Suzuki Grand Vitara JB627. Manual — part 139

3A-7 Drive Shaft / Axle: Rear

Rear

General Description

Rear Drive Shaft Construction

S6JB0B3121001

Refer to “Front Drive Shaft Construction: Front”.

Repair Instructions

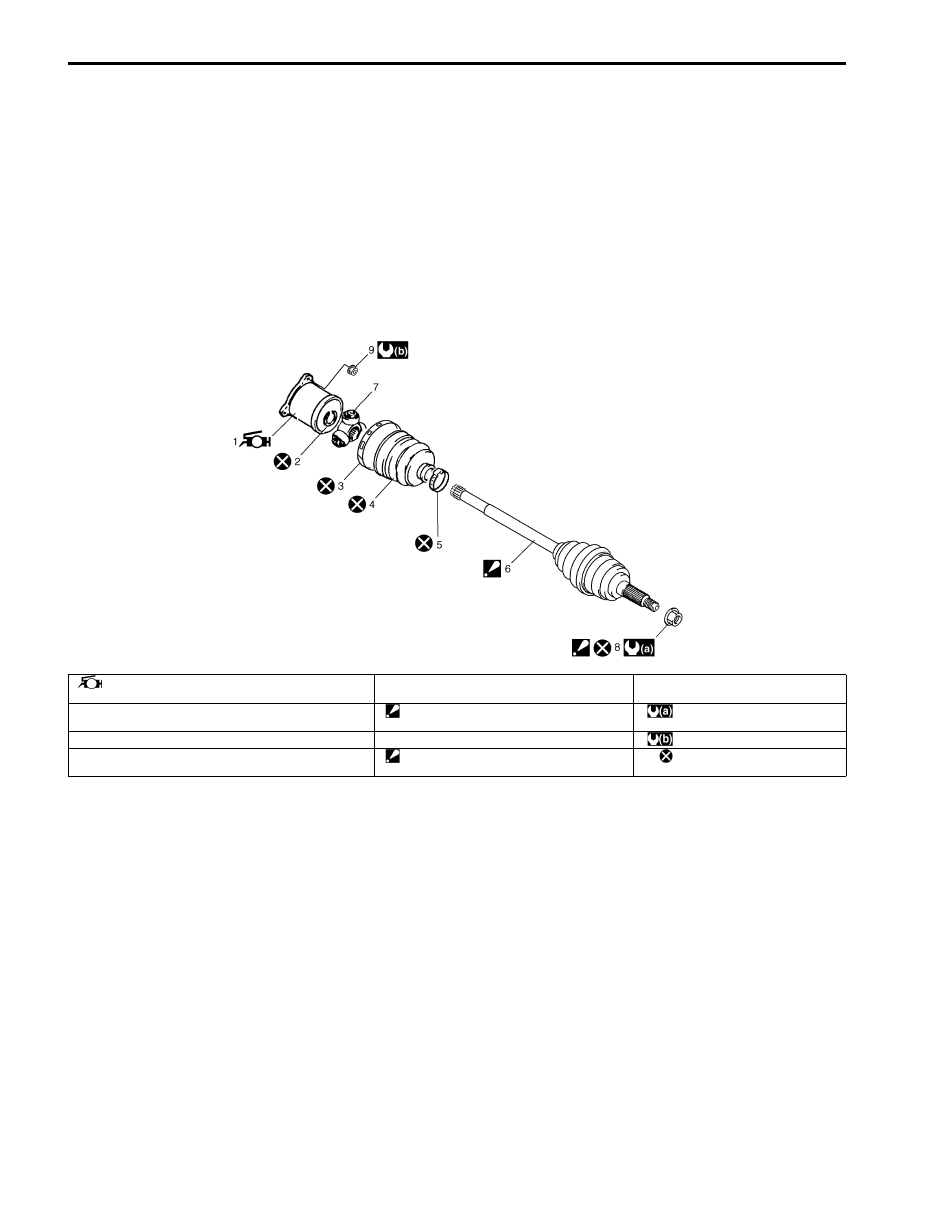

Rear Drive Shaft Components

S6JB0B3126001

I5JB0A312001-02

1. Differential side joint (Constant velocity tripod joint)

: Apply yellow grease included in spare part to joint.

5. Boot band (Small)

9. Rear drive shaft flange nut

2. Snap ring

6. Wheel side joint (Constant velocity ball joint)

: Never disassemble.

: 220 N

⋅m (22.0 kgf-m, 159.5 lb-ft)

3. Boot band (Large)

7. Tripod joint spider

: 80 N

⋅m (8.0 kgf-m, 58.0 lb-ft)

4. Boot (Differential side)

8. Drive shaft nut

: After tightening nut, caulk nut securely.

: Do not reuse.

Drive Shaft / Axle: Rear 3A-8

Rear Drive Shaft Assembly Removal and

Installation

S6JB0B3126002

Removal

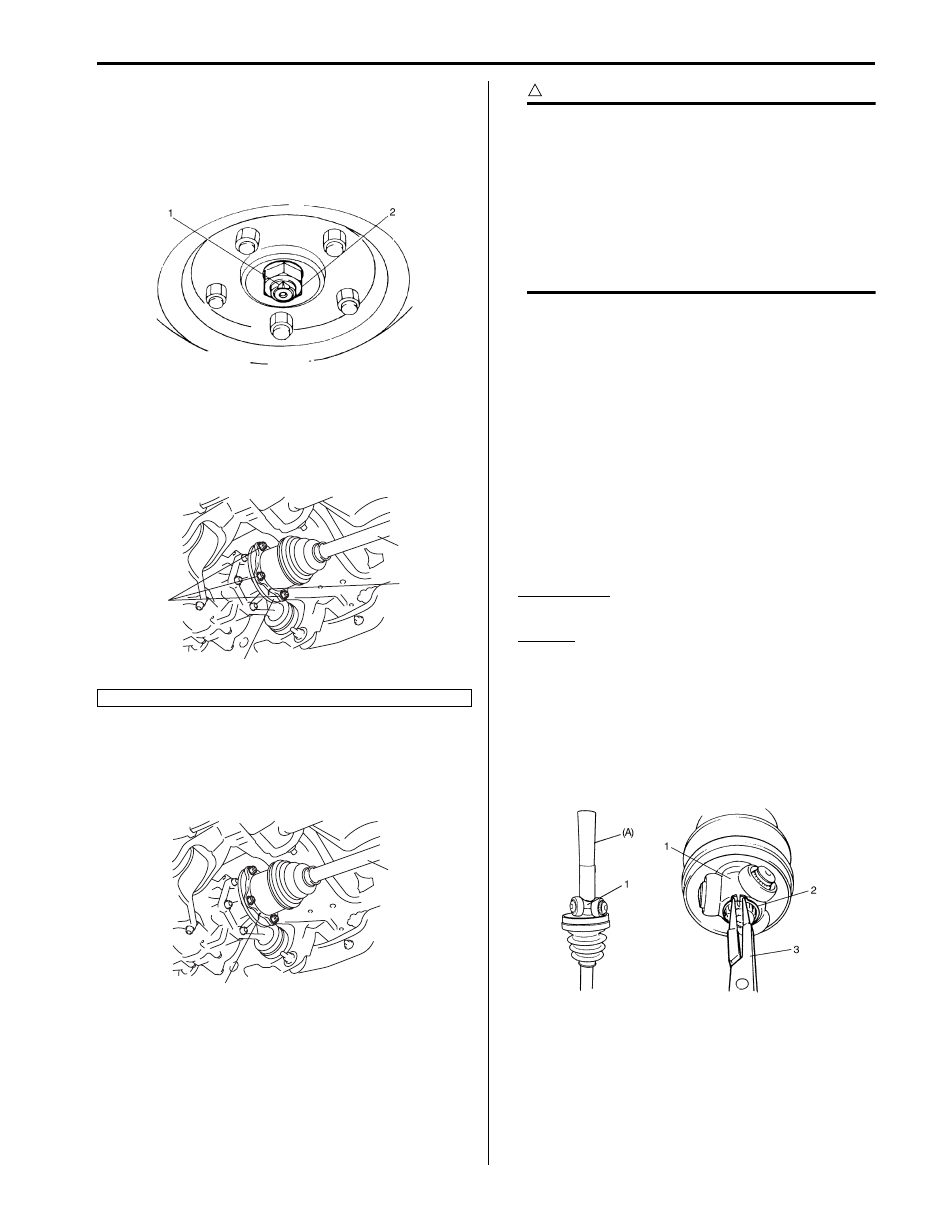

1) Undo caulking (1) of drive shaft nut (2) and then

remove drive shaft nut.

2) Hoist vehicle and remove wheel.

3) Give match mark rear drive shaft flange (3) and rear

drive shaft (4) as shown in figure, and then remove

rear drive shaft flange nuts (1), and then remove rear

drive shaft.

Installation

Install drive shaft assembly by reversing removal

procedure and noting the following points.

• Install rear drive shaft (1) aligning match marks (2).

CAUTION

!

• Protect oil seals and boots from any

damage, preventing them form

unnecessary contact while installing drive

shaft.

• Do not hit joint boot with hammer.

Inserting joint only by hands is allowed.

• Make sure that differential side joint is

inserted fully and its snap ring is seated as

it was.

• Tighten each nuts to specified torque referring to

“Rear Drive Shaft Components: Rear”.

Rear Drive Shaft Disassembly and Assembly

S6JB0B3126003

Disassembly

Refer to “Front Drive Shaft Disassembly and Assembly:

Front”.

Assembly

Assemble rear drive shaft assembly referring to “Front

Drive Shaft Disassembly and Assembly: Front” and

noting the following points which are different from that

of the front drive shaft assembly.

• Apply grease to differential side joint.

Grease color

: Yellow

Amount

: 197 – 207 g (6.9 – 7.3 oz)

• Install tripod joint spider (1) on shaft by using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (2) using snap ring plier (3).

Special tool

(A): 09913–84510

2. Match mark

I5JB0A311003-01

1

3

2

4

I5JB0A312002-02

2

1

I5JB0A312003-01

I5JB0A312004-03

3A-9 Drive Shaft / Axle: Rear

Specifications

Tightening Torque Specifications

S6JB0B3127001

NOTE

The specified tightening torque is also described in the following.

“Rear Drive Shaft Components: Rear”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S6JB0B3128001

NOTE

Required service material is also described in the following.

“Rear Drive Shaft Components: Rear”

Special Tool

S6JB0B3128002

09913–84510

Bearing installer

)

Differential: Front 3B-1

Driveline / Axle

Differential

Front

General Description

Front Differential Construction

S6JB0B3211001

The differential assembly uses a hypoid bevel pinion and gear.

The differential assembly is decisive in that the drive power is concentrated there. Therefore, use of genuine parts and

specified torque is compulsory. Further, because of sliding tooth meshing with high pressure between bevel pinion and

gear, it is mandatory to lubricate them by hypoid gear oil.

Diagnostic Information and Procedures

Front Differential Symptom Diagnosis

S6JB0B3214001

Condition

Possible cause

Correction / Reference Item

Gear noise

Deteriorated or water mixed lubricant

Repair and replenish referring to “Front

Differential Oil Change: Front”.

Inadequate or insufficient lubricant

Repair and replenish referring to “Front

Differential Oil Change: Front”.

Maladjusted backlash between drive

bevel pinion and gear

Adjust as prescribed referring to “Front

Differential Assembly Disassembly and

Reassembly: Front”.

Improper tooth contact in the mesh

between drive bevel pinion and gear

Adjust or replace referring to “Front Differential

Assembly Disassembly and Reassembly:

Front”.

Loose drive bevel gear securing bolts

Replace or retighten referring to “Front

Differential Assembly Disassembly and

Reassembly: Front”.

Damaged differential gear(s) or

differential pinion(s)

Replace referring to “Front Differential

Inspection: Front”.

Bearing noise

(Constant noise) Deteriorated or water

mixed lubricant

Repair and replenish referring to “Front

Differential Oil Change: Front”.

(Constant noise) Inadequate or

insufficient lubricant

Repair and replenish referring to “Front

Differential Oil Change: Front”.

(Noise while coasting) Damaged

bearing(s) of drive bevel pinion

Replace referring to “Front Differential

Inspection: Front”.

(Noise while turning) Damaged

differential side bearing(s) or axle

bearing(s)

Replace referring to “Front Differential

Inspection: Front”.

Oil leakage

Clogged breather plug

Clean.

Worn or damaged oil seal

Replace.

Excessive oil

Adjust oil level referring to “Front Differential

Oil Change: Front”.

Loose differential carrier bolts

Replace or retighten.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст