Suzuki Grand Vitara JB627. Manual — part 3

00-9 Precautions:

Precautions for Catalytic Converter

S6JB0B0000004

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary,

make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the

shortest possible time.

• Avoid situations which can result in engine misfire

(e.g. starting the engine when the fuel tank is nearly

empty.)

Precaution for CAN Communication System

S6JB0B0000005

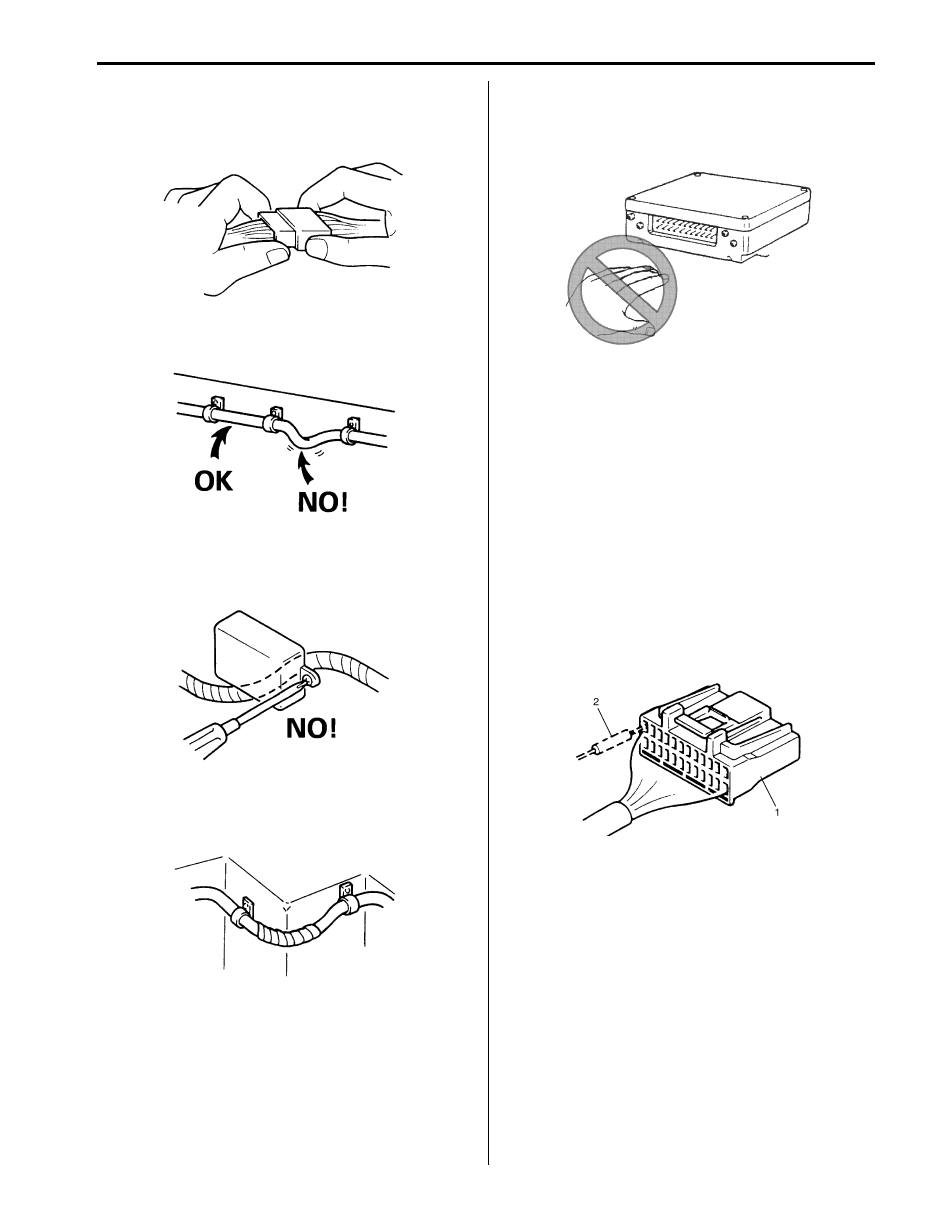

• The loose (1) in the wire harnesses twist of the CAN

lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a

bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

Precautions for Electrical Circuit Service

S6JB0B0000006

• When replacing a fuse, make sure to use a fuse of the

specified capacity. Use of a fuse with a larger capacity

will cause a damage to the electrical parts and a fire.

• When disconnecting and connecting coupler, make

sure to turn ignition switch OFF, or electronic parts

may get damaged.

• When disconnecting connectors, never pull the wiring

harness. Unlock the connector lock first and then pull

them apart by holding connectors themselves.

2. Controller

3

3

2

2

1

I4JA01000002-01

1

I4JA01000003-01

I2RH01010038-01

I2RH01010039-01

I2RH01010040-01

Precautions: 00-10

• When connecting connectors, also hold connectors

and put them together until they lock securely (a click

is heard).

• When installing the wiring harness, fix it with clamps

so that no slack is left.

• When installing vehicle parts, be careful so that the

wiring harness is not interfered with or caught by any

other part.

• To avoid damage to the harness, protect its part which

may contact against a part forming a sharp angle by

winding tape or the like around it.

• Be careful not to touch the electrical terminals of parts

which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or

whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit

with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter.

Otherwise, accurate measurements may not be

obtained or personal injury may result. If not specified,

use a voltmeter with high impedance (M

Ω/V

minimum) or a digital type voltmeter.

• When taking measurements at electrical connectors

using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1).

I2RH01010041-01

I2RH01010042-01

I2RH01010043-01

I2RH01010044-01

I3RM0A000004-01

I2RH01010046-01

00-11 Precautions:

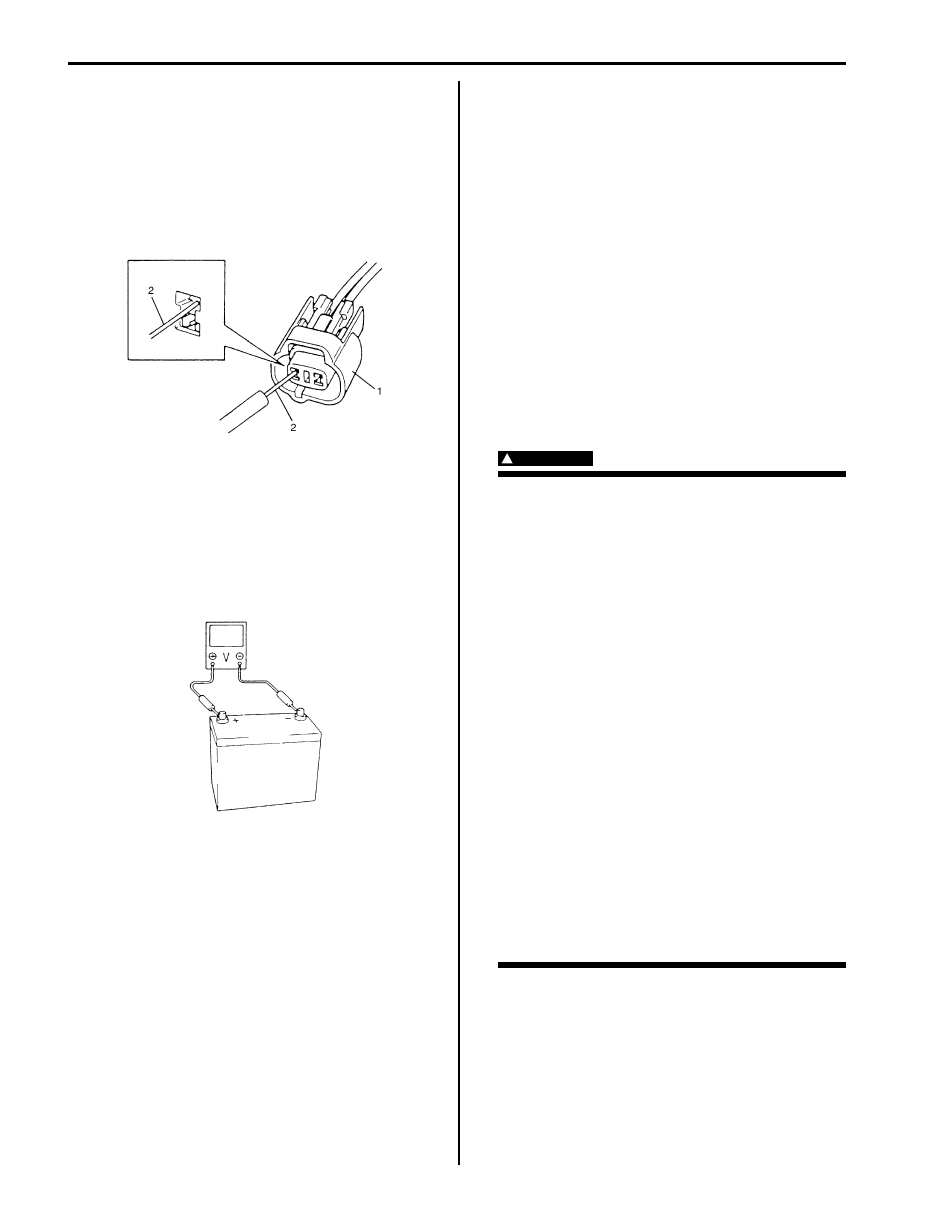

• When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

• Before measuring voltage at each terminal, check to

make sure that battery voltage is 11 V or higher. Such

terminal voltage check at low battery voltage will lead

to erroneous diagnosis.

Precautions for Installing Mobile

Communication Equipment

S6JB0B0000007

When installing mobile communication equipment such

as CB (Citizens-Band)-radio or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the

vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.)

away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire

harnesses.

• Confirm that the antenna and feeder are correctly

adjusted.

Air Bag Warning

S6JB0B0000008

WARNING

!

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

• Service on and around the air bag system

components or wiring must be performed

only by an authorized SUZUKI dealer. Refer

to “Air Bag System Components, Wiring

and Connectors Location in Section 8B” in

order to confirm whether you are

performing service on or near the air bag

system components or wiring. Please

observe all “WARNING”s and “Precautions

on Service and Diagnosis of Air Bag

System in Section 8B” before performing

service on or around the air bag system

components or wiring. Failure to follow

“WARNING”s could result in unintentional

activation of the system or could render

the system inoperative. Either of these two

conditions may result in severe injury.

• Technical service work must be started at

least 90 seconds after the ignition switch is

turned to the “LOCK” position and the

negative cable is disconnected from the

battery. Otherwise, the system may be

activated by reserve energy in the Sensing

and Diagnostic Module (SDM).

I2RH01010047-01

I2RH01010048-01

Precautions: 00-12

Discharge Headlight Warning

S6JB0B0000009

WARNING

!

When performing service on and around the

discharge headlight, observe “Precautions

for Discharge Headlight Service (If Equipped)

in Section 9B”. Neglecting the warnings may

result in personal injury.

A/C System Caution

S6JB0B0000010

CAUTION

!

The air conditioning system of this vehicle

uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and

component parts is interchangeable between

two types of A/C: one using refrigerant CFC-

12 (R-12) and the other using refrigerant HFC-

134a (R-134a).

Be sure to check which refrigerant is used

before any service work including inspection

and maintenance. For identification between

these two types, refer to “A/C Refrigerant

Type Description in Section 7B”.

When replenishing or changing refrigerant

and compressor oil and when replacing

parts, make sure that the material or the part

to be used is appropriate to the A/C installed

in the vehicle being serviced.

Use of incorrect one will result in leakage of

refrigerant, damage in parts or other faulty

condition.

Fastener Caution

S6JB0B0000011

CAUTION

!

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number

fastener for that application. If the correct

part number fastener is not available, a

fastener of equal size and strength (or

stronger) may be used. Fasteners that are not

reused, and those requiring thread-locking

compound, will be called out. The correct

torque value must be used when installing

fasteners that require it. If the above

procedures are not followed, parts or system

damage could result.

Suspension Caution

S6JB0B0000012

CAUTION

!

• All suspension fasteners are an important

attaching part in that it could affect the

performance of vital parts and systems,

and/or could result in major repair

expense. They must be replaced with one

of the same part number or with an

equivalent part if replacement becomes

necessary. Do not use a replacement part

of lesser quality or substitute design.

Torque values must be used as specified

during reassembly to assure proper

retention of this part.

• Never attempt to heat, quench or

straighten any suspension part. Replace it

with a new part or damage to the part may

result.

Wheels and Tires Caution

S6JB0B0000013

CAUTION

!

All wheel fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of the same part

number or with an equivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts.

There is to be no welding as it may result in

extensive damage and weakening of the

metal.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст