Suzuki Grand Vitara JB627. Manual — part 196

4F-23 Electronic Stability Program:

DTC C1015 / C1017 / C1023: Longitudinal G Sensor / Lateral G Sensor / Yaw Rate Sensor in Yaw Rate

/ G Sensor Assembly Failure

S6JB0B4604025

DTC Detecting Condition and Trouble Area

6

1) Check if communication is possible by trying

communication with other controller (ECM, TCM, BCM,

4WD control module or SDM).

Is it possible to communicate with other controller?

Go to Step 7.

Repair open in common

section of serial data

circuit (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

7

1) Turn ignition switch to ON position.

2) Measure voltage between terminal B of data link

connector and vehicle body ground.

Is voltage 10 – 12 V?

Go to step 8.

Terminal B circuit open

or shorted to ground.

8

1) Turn ignition switch to OFF position.

2) Measure resistance between the following terminals;

• Terminal G of data link connector and vehicle body

ground.

• Terminal G1 of data link connector and vehicle body

ground.

Is each resistance 1

Ω

or less?

Go to step 9.

Terminal G and/or G1

circuit open or high

resistance.

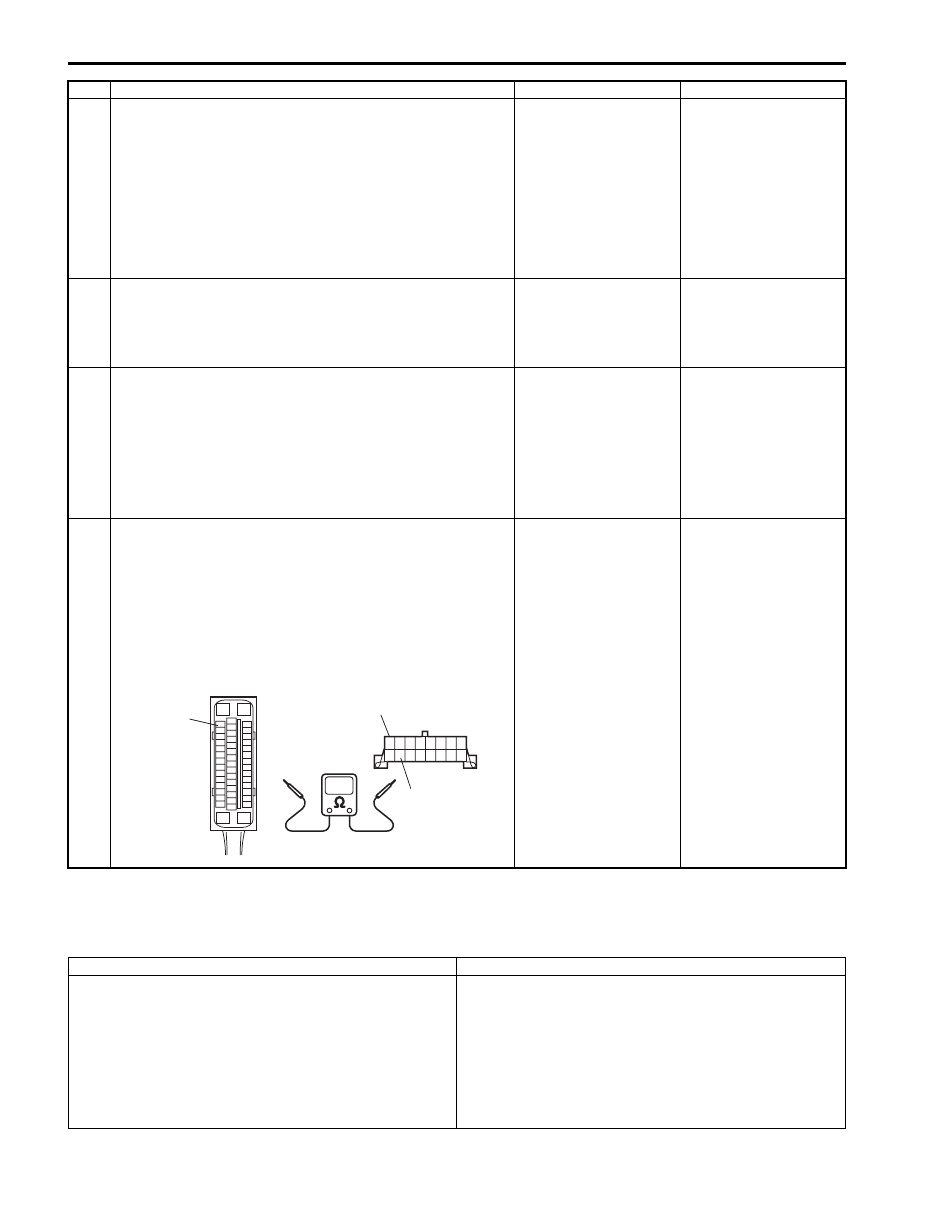

9

1) Turn ignition switch to OFF position.

2) Check proper connection at “E53-33” (“PPL/WHT” wire)

terminal for serial data circuit.

3) If OK, then check resistance between “E53-33” (“PPL/

WHT” wire) terminal and “PPL/WHT” wire terminal (2) for

serial data circuit in DLC (1).

Is resistance 1

Ω

or less?

Substitute a known-

good ESP

® hydraulic

unit / control module

and recheck.

Repair high resistance

or open in “PPL/WHT”

wire circuit for anti lock

brake system.

Step

Action

Yes

No

“E53-33”

2

1

I6JB01460015-01

DTC Detecting Condition

Trouble Area

C1015:

Longitudinal G sensor signal is out of specified range.

(4WD model)

C1017:

Lateral G sensor signal is out of specified range.

C1023:

• Yaw rate sensor signal is out of range.

• Vehicle behavior and yaw rate signal is disagreed.

• Yaw rate / G sensor assembly

• ESP

® control module

Electronic Stability Program: 4F-24

DTC Troubleshooting

DTC C1016: Brake Light Switch Circuit Failure

S6JB0B4604026

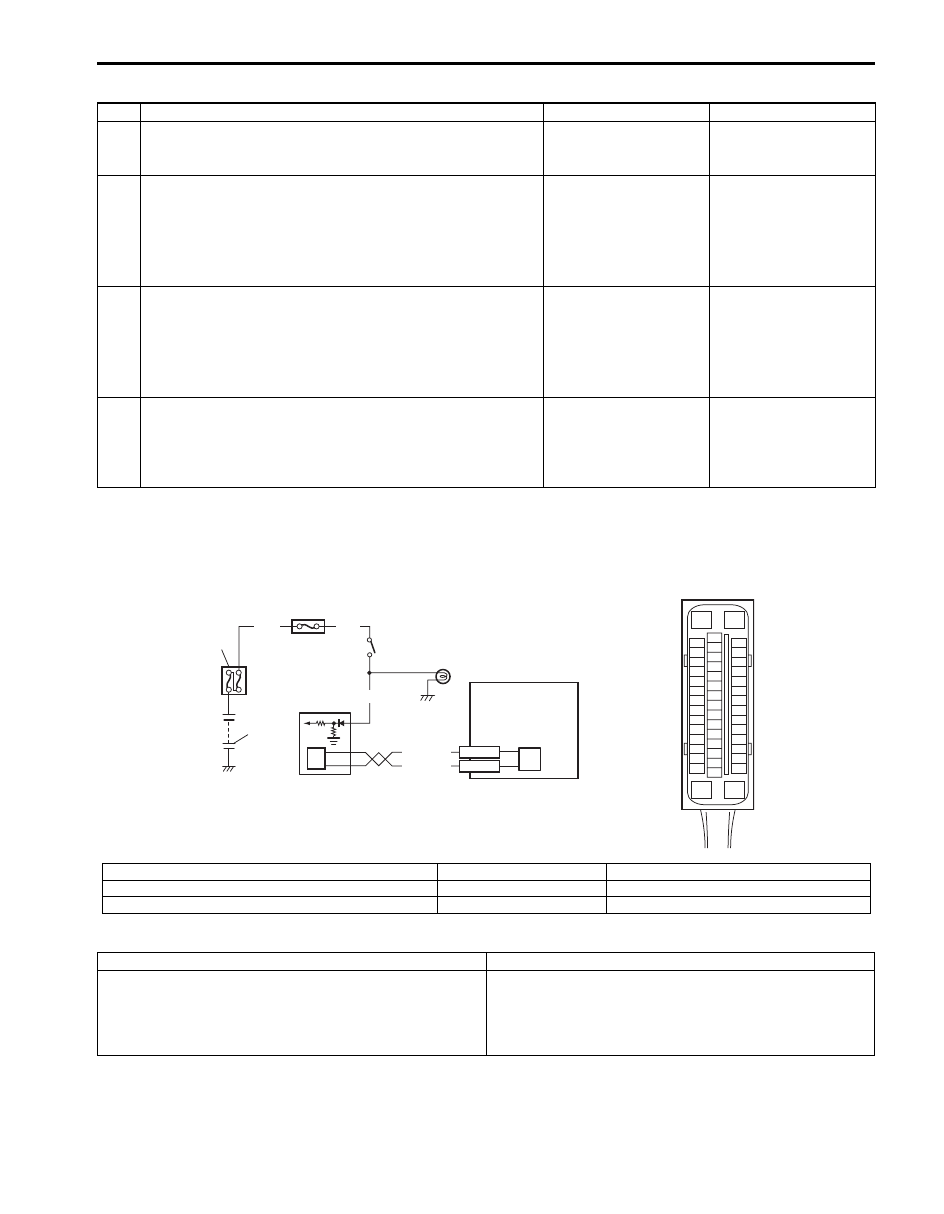

Wiring Diagram

DTC Detecting Condition and Trouble Area

Step

Action

Yes

No

1

Was “Electronic Stability Program Check” performed?

Go to Step 2.

Go to “Electronic

Stability Program

Check”.

2

DTC check for ESP

®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP

®.

Are DTC C1034 and/or C1073 detected?

Go to applicable DTC

diagnosis flow for

troubleshooting.

Go to Step 3.

3

Check sensor calibration

1) Calibrate yaw rate / G sensor assembly referring to

2) Clear all DTCs and check DTC for ESP

®.

Are DTC C1015, C1017 and/or C1023 still detected?

Go to Step 4.

Yaw rate / G sensor

assembly calibration is

incompleted.

4

Check yaw rate / G sensor assembly

1) Check yaw rate / G sensor assembly referring to “Yaw

Rate / G Sensor Assembly On-Vehicle Inspection”.

Is it good condition?

Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and check

DTC.

Replace yaw rate / G

sensor assembly.

3

2

1

[A]

GRN

WHT

E53-42

E53-46

6

7

E53

16

1

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHT/RED

WHT/BLU

GRN/WHT

4

5

7

8

I6JB01460016-01

[A]: ESP

® control module connector (viewed from terminal side)

3. Junction block assembly

6. ECM

1. Battery

4. Brake light switch

7. CAN driver

2. Main fuse box

5. Brake light

8. ESP

® hydraulic unit control module assembly

DTC Detecting Condition

Trouble Area

Vehicle behavior and brake light switch signal is disagreed

for specified time.

• Brake light switch circuit

• Brake light switch

• ECM

• ESP

® control module

4F-25 Electronic Stability Program:

DTC Troubleshooting

DTC C1018: Brake Fluid Level Switch Failure

S6JB0B4604027

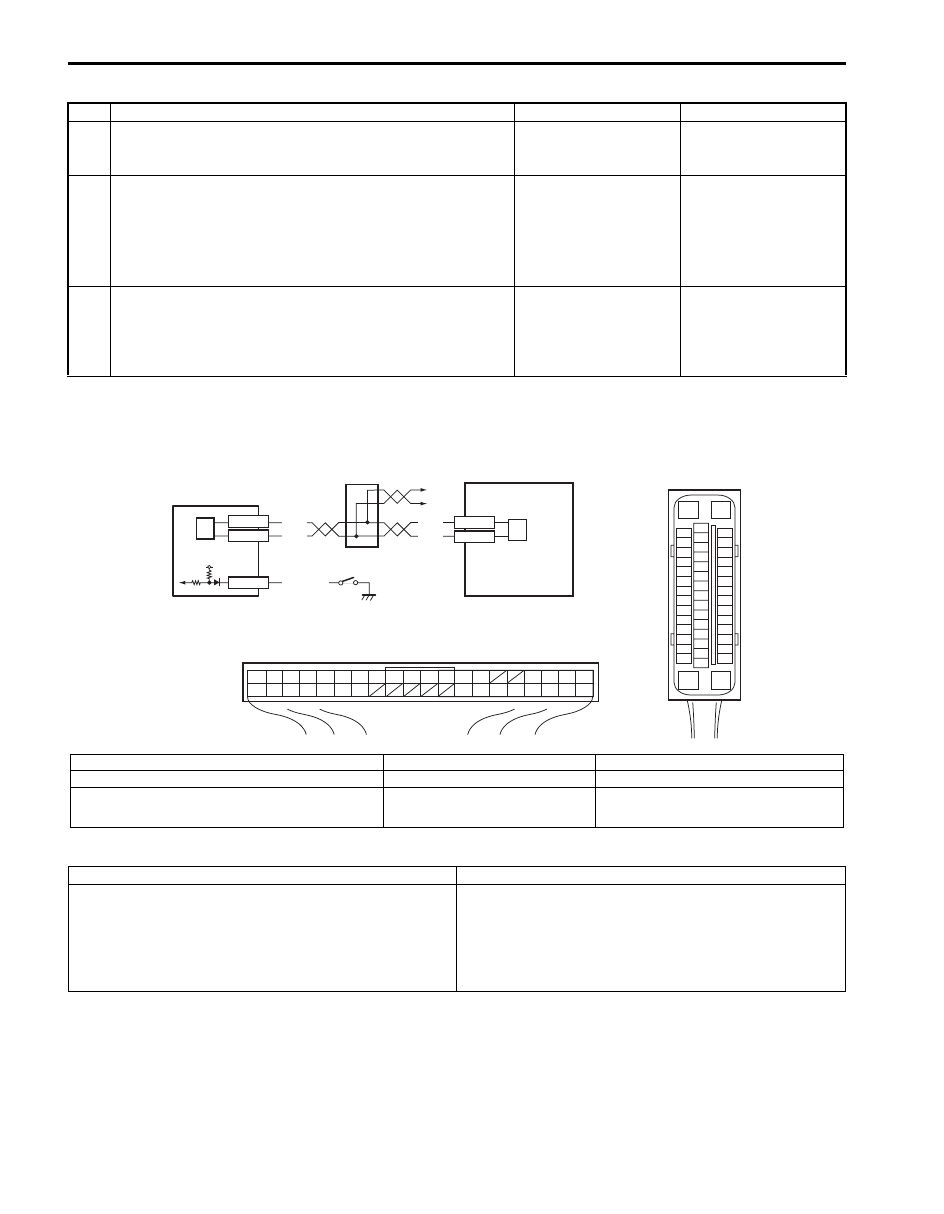

Wiring Diagram

DTC Detecting Condition and Trouble Area

Step

Action

Yes

No

1

Was “Electronic Stability Program Check” performed?

Go to Step 2.

Go to “Electronic

Stability Program

Check”.

2

DTC check for ESP

®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP

®.

Is DTC U1100 detected?

Go to “DTC U1100: Lost

Communication with

ECM (Reception Error)”

for troubleshooting.

Go to Step 3.

3

DTC check for ECM

1) Check DTC for ECM.

Is there any DTC(s) for ECM?

Go to applicable DTC

diagnosis flow for

troubleshooting.

Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and check

DTC.

[A]

E53

16

1

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

RED/BLK

E53-13

E53-44

RED

WHT

RED

WHT

12V

1

2

3

4

5

6

2

G31-1

G31-3

G31-7

G31

1

2

3

4

7

8

9

10

11

14

15

16

36

34

35

24 23

21

22

28 27

25

26

37

39 38

40

18 17

13 12

19

20

[B]

I6JB01460017-02

[A]: ESP

® control module connector (viewed from terminal side)

2. CAN driver

5. Brake fluid level switch

[B]: BCM connector (viewed from harness side)

3. Junction connector

6. ESP

® hydraulic unit control module assembly

1. BCM

4. To TCM, 4WD control module, keyless

start control module, combination

meter and steering angle sensor

DTC Detecting Condition

Trouble Area

• Brake fluid level is too low.

• Input voltage of brake fluid level switch to BCM is low.

• Brake fluid level

• Brake fluid level switch circuit

• Brake fluid level switch

• BCM

• ESP

® control module

Electronic Stability Program: 4F-26

DTC Troubleshooting

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure

S6JB0B4604028

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

1) Turn ignition switch to OFF position.

2) Check for proper connection from harness to ESP

® control module.

3) If OK, substitute an ESP

® hydraulic unit / control module assembly with correct part number.

4) Recheck system.

Step

Action

Yes

No

1

Was “Electronic Stability Program Check” performed?

Go to Step 2.

Go to “Electronic

Stability Program

Check”.

2

Check brake fluid level

1) Check brake fluid level in reservoir.

Is brake fluid level upper than the minimum level?

Go to Step 3.

Replenish brake fluid to

reservoir.

3

DTC check for ESP

®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP

®.

Is DTC U1140 detected?

Go to “DTC U1140: Lost

Communication with

BCM (Reception Error)”.

Go to Step 3.

4

Check brake fluid level switch

1) Turn ignition switch to OFF position.

2) Disconnect brake fluid level switch connector.

3) Check for proper connection at each terminal of brake

fluid level switch connector.

4) If OK, then check brake fluid level switch referring to

“Brake Fluid Level Switch Inspection in Section 9C”.

Is check result OK?

Go to Step 5.

Replace brake fluid

level switch.

5

Check brake fluid level switch circuit

1) Disconnect BCM connector.

2) Check for proper connection to BCM connector at “G31-

7” terminal.

3) If OK, then check resistance between “G31-7” terminal

and vehicle body ground.

Is resistance infinity?

Go to Step 6.

“BLKL/RED” wire circuit

is shorted to ground.

6

Check BCM

1) Connect brake fluid level switch connector and BCM

connector.

2) Check DTC for BCM.

Is there any DTC(s) in BCM?

Go to applicable DTC

diagnosis flow for

troubleshooting.

Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and check

DTC.

DTC Detecting Condition

Trouble Area

Power supply voltage to master cylinder pressure sensor

in ESP

® hydraulic unit / control module assembly is too

low.

• ESP

® control module

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст