Suzuki: Engine K6A-YH6. Manual — part 6

4

4-1

Chapter 4

Theory of Operation

General Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Air Intake, Fuel, and Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Front Cover, Timing Chain, and Tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Tension Adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Cylinder Head and Valve Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Head Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Cylinder Block and Lower Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Connecting Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Piston, Piston Rings, and Piston Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-2

THEORY OF OPERATION

4

4.1 General Engine Operation

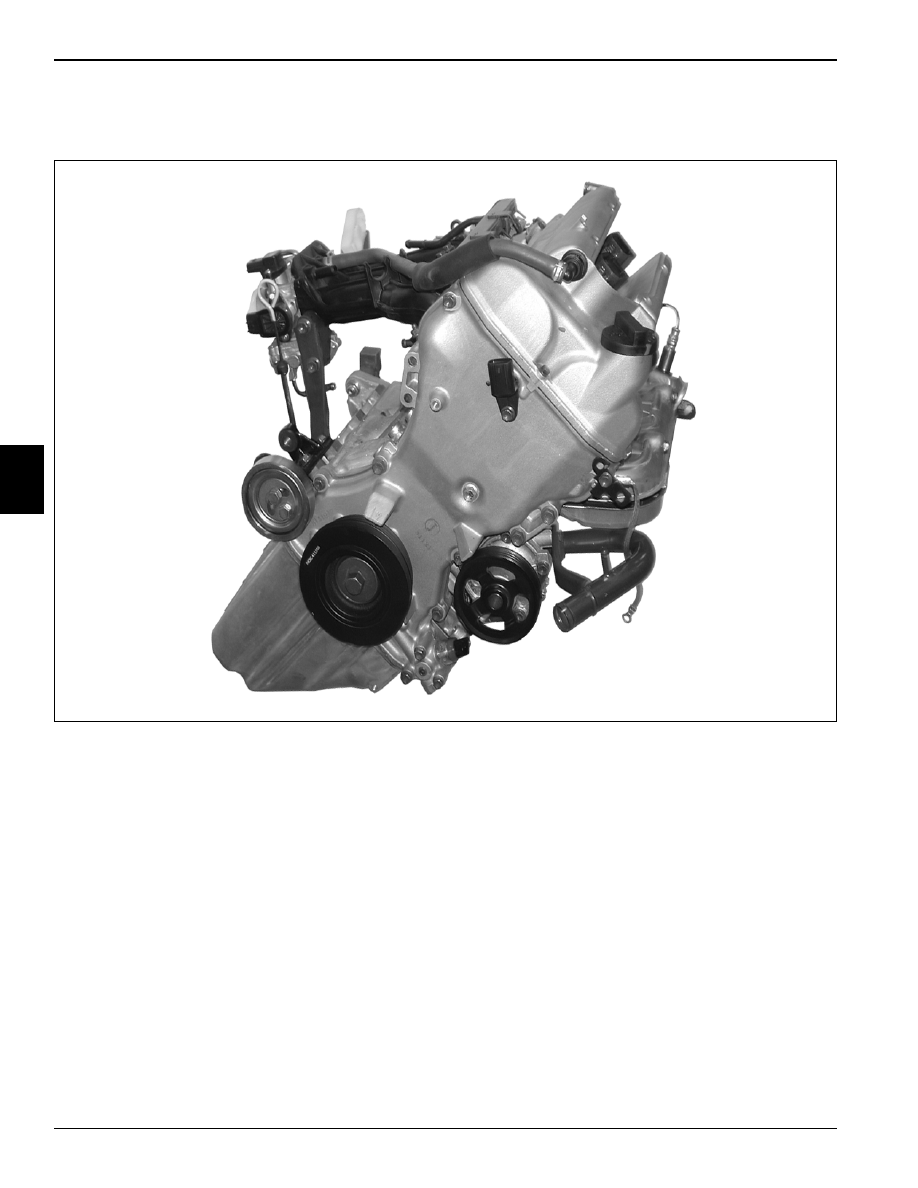

Figure 4-1

The K6A engine is an in-line, 3-cylinder, twin overhead

cam, 4-valve per cylinder, naturally aspirated, liquid

cooled, gasoline engine.

The compact K6A engine is constructed primarily of

durable, lightweight, heat-dissipating materials.

The cylinder head is a twin cam 4-valve type and made of

aluminum alloy that is light in weight and excellent in heat

dissipation. Valves are direct driven from camshafts by

way of shim-adjustable tappets placed on top of valves.

The combustion chamber is a pent-roof type with the

spark plug arranged in the center for improved

combustion. Spark plugs are fired by direct mounted

individual coils for each plug.

The camshafts are made of lightweight hollow cast iron.

Camshaft drive is done with a chain drive that is

automatically adjusted by a chain tensioner. The chain

tensioner uses lubrication system pressure and spring

pressure to automatically compensate for chain wear.

The cylinder head gasket is of 2-layer laminated stainless

steel which is excellent in durability and reliability. Use of

advanced coatings further enhance the fluid sealing

capabilities of the gasket.

The cylinder block is of a lightweight aluminum two-piece

design, consisting of upper and lower castings. The lower

casting is a ladder design that incorporates the main

journal caps for added rigidity. Semi-wet pressed-in

cylinder sleeves are contained in the upper block casting.

The crankshaft is constructed of cast iron and utilizes

four main journals and three rod journals. Counter-

balancing is achieved by weights on two of the journals.

Rod and main journal bearings are of a two-piece design

with the third main journal incorporating a thrust bearing.

Connecting rods are of a two-piece design made of

carbon steel. The rod cap is retained, using special

reamer type rod bolts and nuts.

TN0746

THEORY OF OPERATION

4-3

4

Pistons attached to connecting rods are made of an

aluminum alloy and use a full-floating piston pin. Piston

pin holes are equipped with a “Ricardo Groove” to aid in

lubrication. Pistons incorporate a slipper skirt with three

rings: two compression and one oil type.

The engine lubrication system incorporates a lightweight

aluminum oil pan with internal crankshaft baffle. Engine

oil is removed from the pan through a strainer pickup by a

crankshaft driven oil pump with integral oil pressure

regulator. Engine oil is routed through a full-flow oil filter

that houses an internal filter bypass valve and then

distributed throughout the engine.

A belt-driven water pump removes coolant from a full-flow

radiator and circulates the coolant through the entire

engine. The coolant temperature is controlled by the

cylinder-head-mounted thermostat housing containing

the thermostat.

The electronically controlled fuel injection system

efficiently supplies fuel to the engine, while maintaining

optimum performance and throttle response. Port

injectors with a common fuel rail in conjunction with a

throttle body are used for fuel distribution.

4-4

THEORY OF OPERATION

4

4.2 Air Intake, Fuel, and Exhaust

Figure 4-2

Fuel is supplied from the fuel rail (2) to each cylinder via

electronically controlled fuel injectors (1), mounted to the

intake manifold (3) runners.

Air flow into the intake manifold is metered with a throttle

body assembly (4), which is fastened and sealed to the

intake manifold. The throttle body is controlled and

monitored by the ECM to adjust fuel/air mixtures.

Exhaust gases are expelled through the exhaust side of

the cylinder head into the exhaust manifold (5), which is

fastened and sealed to the cylinder head. Exhaust gases

are monitored with the oxygen sensor (6), which provides

the ECM with data to adjust fuel/air mixtures. The entire

exhaust manifold is surrounded by a heat shield (7) to aid

in prevention of accidental burns.

1

Injector (3 used)

5

Exhaust Manifold

2

Fuel Rail

6

Oxygen Sensor

3

Intake Manifold

7

Heat Shield

4

Throttle Body Assembly

TN0690

1

2

3

4

5

6

7

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст