Suzuki Grand Vitara JB627. Manual — part 142

3B-10 Differential: Front

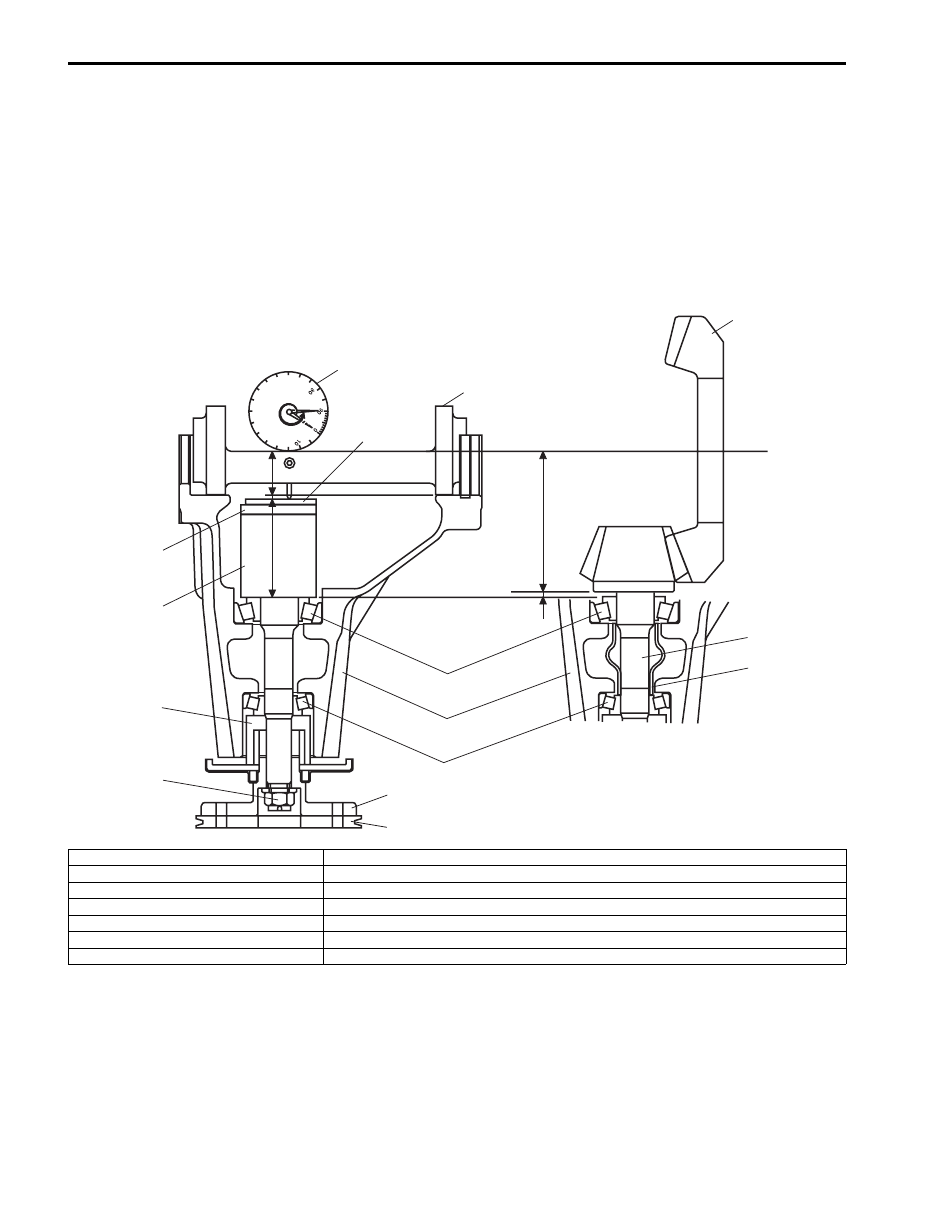

8) To engage drive bevel pinion and gear correctly, it is pre-required to install drive bevel pinion to differential carrier

properly by using adjusting shim as described on the followings. Shown below is relative positions of drive bevel

pinion, differential carrier and mounting dummy.

Special tool

(A): 09900–20607

(B): 09926–78320

(C): 09922–75222

(D): 09951–16070

(E): 09951–46010

(F): 09926–78311–002

(G): 09922–76520

(A)

(B)

(D)

(F)

(E)

2

(G)

“a”

“b”

“d”

“e”

“c”

(C)

1

5

4

3

8

7

6

I5JB0A321029-02

1. Universal Joint flange

8. Drive bevel gear

2. Nut

“a”: Pinion dummy height + Attachment height

3. Front bearing

“b”: Axle dummy radius

4. Differential carrier

“a” + “b”: Mounting dummy size 103.0 mm/4.0551 in.

5. Rear bearing

“c”: Measured dimension

6. Spacer

“d”: Drive bevel pinion mounting distance 102.0 mm/4.0157 in.

7. Drive bevel pinion

“e”: Shim size for mounting distance adjustment (= “c” + 1)

Differential: Front 3B-11

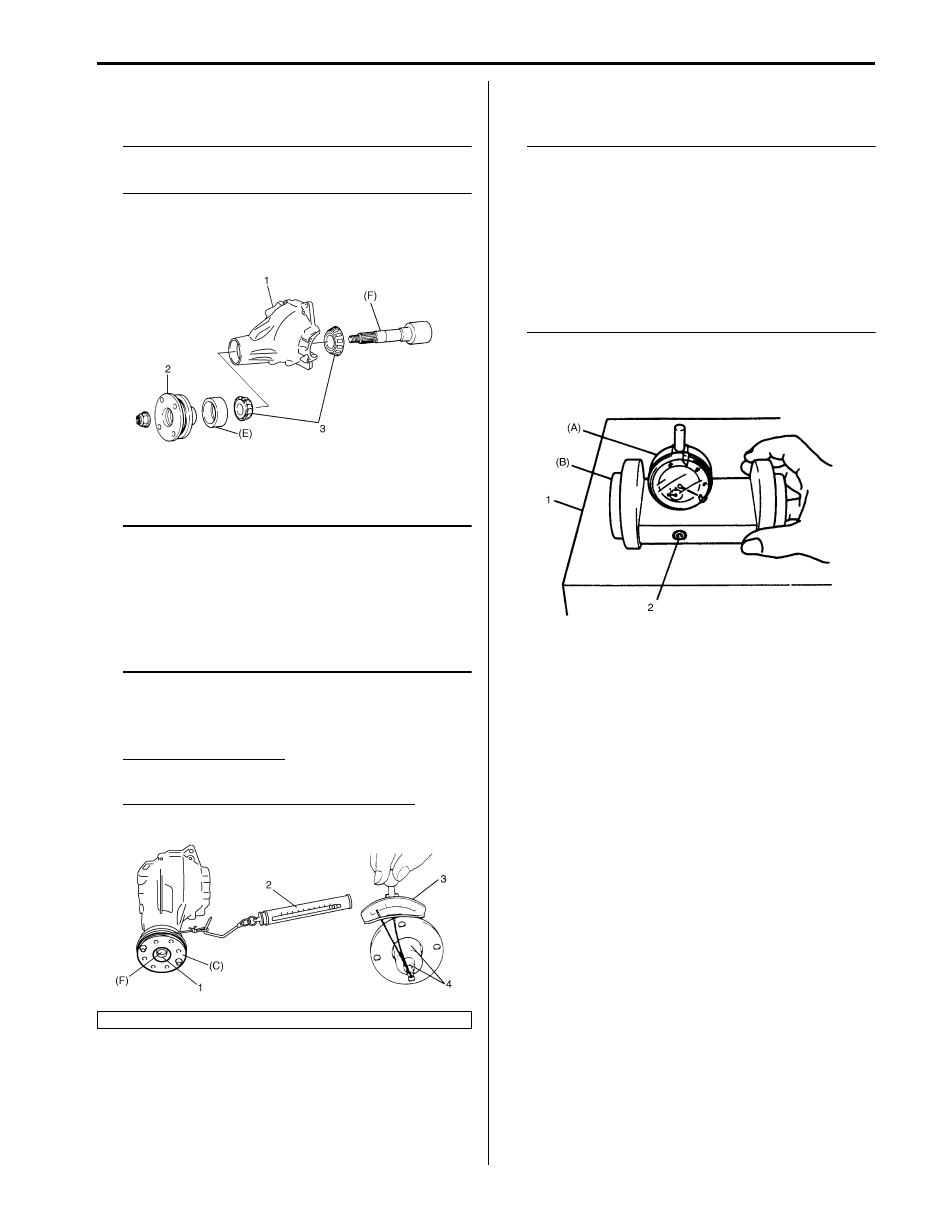

9) Install special tools with bearings (3) and flange (2)

to differential carrier (1).

NOTE

This installation requires no spacer or oil

seal.

Special tool

(E): 09951–46010

(F): 09926–78311–002

10) Tighten flange nut (1) so that specified bearing

preload is obtained.

NOTE

• Before taking measurement with spring

balance (2) or torque wrench (3), check for

rotation by hand and apply small amount

of differential oil to bearings.

• On measuring preload, rotate the drive

bevel pinion about 1 rotation per 2

seconds.

Special tool

(C): 09922–75222

(F): 09926–78311–002

Pinion bearing preload

0.9 – 1.7 N

⋅m (9.0 – 17.0 kg-cm, 7.8 – 14.7 lb-in.)

Spring measure reading with special tool

20 – 40 N (2.0 – 4.0 kg, 4.4 – 8.8 lb)

11) Set dial gauge to mounting dummy and make 0

(zero) adjustment on surface plate (1).

NOTE

• When setting dial gauge to mounting

dummy, tighten screw (2) lightly. Be careful

not to overtighten it, which will cause

damage to dial gauge.

• With dial gauge set, turn dummy back and

force by hand a couple of times and attain

accurate 0 (zero) adjustment.

• It is desirable that short pointer indicates

beyond 2 mm when long one is at 0 (zero).

Special tool

(A): 09900–20607

(B): 09926–78320

4. Socket with adapter

I5JB0A321030-01

I5JB0A321031-01

IYSQ01322033-01

3B-12 Differential: Front

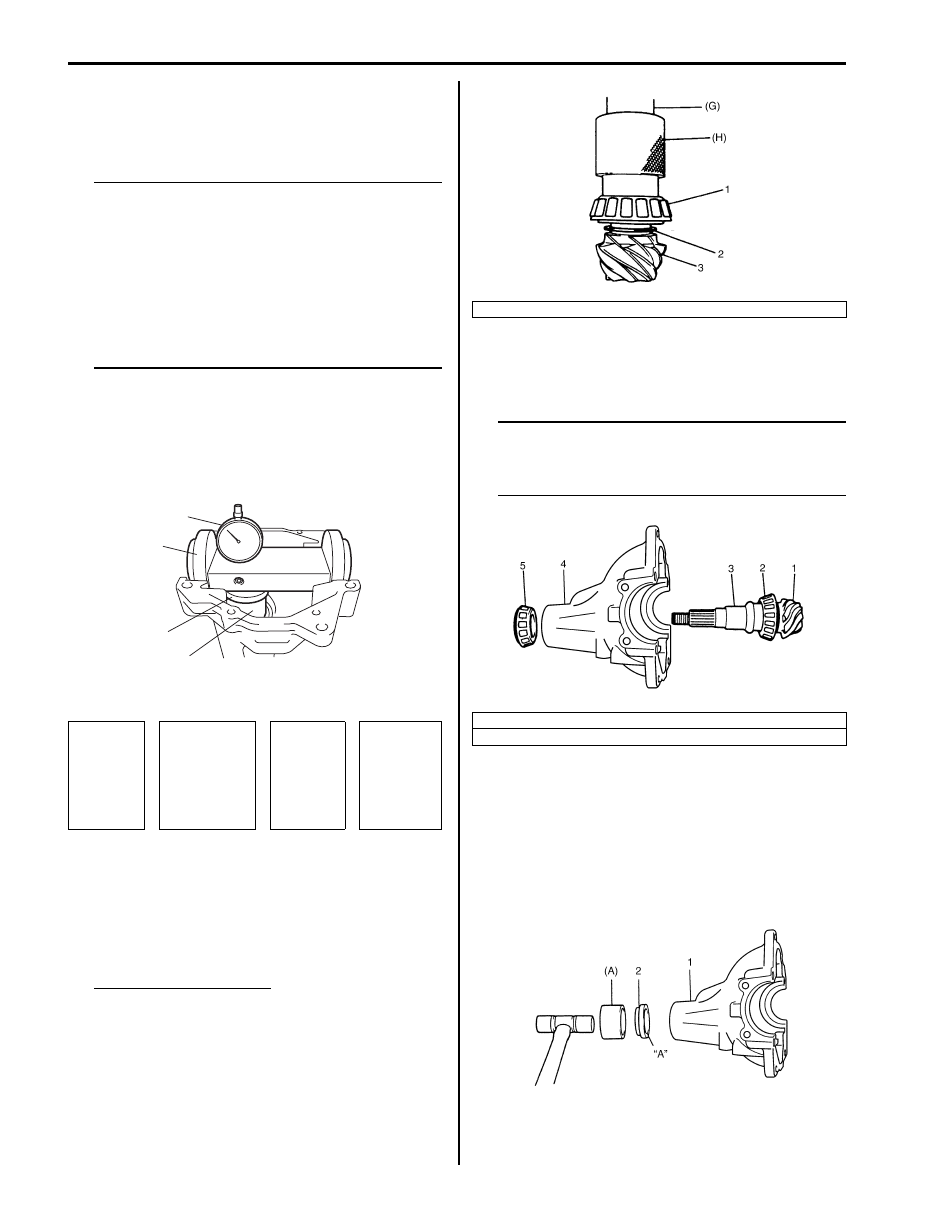

12) Place zero-adjusted mounting dummy and dial

gauge set on pinion mounting dummy and take

measurement between zero position and extended

dial gauge measuring tip.

NOTE

• Repeat turning back and force of dummy

and measure distance as far as top surface

of pinion dummy accurately.

• When dial gauge measuring tip extends

from 0 (zero) position, pointer turns

counterclockwise.

• Measured value may exceed 1 mm.

Therefore, it is also necessary to know

reading of short pointer.

Special tool

(A): 09900–20607

(B): 09926–78311

(D): 09951–16070

(F): 09926–78311–002

: 09922–76520

13) Obtain adjusting shim thickness by the following

equation.

14) Select adjusting shim(s) (2) closest to calculated

value from among the following available sizes and

put it in place and then press-fit rear bearing (1).

Special tool

(G): 09913–85210

(H): 09940–53111

Available shim thickness

1.00, 1.03, 1.06, 1.09, 1.12, 1.15, 1.18, 1.21,1.24,

1.27, 1.30 and 0.3 mm

(0.039, 0.040, 0.042, 0.043, 0.044, 0.045, 0.046,

0.047 0.048, 0.049, 0.050 and 0.012 in.)

15) With new pinion spacer (3) inserted as shown in the

figure, install front bearing (5) to differential carrier

(4).

NOTE

• Make sure to use new spacer for

reinstallation.

• Apply differential oil to bearings.

16) Using special tool and plastic hammer, drive oil seal

(2) into differential carrier (1) as shown in figure.

Then apply grease “A” to oil seal lip.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Special tool

(A): 09951–18210

Necessary

shim

thickness

“e”

=

Mounting

dummy size

103.0 mm/

4.0551 in.

“a” + “b”

+

Measured

dimension

“c”

–

Drive bevel

pinion

mounting

distance

102 mm/

4.0157 in.

(F)

(D)

(B)

(A)

I5JB0A321032-01

3. Drive bevel pinion

1. Drive bevel pinion

2. Rear bearing

I5JB0A321033-01

I5JB0A321034-01

I5JB0A321035-01

Differential: Front 3B-13

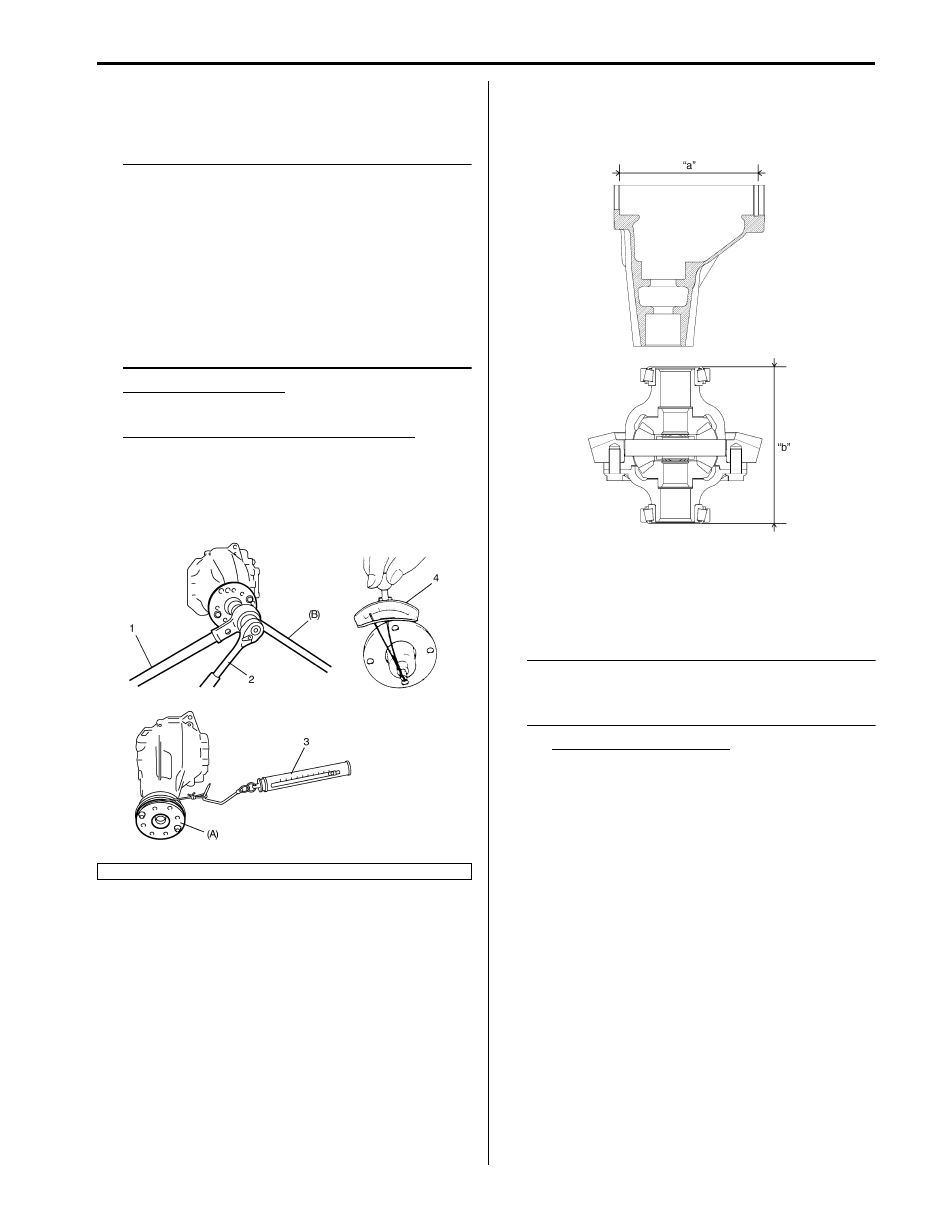

17) While tightening flange nut gradually with special

tool and power wrench (4 – 10 magnification) (1), set

preload of pinion to specification.

NOTE

• Before taking measurement with spring

balance (3) or torque wrench (4), check for

smooth rotation by hand.

• On measuring preload, rotate the drive

bevel pinion about 1 rotation per 2

seconds.

• Be sure to tighten gradually and carefully

till specified starting torque is obtained.

Turning back overtightened flange nuts

should be avoided.

Pinion bearing preload

0.9 – 1.7 N

⋅m (9.0 – 17.0 kg-cm, 7.8 – 14.7 lb-in.)

Spring measure reading with special tool

20 – 40 N (2.0 – 4.0 kg, 4.4 – 8.8 lb)

Special tool

(A): 09922–75222

(B): 09922–66021

18) Select differential side bearing shim as follows.

a) Measure dimension “a” and “b” using vernier

caliper.

b) Calculate dimension “a” – “b”, and select shims

from among following available size so that total

of thickness of right side and left side shims may

reach the calculated value.

NOTE

Select shims so that thickness of right side

shims and left side shims become almost

even.

Available shim thickness

Right side: 1.75, 1.85, 1.95, 2.00, 2.05, 2.15

and 2.25 mm (0.069, 0.073, 0.077, 0.079, 0.081,

0.085 and 0.089 in.)

Left side: 2.75, 2.85, 2.95, 3.00, 3.05, 3.15 and

3.25 mm (0.108, 0.112, 0.116, 0.118, 0.120,

0.124 and 0.128 in.)

2. Socket wrench

I5JB0A321036-02

I5JB0A321037-04

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст