Suzuki Grand Vitara JB627. Manual — part 2

00-5 Precautions:

• Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service

materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service

materials, wear moisture-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service

materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s

reach.

• Make sure the bonnet is fully closed and

latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

CAUTION

!

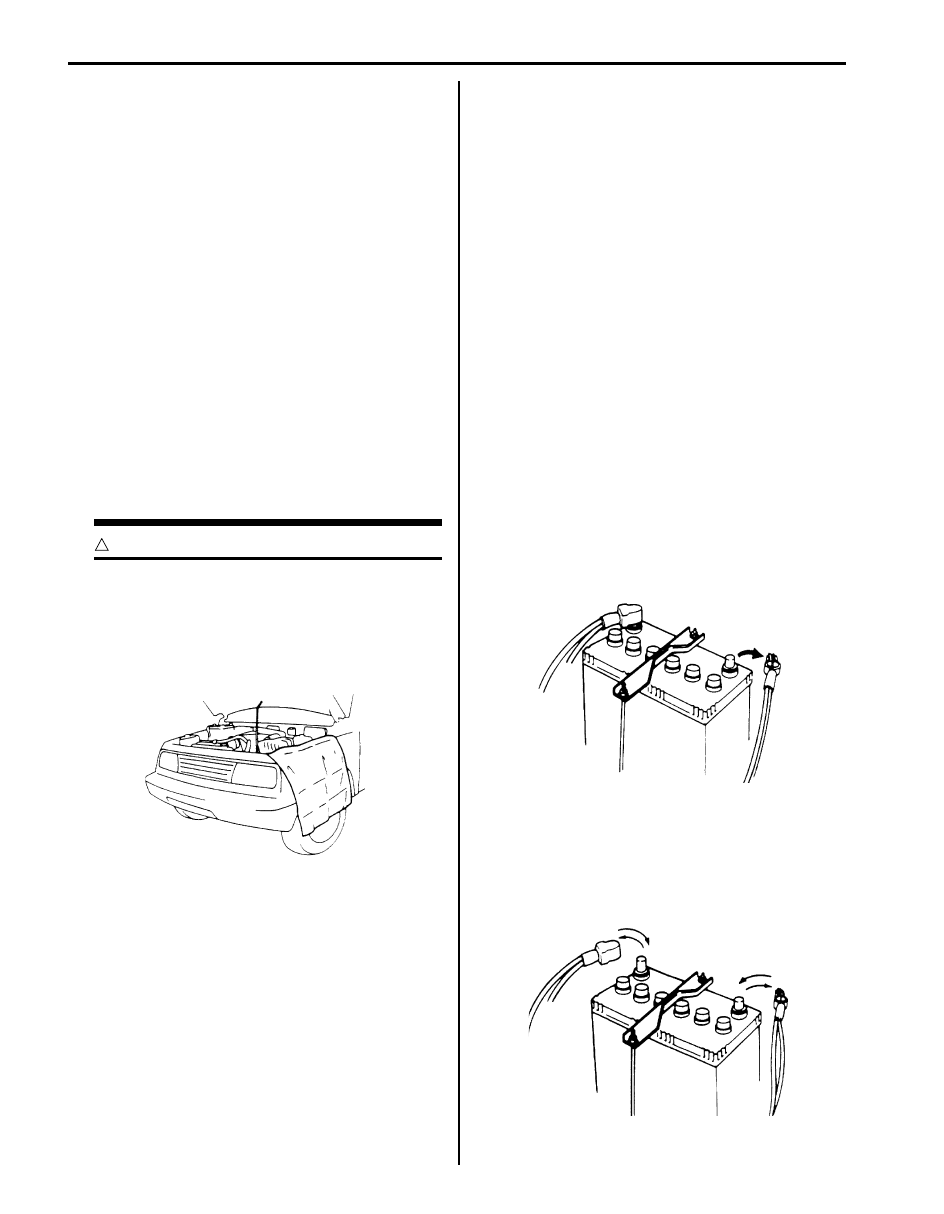

• Before starting any service work, cover

fenders, seats and any other parts that are

likely to get scratched or stained during

servicing. Also, be aware that what you

wear (e.g. buttons) may cause damage to

the vehicle’s finish.

• When performing service to electrical parts

that does not require use of battery power,

disconnect the negative cable of the

battery.

• When disconnecting the negative cable

from the battery, be careful to the

following.

– Check and record DTCs in ECM and

TCM if necessary before disconnecting.

– Record displayed contents of the clock

and/or audio system, etc. before

disconnecting and reset it as before

after connecting.

– For vehicle equipped with electric

throttle body system, perform electric

throttle body system calibration

referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the

battery.

– For vehicle equipped with power sliding

roof (sunroof), initialize sliding roof

position data in motor unit by

performing “How to reactivate the

system to prevent being pinched by the

sunroof” in Sunroof section of Owner’s

manual.

• When removing the battery, be sure to

disconnect the negative cable first and

then the positive cable. When

reconnecting the battery, connect the

positive cable first and then the negative

cable, and replace the terminal cover.

IYSQ01010004-01

I2RH01010026-01

I2RH01010027-01

Precautions: 00-6

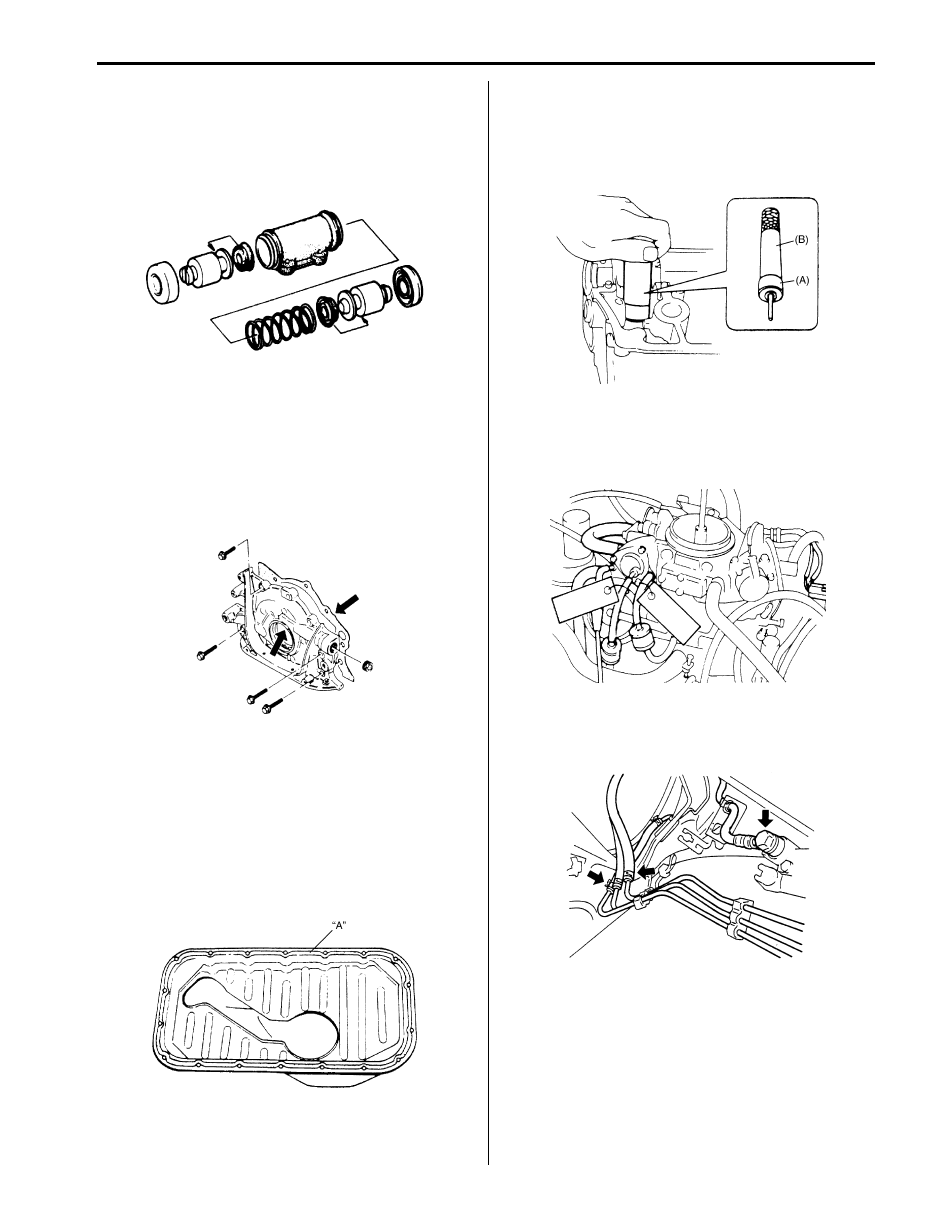

• When removing parts that are to be reused,

be sure to keep them arranged in an

orderly manner so that they may be

reinstalled in the proper order and

position.

• Whenever you use oil seals, gaskets,

packing, O-rings, locking washers, split

pins, self-locking nuts, and certain other

parts as specified, be sure to use new

ones. Also, before installing new gaskets,

packing, etc., be sure to remove any

residual material from the mating surfaces.

• Make sure that all parts used in

reassembly are perfectly clean.

• When use of a certain type of lubricant,

bond or sealant is specified, be sure to

remove the old one thoroughly and use the

specified type.

“A”: Sealant 99000–31150 (SUZUKI Bond

No.1207C)

• Be sure to use special tools when

instructed.

Special tool

(A): 09917–98221

(B): 09916–58210

• When disconnecting vacuum hoses, attach

a tag describing the correct installation

positions so that the hoses can be

reinstalled correctly.

• After servicing fuel, oil, coolant, vacuum,

exhaust or brake systems, check all lines

related to the system for leaks.

IYSQ01430019-01

I2RH01010029-01

I2RH01010030-01

I2RH01010031-01

I2RH01010032-01

I2RH01010033-01

00-7 Precautions:

• For vehicles equipped with fuel injection

systems, never disconnect the fuel line

between the fuel pump and injector

without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

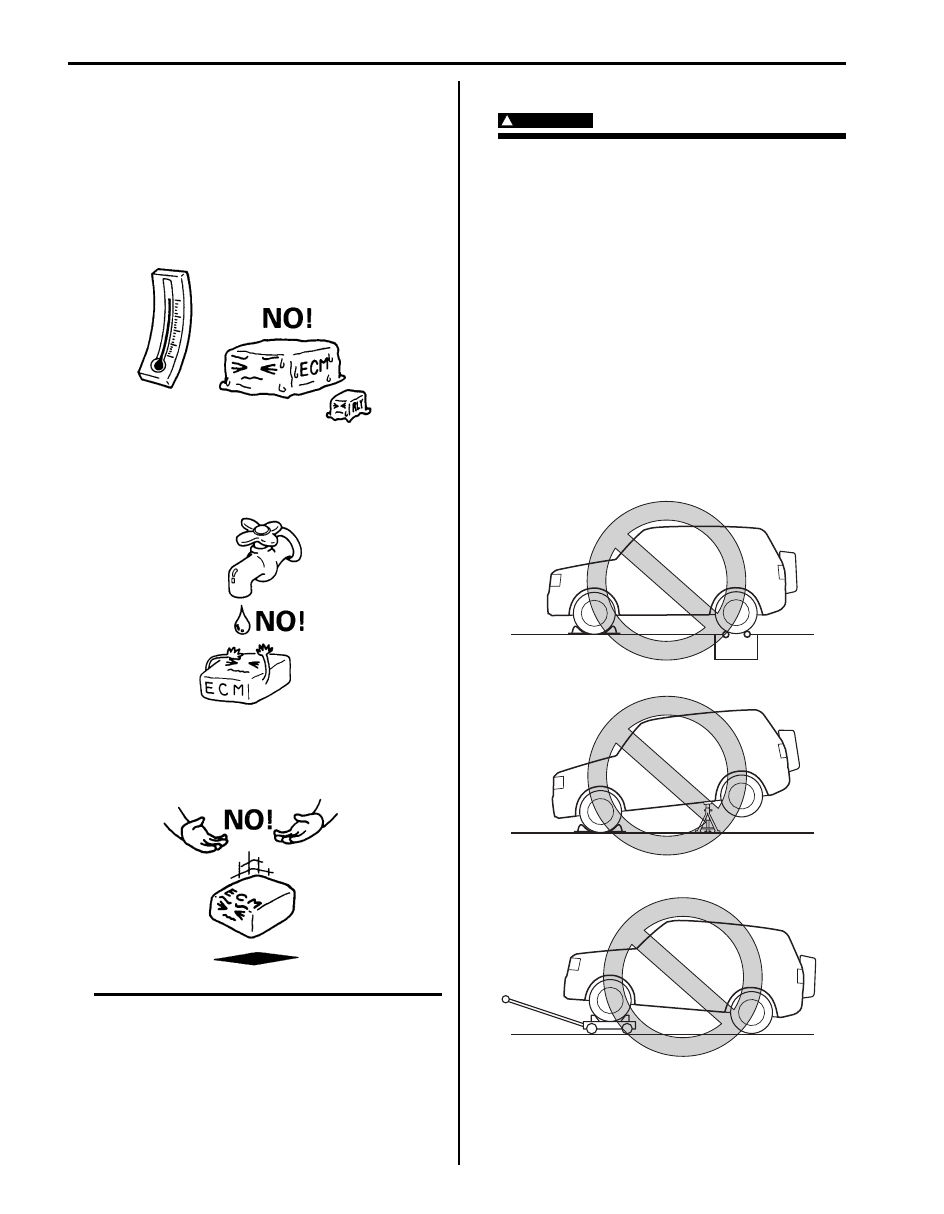

• When performing a work that produces a

heat exceeding 80

°C in the vicinity of the

electrical parts, remove the heat sensitive

electrical part(s) beforehand.

• Use care not to expose connectors and

electrical parts to water which will be a

cause of a trouble.

• Always be careful not to handle electrical

parts (computer, relay, etc.) in a rough

manner or drop them.

Precaution in Servicing Full-Time 4WD Vehicle

S6JB0B0000003

WARNING

!

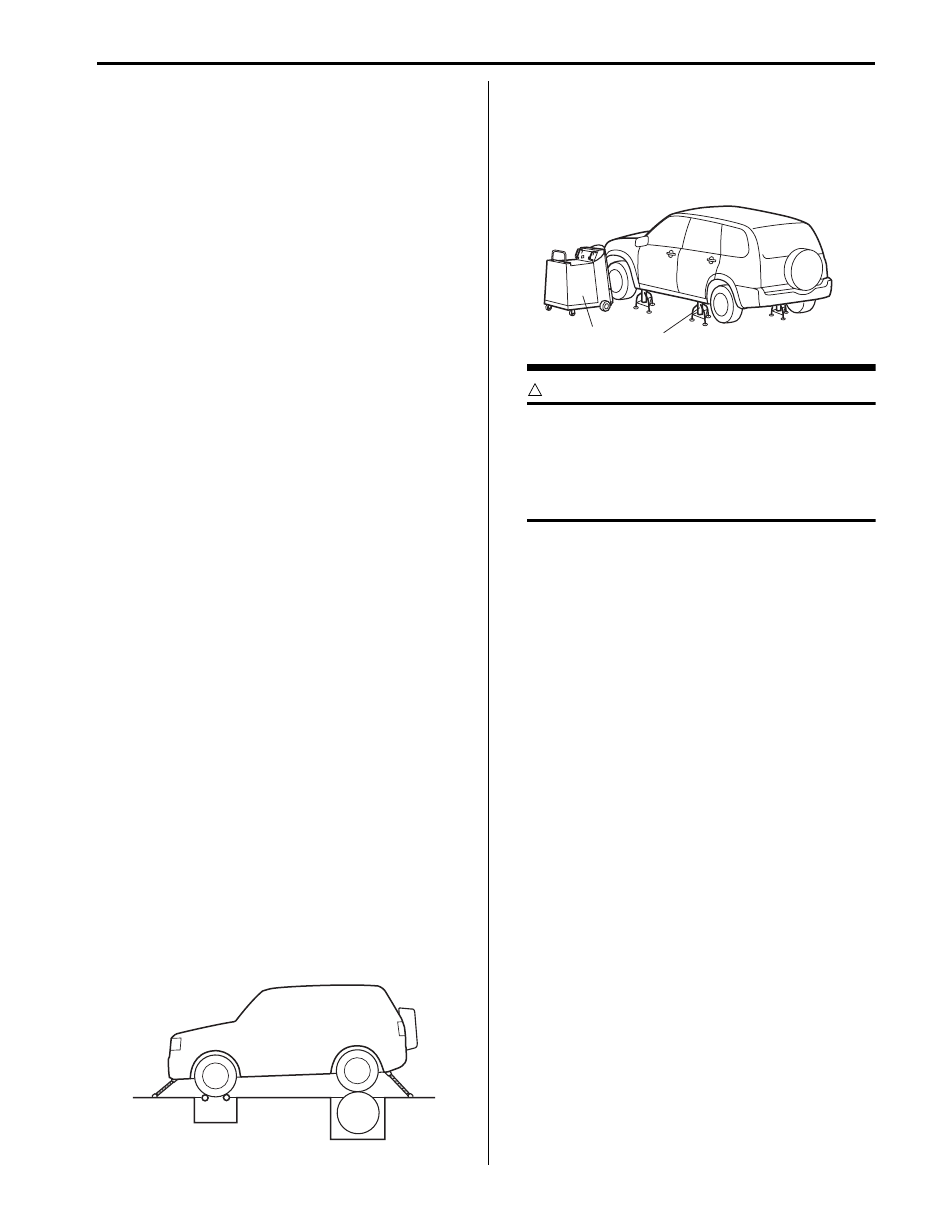

This full-time 4WD vehicle can not be

converted to 2WD manually.

Observe the following caution in servicing.

Otherwise, front wheels drive rear wheels or

vise-versa and vehicle accidents, drivetrain

damage and personal injury may result.

• Never perform any of the following types

of service work.

[A]:

Testing with 2-wheel chassis

dynamometer, speedometer tester (which

tester roller is driven by vehicle wheels).

[B]:

Driving front or rear wheels, which are

jacked up.

[C]:

Towing under the condition where either

front or rear wheels can not rotate.

I2RH01010034-01

I2RH01010035-01

I2RH01010036-01

[A]

[B]

[C]

I5JB0A000004-02

Precautions: 00-8

• When testing with 2-wheel brake tester, be

sure to observe the following instructions.

Otherwise, drivetrain damage and personal

injury may result.

– Shift transmission to N (Neutral)

position.

– Shift transfer to N (Neutral) position if

transfer position is selectable.

– Run engine at specified idle speed.

– Rotate wheels (tires) by brake tester at

vehicle speed below 5 km/h (3 mile/h).

– Do not rotate wheels (tires) for 1 min. or

more.

• When testing with 2-wheel speedometer

tester (which wheels are driven by tester),

be sure to observe the following

instructions. Otherwise, drivetrain damage

and personal injury may result.

– Set rear wheels on tester roller and front

wheels on free roller.

– Shift transmission to N (Neutral)

position.

– Shift transfer to N (Neutral) position if

transfer position is selectable.

– Rotate wheels (tires) by tester at vehicle

speed below 60 km/h (37 mile/h).

– Do not rotate wheels (tires) for 1 min. or

more.

– Ensure that vehicle does not move using

wire ropes or chains.

• When testing with 2-wheel chassis

dynamometer, be sure to make the vehicle

as rear wheel drive by removing front

propeller shaft or as front wheel drive by

removing rear propeller shaft, referring to

“Transfer Warning in Section 3C”.

Note that speedometer of vehicle does not

display vehicle speed because rear wheel

speed sensor signal is not output if rear

propeller shaft is removed.

• When testing with 4-wheel free chassis

dynamometer or speedometer tester

(which tester roller is driven by vehicle

wheels), be sure to shift transfer to 4H-

Lock position according to the step 4) in

“Transfer Warning in Section 3C”.

• When using On-vehicle type wheel

balancing equipment (1), be sure to jack up

all four wheels, off the ground completely

and support vehicle with safety stands (2).

Be careful of the other wheels, which will

rotate at the same time.

CAUTION

!

• This vehicle should be towed under one of

the following condition:

– With all wheels on a flatbed truck.

– With front or rear wheels lifted and a

dolly under the other wheels.

Precaution for Vehicle Equipped with ESP

®

System

S6JB0B0000016

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP

®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

When vehicle acceleration is not sensed and wheels

are rotating, ESP

® control module judges that wheels

are in slip condition and controls engine torque to

reduce by TCS control.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

– Etc.

ESP

® control module

• When ESP

® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP

® control

module.

• When any of the following operation is done, calibrate

steering angle sensor, G sensor and master cylinder

pressure sensor (in ESP

® control module) referring to

“Sensor Calibration in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

– When ESP

® control module is removed.

– When yaw rate / G sensor assembly is removed.

I5JB0A000006-01

1

2

I5JB0A000005-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст