Suzuki Grand Vitara JB627. Manual — part 98

1D-73 Engine Mechanical:

Rear Oil Seal and Flywheel Inspection

S6JB0B1406047

Rear Oil Seal

Carefully inspect oil seal for wear or damage. If lip

portion is worn or damaged, replace oil seal.

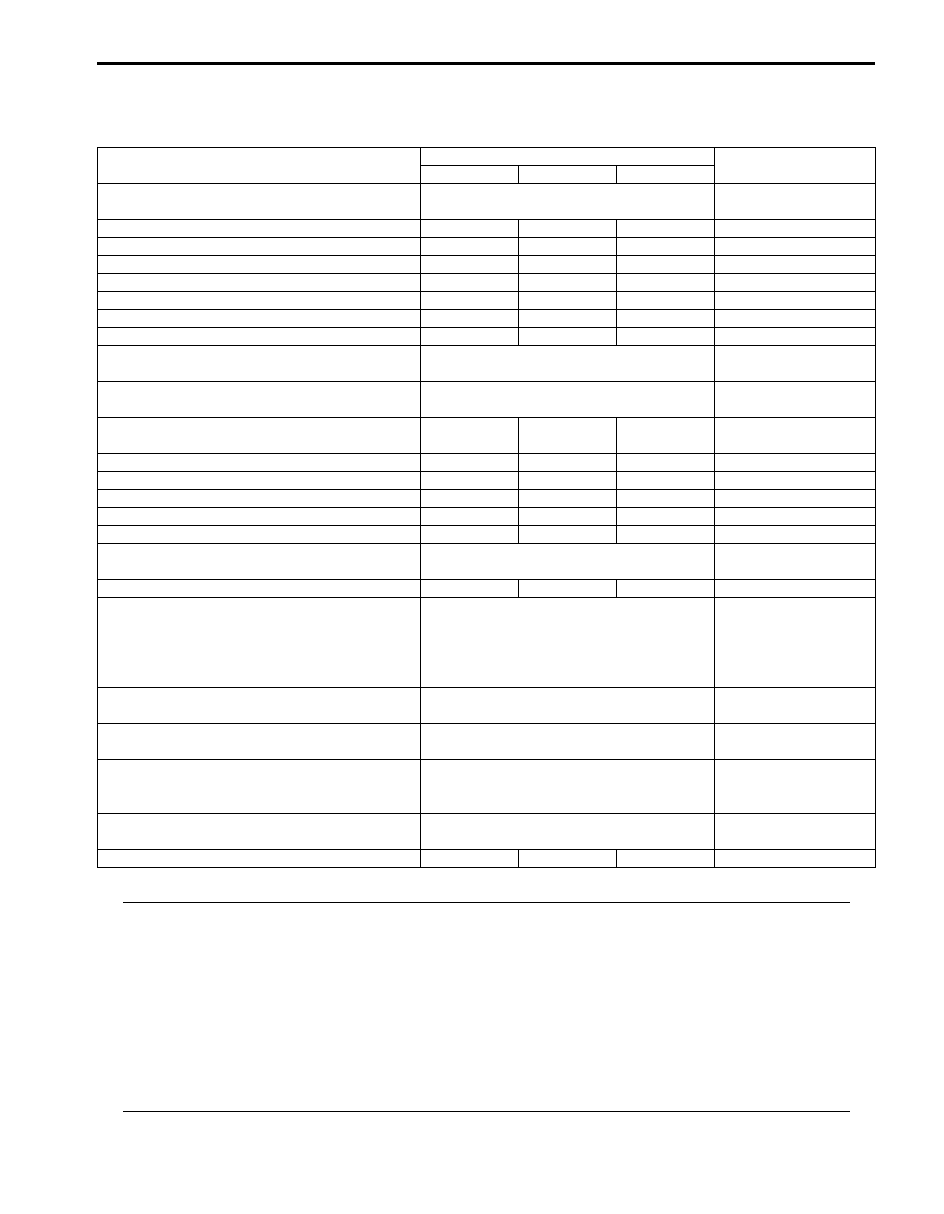

Flywheel

• If ring gear is damaged, cracked or worn, replace

flywheel.

• If the surface contacting clutch disc is damaged or

excessively worn, replace flywheel.

• Check flywheel for face runout with a dial gauge. If

runout exceeds its limit, replace flywheel.

Flywheel runout

Limit: 0.2 mm (0.0078 in.)

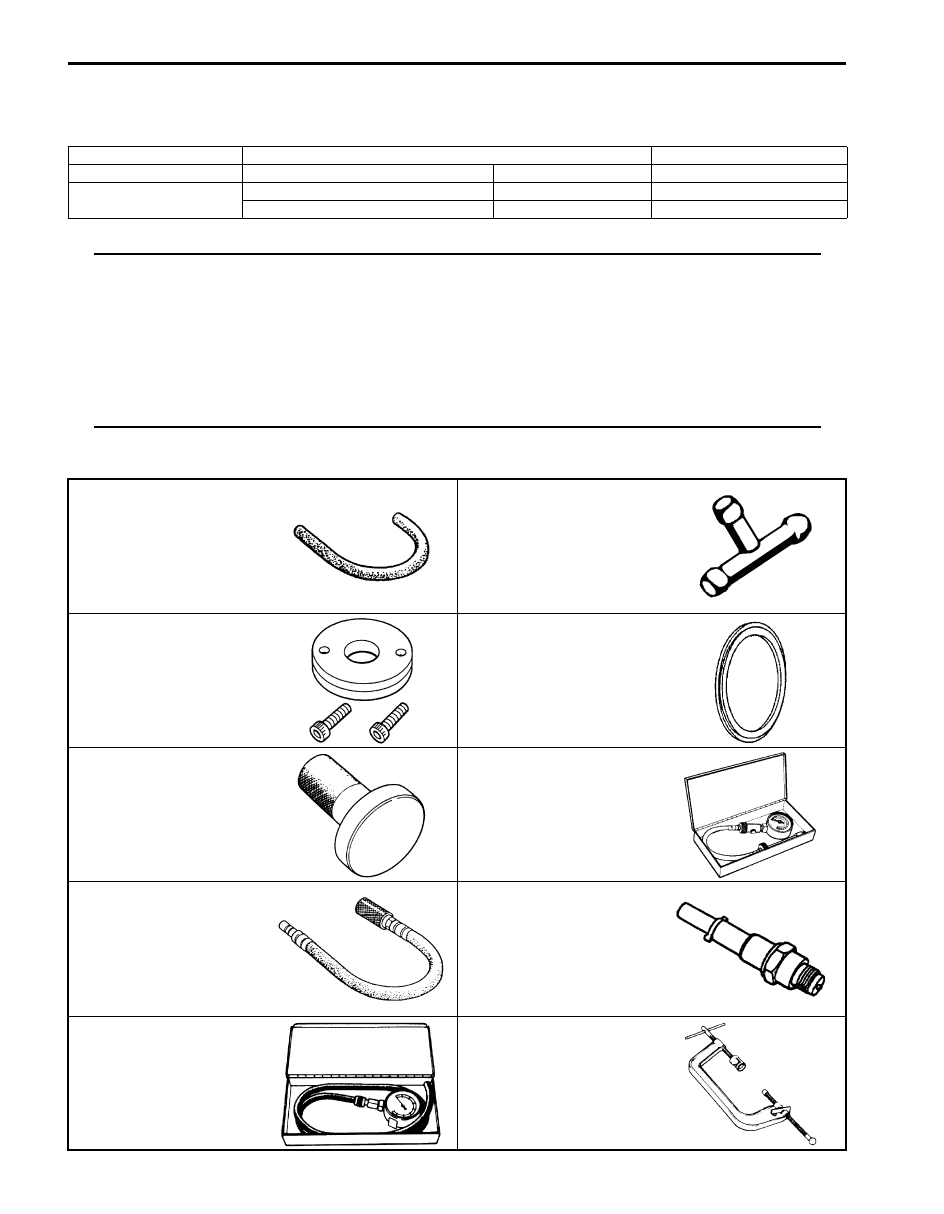

Cylinder Block Inspection

S6JB0B1406048

Distortion of Gasketed Surface

Using straightedge and thickness gauge, check

gasketed surface for distortion. If flatness exceeds its

limit, correct or replace it.

Gasketed surface flatness

Limit: 0.06 mm (0.0024 in.)

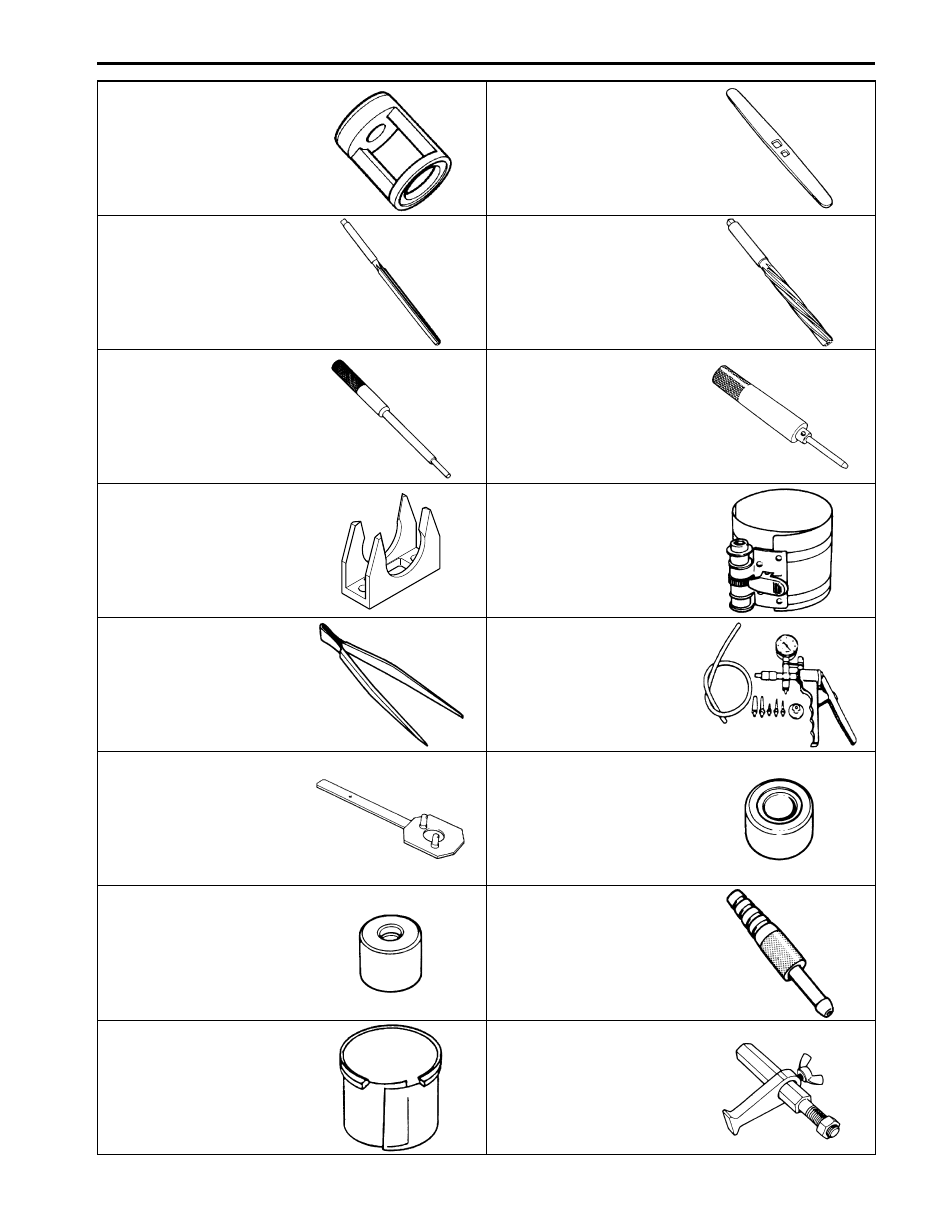

Honing or reboring cylinders

1) When any cylinder needs reboring, all other

cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of

cylinder wear.

Oversize piston diameter

88.470 – 88.490 mm (3.4831 – 3.4838 in.)

3) Using micrometer, measure piston diameter.

4) Calculate cylinder bore diameter to be rebored as

follows.

D = A + B – C

D: Cylinder bore diameter to be rebored

A: Piston diameter as measured

B: Piston clearance = 0.02 – 0.04 mm (0.0008 –

0.0015 in.)

C: Allowance for honing = 0.02 mm (0.0008 in.)

5) Rebore and hone cylinder to calculated dimension.

NOTE

Before reboring, install lower crankcase in

place and tighten to specification to avoid

distortion of bearing bores.

6) Measure piston clearance after honing.

IYSQ01143168-01

IYSQ01143169-01

“a”: 26.5 mm (1.04 in.)

IYSQ01143170-01

I6JB01140107-01

Engine Mechanical: 1D-74

Specifications

Tightening Torque Specifications

S6JB0B1407001

NOTE

The specified tightening torque is also described in the following.

“Air Intake System Components”

“Engine Mounting Components”

“Timing Chain Cover Components”

“LH (No.1) Bank 2nd Timing Chain and Chain Tensioner Components”

“1st Timing Chain and Chain Tensioner Components”

“RH (No.2) Bank 2nd Timing Chain and Chain Tensioner Components”

“Camshafts, Tappets and Shims Components”

“Valves and Cylinder Heads Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Camshaft housing bolts

11 N

⋅m (1.1 kgf-m, 7.5 lb-ft) by the specified

procedure

Camshaft housing bolt

11

1.1

8.0

Cylinder head cover nut

10.5

1.1

7.5

Engine block heater mounting bolt

11

1.1

8.0

Timing chain cover bolt

11

1.1

8.0

Crankshaft pulley bolt

150

15

108.5

Timing chain guide No.4 bolt

11

1.1

8.0

Camshaft timing sprocket bolt

80

8.0

58.0

Timing chain tensioner adjuster No.3 bolt

Tighten 11 N

⋅m (1.1 kgf-m, 7.5 lb-ft) by the

specified procedure

Timing chain tensioner adjuster No.3 nut

Tighten 45 N

⋅m (4.5 kgf-m, 32.5 lb-ft) by the

specified procedure

RH (No.2) bank 1st timing chain intake camshaft

sprocket bolt

80

8.0 58.0

Timing chain tensioner nut

25

2.5

18.0

Idler sprocket No.1 bolt

55

5.5

40.0

Timing chain tensioner adjuster No.1 bolt

11

1.1

8.0

Timing chain guide No.1 and No.2 bolt

9

0.9

6.5

Timing chain tensioner adjuster No.2 bolt

11

1.1

8.0

Camshaft housing bolt

11 N

⋅m (1.1 kgf-m, 8.0 lb-ft) by the specified

procedure

Timing chain guide No.3 bolt

11

1.1

8.0

Cylinder head bolt

Tighten 53 N

⋅m (5.3 kgf-m, 38.5 lb-ft), 84

N

⋅m (8.4 kgf-m, 61.0 lb-ft), 0 N⋅m (0 kgf-m,

0 lb-ft), 53 N

⋅m (5.3 kgf-m, 38.5 lb-ft) and

105 N

⋅m (10.5 kgf-m, 76.0 lb-ft) by the

specified procedure

Cylinder head bolt (hex hole bolt)

Tighten 11 N

⋅m (1.1 kgf-m, 7.5 lb-ft) by the

specified procedure

Connecting rod bolt

Tighten 15 N

⋅m (1.5 kgf-m,11.0 lb-ft), 45°

and 45

° by the specified procedure.

Lower crankcase bolt (10 mm (0.39 in.) thread

diameter)

Tighten 30 N

⋅m (3.0 kgf-m,22.0 lb-ft), 0 N⋅m

(0 kgf-m, 0 lb-ft), 42 N

⋅m (4.2 kgf-m, 30.5 lb-

ft) and 40

° by the specified procedure

Lower crankcase bolt (8 mm (0.31 in.) thread

diameter)

27 N

⋅m (2.7 kgf-m,19.5 lb-ft) by the

specified procedure

Flywheel (or drive plate) bolt

70

7.0

51.0

1D-75 Engine Mechanical:

Special Tools and Equipment

Recommended Service Material

S6JB0B1408001

NOTE

Required service material is also described in the following.

“Timing Chain Cover Components”

“LH (No.1) Bank 2nd Timing Chain and Chain Tensioner Components”

“1st Timing Chain and Chain Tensioner Components”

“RH (No.2) Bank 2nd Timing Chain and Chain Tensioner Components”

“Camshafts, Tappets and Shims Components”

“Valves and Cylinder Heads Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Special Tool

S6JB0B1408002

Material

SUZUKI recommended product or Specification

Note

Sealant

SUZUKI Bond No.1217G

P/No.: 99000–31260

Water tight sealant

SUZUKI Bond No.1207B

P/No.: 99000–31140

SUZUKI Bond No.1207F

P/No.: 99000–31250

09355–35754–600

09367–04002

Hose

3-way joint

09911–97710

09911–97811

Oil seal guide

Oil seal installer

09913–75510

09915–64512

Bearing installer

Compression gauge

09915–64530

09915–67010

Compression gauge hose

Compression gauge

attachment (C)

09915–67311

09916–14510

Vacuum gauge

Valve lifter

Engine Mechanical: 1D-76

09916–14910

09916–34542

Valve spring compressor

attachment

Reamer handle

09916–37810

09916–38210

Valve guide reamer (6 mm)

Valve guide reamer (11 mm)

09916–44910

09916–58210

Valve guide installer &

remover

Valve guide installer handle

09916–66510

09916–77310

Tappet holder

Piston ring compressor (50-

125 mm)

09916–84511

09917–47011

Forceps

Vacuum pump gauge

09917–68221

09917–87810

Camshaft pulley holder

Valve guide installer

attachment (protrusion: 13.5

mm)

09917–98221

09918–08210

Valve guide stem

attachment

Vacuum gauge hose joint

09919–28610

09924–17811

Protector sleeve

Flywheel holder

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст