Suzuki Grand Vitara JB627. Manual — part 189

4E-37 ABS:

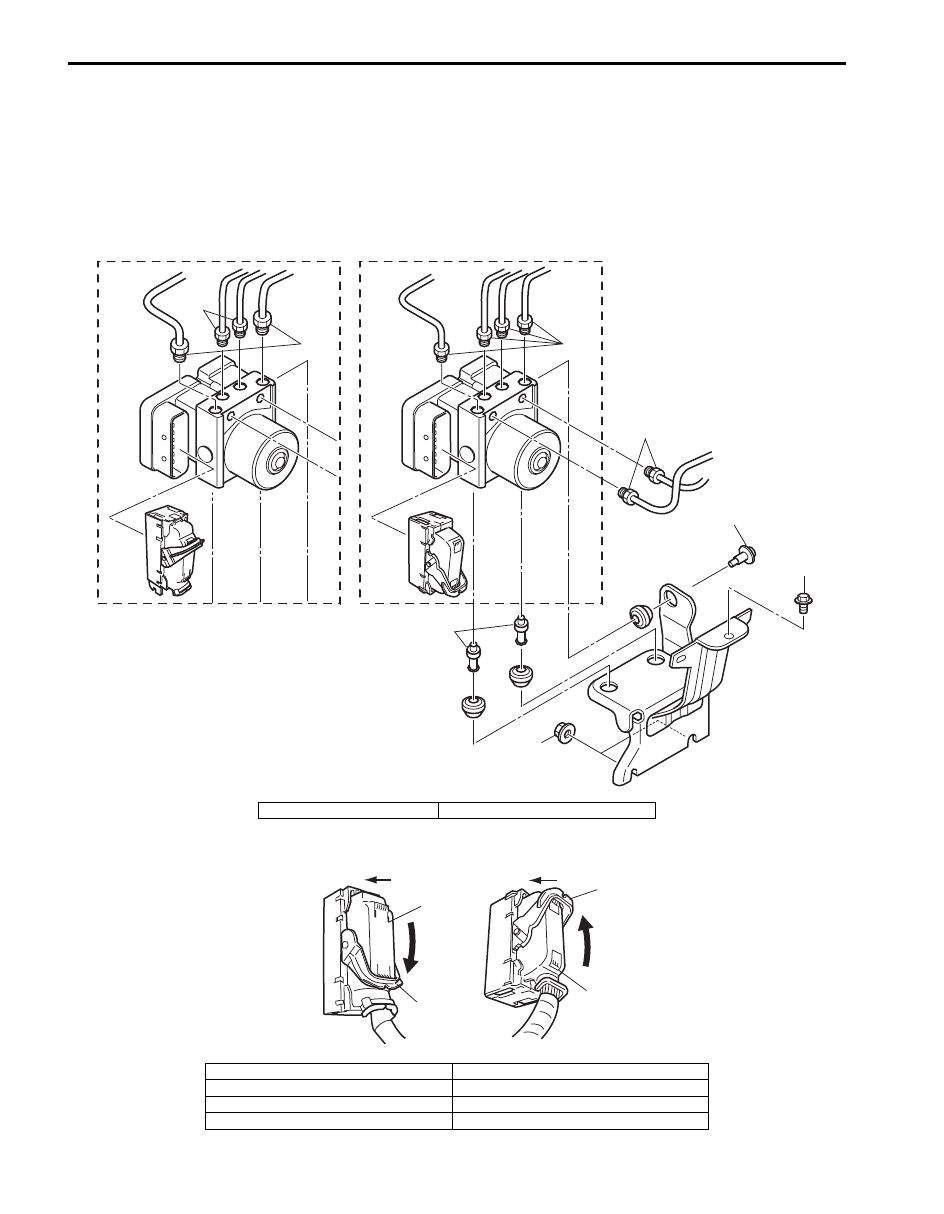

Installation

1) Install hydraulic unit / control module assembly by reversing removal procedure.

Tightening torque

Brake pipe flare nut (M10) (a): 16 N·m (1.6 kgf-m, 11.5 lb-ft)

Brake pipe flare nut (M12) (b): 19 N·m (1.9 kgf-m, 14.0 lb-ft)

ABS (ESP

®) hydraulic unit / control module assembly bolt (c): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ABS (ESP

®) hydraulic unit / control module assembly bracket bolt (d): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

ABS (ESP

®) hydraulic unit / control module assembly bracket nut (e): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Connect ABS (ESP

®) control module connector and lock it as shown in figure.

(d)

[A]

[B]

(a)

(a)

(b)

(c)

(a)

(d)

(c)

(e)

I6JB01450017-06

[A]: ESP

® model

[B]: Non-ESP

® model

[A]: ESP

® model

1. ESP

® control module connector

[B]: Non-ESP

® model

2. ABS control module connector

C: Pull down until lock to disconnect

3. Lock

D: Pull up until lock to disconnect

C

D

[A]

[B]

1

3

3

2

I6JB01450018-03

ABS: 4E-38

3) Connect harness clamp to bracket.

4) Install ECM referring to “Engine Control Module (ECM) Removal and Installation in Section 1C”.

5) Connect negative cable at battery.

6) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) For ESP

® model, perform “Sensor Calibration in Section 4F”.

9) Perform “Hydraulic Unit Operation Check”.

10) Turn ignition switch to OFF position once and then ON position. In this state, make sure that warning / indicator

lights are turn off.

11) Check DTC(s) are not stored in hydraulic unit / control module.

Front Wheel Speed Sensor On-Vehicle

Inspection

S6JB0B4506005

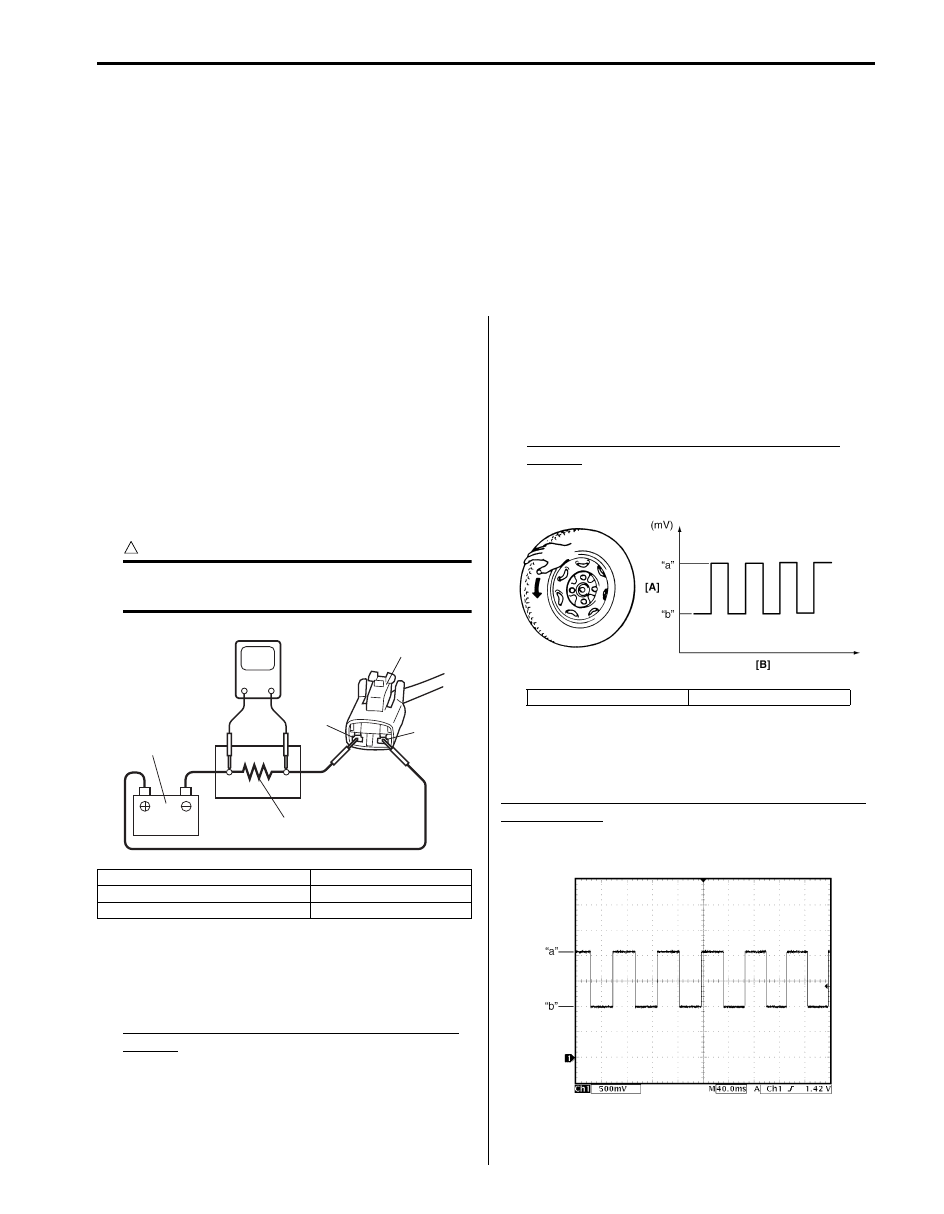

Output Voltage Inspection

1) Disconnect negative cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the

resistance to 115

Ω and the power supply voltage to

12 V.

CAUTION

!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

6) Measure voltage at resistance without wheel

rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation

and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

1. Wheel speed sensor connector

4. “BLK” wire terminal

2. Resistance (115

Ω)

5. Power supply (12 V)

3. “WHT” wire terminal

V

4

1

3

2

5

I5JB0A450026-03

[A]: Voltage

[B]: Time

I5JB0A450027-01

I5JB0A450028-02

4E-39 ABS:

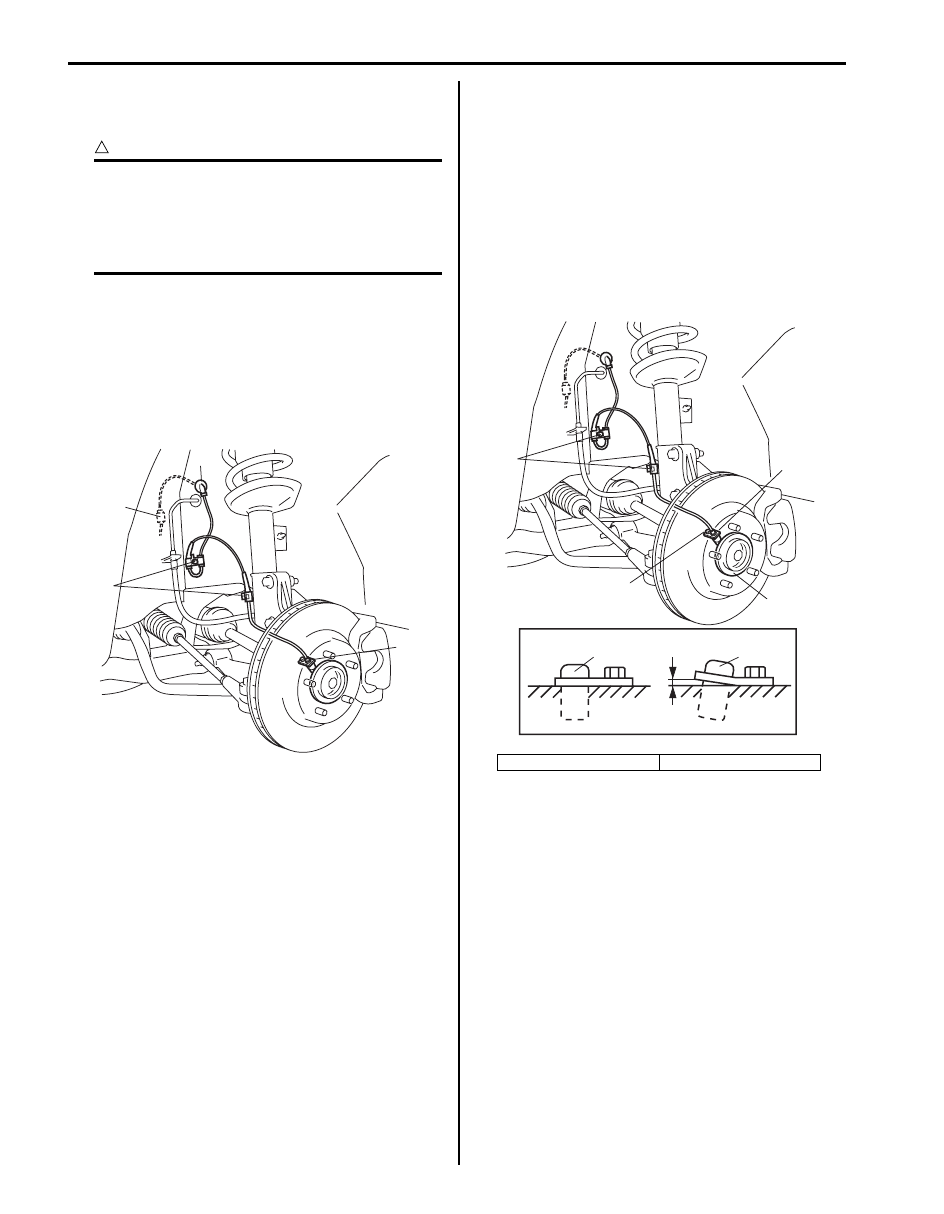

Front Wheel Speed Sensor Removal and

Installation

S6JB0B4506006

CAUTION

!

• Do not pull wire harness when removing

and installing front wheel speed sensor.

• Do not cause damage to surface of front

wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Removal

1) Disconnect negative cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolts (2) and

grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

Installation

1) Check that no foreign material is attached to sensor

(1) and mating encoder (2).

2) Install it by reversing removal procedure.

Tightening torque

Front wheel speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Check that there is no clearance between sensor

and knuckle.

2

1

3

4

I5JB0A450029-01

[A]: OK

[B]: NG

[A]

[B]

2

2

(a)

2

1

(b)

I5JB0A450030-01

ABS: 4E-40

Front Wheel Speed Sensor Inspection

S6JB0B4506007

Check sensor for damage.

If any malcondition is found, replace.

Rear Wheel Speed Sensor On-Vehicle

Inspection

S6JB0B4506008

Refer to “Front Wheel Speed Sensor On-Vehicle

Inspection” since rear wheel speed sensor is the same

as front wheel speed sensor.

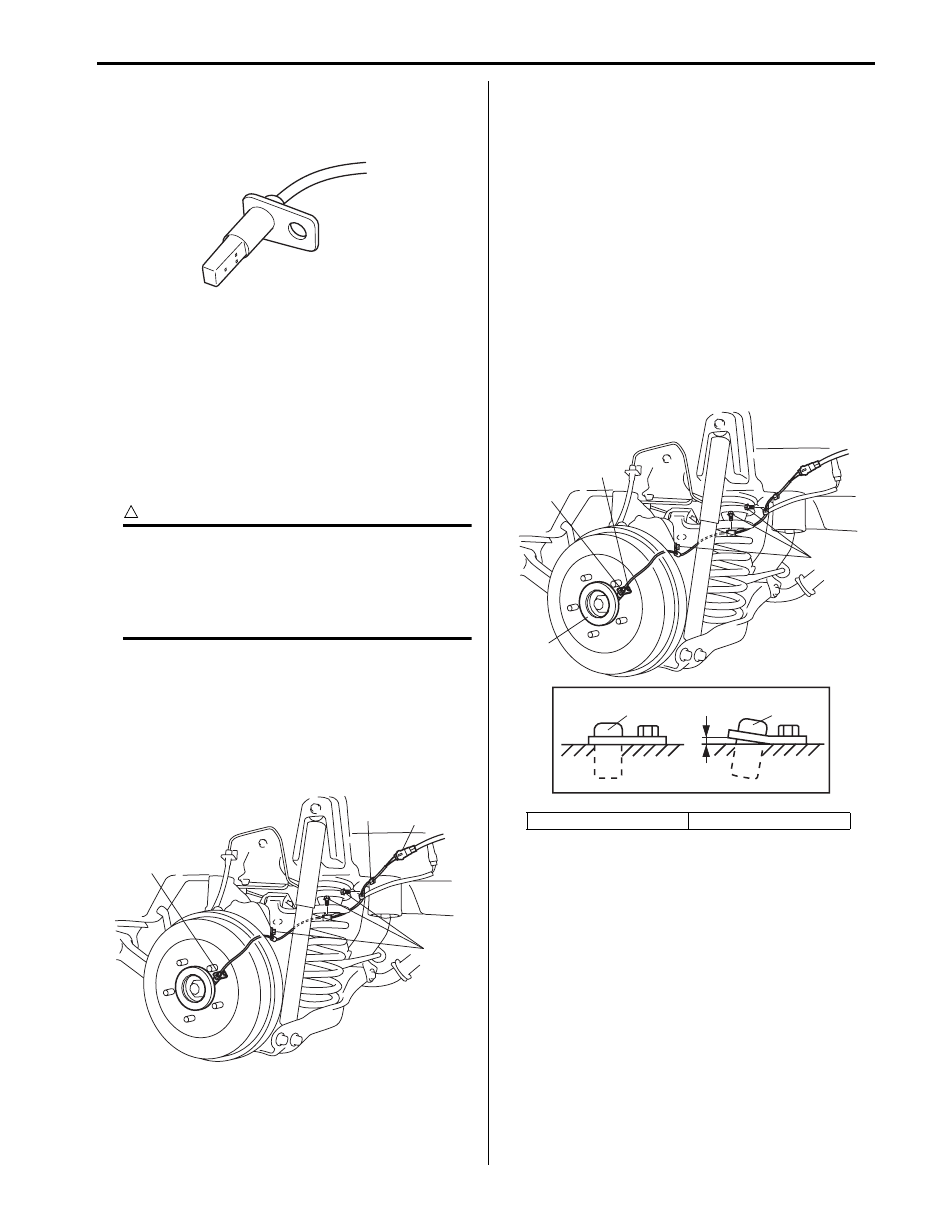

Rear Wheel Speed Sensor Removal and

Installation

S6JB0B4506009

CAUTION

!

• Do not pull wire harness when removing

and installing rear wheel speed sensor.

• Do not cause damage to surface of rear

wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Removal

1) Disconnect negative cable from battery.

2) Disconnect rear wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp (4) and clamp bolts (2).

5) Remove rear wheel speed sensor (3) from knuckle.

Installation

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor

(1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt

at the correct (upper) position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

• Check that there is no clearance between sensor and

brake back plate.

I5JB0A450031-01

3

1

2

4

I5JB0A450032-02

[A]: OK

[B]: NG

[A]

[B]

2

1

(a)

(b)

1

1

I5JB0A450033-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст