Suzuki Grand Vitara JB627. Manual — part 149

3B-38 Differential: Rear

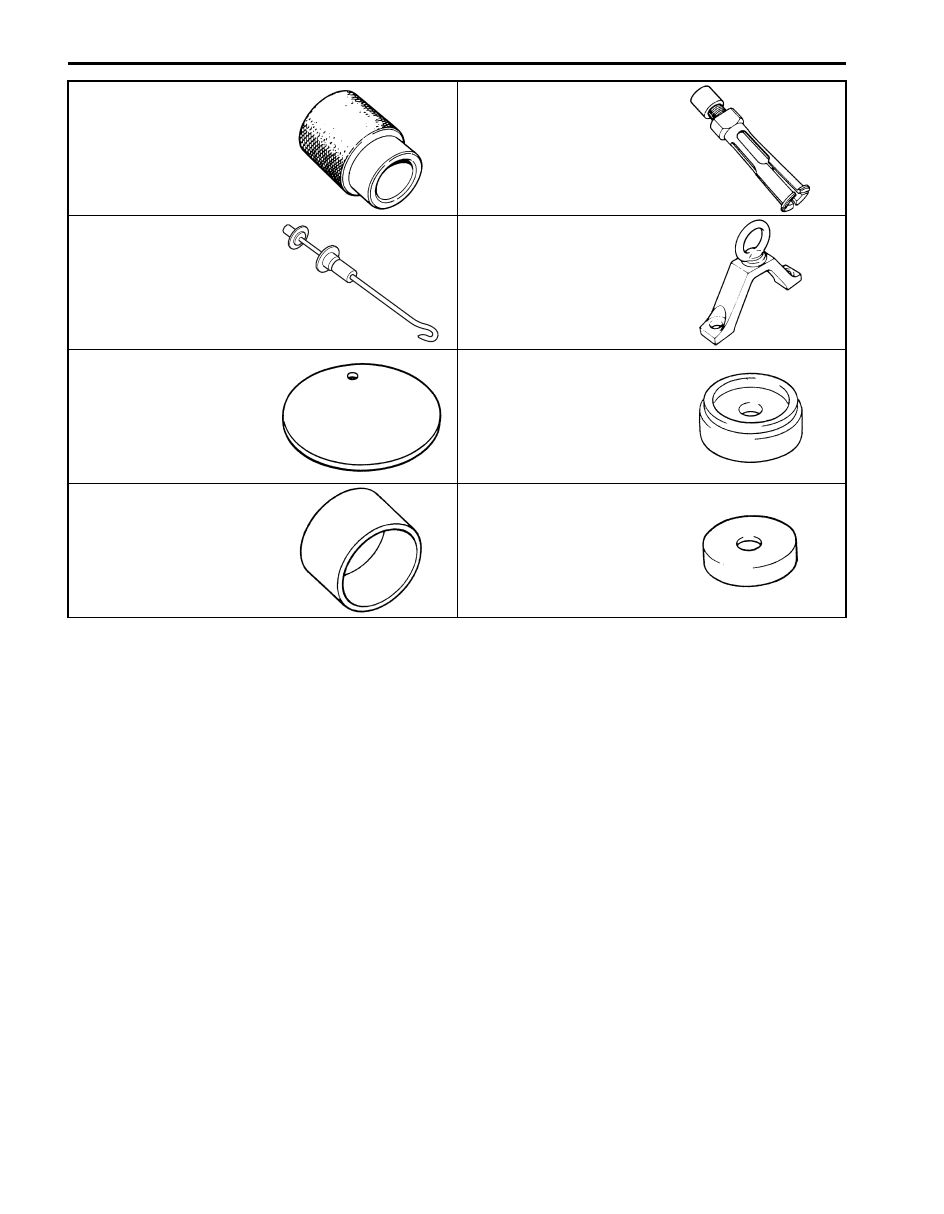

09940–53111

09941–64511

Differential side bearing

installer

Bearing and oil seal remover

(30 mm Min.)

09942–15511

09943–17912

Sliding hammer

Wheel hub remover

09951–16070

09951–16090

Shim adjuster attachment

Oil seal installer

09951–18210

09951–46010

Oil seal remover & installer

No. 2

Drive shaft oil seal installer

Transfer: 3C-1

Driveline / Axle

Transfer

Precautions

Transfer Warning

S6JB0B3300001

WARNING

!

This transfer has a center differential.

When testing with 2-wheel chassis

dynamometer or speedometer tester (which

tester roller is driven by vehicle wheels), be

sure to make the vehicle as rear wheel drive

or as front wheel drive temporarily as

follows.

Otherwise, front wheels drive rear wheels or

vise-versa and personal injury may result.

1) Remove front propeller shaft or rear propeller shaft

referring to “Propeller Shaft Removal and Installation

in Section 3D”.

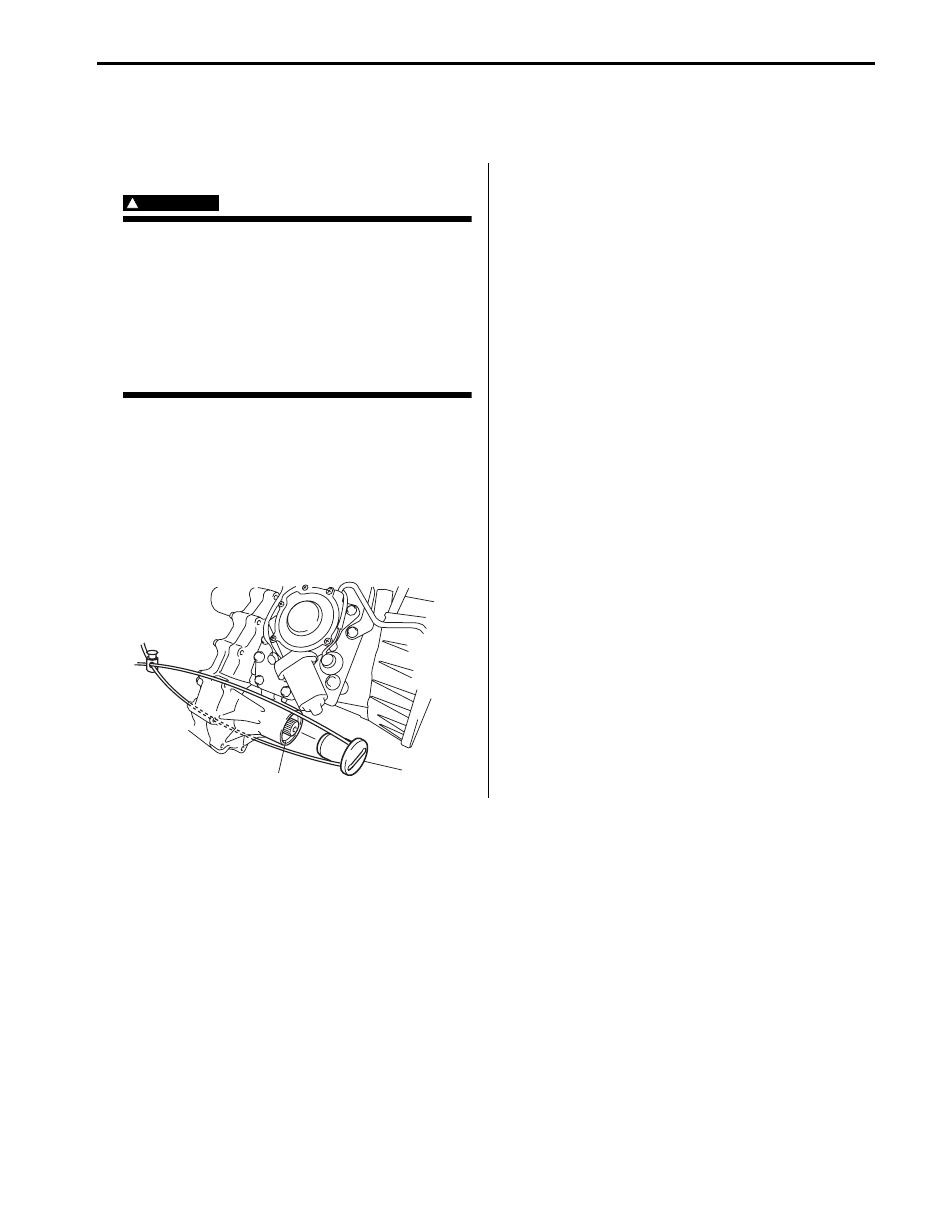

2) Install special tool (cap) to flange yoke cover hole

(front or rear) of transfer (1) and fix it to transfer or

hook with string to prevent oil leakage from transfer.

Special tool

(A): 09928–36510

3) Pour specified oil into transfer up to lever plug hole if

front propeller shaft is removed.

4) Shift transfer to 4H-lock position by turning transfer

switch.

Precautions in Diagnosing Trouble

S6JB0B3300002

• Do not disconnect the following parts before

confirming diagnostic information (DTC, etc.) stored in

4WD control module memory. These actions will

erase memorized information in 4WD control module

memory.

– Disconnection of coupler from 4WD control module

– Disconnection of battery cable from battery

– Disconnection of ground wire harness of 4WD

control module

– Disconnect main fuse from fuse box

• Diagnostic information stored in 4WD control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• Be sure to read “Precautions for Electrical Circuit

Service:” before inspection and observe what is

written there.

General Description

Transfer Description

S6JB0B3301001

The aluminum transfer case directly connected to the back of the transmission contains input gear, counter gear, rear

output shaft, front output shaft, center differential, drive chain and their accompanying gears, hubs, sleeves, fork, etc.

The center differential is installed in the transfer. With the torque induction type LSD used in the center differential, the

effect of LSD works when a rotation difference between front and rear wheels is occurring.

The transfer has such a selective mechanism as to enable the shift actuator to make selection of high speed (direct

connection with transmission output: main shaft), low speed (speed reduction by input gear, counter gear and low

gear) or neutral by way of the reduction shift sleeve located between the input gear and low gear, and selection of

center differential lock or not by way of the differential lock clutch sleeve located at the center of the rear output shaft.

The case has an oil pump to provide proper lubrication.

(A)

1

I5JB0A331107-03

3C-2 Transfer:

4WD Control System Description

S6JB0B3301003

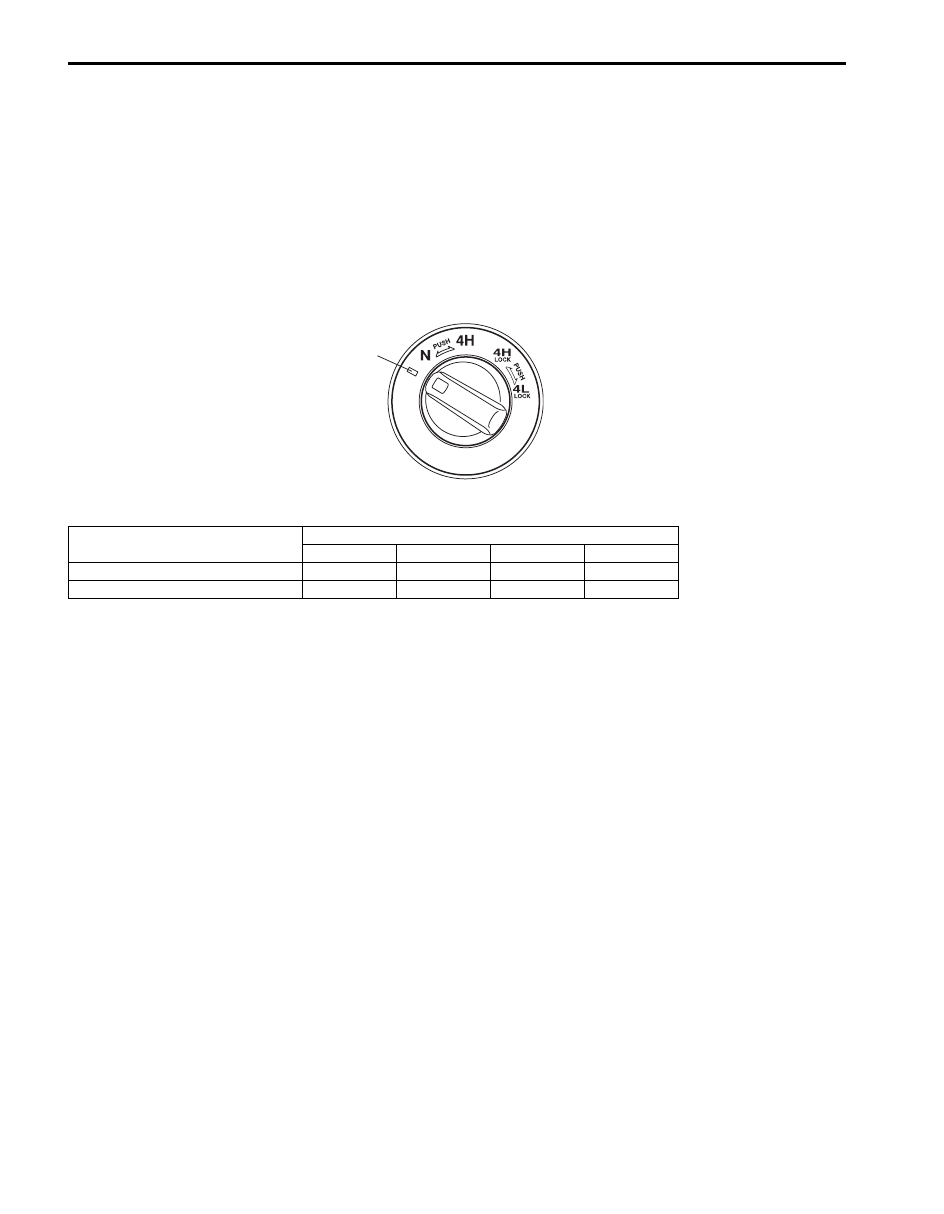

Transfer Shift Control

The 4WD control module controls the transfer shift actuator based on the signal from the transfer switch so that the

transfer is shifted to the selected position (4H, 4H-lock, N or 4L-lock). (Shifting to the N position requires that the

switch to “” position (1) keep it there for about 10 seconds then turn it to “N” position.)

The transfer actuator consists of the actuator motor and the actuator motor position switch. The 4WD control module

detects the position of the actuator motor using the position switch and controls the actuator motor running / stopping

operation.

Also, the 4L/N switch and center differential lock switch that detect the each position of the High / Low shift fork and

the differential lock shift fork are installed the transfer assembly. The 4WD control module detects the transfer actual

shift position (4H, 4H-lock, N or 4L-lock) by the signals from the 4L/N switch and center differential lock switch as

follows.

Relationship of transfer shift position and switches

When the transfer shift actuator motor position detected by motor position switch and transfer actual shift position

detected by the above-mentioned switches match, the 4WD control module judges that the transfer shifting is

complete.

Retry Control

When 4WD control module cannot judge the shifting to the target position, it commands to retry the shifting up to 3

times. If retry shifting is not possible, previous shift position is restored and notify failure of the shifting with the

indicator and buzzer.

Indicator And Buzzer Operation

The 4WD control module output operation signal of the differential lock indicator, 4L indicator, N indicator and the

buzzer to BCM. Indicators and buzzer as follows in order to inform what state the transfer control system is.

Switch

Transfer shift position

4H

4H-lock

N

4L-lock

4L/N switch

OFF

OFF

ON

ON

Center differential lock switch

ON

OFF

ON

OFF

1

I5JB0A332002-01

Transfer: 3C-3

Operation

Condition

Indicator

Buzzer

Differential

lock

indicator

OFF

—

• Ignition switch is OFF.

• Transfer is at 4H/N position.

ON

—

• Within 2 seconds after ignition switch is turn ON (checking

indicator operation).

• Transfer is at 4H-lock/4L-lock position.

Flashes at 0.25

seconds for 3

times, at intervals

of 20 seconds.

Sounds at 1

second at

intervals of 20

seconds.

• The transfer shift position is different for transfer switch.

Flashes at

intervals of 0.25

seconds

continuously

—

• 4WD control module detects DTC of 4WD control system.

Flashes at

intervals of 0.5

seconds

continuously

—

• Transfer is shifting from 4H to 4H-lock.

• Transfer is shifting from 4H-lock to 4H.

• Transfer could not complete shifting to 4H-lock.

4L indicator

OFF

—

• Ignition switch is OFF.

• Transfer is at 4H-lock/N position.

ON

—

• Within 2 seconds after ignition switch is turn ON (checking

indicator operation).

• Transfer is at 4L-lock position.

Flashes at 0.25

seconds for 3

times, at intervals

of 20 seconds.

Sounds at 1

second at

intervals of 20

seconds.

• The transfer shift position is different for transfer switch.

Flashes at

intervals of 0.25

seconds

continuously

—

• 4WD control module detects DTC of 4WD control system.

Flashes at

intervals of 0.5

seconds

continuously

—

• Transfer is shifting from 4H-lock to 4L-lock.

• Transfer is shifting from 4L-lock to 4H-lock.

• Transfer could not complete shifting to 4L-lock.

N indicator

OFF

—

• Ignition switch is OFF.

• Transfer is at 4H/4H-lock/4L-lock position.

ON

—

• Within 2 seconds after ignition switch is turn ON (checking

indicator operation).

• Transfer is at N position.

Flashes at 0.25

seconds for 3

times, at intervals

of 20 seconds.

Sounds at 1

second at

intervals of 20

seconds.

• The transfer shift position is different for transfer switch.

Flashes at

intervals of 0.2

seconds

continuously

—

• 4WD control module detects DTC of 4WD control system.

Flashes at 0.5

seconds

continuously

—

• Transfer could not complete shifting to N.

—

—

Sounds at 0.2

seconds for 2

times, at intervals

of 3 seconds.

• Transfer is at N position.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст