Suzuki Grand Vitara JB627. Manual — part 105

1G-3 Fuel System:

Diagnostic Information and Procedures

Fuel Pressure Inspection

S6JB0B1704001

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

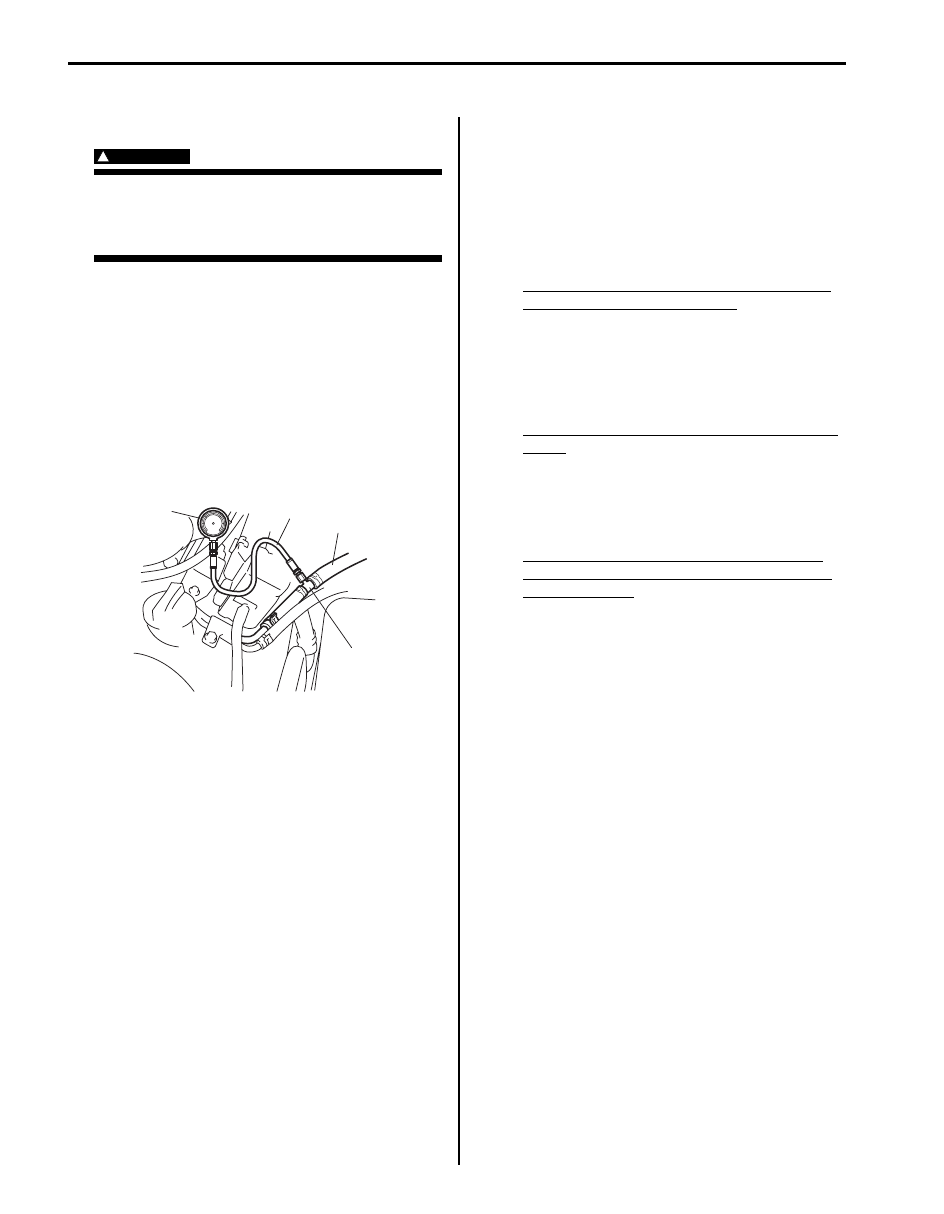

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel No.2 pipe.

3) Connect special tools and hose between fuel feed

hose (1) and fuel No.2 pipe as shown in figure, and

clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.

If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and

after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification with fuel pump

operating and engine stopped

: 250 – 310 kPa (2.5 – 3.1 kg/cm

2

, 35.5 – 44.0

psi)

b) Start engine and warm it up to normal operating

temperature, and measure fuel pressure at

idling.

Fuel pressure specification at specified idle

speed

: 210 – 260 kPa (2.1 – 2.6 kg/cm

2

, 29.9 – 36.9

psi)

c) Stop engine, and measure fuel pressure at one

minute after stopping.

Fuel pressure specification in 1 min. after

engine (fuel pump) stop (Pressure reduces

as time passes)

Over 180 kPa (1.8 kg/cm

2

, 25.6 psi)

(C)

1

(A)

(B)

I6JB01170002-01

Fuel System: 1G-4

6) After checking fuel pressure, remove fuel pressure

gauge.

WARNING

!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag and loosen joint nut

slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel No.2 pipe and fuel

feed hose.

8) Connect fuel feed hose to fuel No.2 pipe and clamp it

securely.

9) With engine OFF and ignition switch ON, check for

fuel leaks.

Fuel Cut Operation Inspection

S6JB0B1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral position (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

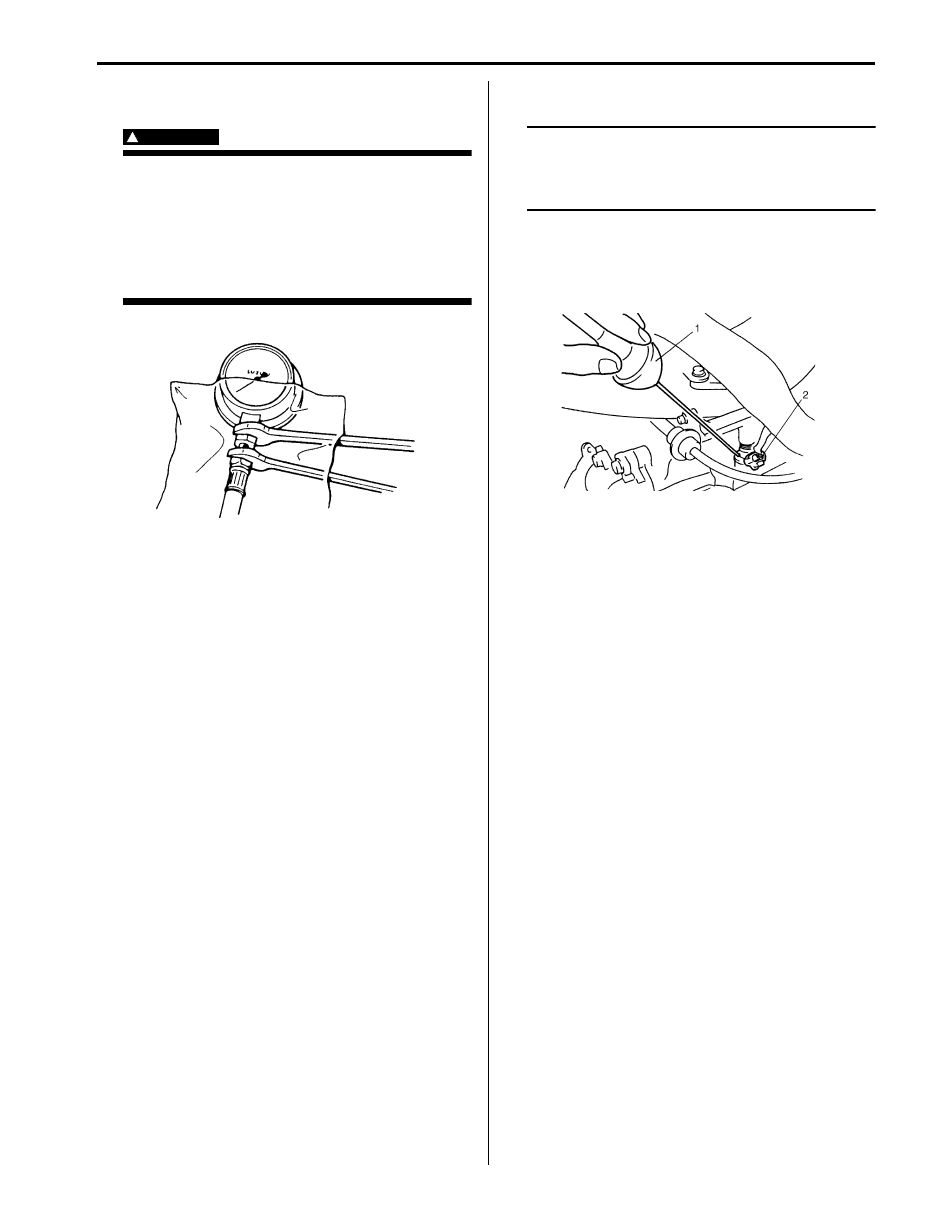

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using

sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is

stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I2RH01170032-01

I6JB01170003-01

1G-5 Fuel System:

Repair Instructions

Fuel System Components

S6JB0B1706001

11

(b)

13

2

26

1

27

10

9

10

30

5

3

4

8-1

8-2

14

(a)

12

15

15

16

(c)

19

19

20

23

(b)

25

17

18

31

24

(d)

24

(d)

24

(d)

28

28

28

32

6

7

21

33

22

(e)

29

21

I6JB0B170003-01

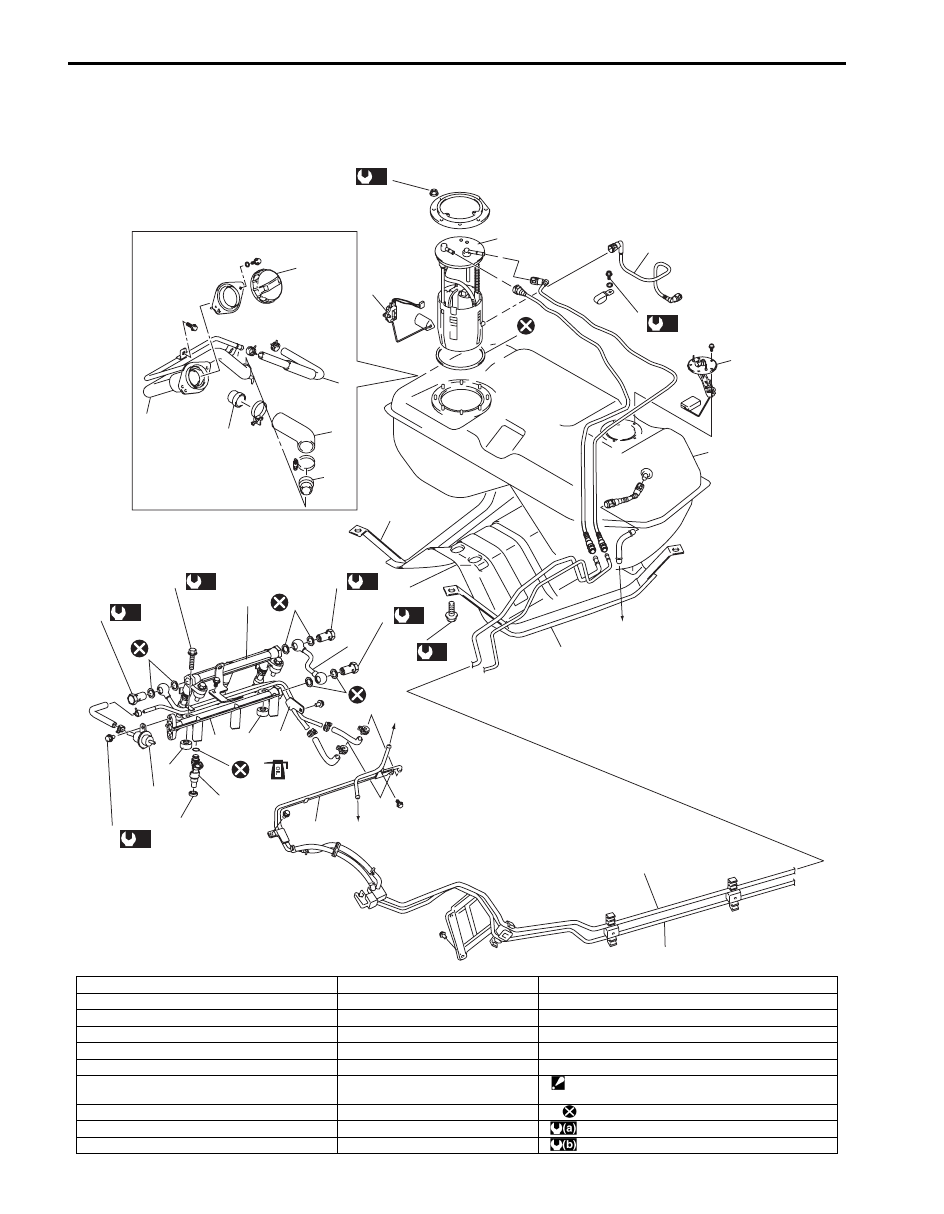

1. Fuel tank

14. Fuel filler neck

28. Fuel delivery pipe gasket

2. Fuel pump assembly

15. Fuel delivery pipe

29. O-ring

3. Fuel recirculation hose

16. Fuel delivery pipe bolt

30. Fuel suction hose

4. Fuel tank filler hose

17. Fuel injector

31. Fuel connect pipe

5. Fuel filler cap

18. Injector cushion

32. Fuel No.1 pipe

6. Fuel feed line

19. Fuel delivery pipe insulator

33. Fuel No.2 pipe

7. Fuel return line

20. Fuel pressure regulator

34. Fuel EVAP valve assembly (included in fuel tank)

: Securely insert hook through end of bracket.

8-1. Fuel tank inlet valve (fuel filler neck side)

21. To canister

: Do not reuse.

8-2. Fuel tank inlet valve (fuel tank side)

22. Fuel pipe clamp bolt

: 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

9. Fuel tank protector

23. Fuel pressure regulator bolt

: 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

Fuel System: 1G-6

Fuel Hose Disconnecting and Reconnecting

S6JB0B1706002

WARNING

!

Before starting the following procedure, be sure to observe “Precautions on Fuel System Service” in

order to reduce the risk or fire and personal injury.

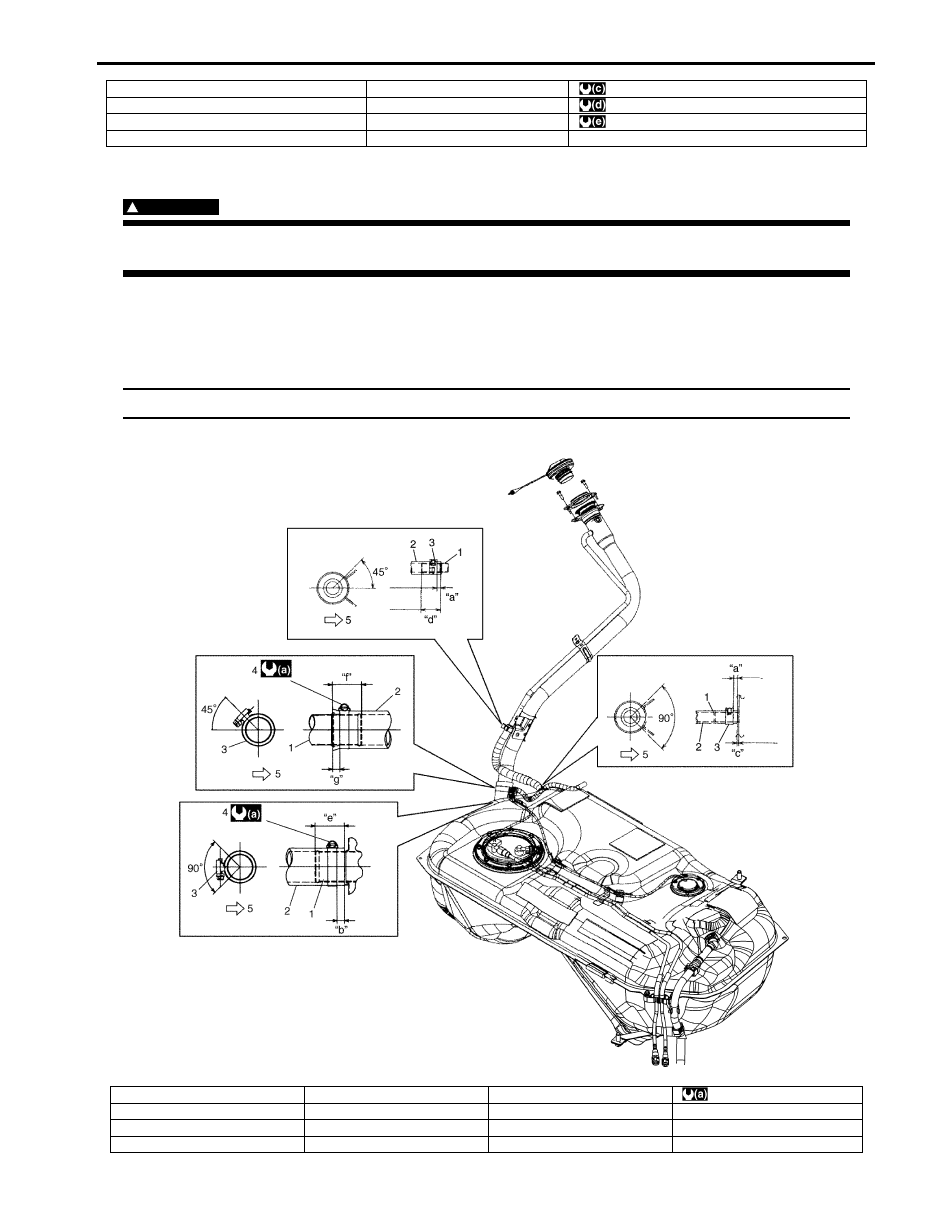

Be sure to connect and clamp each hose correctly as shown in figure.

For Normal Clamp

Fuel tank system

NOTE

Be sure to install hose to spool of pipe surely.

10. Fuel tank belt

24. Fuel union bolt

: 25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Fuel pump gasket

25. To EVAP canister purge valve

: 30 N

⋅m (3.0 kgf-m, 22.0 lb-ft)

12. Fuel tank bolt

26. Sub fuel level sensor

: 5 N

⋅m (0.5 kgf-m, 3.6 lb-ft)

13. Fuel pump nut

27. Main fuel level sensor

I7JB01170002-01

1. Pipe

5. Vehicle forward

“d”: 25 – 30 mm (0.98 – 1.18 in.)

: 4 N

⋅m (0.4 kgf-m, 3.0 lb-ft)

2. Hose

“a”: 3 – 7 mm (0.12 – 0.28 in.)

“e”: 33 mm (1.30 in.)

3. Clamp

“b”: 5 – 12 mm (0.20 – 0.48 in.)

“f”: 38 mm (1.50 in.)

4. Fuel filler hose clamp screw

“c”: 2 mm (0.08 in.)

“g”: 8 – 15 mm (0.32 – 0.59 in.)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст