Suzuki Grand Vitara JB627. Manual — part 141

3B-6 Differential: Front

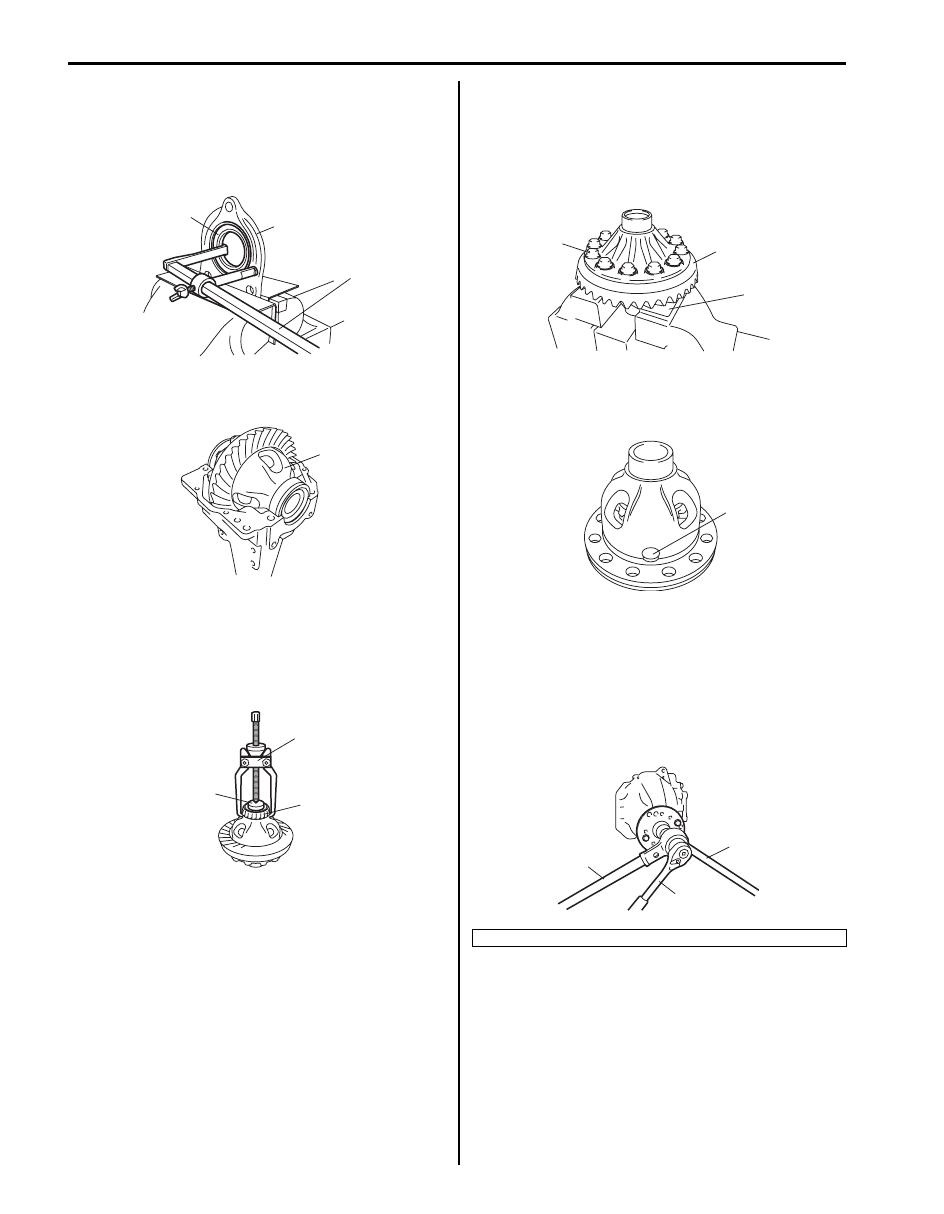

5) Support differential side right retainer (1) with soft

jawed vise and remove oil seal (2) from differential

side right retainer using special tool, if necessary.

Special tool

(A): 09913–50121

6) Take out differential assembly (1), outer race and

shim all at once.

7) Pull out differential side bearing (1) using special

tools.

Special tool

(A): 09913–65135

(B): 09925–86010

8) Remove drive bevel gear (hypoid gear), differential

gears, differential pinions and pinion shaft as follows.

a) With aluminum plates (2) placed on vise first,

grip differential case with it and remove drive

bevel gear (hypoid gear) (3) by removing its bolts

(1).

b) Remove pinion shaft (1), differential gears,

washers, differential pinions, spring washers and

thrust washers.

9) Remove drive bevel pinion (hypoid gear) assembly

as follows.

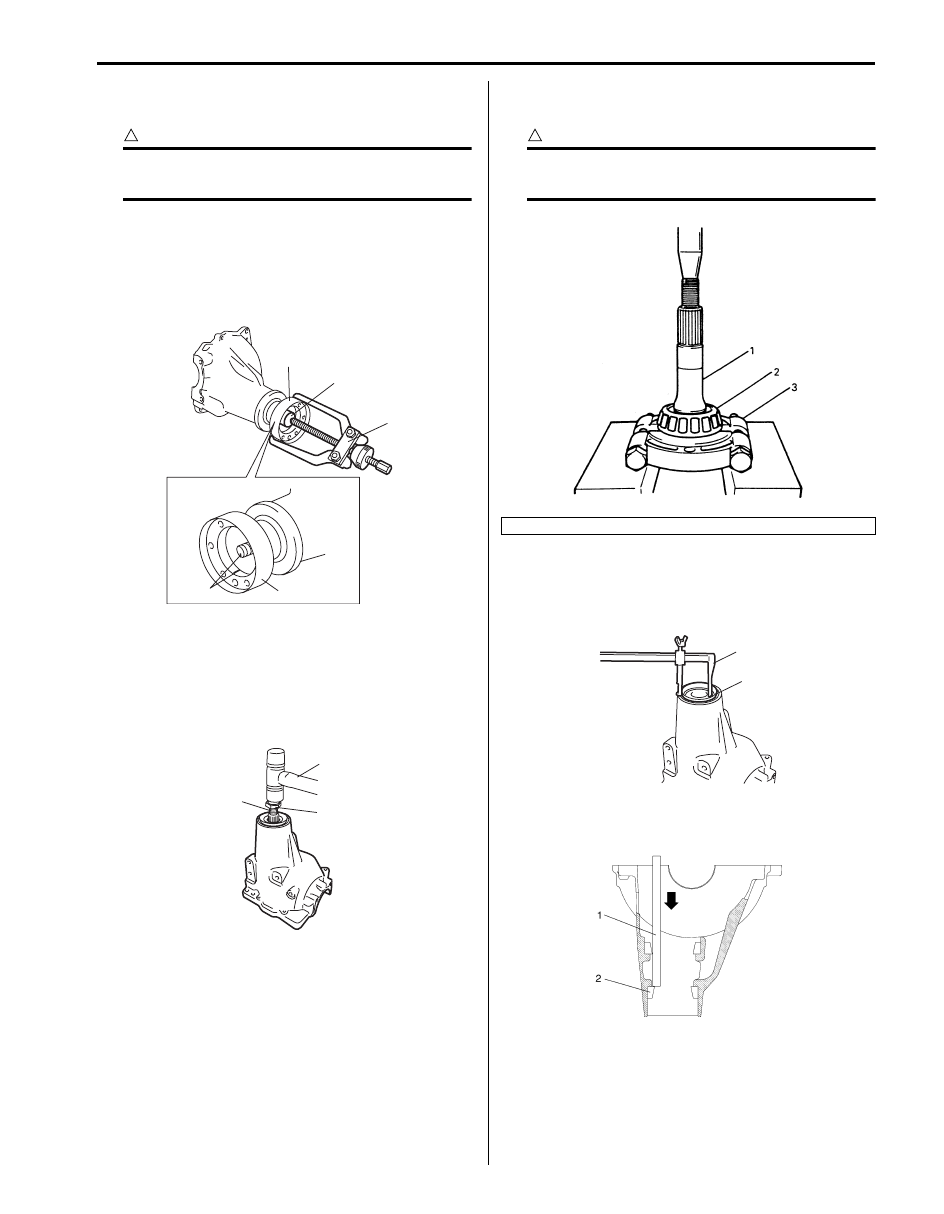

a) Hold joint flange with special tool and then

remove flange nut by using power wrench (4 –

10 magnification) (2).

Special tool

(A): 09922–66021

1

(A)

2

I5JB0A321011-01

1

I5JB0A321012-02

1

(B)

(A)

I5JB0A321013-02

1. Socket wrench

3

2

1

I5JB0A321014-02

1

I5JB0A321015-02

(A)

2

1

I5JB0A321016-02

Differential: Front 3B-7

b) Make mating marks (1) on drive bevel pinion and

companion flange.

CAUTION

!

Do not make mating mark on the coupling

surface of the flange.

c) Remove flange (2) from drive bevel pinion. Use

special tool if it is hard to remove.

Special tool

(A): 09913–65135

(B): 09925–88210

d) Remove drive bevel pinion (1) with rear bearing,

shim and spacer from carrier.

If it is hard to remove, screw an used nut (2) into

drive bevel pinion and hammer (3) on that nut

with a plastic hammer but never directly on drive

bevel pinion.

e) Remove drive bevel pinion rear bearing (2) by

using bearing puller (3) and hydraulic press.

CAUTION

!

To avoid rear bearing from being damaged,

support it at flat side of bearing puller.

10) Remove oil seal (1) using special tool.

Special tool

(A): 09913–50121

11) Using a hammer and brass bar (1), drive out front

bearing outer race (2).

2

(B)

(A)

2

1

I5JB0A321017-02

3

2

1

I5JB0A321018-01

1. Drive bevel pinion

I1JA01322006-01

(A)

1

I5JB0A321019-01

I5JB0A321020-01

3B-8 Differential: Front

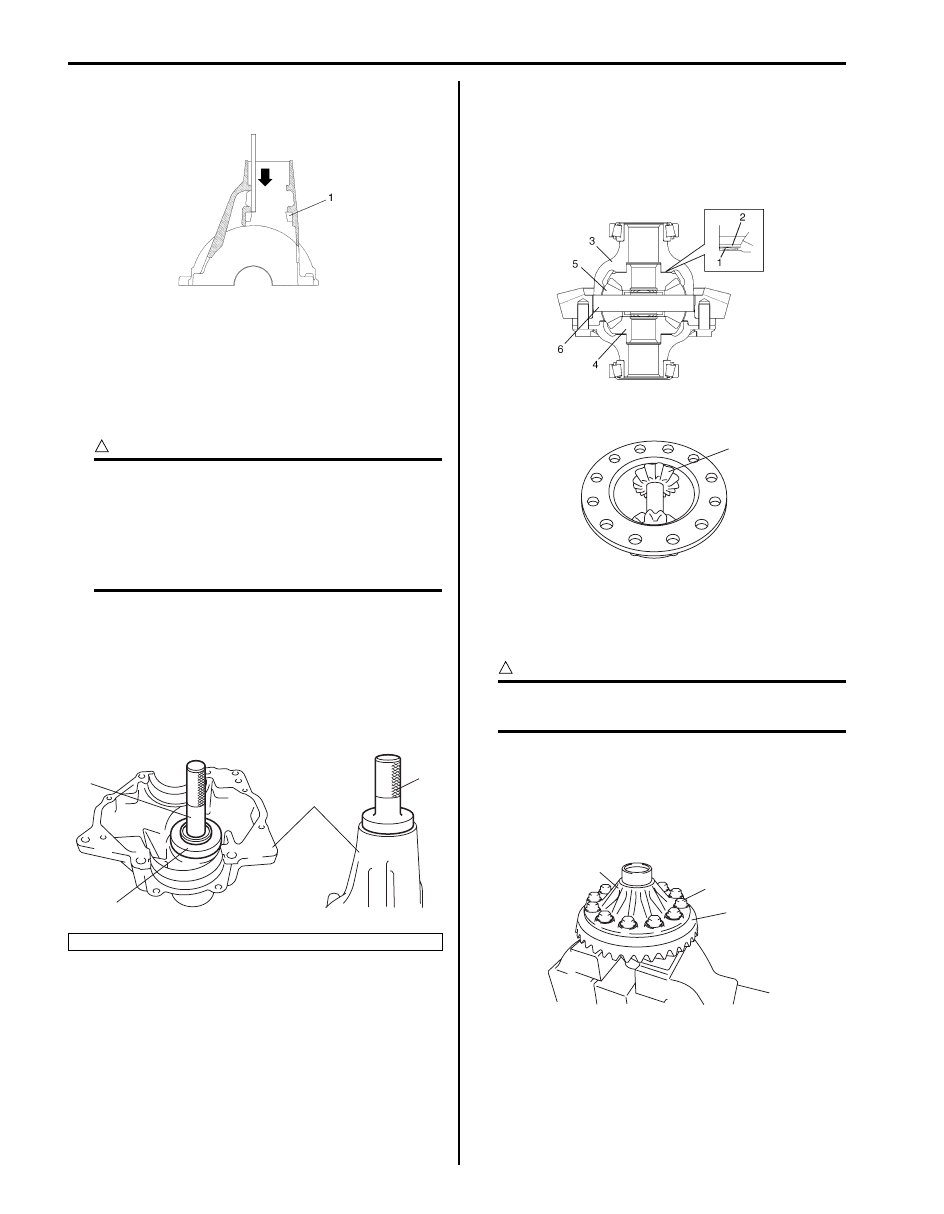

12) Drive out rear bearing outer race (1) in the same

manner as Step 11).

Reassembly

Judging from faulty conditions noted before disassembly

and what is found through visual check of bearing and

gear tooth etc. after disassembly, prepare replacing

parts and proceed to reassembly according to

procedures as described.

CAUTION

!

• Drive bevel gear and pinion must be

replaced as a set when either replacement

becomes necessary.

• When replacing taper roller bearing,

replace as inner race and outer race

assembly.

1) For press-fitting drive bevel pinion bearing outer

races, use special tools and press as shown in the

figure.

Special tool

(A): 09924–74510

(B): 09925–14520

(C): 09913–75510

2) After applying differential oil to differential gear (4),

pinions (5), pinion shaft (6), pinion washer, thrust

washer (2) and spring washer (1), install them in

differential right case (3).

For correct installing direction of thrust washer (2)

and spring washer (1), refer to the figure.

3) Check differential pinion gear (1) for smooth rotation.

4) Put drive bevel gear (3) on differential case (1) and

fasten them with bolts (2) by tightening them to

specified torque. Use thread lock cement for bolts

(2).

CAUTION

!

Use of any other bolts than that specified is

prohibited.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Bevel gear bolt (a): Tighten 40 N

⋅m (4.0 kgf-m,

29.5 lb-ft) + 50

°

1. Differential carrier

I5JB0A321021-01

(B)

(A)

1

(C)

I5JB0A321022-01

I5JB0A321023-05

1

I5JB0A321024-04

2, (a), “A”

3

1

I5JB0A321025-01

Differential: Front 3B-9

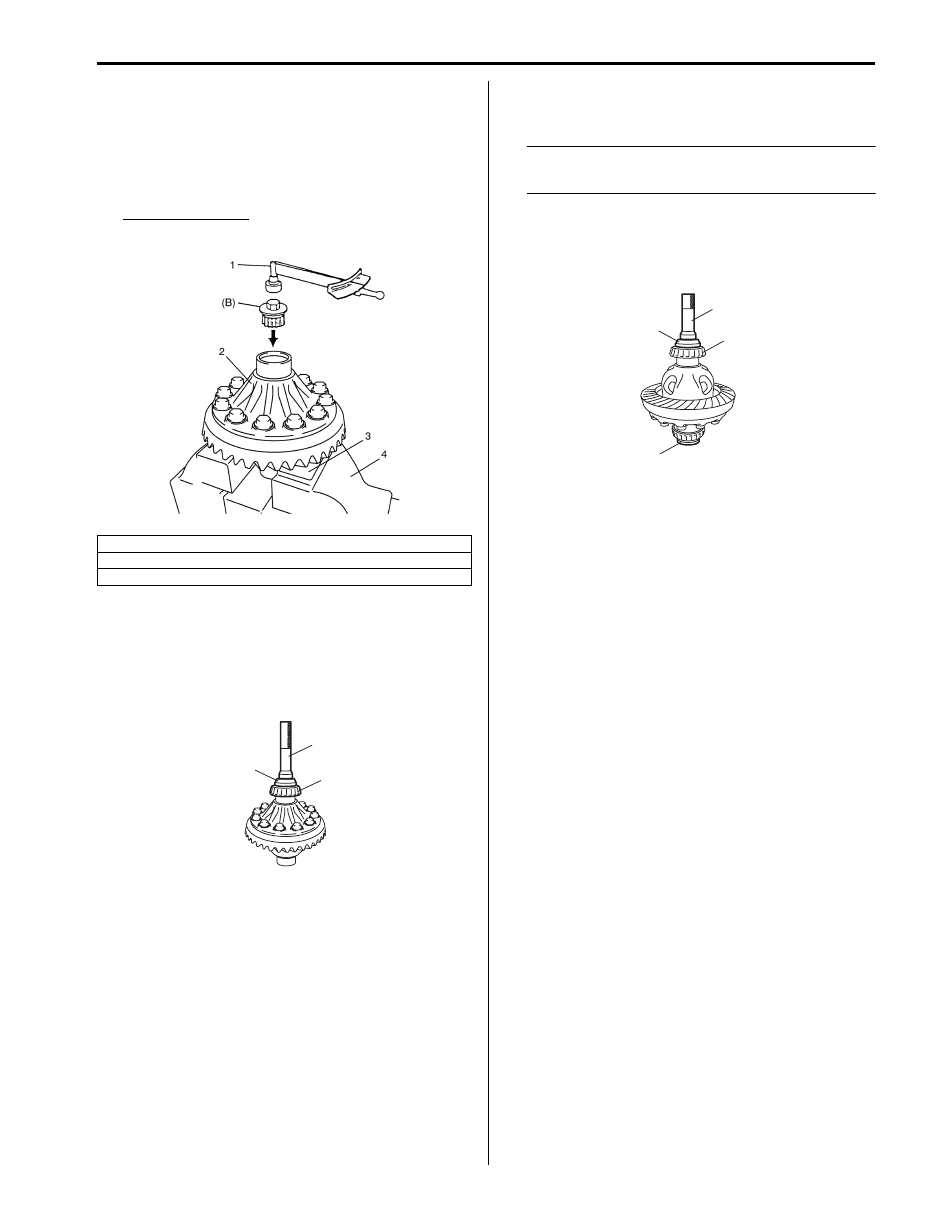

5) Install special tool to differential case assembly (2)

and check that preload is within specification. If

preload exceeds specified value, check if foreign

matter is caught or gear is damaged.

Special tool

(B): 09928–06510

Side gear preload

Max. 2.5 N

⋅m (0.25 kgf-m, 1.8 lb-ft)

6) Press-fit left side bearing (1) with special tool and

hydraulic press.

Special tool

(A): 09913–75821

(B): 09924–84510–004

7) Press-fit right side bearing (1) with special tools and

hydraulic press.

NOTE

Be sure to use bearing holder for the purpose

of protecting lower bearing.

Special tool

(A): 09913–75821

(B): 09924–84510–004

(C): 09924–84510–005

1. Torque wrench

3. Aluminum plate

4. Vise

I5JB0A321026-01

(B)

(A)

1

I5JB0A321027-01

(B)

(A)

1

(C)

I5JB0A321028-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст