Suzuki Grand Vitara JB627. Manual — part 201

4F-43 Electronic Stability Program:

6

DTC check for ESP

®

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Connect connectors to ESP

® control module and BCM.

4) Check DTC for ESP

®.

Is DTC U1140 detected?

Go to Step 7.

Go to Step 9.

7

DTC Check for ECM

1) Check DTC for ECM.

Is DTC U0140 detected?

Go to Step 8.

Check ESP

® control

module power and

ground circuit. If circuit

is OK, substitute a

known-good ESP

®

control module and

check DTC.

8

CAN communication circuit check

1) Turn ignition switch to OFF position

2) Disconnect connectors of ESP

® control module, BCM

and ECM communicating by means of CAN.

3) Measure resistance at following terminals.

• Between “WHT/BLU” and “WHT” wire terminals of

ESP

® control module connector

• Between “WHT/RED” and “RED” wire terminals of

ESP

® control module connector

Is resistance below 1

Ω

?

Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

check DTC.

Substitute a known-

good ESP

® control

module and check DTC.

9

CAN communication circuit check

1) Turn ignition switch to OFF position.

Is each CAN communication circuit between disconnected

control modules (other than ESP

®

control module and BCM)

opened, shorted or high resistance?

Repair or replace the

CAN communication

line.

Go to Step 10.

10 DTC check for ESP

®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector.

• ECM

• TCM (A/T model)

• BCM

• 4WD control module (if equipped)

• Keyless start control module (if equipped)

• Steering angle sensor

3) Check DTC for ESP

®.

Is DTC U1140 detected?

Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP

®

hydraulic unit / control

module assembly and

check DTC.

Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and check DTC.

Step

Action

Yes

No

Electronic Stability Program: 4F-44

Repair Instructions

Hydraulic Unit Operation Check

S6JB0B4606001

Refer to “Hydraulic Unit Operation Check in Section 4E”.

Sensor Calibration

S6JB0B4606015

CAUTION

!

If any DTC(s) other than C1075, C1076, C1077

or C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, dome fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP

® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

Sensor Calibration (Using SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076, C1077 and/or

C1078 is detected. If any other DTC are detected,

repair the detected DTC.

4) Park and level the vehicle with parking brake, stop

engine with ignition switch ON, set steering in

straight and without stepping on the brake pedal.

CAUTION

!

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibration, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC.

Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

CAUTION

!

When power is not supplied to the steering

angle sensor by removing battery or fuse,

steering angle sensor should be calibrated.

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start

engine.

CAUTION

!

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

light (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator light flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5

mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator light is OFF.

(A)

1

I5JB0A450008-01

1

I6JB01460024-02

4F-45 Electronic Stability Program:

ESP

® Hydraulic Unit / Control Module

Assembly Components

S6JB0B4606002

®) hydraulic unit / control module

Assembly Components in Section 4E”.

ESP

® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S6JB0B4606003

®) hydraulic unit / control module

Assembly On-Vehicle Inspection in Section 4E”.

ESP

® Hydraulic Unit / Control Module

Assembly Removal and Installation

S6JB0B4606004

®) hydraulic unit / control module

Assembly Removal and Installation in Section 4E”.

Front Wheel Speed Sensor On-Vehicle

Inspection

S6JB0B4606005

Refer to “Front Wheel Speed Sensor On-Vehicle

Inspection in Section 4E”.

Front Wheel Speed Sensor Removal and

Installation

S6JB0B4606006

Refer to “Front Wheel Speed Sensor Removal and

Installation in Section 4E”.

Front Wheel Speed Sensor Inspection

S6JB0B4606007

Refer to “Front Wheel Speed Sensor Inspection in

Section 4E”.

Rear Wheel Speed Sensor On-Vehicle

Inspection

S6JB0B4606008

Refer to “Front Wheel Speed Sensor On-Vehicle

Inspection” since rear wheel speed sensor is the same

as front wheel speed sensor.

Rear Wheel Speed Sensor Removal and

Installation

S6JB0B4606009

Refer to “Rear Wheel Speed Sensor Removal and

Installation in Section 4E”.

Rear Wheel Speed Sensor Inspection

S6JB0B4606010

Refer to “Front Wheel Speed Sensor Inspection” since

rear wheel speed sensor is the same as front wheel

speed sensor.

Front Wheel Encoder On-Vehicle Inspection

S6JB0B4606011

Refer to “Front Wheel Encoder On-Vehicle Inspection in

Section 4E”.

Front Wheel Encoder Removal and Installation

S6JB0B4606012

CAUTION

!

Front wheel encoder is included in front

wheel hub assembly. If front wheel encoder

needs to replaced, replace it as a front wheel

hub assembly.

For removal and installation of front wheel hub

assembly, referring to “Front Wheel Hub Assembly

Removal and Installation in Section 2B”.

Rear Wheel Encoder On-Vehicle Inspection

S6JB0B4606013

Refer to “Rear Wheel Encoder On-Vehicle Inspection in

Section 4E”.

Rear Wheel Encoder Removal and Installation

S6JB0B4606014

CAUTION

!

Rear wheel encoder is included in rear wheel

hub assembly. If rear wheel encoder needs to

replaced, replace it as a rear wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Assembly

Removal and Installation in Section 2C”.

Master Cylinder Pressure Sensor On-Vehicle

Inspection

S6JB0B4606016

1) Calibrate yaw rate / G sensor assembly referring to

2) Check that basic brake system other than ESP

®

refer to “Brake Diagnosis Note in Section 4A”.

3) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

(A)

1

I5JB0A450008-01

Electronic Stability Program: 4F-46

4) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) When brake pedal is released, check “Master Cyl

Press” under “DATA LIST” of SUZUKI scan tool.

If pressure is out of specification, replace ESP

®

hydraulic unit / control module assembly.

Master cylinder pressure specification

Brake pedal released: 0

± 0.8 MPa (0 ± 8 kg/cm

2

, 0

± 113 psi)

6) Hoist vehicle and remove right-side front wheel.

7) Connect special tool with rubber hose (1) to Front

brake caliper bleeder plug (2).

Special tool

(A): 09956–02311

8) When bleeder plug loosen and depress brake pedal

to make special tool gauge reading 10 MPa (100 kg/

cm

2

, 1422 psi), check “Master Cyl Press” under

“DATA LIST” of SUZUKI scan tool.

If pressure displayed on SUZUKI scan tool is out of

specification, replace ESP

® hydraulic unit / control

module assembly.

Master cylinder pressure specification

Brake pedal depressed 10 MPa (100 kg/cm

2

, 1422

psi): 10

± 1.2 MPa (100 ± 12 kg/cm

2

, 1422

± 170

psi)

9) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

10) Tighten bleeder plug and bleed air from brake

system, referring to “Air Bleeding of Brake System in

Section 4A”.

Yaw Rate / G Sensor Assembly On-Vehicle

Inspection

S6JB0B4606017

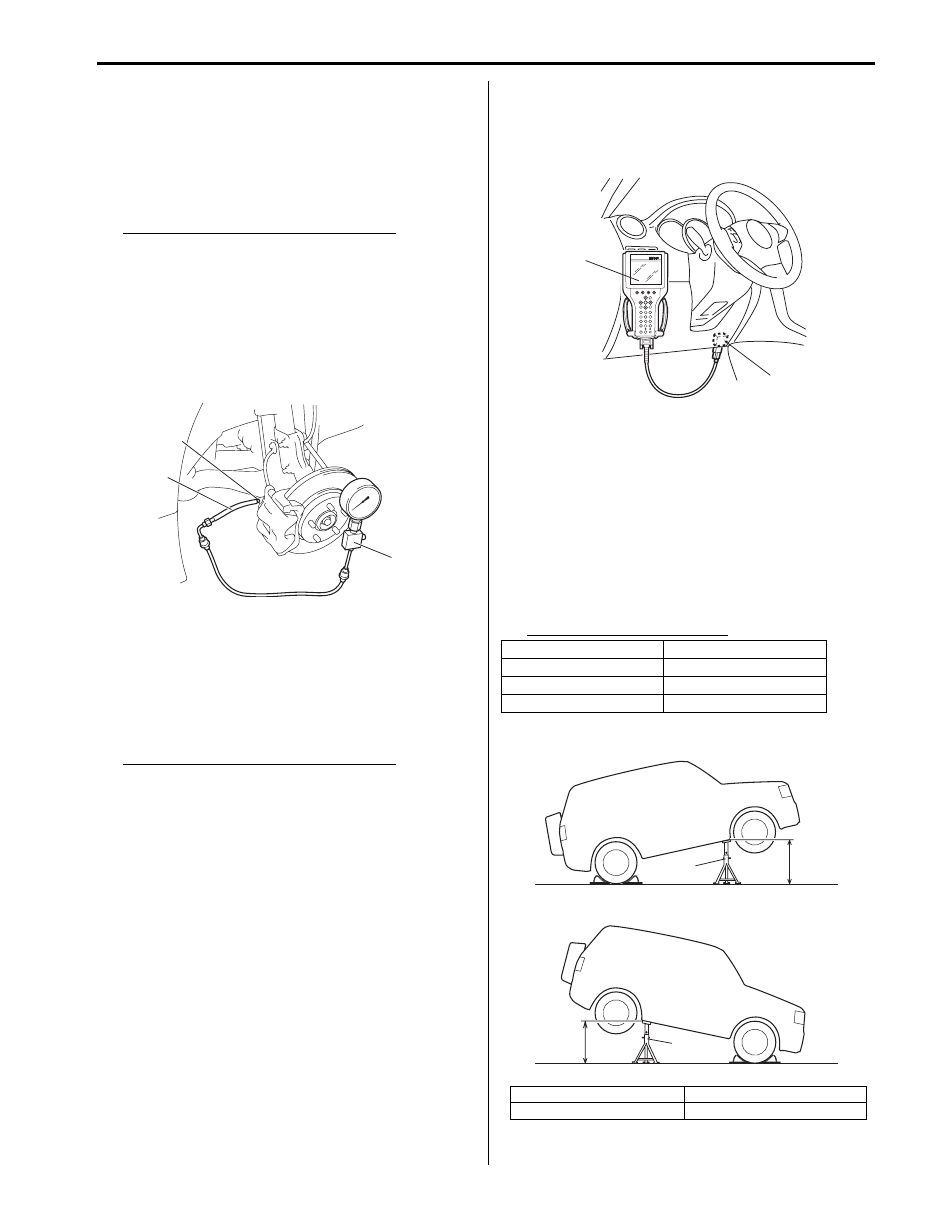

Longitudinal G Inspection

1) Calibrate yaw rate / G sensor assembly referring to

2) Park and level the vehicle with parking brake and fix

wheels with chokes.

3) Check yaw rate / G sensor assembly installation

condition.

4) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

5) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

6) Check “G Sensor” under “DATA LIST” of SUZUKI

scan tool in the following vehicle conditions.

• Level condition

• Front-up condition

• Rear-up condition

If Longitudinal G condition is out of specification,

replace yaw rate / G sensor assembly.

Longitudinal G specification

2

(A)

1

I6JB01460025-01

Vehicle condition

Longitudinal G

Level condition

0

± 0.1 G

Front-up condition

0.1

± 0.1 G

Rear-up condition

–0.1

± 0.1 G

[A]: Front-up condition

“a”: Approx 400 mm (15.75 in.)

[B]: Rear-up condition

1. Safety stand

(A)

1

I5JB0A450008-01

[A]

[B]

“a”

“a”

1

1

I6JB01460026-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст