Suzuki Grand Vitara JB627. Manual — part 253

5C-3 Clutch:

Diagnostic Information and Procedures

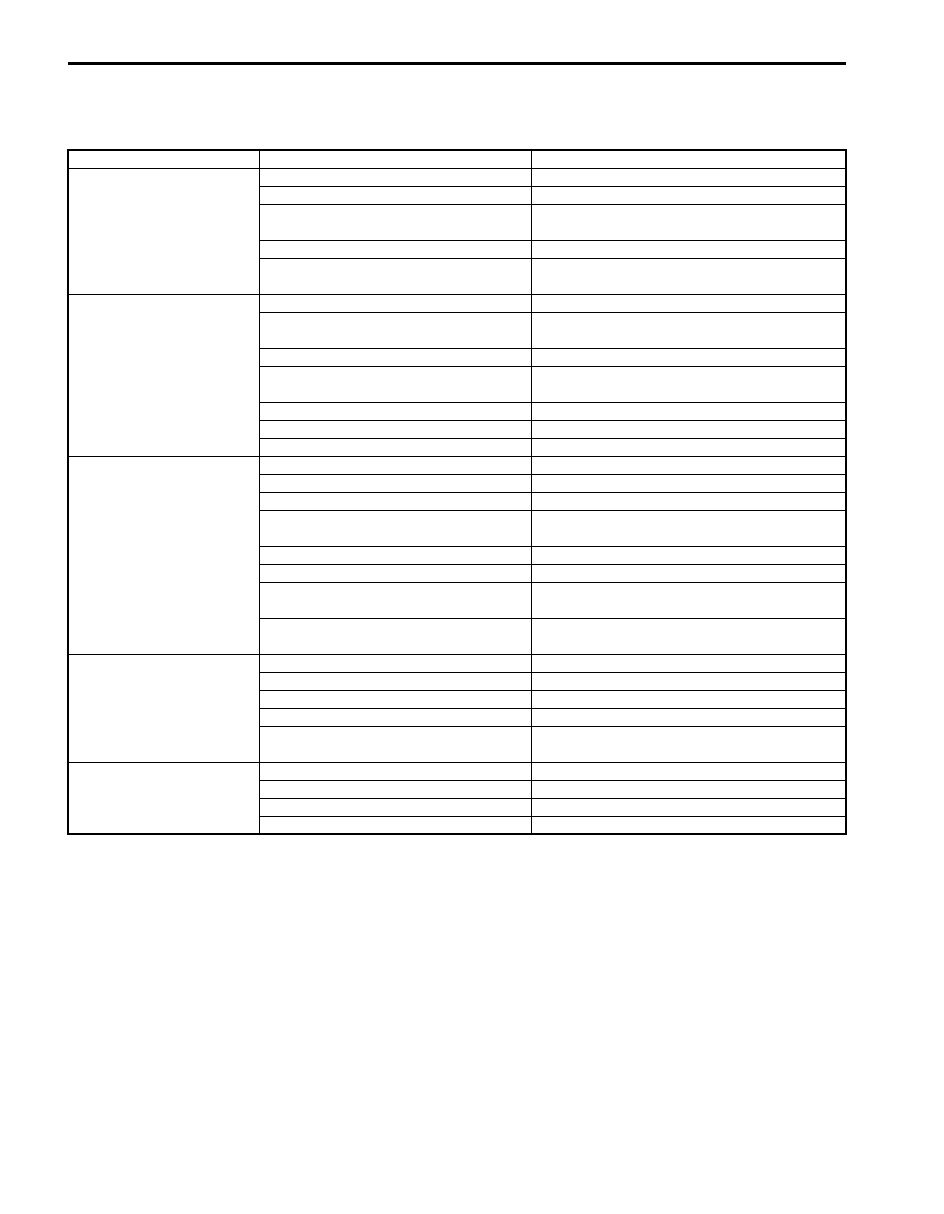

Clutch (Hydraulic Type) Symptom Diagnosis

S6JB0B5304001

Condition

Possible cause

Correction / Reference Item

Slipping

Improper clutch pedal free travel

Bleed air or replace master cylinder.

Worn or oily clutch disc facing

Replace disc.

Warped disc, pressure plate or flywheel

surface

Replace disc, clutch cover or flywheel.

Weakened diaphragm spring

Replace clutch cover.

Master cylinder piston or seal cup not

returning

Repair master cylinder.

Dragging clutch

Improper clutch pedal free travel

Bleed air or replace master cylinder.

Weakened diaphragm spring, or worn

spring tip

Replace clutch cover.

Rusted input shaft splines

Lubricate.

Damaged or worn splines of

transmission input shaft

Replace input shaft.

Excessively wobbly clutch disc

Replace disc.

Clutch facings broken or dirty with oil

Replace disc.

Fluid leakage

Repair or replace.

Clutch vibration

Glazed (glass-like) clutch facings

Repair or replace disc.

Clutch facings dirty with oil

Replace disc.

Release bearing slides unsmoothly

Replace clutch operating cylinder assembly.

Wobbly clutch disc, or poor facing

contact

Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose

Replace disc.

Distorted pressure plate or flywheel

surface

Replace clutch cover or flywheel.

Weakened or loosened engine mounting

bolt or nut

Retighten or replace mounting.

Noisy clutch

Worn or broken release bearing

Replace clutch operating cylinder assembly.

Input shaft front bearing worn down

Replace input shaft bearing.

Excessive rattle of clutch disc hub

Replace disc.

Cracked clutch disc

Replace disc.

Pressure plate and diaphragm spring

rattling

Replace clutch cover.

Grabbing clutch

Clutch disc facings soaked with oil

Replace disc.

Clutch disc facings excessively worn

Replace disc.

Rivet heads showing out of facing

Replace disc.

Weakened torsion springs

Replace disc.

Clutch: 5C-4

Repair Instructions

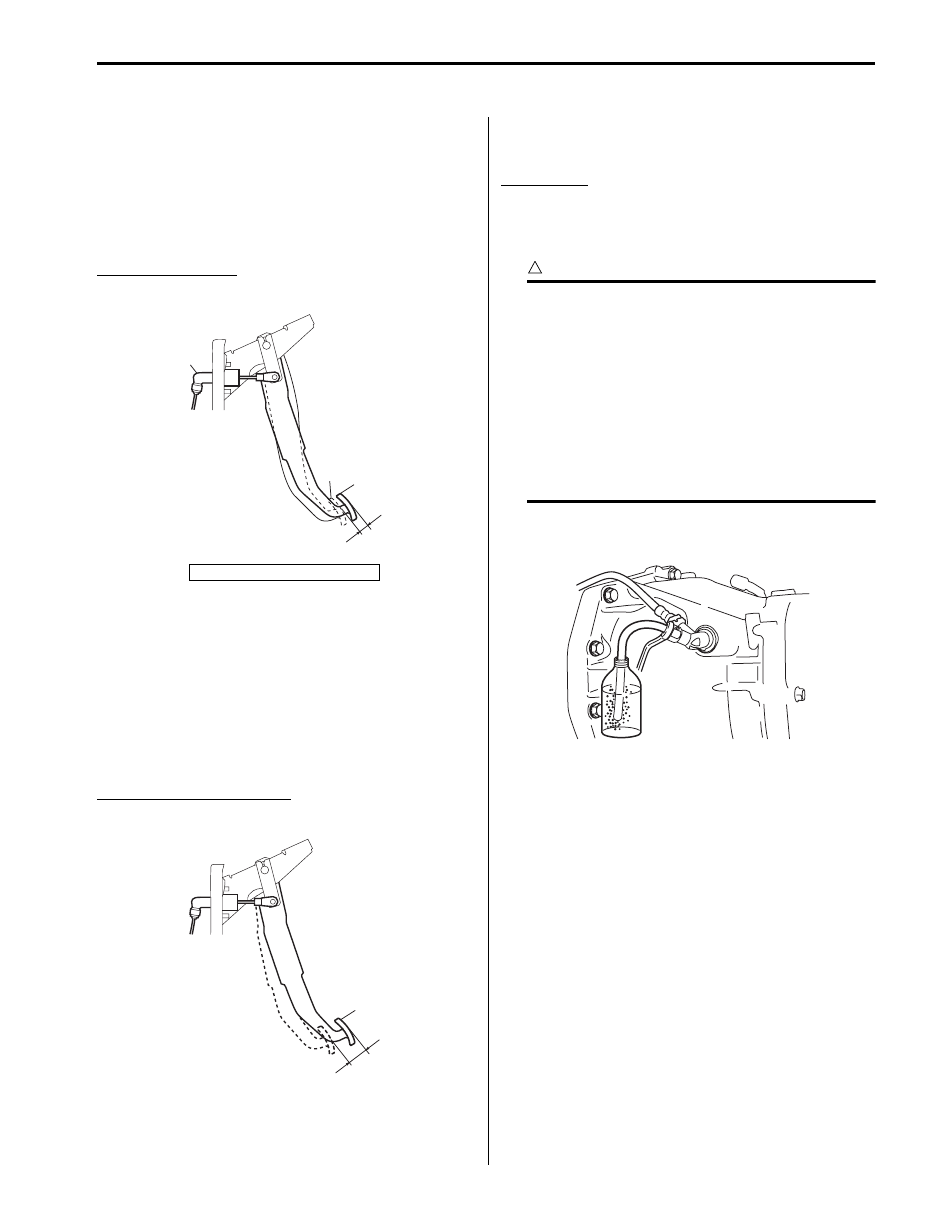

Clutch Pedal Height Inspection

S6JB0B5306011

Measure clutch pedal height “a” from brake pedal (2). If

pedal height is excessive low or high, check installation

position of clutch position switch, clutch fluid leakage,

bending of clutch pedal arm and bending of push rod of

clutch master cylinder (3). If any abnormality is found,

adjust or replace it with a new one.

Clutch pedal height

“a”: Approx. 20 mm (0.79 in.)

Clutch Pedal Free Travel Check

S6JB0B5306012

Depress clutch pedal (1), stop the moment clutch

resistance is felt and measure distance (clutch pedal

free travel). Free travel should be within the following

specification. If free travel is out of specification, check

installation position of clutch pedal position switch, clutch

fluid leakage, bending of clutch pedal arm and bending

of push rod of clutch master cylinder. If any abnormality

is found, adjust or replace it with a new one.

Clutch pedal free travel “a”

: 0 – 10 mm (0 – 0.4 in.)

Clutch Fluid Inspection

S6JB0B5306013

Refer to “Brake Fluid Level Check in Section 4A”.

Clutch Fluid

: Refer to brake reservoir cap

Air Bleeding of Clutch System

S6JB0B5306014

CAUTION

!

• Brake fluid is extremely damaging to paint.

If fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

• When operating the pedal stroke for air

bleeding of clutch system, after releasing

the clutch pedal, be sure to wait 1 second

or more before depressing it again.

Otherwise, the oil seal of operating

cylinder will be damaged, resulting in oil

leakage.

Bleed air from clutch system. Refer to “Air Bleeding of

Brake System in Section 4A” for air bleeding procedure.

1. Clutch pedal

3

2

1

“a”

I5JB0A530003-01

1

“a”

I5JB0A530004-01

I5JB0A530015-03

5C-5 Clutch:

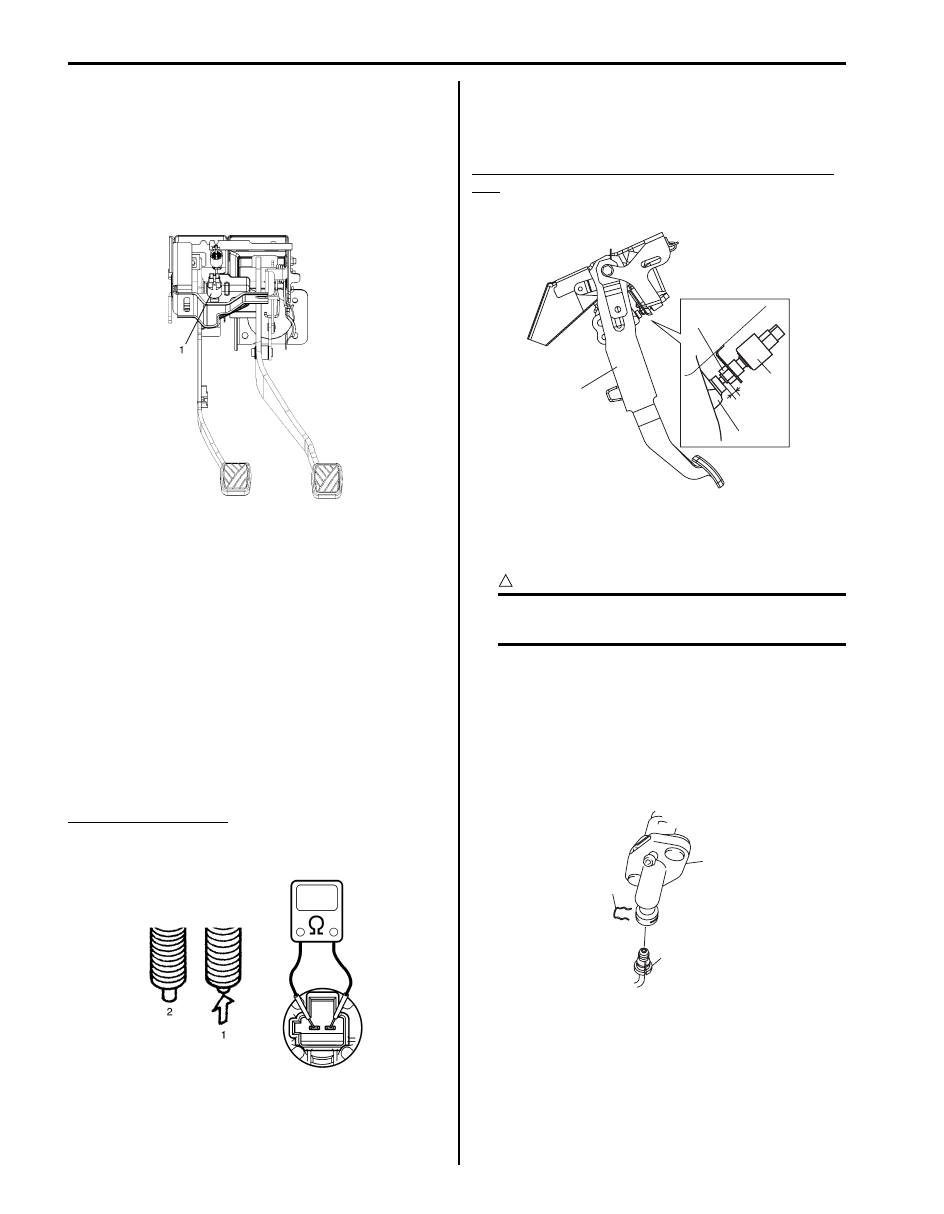

Clutch Pedal Position (CPP) Switch Removal

and Installation

S6JB0B5306001

Removal

1) Disconnect connector of CPP switch (1) with ignition

switch OFF.

2) Remove CPP switch (1) from pedal bracket.

Installation

1) Instal CPP switch to pedal bracket.

2) Adjust switch position referring to “Clutch Pedal

Position (CPP) Switch Inspection and Adjustment”.

3) Connect connector to CPP switch securely.

Clutch Pedal Position (CPP) Switch Inspection

and Adjustment

S6JB0B5306002

Inspection

Check for resistance between terminals under each

condition below. If check result is not satisfactory,

replace.

CPP switch resistance

When switch shaft is pushed (1): Continuity

When switch shaft is free (2): No continuity

Adjustment

With clutch pedal (1) released, adjust switch (2) position

so that clearance between end of thread and clutch

pedal arm is within specification.

Clearance between end of thread and clutch pedal

arm

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.)

Clutch Fluid Pipe and Hose Removal and

Installation

S6JB0B5306003

CAUTION

!

Do not allow fluid to get on painted surface. It

may cause painted surface damage.

Removal

1) Remove dust and dirt from each joint of hose and

pipe to be disconnected and clean around reservoir

cap of brake master cylinder.

2) Take out fluid with syringe or such.

3) Remove clamp (1) of clutch master cylinder (2) and

disconnect fluid pipe (3).

I5JB0A530005-02

I5JB0A530006-01

1

1

2

3

“a”

I5JB0A530007-02

1

2

3

I5JB0A530008-01

Clutch: 5C-6

4) Pull clamp (1) of fluid pipe joint (2) and disconnect

fluid hose (3).

Installation

Reverse removal sequence noting the following points.

• Tighten hose bracket nut (1) to specified torque.

Tightening torque

Clutch fluid hose bracket nut (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

• Install each clamp securely.

• After installation, check clutch pedal free travel and

bleed air from system.

• Check fluid leakage.

• Add fluid close to MAX level of reservoir.

Clutch Fluid Pipe and Hose Inspection

S6JB0B5306004

Check pipe (1) and hose (2) for dent, kink, crack, dirt and

dust. Replace if check result is not satisfactory.

Clutch Master Cylinder Removal and

Installation

S6JB0B5306005

CAUTION

!

• Do not allow fluid to get on painted

surfaces. It may cause painted surface

damage.

• Do not disassemble clutch master

cylinder.

Removal

1) Clean around reservoir cap of brake master cylinder

and take out fluid with syringe or such.

2) Detach main fuse box.

3) Disconnect fluid pipe (2) and reservoir hose (4) from

master cylinder assembly (1).

4) Remove clip (6) and push rod clevis pin (5).

5) Remove master cylinder attaching nuts (3).

6) Remove master cylinder assembly (1) and gasket.

1

3

2

I5JB0A530010-02

1, (a)

I6JB01530001-02

2

1

I6JB01530002-02

1

2

3

4

3

6

5

I5JB0A530013-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст