Suzuki Grand Vitara JB627. Manual — part 77

1C-6 Engine Electrical Devices:

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection

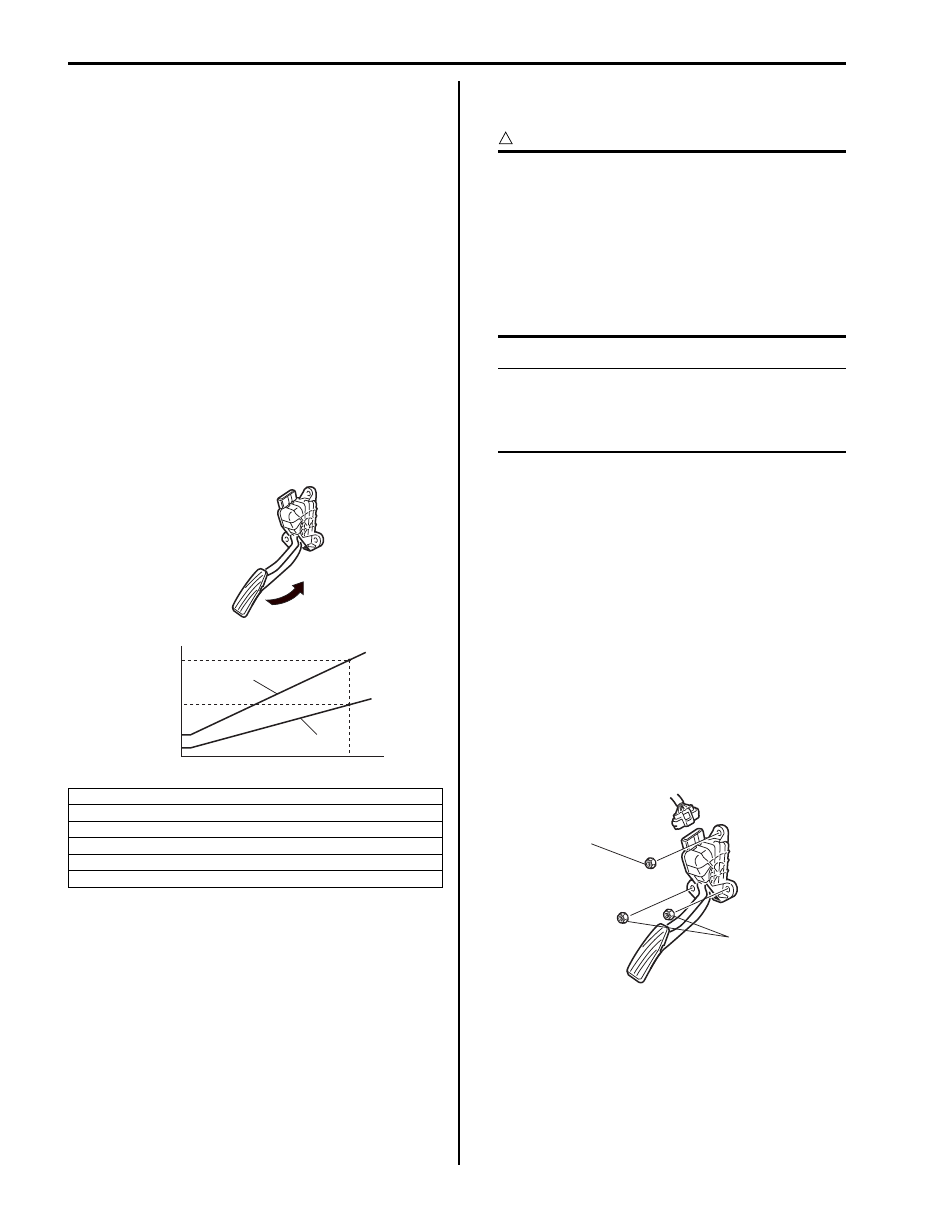

S6JB0B1306006

1) Check that accelerator pedal position (APP) sensor

assembly has been mounted to vehicle body

properly (no pinched floor carpet, etc.).

If mounting is not properly, reinstall accelerator pedal

position (APP) sensor assembly properly referring to

“Accelerator Pedal Position (APP) Sensor Assembly

Removal and Installation”.

2) Connect scan tool to DLC with ignition switch turned

OFF.

3) Turn ON ignition switch and select “Data List” mode

on scan tool.

4) Check that accelerator pedal position sensor voltage

varies as the following graph.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, check

accelerator pedal position (APP) sensor assembly

referring to “Accelerator Pedal Position (APP)

Sensor Assembly Inspection”.

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation

S6JB0B1306007

CAUTION

!

• Do not expose accelerator pedal position

(APP) sensor assembly to excessive shock

like a dropping it. If accelerator pedal

position (APP) sensor assembly has been

exposed to excessive shock, it should be

replaced.

• Be careful not to expose sensor section of

accelerator pedal position (APP) sensor

assembly to water.

NOTE

After replacing accelerator pedal position

(APP) sensor assembly, perform calibration

of throttle valve referring to “Electric Throttle

Body System Calibration”.

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from accelerator pedal

position (APP) sensor assembly.

3) Remove accelerator pedal position (APP) sensor

assembly from its bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten accelerator pedal position (APP) sensor

assembly upper nut (1) first and then lower nuts (2) to

specified torque.

Tightening torque

Accelerator pedal position (APP) sensor assembly

nut (a): 6.0 N·m (0.6 kgf-m, 4.5 lb-ft)

• If APP sensor assembly bracket is removed, tighten

its mounting nuts to specified torque.

Tightening torque

APP sensor assembly bracket nut (a): 6.0 N·m (

0.6 kgf-m, 4.3 lb-ft)

• Connect connector to accelerator pedal position

(APP) sensor assembly securely.

[A]: Accelerator pedal position (APP) sensor (main) voltage

[B]: Accelerator pedal position (APP) sensor (sub) voltage

[C]: Sensor output voltage

[D]: Idle position of accelerator pedal

[E]: Full depressed position of accelerator pedal

[F]: Pedal stroke

[C]

[B]

[D]

[F]

[E]

[A]

1.74 - 2.17 V

0.65 - 0.82 V

3.50 - 4.27 V

0.30 - 0.44 V

I5JB0A130018-05

1, (a)

2, (a)

I5JB0A130036-01

Engine Electrical Devices: 1C-7

Accelerator Pedal Position (APP) Sensor

Assembly Inspection

S6JB0B1306008

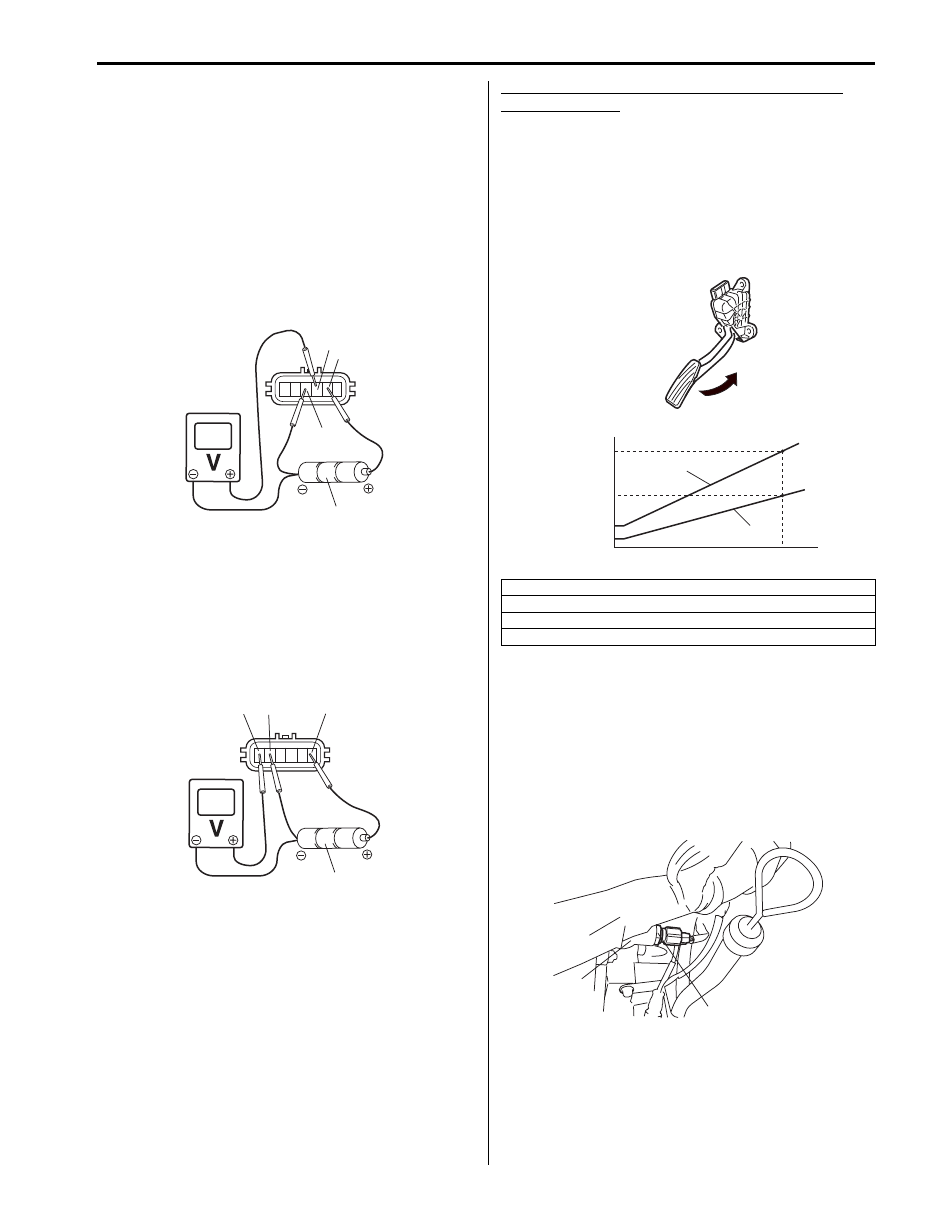

Check accelerator pedal position (APP) sensor (main

and sub) output voltage as following steps.

1) For accelerator pedal position (APP) sensor (main),

arrange 3 new 1.5 V batteries (1) in series (check

that total voltage is 4.7 – 5.0 V) and connect its

positive terminal to “Vin 1” terminal (2) and negative

terminal to “Ground 1” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to “Vout 1”

terminal (4) of sensor and negative terminal to

battery.

2) For accelerator pedal position (APP) sensor (sub),

arrange 3 new 1.5 V batteries (1) in series (check

that total voltage is 4.7 – 5.0 V) and connect its

positive terminal to “Vin 2” terminal (2) and negative

terminal to “Ground 2” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to “Vout 2”

terminal (4) of sensor and negative terminal to

battery.

3) Measure output voltage variation while accelerator

pedal is no depressed and fully depressed as

following specification.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, replace accelerator

pedal position (APP) sensor assembly.

Accelerator pedal position (APP) sensor output

voltage variation

Accelerator pedal position (APP) sensor (main)

output voltage variation [A]: 0.82 – 3.50 V at

minimum variation, varying according to depressed

extent of accelerator pedal

Accelerator pedal position (APP) sensor (sub)

output voltage variation [B]: 0.44 – 1.74 V at

minimum variation, varying according to depressed

extent of accelerator pedal

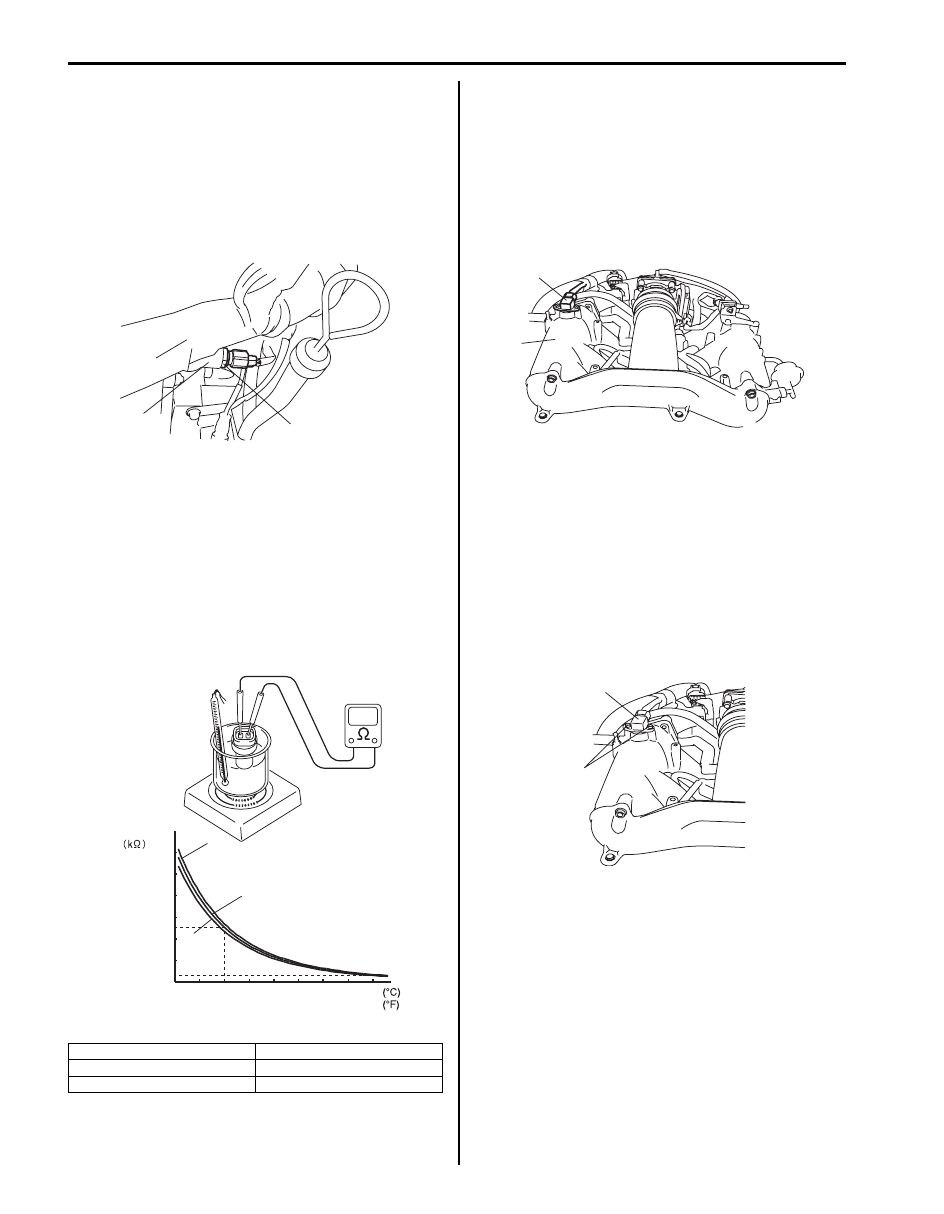

Engine Coolant Temperature (ECT) Sensor

Removal and Installation

S6JB0B1306009

Removal

1) Disconnect negative cable from battery.

2) Drain cooling system.

3) Disconnect coupler from ECT sensor (1).

4) Remove ECT sensor (1) from water outlet cap (2).

1

2

3

4

I5JB0A130019-02

1

2

3

4

I5JB0A130020-02

[C]: Sensor output voltage

[D]: Idle position of accelerator pedal

[E]: Fully depressed position of accelerator pedal

[F]: Pedal stroke

[C]

[B]

[D]

[F]

[E]

[A]

1.74 - 2.17 V

0.65 - 0.82 V

3.50 - 4.27 V

0.30 - 0.44 V

I5JB0A130021-05

1

2

I6JB01130014-01

1C-8 Engine Electrical Devices:

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of sensor and water outlet cap

(1).

• Use new O-ring.

• Tighten ECT sensor to specified torque.

Tightening torque

ECT sensor (a): 12 N·m (1.2 kgf-m, 8.5 lb-ft)

• Connect coupler to sensor securely.

• Refill cooling system.

Engine Coolant Temperature (ECT) Sensor

Inspection

S6JB0B1306010

Immerse temperature sensing part of ECT sensor in

water and measure resistance between sensor terminals

while heating water gradually. If measured resistance

doesn’t show characteristics as shown in the figure,

replace ECT sensor.

Manifold Absolute Pressure (MAP) Sensor

Removal and Installation (If Equipped)

S6JB0B1306011

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from manifold absolute

pressure sensor (1).

3) Remove manifold absolute pressure sensor (1) from

intake manifold (2).

Installation

1) Confirm that vacuum passage on intake manifold is

free from clog.

2) Apply engine oil to O-ring of manifold absolute

pressure sensor.

3) Install manifold absolute pressure sensor (1) onto

intake manifold.

4) Tighten MAP sensor bolt (2) to specified torque.

Tightening torque

MAP sensor bolt (a): 5 N·m (0.5 kgf-m, 3.5 lb-ft)

5) Connect connector to manifold absolute pressure

sensor securely.

[A]: Lower limit

[D]: Resistance

[B]: Normal

[E]: Temperature

[C]: Upper limit

(a)

1

I6JB01130015-02

20

0

68

32

104

140

176

40

60

80

[E]

2.29 - 2.62

0.309 - 0.331

[A]

[B]

[C]

[D]

I5JB0A130037-01

1

2

I6JB01130016-01

1

2, (a)

I6JB0B130001-01

Engine Electrical Devices: 1C-9

Manifold Absolute Pressure (MAP) Sensor

Inspection

S6JB0B1306012

1) Check sensor O-ring (1) for damage and

deterioration. Replace as necessary.

2) Arrange new three 1.5 V batteries (2) in series and

connect its positive terminal to “Vin” terminal and

negative terminal to “Ground” terminal. Then, check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is slowly applied up

to 400 mmHg by using vacuum pump (3). If check

result is not satisfactory, replace manifold absolute

pressure sensor (1).

CAUTION

!

As connection to wrong terminal will cause

damage to manifold absolute pressure

sensor, make absolutely sure to connect

properly as shown in the figure.

Manifold absolute pressure output voltage (“Vin”

voltage: 4.7 – 5.5 V, ambient temp. 20 – 30

°C (68 –

86

°F))

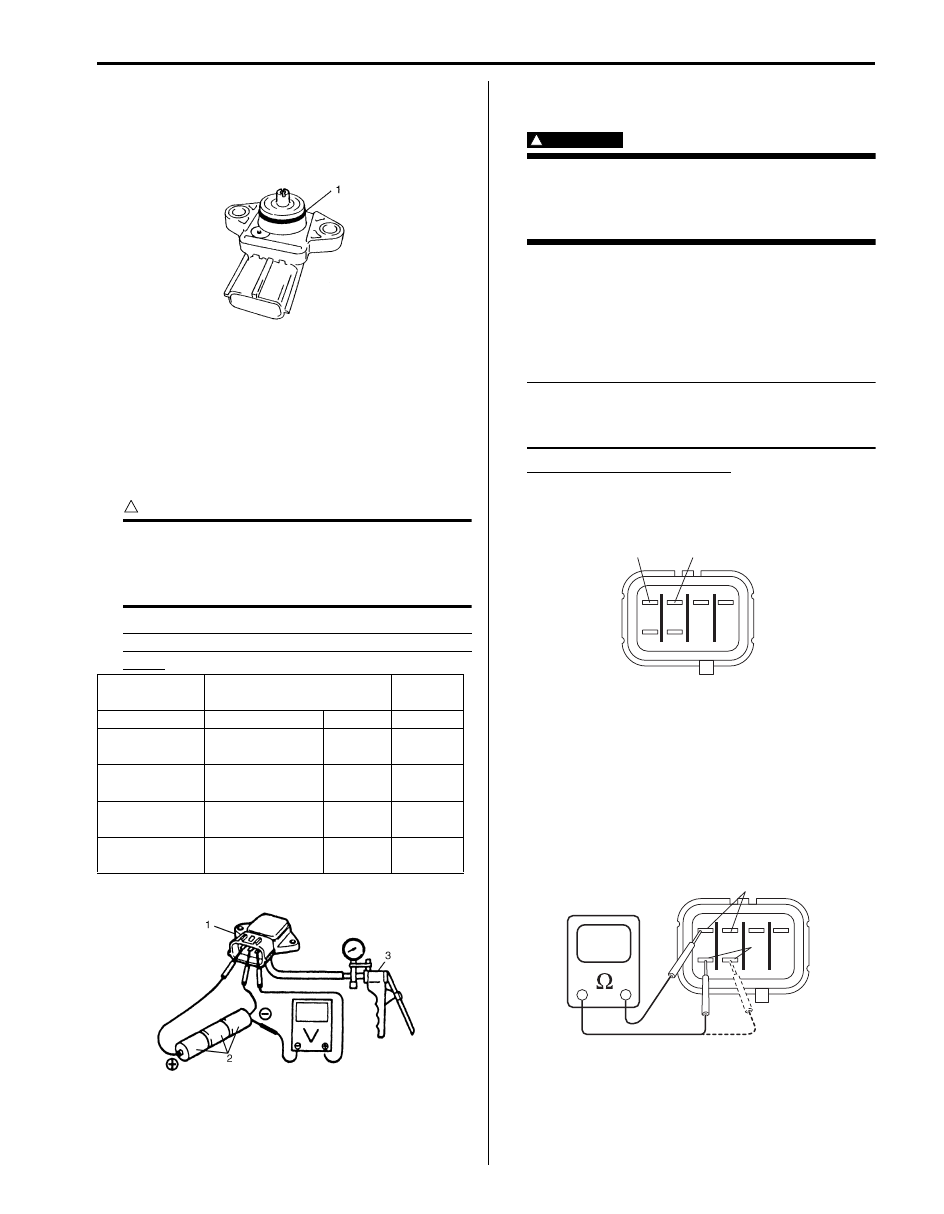

Air Fuel Ratio (A/F) Sensor On-Vehicle

Inspection

S6JB0B1306013

WARNING

!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Sensor inspection should be performed

when system is cool.

Heater

1) Disconnect A/F sensor connector.

2) Using ohmmeter, measure resistance of Sensor

heater between terminals “V

B

” and “GND” at sensor

connector. If found faulty, replace A/F sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

A/F sensor heater resistance

2 – 3

Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect A/F sensor connector securely.

Circuit Insulation Check

1) Disconnect connector from A/F sensor.

2) Using ohmmeter, check circuit insulation of A/F

sensor. If faulty is found, replace A/F sensor.

• Between each heater terminal (1) and other than

heater terminals (2).

Viewed from terminal side

Altitude

(Reference)

Barometric pressure

Output

voltage

(ft (m))

(mmHg)

(kPa)

(V)

0 – 2000

(0 – 610)

760 – 707

100 – 94 3.3 – 4.3

2001 – 5000

(611 – 1524)

Under 707, Over

634

94 – 85 3.0 – 4.1

5001 – 8000

(1525 – 2438)

Under 634, Over

567

85 – 76 2.7 – 3.7

8001 – 10000

(2439 – 3048)

Under 567, Over

526

76 – 70 2.5 – 3.3

I1SQ01130005-01

IYSQ01130006-01

“GND”

“V

B

”

I5JB0A130001-02

1

2

I6JB01130034-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст