Suzuki Grand Vitara JB627. Manual — part 138

3A-3 Drive Shaft / Axle: Front

Front Drive Shaft Assembly Removal and

Installation

S6JB0B3116003

Removal

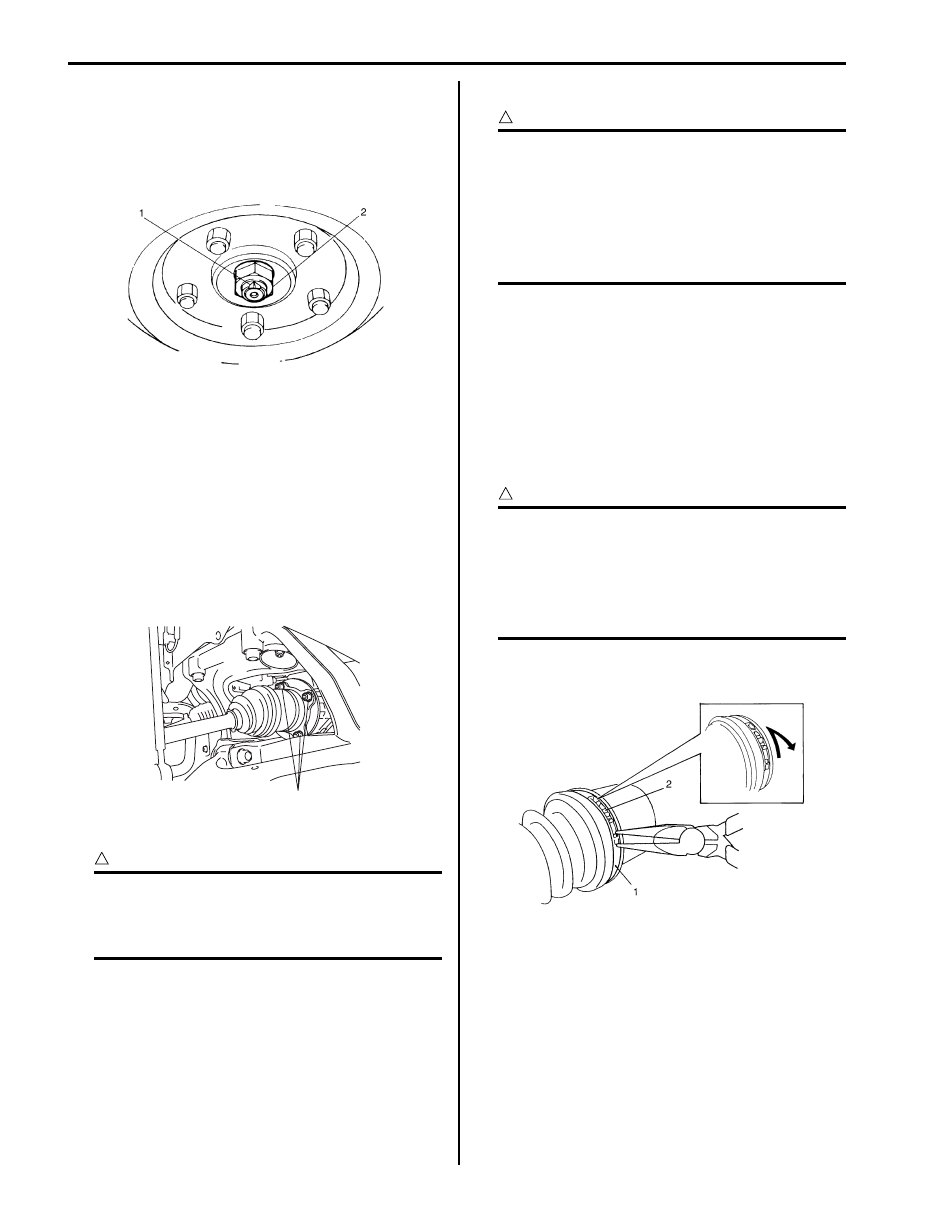

1) Undo caulking (1) and remove drive shaft nut (2).

2) Hoist vehicle and remove wheel.

3) Drain front differential oil.

4) Disconnect tie-rod end from steering knuckle

referring to “Steering Knuckle Removal and

Installation in Section 2B”.

5) Remove stabilizer joint from stabilizer bar.

6) Remove brake hose mounting bolt.

7) Remove suspension control arm referring to

“Suspension Control Arm Removal and Installation

in Section 2B”.

8) Remove front drive shaft flange nuts (1).

9) Remove drive shaft assembly from front differential.

CAUTION

!

To prevent breakage of boots (wheel side and

differential side), do not contact them with

other parts when removing drive shaft

assembly.

Installation

CAUTION

!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer.

Inserting joint only by hands is allowed.

• Make sure that differential side joint is

inserted fully and its snap ring is seated as

it was.

Install drive shaft assembly by reversing removal

procedure and noting the following points.

• Tighten each bolts and nuts to the specified torque

referring to “Front Drive Shaft Components: Front”

and “Front Suspension Construction in Section 2B”.

Front Drive Shaft Disassembly and Assembly

S6JB0B3116004

Disassembly

CAUTION

!

• Disassembly of wheel side joint assembly

is not allowed. If any noise or damage

exists in it, replace it as assembly.

• Do not disassemble tripod joint spider. If

any malcondition is found in it, replace it

as differential side joint assembly.

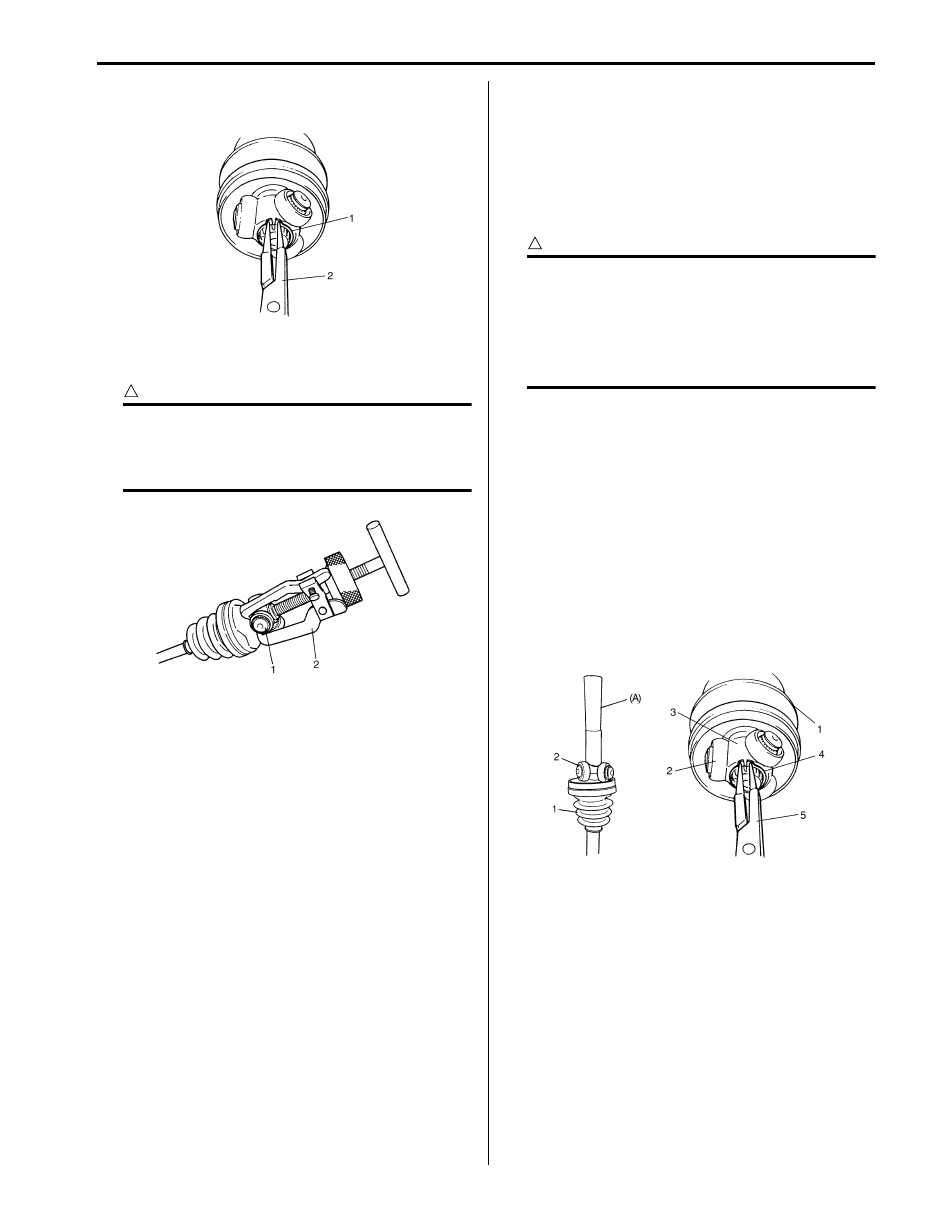

1) Draw hooks (2) of boot big band together and

remove differential side boot big band (1).

I5JB0A311003-01

1

I5JB0A311004-01

I5JB0A311005-01

Drive Shaft / Axle: Front 3A-4

2) Wipe off grease from shaft and take off snap ring (1)

using snap ring plier (2).

3) Remove tripod joint spider (1) using 3 arms puller

(2).

CAUTION

!

To prevent any problem caused by washing

solution, do not wash tripod joint except its

housing. Degreasing of tripod joint with cloth

is allowed.

4) Remove differential side boot small band, and then

pull out differential side boot from shaft.

Assembly

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that tripod joint housing is washed thoroughly

and air dried.

Replace boot with new one.

CAUTION

!

• Do not wash boots in degreaser such as

gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as

designed, apply grease of specified

volume and color to joint.

1) Wash disassembled parts (except boots). After

washing, dry parts completely by blowing air.

2) Clean boots with cloth.

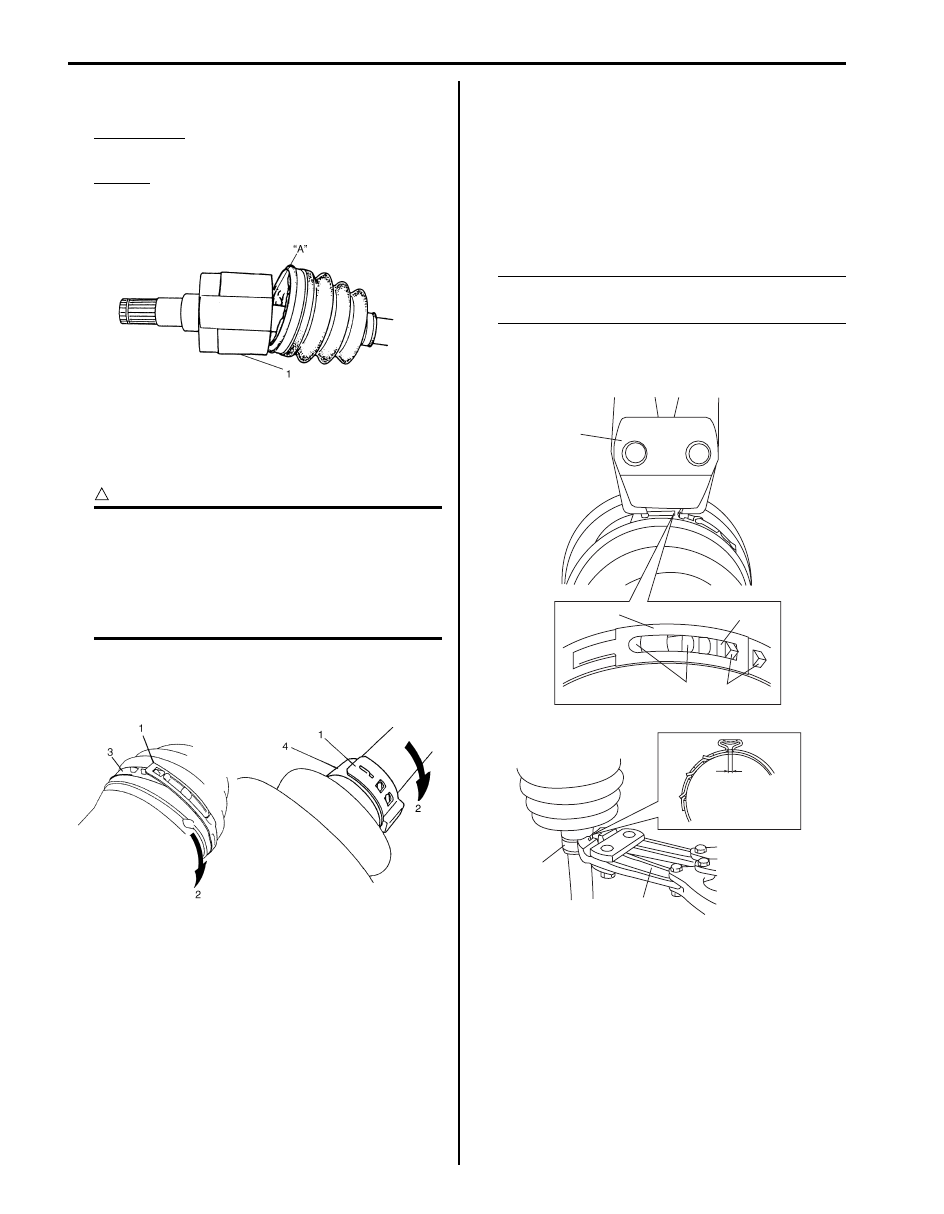

3) Set new differential side small band and new

differential side boot (1) on shaft temporarily, and

then apply grease to tripod joint (2). Use specified

grease in tube included in spare parts.

4) Install tripod joint spider (3) on shaft using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (4) using snap ring plier (5).

Special tool

(A): 09913–80113

I5JB0A311008-01

I3RH0A311004-01

I5JB0A311009-01

3A-5 Drive Shaft / Axle: Front

5) Apply grease (including in spare parts) to inside of

tripod joint housing (1), joint it with tripod joint.

Grease color

“A”: Yellow

Amount

“A”: 127 – 137 g (4.5 – 4.8 oz) (right side)

“A”: 170 – 180 g (6.0 – 6.3 oz) (left side)

6) Fit boot to grooves of shaft and housing.

7) Insert screw driver into boot and allow air to enter

boot so that air pressure in boot becomes the same

as atmospheric pressure.

CAUTION

!

• Bend each boot band against forward

rotation.

• Do not squeeze or distort boot when

fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

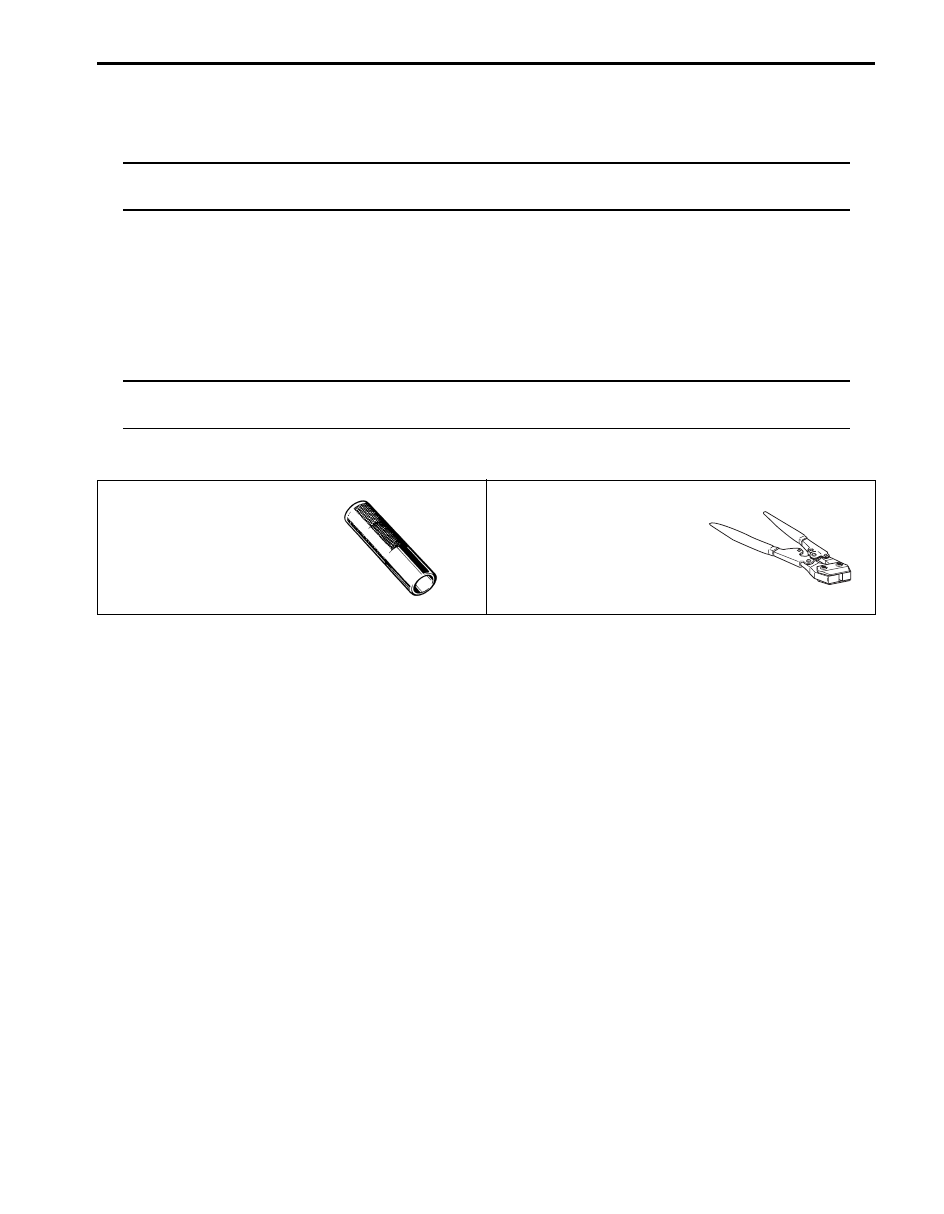

8) Place differential side boot new big band (3) and new

small band (4) onto boot putting band outer end (1)

against forward rotation (2) as shown in figure.

9) Fasten differential side boot big band.

• For differential side boot big band

Fasten band (1) by drawing hooks (2) with special

tool and engage hooks (3) in slot and window (4).

Special tool

(A): 09943–57010

• For differential side boot small band

Fasten band (5) securely using special tool.

NOTE

Fasten boot small band securely until

complete contact “a” is obtained.

Special tool

(A): 09943–57010

I4RS0B310003-01

I5JB0A311006-01

(A)

1

4

2

3

(B)

5

“a”

I5JB0A311007-03

Drive Shaft / Axle: Front 3A-6

Specifications

Tightening Torque Specifications

S6JB0B3117001

NOTE

The specified tightening torque is also described in the following.

“Front Drive Shaft Components: Front”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S6JB0B3118001

NOTE

Required service material is also described in the following.

“Front Drive Shaft Components: Front”

Special Tool

S6JB0B3118002

09913–80113

09943–57010

Bearing installer

Band compressor

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст