Suzuki Grand Vitara JB627. Manual — part 23

1A-41 Engine General Information and Diagnosis:

DTC Check

S6JB0B1104007

NOTE

The MIL is turned on when the ECM and/or

TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its memory

and outputs the DTC to the scan tool.

Therefore, check both of the ECM and TCM

for any DTC with the scan tool because the

DTC stored in ECM and TCM is not read and

displayed at a time. However, each of the

ECM and TCM needs not to be checked with

the generic scan tool because the DTC stored

in ECM and TCM is read and displayed at a

time.

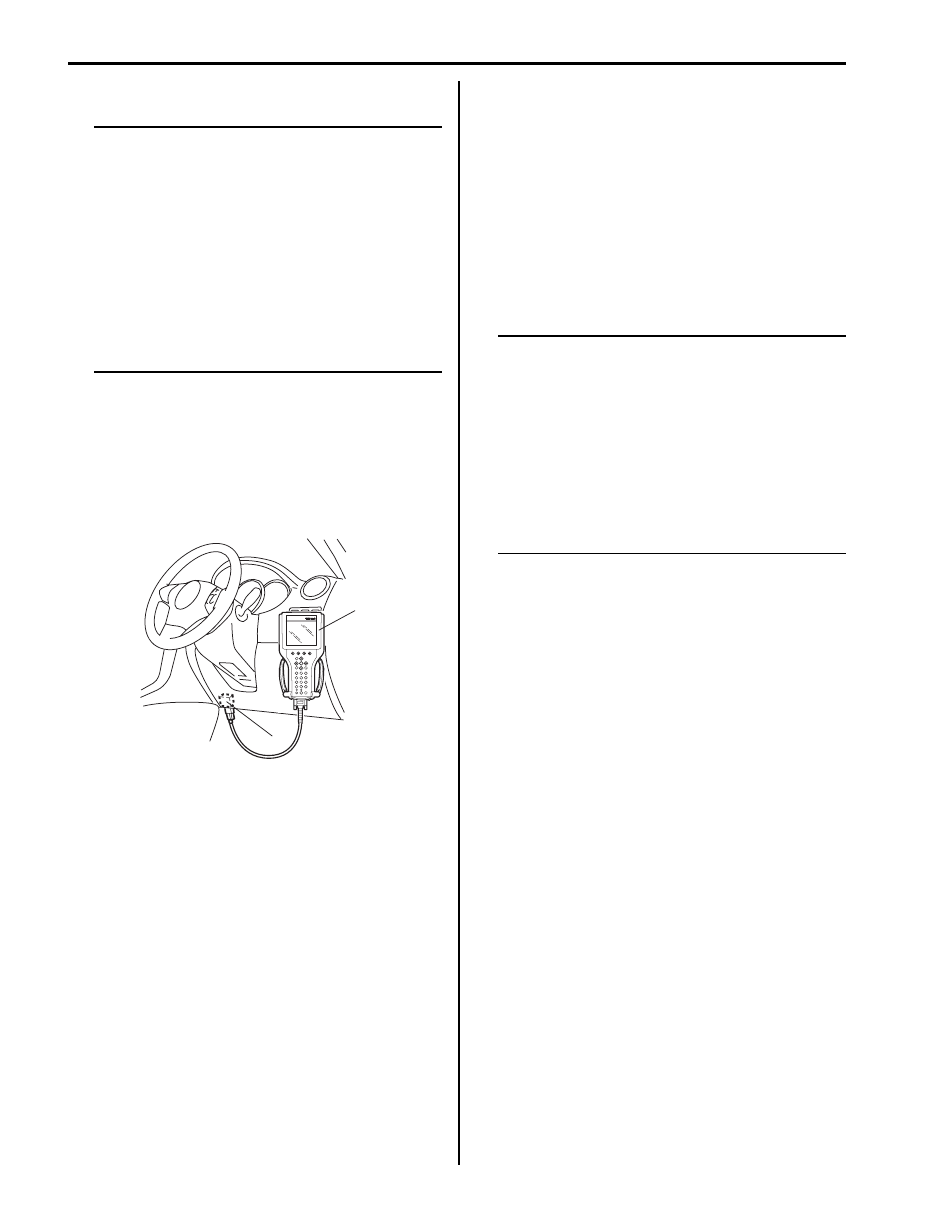

1) Prepare OBD generic scan tool or SUZUKI scan

tool.

2) With ignition switch OFF, connect it to DLC (1)

located on underside of instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC and freeze frame data according to

instructions displayed on scan tool and print them or

write them down. Refer to scan tool operator’s

manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible.

5) After completing the check, turn ignition switch off

and disconnect scan tool from data link connector.

DTC Clearance

S6JB0B1104008

1) With ignition switch OFF, connect OBD generic scan

tool or SUZUKI scan tool to DLC.

2) Turn ignition switch ON.

3) Erase DTC according to instructions displayed on

scan tool. Freeze frame data is cleared with the

DTC. Refer to scan tool operator’s manual for further

details.

4) After completing the clearance, turn ignition switch

off and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by

disconnecting battery cable, removing

fuse or disconnecting ECM (connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles (refer to Warm-Up Cycle of “On-

Board Diagnostic System Description”).

(A)

1

I5JB0C110021-02

Engine General Information and Diagnosis: 1A-42

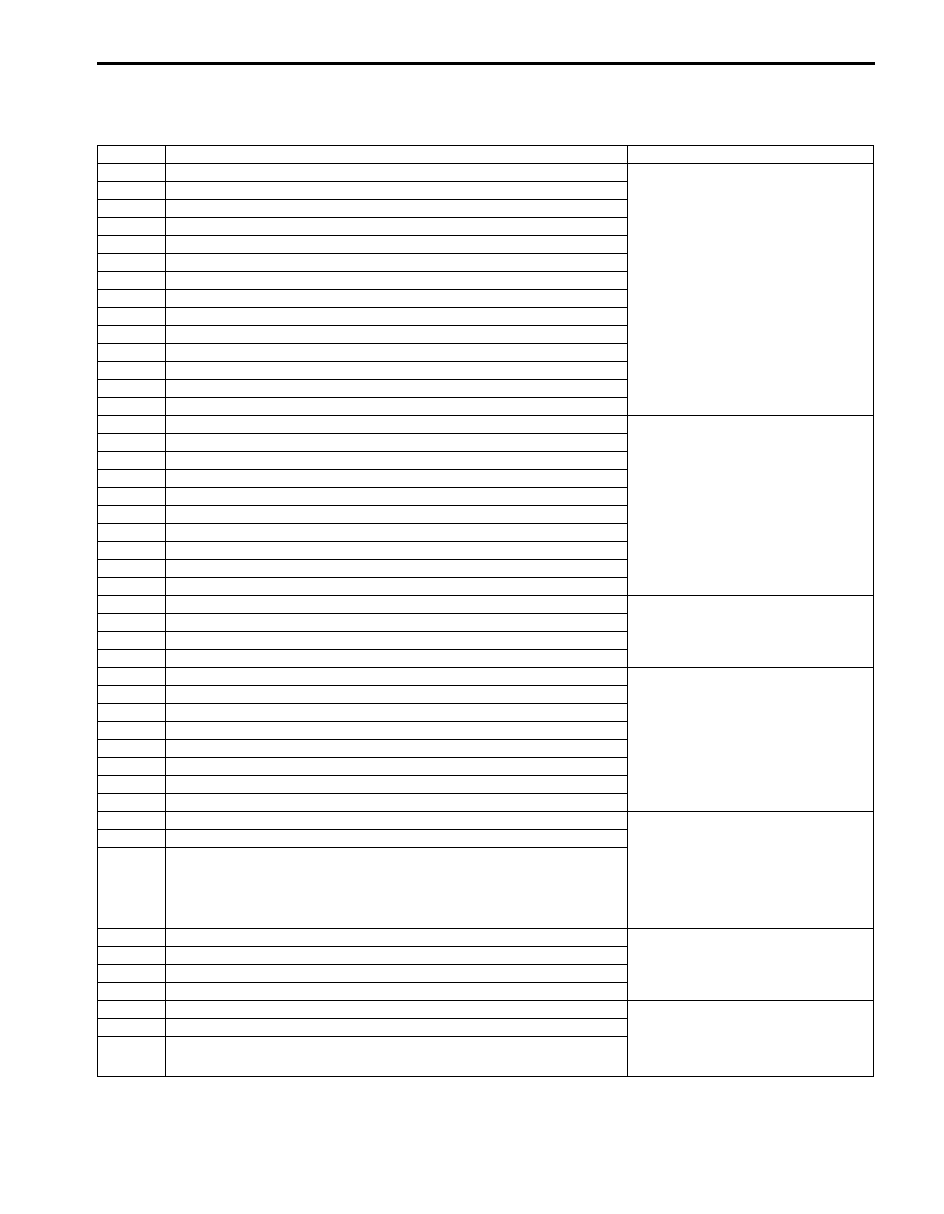

Fail-Safe Table

S6JB0B1104009

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to exist but

that mode is cancelled when ECM detects normal condition after that.

DTC No.

Detected item

Fail-safe operation

P0031 HO2S Heater Control Circuit Low (Bank 1 Sensor 1)

• ECM stops air/fuel ratio control.

• ECM stops A/F sensor heater

control.

P0032 HO2S Heater Control Circuit High (Bank 1 Sensor 1)

P0051 HO2S Heater Control Circuit Low (Bank 2 Sensor 1)

P0052 HO2S Heater Control Circuit High (Bank 2 Sensor 1)

P2237 O2 Sensor Positive Current Control Circuit / Open (Bank 1 Sensor 1)

P2238 O2 Sensor Positive Current Control Circuit Low (Bank 1 Sensor 1)

P2239 O2 Sensor Positive Current Control Circuit High (Bank 1 Sensor 1)

P2240 O2 Sensor Positive Current Control Circuit / Open (Bank 2 Sensor 1)

P2241 O2 Sensor Positive Current Control Circuit Low (Bank 2 Sensor 1)

P2242 O2 Sensor Positive Current Control Circuit High (Bank 2 Sensor 1)

P2252 O2 Sensor Negative Current Control Circuit Low (Bank 1 Sensor 1)

P2253 O2 Sensor Negative Current Control Circuit High (Bank 1 Sensor 1)

P2255 O2 Sensor Negative Current Control Circuit Low (Bank 2 Sensor 1)

P2256 O2 Sensor Negative Current Control Circuit High (Bank 2 Sensor 1)

P0133 O2 Sensor Circuit Slow Response (Bank 1 Sensor 1)

• ECM stops air/fuel ratio control.

P0134 O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 1)

P0153 O2 Sensor Circuit Slow Response (Bank 2 Sensor 1)

P0154 O2 Sensor Circuit No Activity Detected (Bank 2 Sensor 1)

P2195 O2 Sensor Signal Stuck Lean (Bank 1 Sensor 1)

P2196 O2 Sensor Signal Stuck Rich (Bank 1 Sensor 1)

P2197 O2 Sensor Signal Stuck Lean (Bank 2 Sensor 1)

P2198 O2 Sensor Signal Stuck Rich (Bank 2 Sensor 1)

P2A00 O2 Sensor Circuit Range/Performance (Bank 1 Sensor 1)

P2A03 O2 Sensor Circuit Range/Performance (Bank 2 Sensor 1)

P0037 HO2S Heater Control Circuit Low (Bank 1 Sensor 2)

• ECM stops HO2S-2 control.

• ECM stops A/F sensor heater

control.

P0038 HO2S Heater Control Circuit High (Bank 1 Sensor 2)

P0057 HO2S Heater Control Circuit Low (Bank 2 Sensor 2)

P0058 HO2S Heater Control Circuit High (Bank 2 Sensor 2)

P0137 O2 Sensor Circuit Low Voltage (Bank 1 Sensor 2)

• ECM stops HO2S-2 control.

P0138 O2 Sensor Circuit High Voltage (Bank 1 Sensor 2)

P0140 O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 2)

P0157 O2 Sensor Circuit Low Voltage (Bank 2 Sensor 2)

P0158 O2 Sensor Circuit High Voltage (Bank 2 Sensor 2)

P0160 O2 Sensor Circuit No Activity Detected (Bank 2 Sensor 2)

P2A01 O2 Sensor Circuit Range/Performance (Bank 1 Sensor 2)

P2A04 O2 Sensor Circuit Range/Performance (Bank 2 Sensor 2)

P0101 Mass Air Flow Circuit Range/Performance

• ECM controls injector drive time

(fuel injection volume) according

to engine speed and throttle valve

operation angle.

• ECM stops air/fuel ratio control.

• ECM stops EGR valve control.

P0102 Mass Air Flow Circuit Low Input

P0103 Mass Air Flow Circuit High Input

P0107 Manifold Absolute Pressure Circuit Low Input

• ECM stops EGR valve control.

P0108 Manifold Absolute Pressure Circuit High Input

P1107 MAP Sensor Rationality Check-Low

P1108 MAP Sensor Rationality Check-High

P0111 Intake Air Temperature Sensor Circuit Performance

• ECM controls actuators assuming

that intake air temperature is 40

°C (104 °F).

• ECM stops EGR valve control.

P0112 Intake Air Temperature Sensor Circuit Low

P0113 Intake Air Temperature Sensor Circuit High

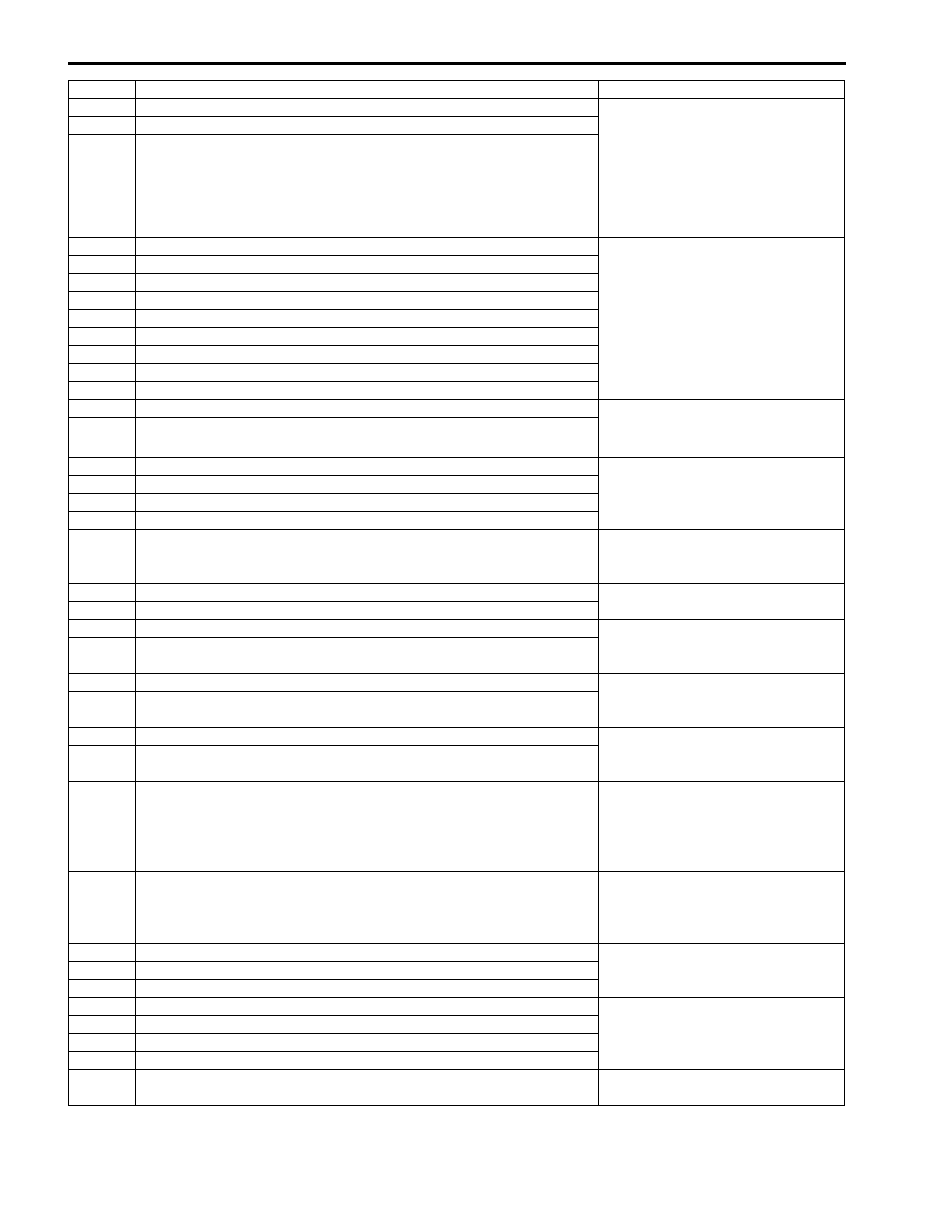

1A-43 Engine General Information and Diagnosis:

P0116 Engine Coolant Temperature Circuit Range / Performance

• ECM controls actuators assuming

that engine coolant temperature

is 80

°C (176 °F) and operates

radiator cooling fan is high speed.

• ECM stops air/fuel ratio control.

• ECM stops EGR valve control.

• ECM stops A/C control.

P0117 Engine Coolant Temperature Circuit Low

P0118 Engine Coolant Temperature Circuit High

P0122 Throttle Position Sensor (Main) Circuit Low

• ECM turns off throttle actuator

control relay and throttle valve is

fixed at the opening of about 10

°

from its completely closed

position (default opening).

• ECM controls fuel cut at specified

engine speed.

P0123 Throttle Position Sensor (Main) Circuit High

P0222 Throttle Position Sensor (Sub) Circuit Low

P0223 Throttle Position Sensor (Sub) Circuit High

P2101 Throttle Actuator Control Motor Circuit Range / Performance

P2102 Throttle Actuator Control Motor Circuit Low

P2103 Throttle Actuator Control Motor Circuit High

P2108 Throttle Actuator Control Module Performance

P2119 Throttle Actuator Control Throttle Body Range / Performance

P0327 Knock Sensor Circuit Low

• ECM stops knock control.

• ECM controls ignition timing

according to engine speed.

P0328 Knock Sensor Circuit High

P0335 Crankshaft Position Sensor Circuit

• ECM stops EGR valve control.

P0336 Crankshaft Position Sensor Circuit Range / Performance

P0340 Camshaft Position Sensor Circuit

P0341 Camshaft Position Sensor Circuit Range / Performance

P0500 Vehicle Speed Sensor

• ECM controls actuators assuming

that vehicle speed is 10 km/h (6

mph).

P0532 A/C Refrigerant Pressure Sensor Circuit Low

• ECM stops A/C system control.

P0533 A/C Refrigerant Pressure Sensor Circuit High

P1603 TCM Trouble Code Detected

• ECM controls actuators assuming

that transmission range switch is

N position.

U0101 Lost Communication with TCM

P2122 Pedal Position Sensor (Main) Circuit Low

• ECM controls throttle valve using

that pedal position sensor (sub)

signal within specified range.

P2123 Pedal Position Sensor (Main) Circuit High

P2127 Pedal Position Sensor (Sub) Circuit Low

• ECM controls throttle valve using

that pedal position sensor (main)

signal within specified range.

P2128 Pedal Position Sensor (Sub) Circuit High

P2135 Throttle Position Sensor (Main / Sub) Voltage Correlation

• ECM controls throttle valve using

that throttle position sensor

(main) or throttle position sensor

(sub) signal within specified

range.

P2138 Pedal Position Sensor (Main / Sub) Voltage Correlation

• ECM controls throttle valve using

that pedal position sensor (main)

or pedal position sensor (sub)

signal within specified range.

P2227 Barometric Pressure Circuit Range / Performance

• ECM controls actuators assuming

that barometric pressure is 10

kPa (760 mmHg).

P2228 Barometric Pressure Circuit Low

P2229 Barometric Pressure Circuit High

P2627 O2 Sensor Pumping Current Trim Circuit Low (Bank 1 Sensor 1)

• ECM controls A/F sensor

assuming that A/F sensor

adjusting resister value is

specified value.

P2628 O2 Sensor Pumping Current Trim Circuit High (Bank 1 Sensor 1)

P2630 O2 Sensor Pumping Current Trim Circuit Low (Bank 2 Sensor 1)

P2631 O2 Sensor Pumping Current Trim Circuit High (Bank 2 Sensor 1)

U0121

Lost Communication with Electronic Stability Program / ABS Control

Module

• ECM stops torque reduction

control

DTC No.

Detected item

Fail-safe operation

Engine General Information and Diagnosis: 1A-44

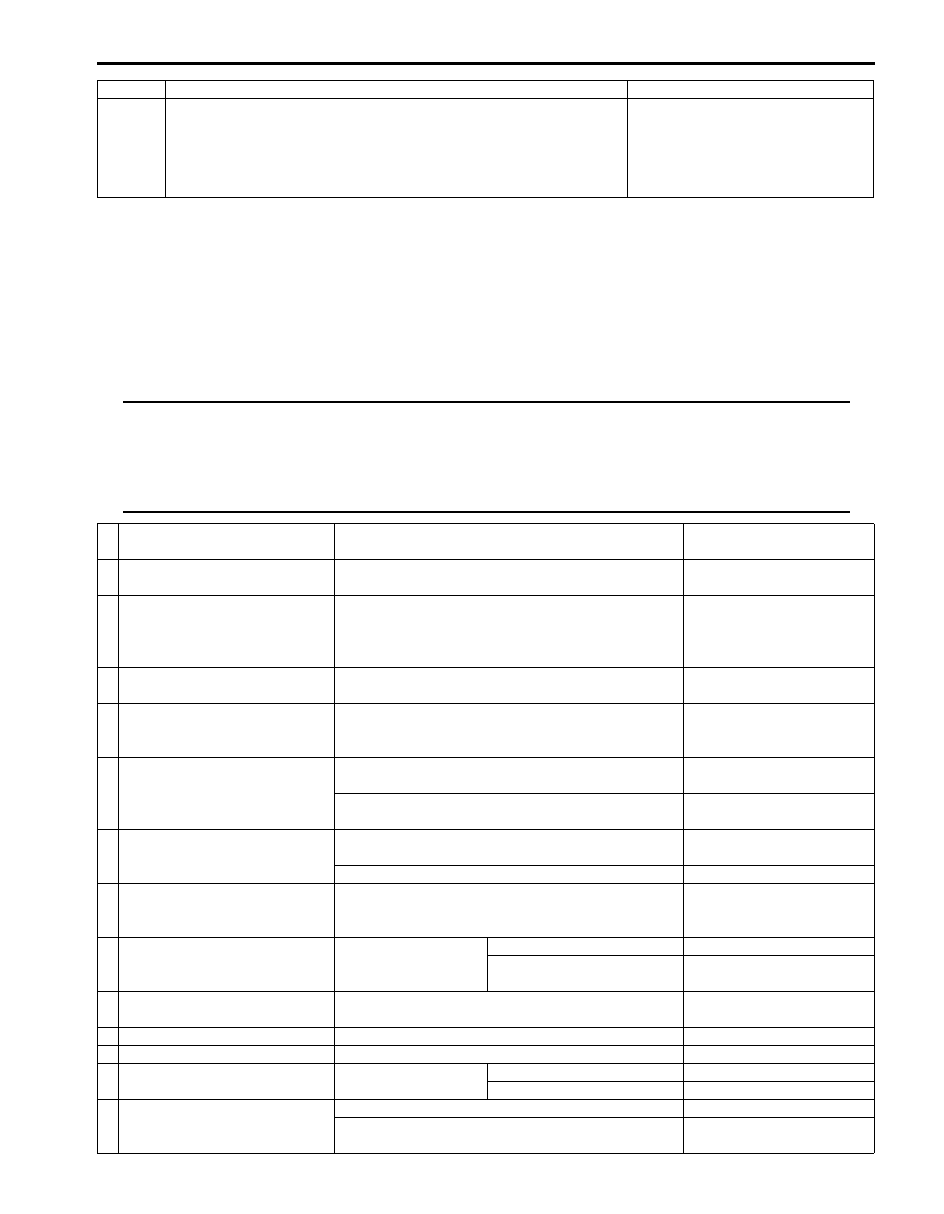

Scan Tool Data

S6JB0B1104010

As the data values are standard values estimated on the basis of values obtained from the normally operating vehicles

by using a scan tool, use them as reference values. Even when the vehicle is in good condition, there may be cases

where the checked value does not fall within each specified data range. Therefore, judgment as abnormal should not

be made by checking with these data alone.

Also, conditions that can be checked by the scan tool are those detected by ECM and output from ECM as commands

and there may be cases where the engine or actuator is not operating (in the condition) as indicated by the scan tool.

Be sure to use the timing light to check the ignition timing. (Refer to “Ignition Timing Inspection in Section 1H”)

NOTE

• With the generic scan tool, only star (*) marked data in the following table can be read.

• When checking the data with the engine running at idle or racing, be sure to shift M/T gear to the

neutral gear position and A/T gear to the “Park” position and pull the parking brake fully. Also, if

nothing or “no load” is indicated, turn OFF A/C (if equipped with A/C), all electric loads, P/S and all

the other necessary switches.

U0140 Lost Communication with Body Control Module

• ECM stops A/C system control.

• ECM controls engine speed not

using electric load signal.

• ECM stops keyless start system

control.

Scan tool data

Vehicle condition

Normal condition /

reference values

*

COOLANT TEMP

(ENGINE COOLANT TEMP.)

At specified idle speed after warming up

82 – 100

°C, 176 – 212 °F

* ) INTAKE AIR TEMP.

At specified idle speed after warming up

–5

°C (23 °F) +

environmental temp. to 40

°C (104 °F) + environmental

temp.

* ) ENGINE SPEED

It idling with no load after warming up

Desired idle speed

± 50

RPM

DESIRED IDLE

(DESIRED IDLE SPEED)

It idling with radiator cooling fan stopped and all

electrical parts turned OFF after warming up, M/T at

neutral

650 RPM

*

(MASS AIR FLOW RATE)

At specified idle speed with no load after warming

up

1.0 – 4.0 g/s

0.14 – 0.52 lb/min.

At 2500 r/min. with no load after warming up

4.0 – 12.0 g/s

0.53 – 1.58 lb/min.

*

CALCULATED LOAD

(CALCULATED LOAD VALUE)

At specified idle speed with no load after warming

up

0 – 10%

At 2500 r/min. with no load after warming up

0 – 10%

*

(INTAKE MANIFOLD

ABSOLUTE PRESSURE)

At specified idle speed with no load after warming

up

24 – 38 kPa, 7.1 – 11.2

in.Hg

*

THROTTLE POSITION

(ABSOLUTE THROTTLE

POSITION)

Ignition switch ON /

warmed up engine

stopped

Accelerator pedal released

0 – 5%

Accelerator pedal depressed

fully

90 – 100%

BAROMETRIC PRES

—

Barometric pressure is

displayed

FUEL TANK LEVEL

Ignition switch ON

0 – 100%

BATTERY VOLTAGE

Ignition switch ON / engine at stop

10 – 14 V

BRAKE SWITCH

Ignition switch ON

Brake pedal is released

OFF

Brake pedal is depressed

ON

INTAKE TUNING SOL

(INTAKE MANIFOLD TUNING

VALVE)

At specified idle speed after warming up

OFF

Engine speed at 1500 rpm or more

ON

DTC No.

Detected item

Fail-safe operation

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст