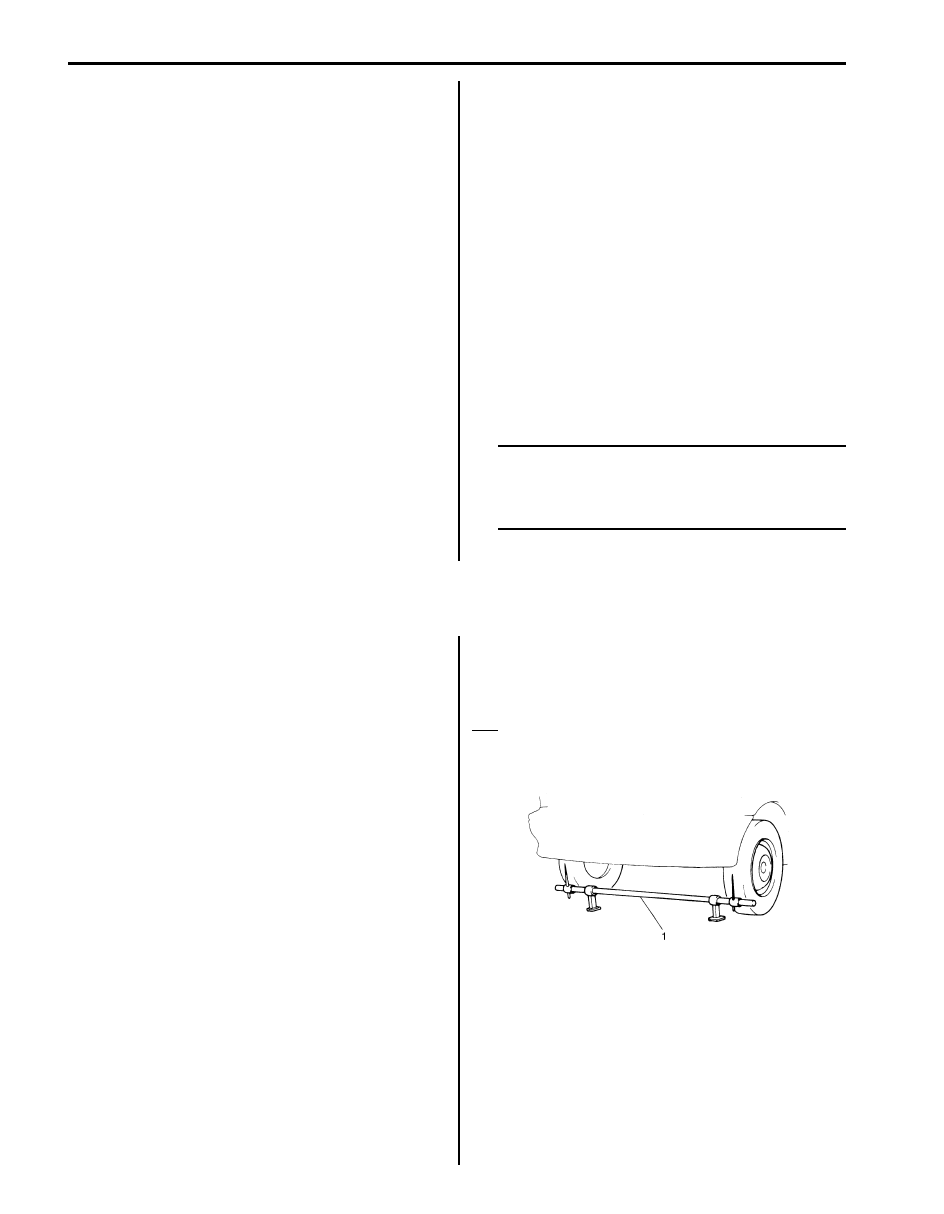

Inspection

Measure toe with toe-in gauge (1).

Toe should be within following specifications.

If toe is out of the specification, adjust toe properly.

Toe

IN 0

± 2.0 mm (0 ± 0.0787 in.)

I2RH01220062-01

Front Suspension: 2B-3

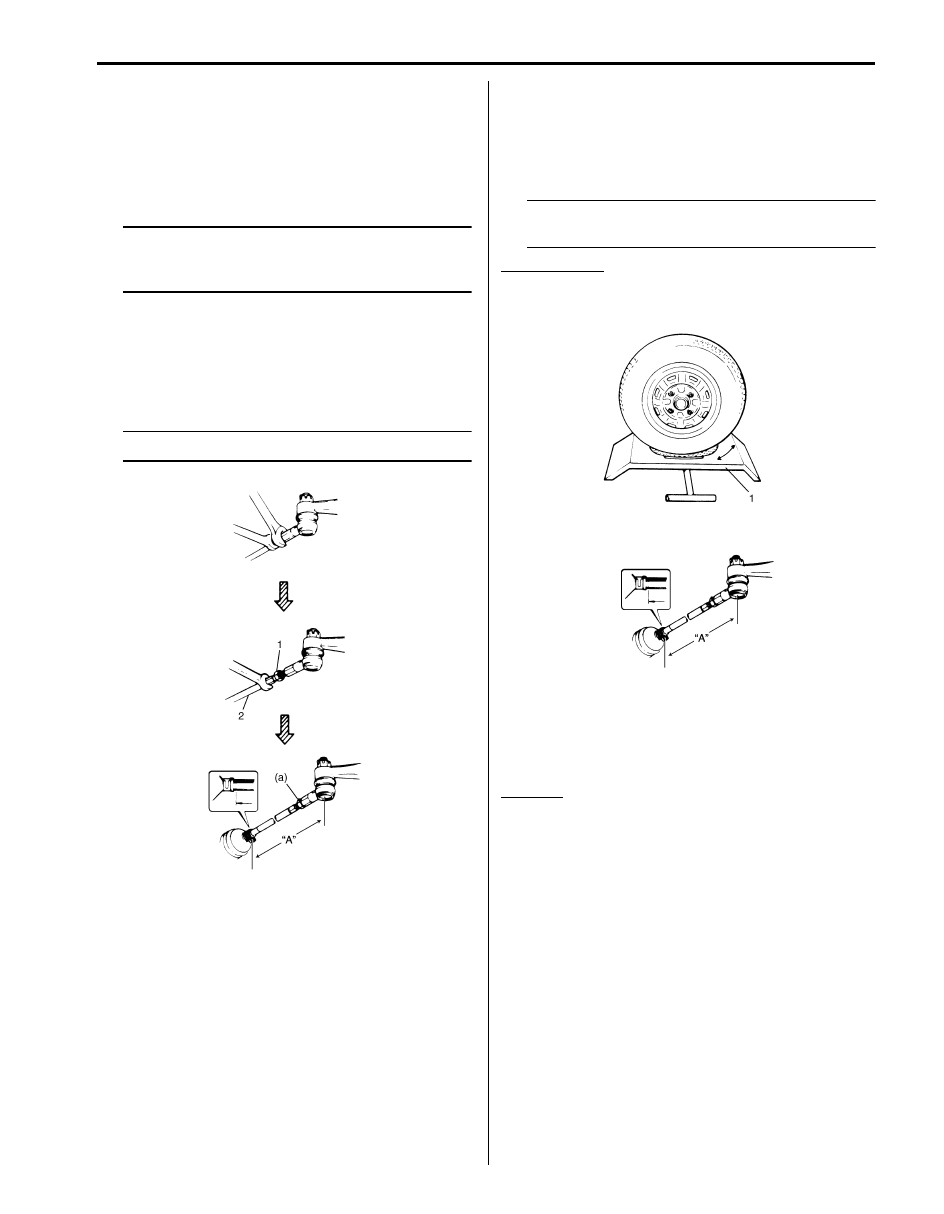

Adjustment

1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount

to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified

torque.

Tightening torque

Tie-rod end lock nut (a): 65 N·m (6.5 kgf-m, 47.0 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge (1).

If steering angle is not correct, check whether right and

left tie-rods length “A” are equal.

NOTE

If tie-rod lengths were changed to adjust

steering angle, reinspect toe-in.

Steering angle

Inside: 37.0

° ± 3°

Outside: 32.0

° ± 3°

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.

Side slip

IN 1.5 to OUT 1.5 (IN 0.0591 to OUT 0.0591)

If side slip is greatly different, toe or front wheel

alignment may not be correct.

I5JB0A220002-01

I5JB0A220003-01

2B-4 Front Suspension:

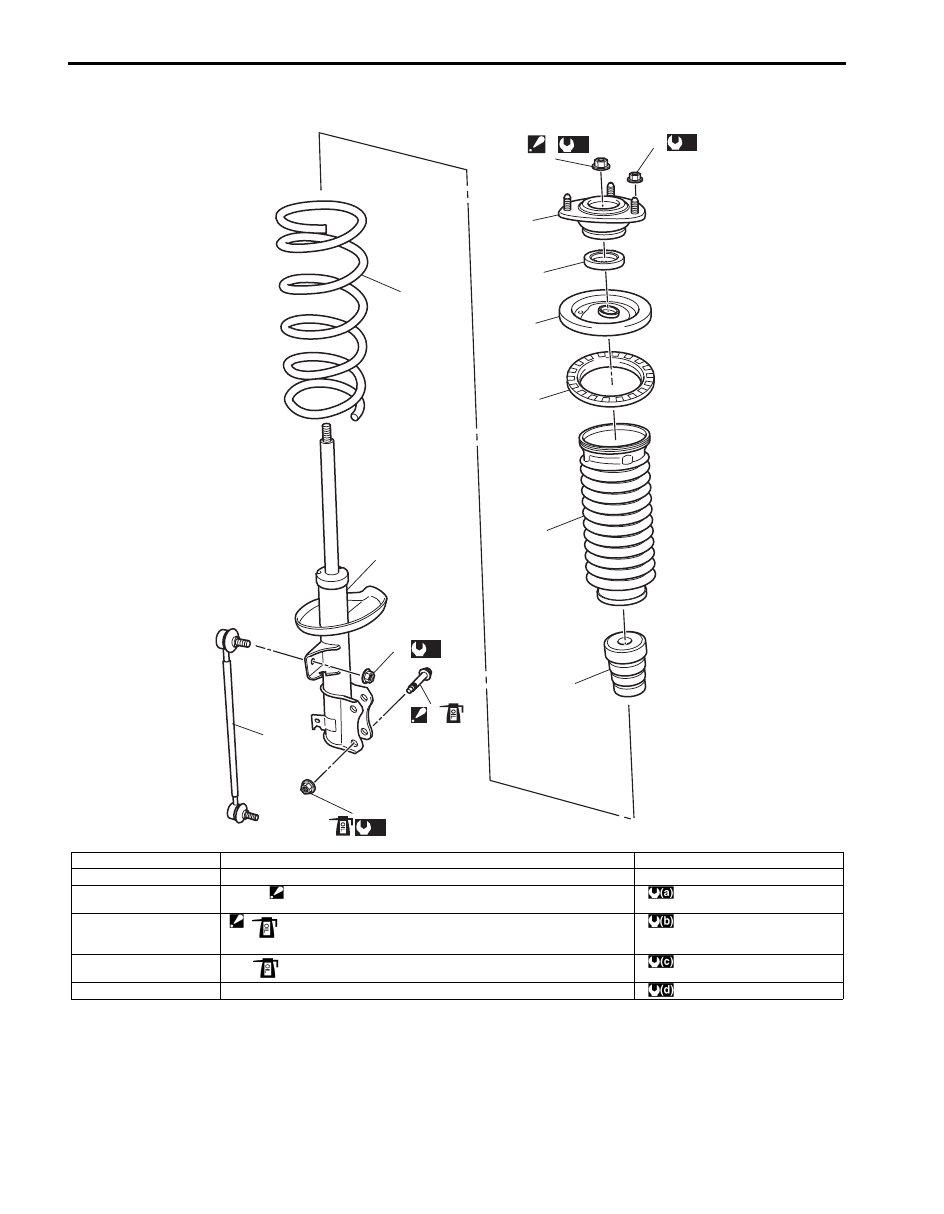

Front Strut Assembly Components

S6JB0B2206002

7

6

5

4

14

2

1

13

3

12

(d)

(a)

8

(b)

9

(c)

11

10

I6JB0B220002-02

1. Strut assembly

7. Strut support

13. Stabilizer joint

2. Coil spring

8. Strut support nut

14. Strut dust cover

3. Bump stopper

9. Strut nut

: Do not reuse caulking nut if used.

: 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

4. Coil spring seat

10. Strut bracket bolt

: Insert from vehicle front side.

: If bolt is reused, apply engine oil to thread, bearing and trunk surface.

: 70 N

⋅m (7.0 kgf-m, 51.0 lb-ft)

5. Coil spring upper seat

11. Strut bracket nut

: If nut is reused, apply engine oil to thread and bearing.

: 135 N

⋅m (13.5 kgf-m, 98.0 lb-ft)

6. Strut bearing

12. Stabilizer joint nut

: 60 N

⋅m (6.0 kgf-m, 43.5 lb-ft)

Front Suspension: 2B-5

Front Strut Assembly Removal and Installation

S6JB0B2206003

Removal

NOTE

When servicing component parts of strut

assembly, remove strut rod cap and then

loosen strut nut a little before removing strut

assembly. This will make service work easier.

Note that the nut must not be removed at this

point.

1) Hoist vehicle, allowing front suspension to hang free.

2) Remove wheel and disconnect stabilizer joint (1)

from strut bracket.

When loosening joint nut, hold stud with hexagon

wrench.

3) Remove brake hose mounting bolt (1) and remove

brake hose (2) from bracket.

4) Disconnect front height sensor (if equipped) from

suspension control arm for left side referring to

“Height Sensor Removal and Installation (If

Equipped) in Section 9B”.

5) Remove wheel speed sensor harness clamp bolt (3)

and then detach front speed sensor harness (5) from

strut bracket as shown in figure.

6) Remove strut bracket bolts and nuts (4).

7) Remove strut support nuts (1).

NOTE

Hold strut by hand so that it will not fall off.

8) Remove strut assembly.

1

I5JB0A220005-02

3

5

4

4

4

1

2

I5JB0A220006-01

1

I5JB0A220007-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст