Suzuki: Engine K6A-YH6. Manual — part 7

THEORY OF OPERATION

4-5

4

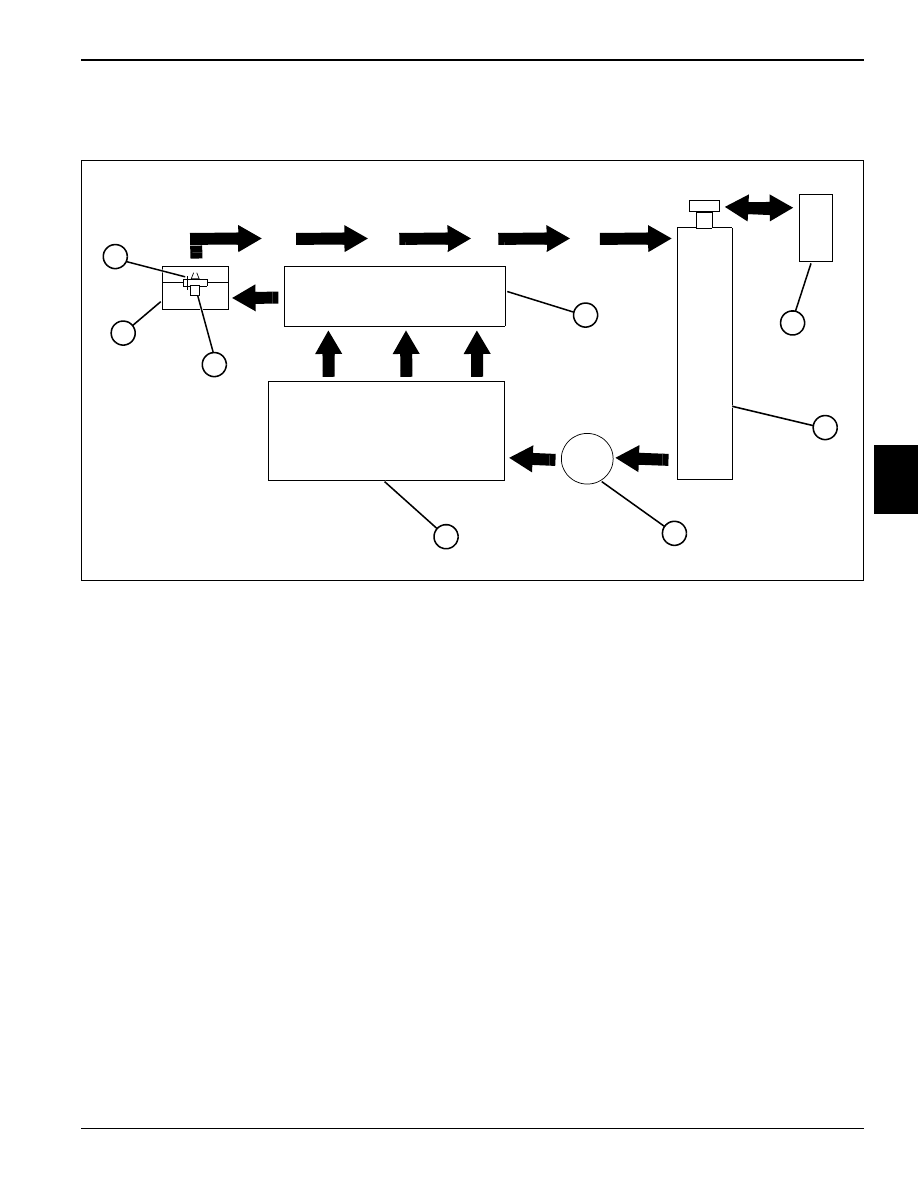

4.3 Cooling System

Figure 4-3

The cooling system includes the radiator (4), water pump

(5), thermostat (7), and engine coolant passages.

Coolant is circulated from the water pump (5) into the

engine coolant passages and circulates around the

cylinders. From the cylinders, coolant flows up through

the block deck passages and into the cylinder head (2).

In the cylinder head (2), the coolant flows through

passages around the intake and exhaust ports, valve

seats, and combustion chambers. Coolant flows toward

the rear of the cylinder head (2) and exits through the

thermostat housing (8).

During the warm-up period, the thermostat (7) is closed

and coolant flows only through the jiggle pin (1) opening

to provide a fast warm-up period. The jiggle pin (1) also

helps ensure that no air is trapped in the engine when

filling the cooling system.

Once the engine has reached operating temperature, the

thermostat (7) opens and allows coolant to flow through

the upper radiator hose to the radiator (4) top tank.

Coolant circulates through the radiator (4), dissipates

heat, and then flows out of the radiator (4) through the

lower hose and into the suction side of the water pump

(5).

If coolant temperature begins to become excessive, the

radiator pressure cap will open and allow excess coolant

to flow into the overflow bottle (3). When coolant

temperature lowers enough, the radiator cap will close.

As the coolant continues to cool, a vacuum will be

created in the radiator (4). This will open a valve in the

radiator cap that will syphon the excess coolant from the

overflow bottle (3) back into the radiator (4).

Coolant continues flowing through the engine and

radiator circuit until the coolant temperature drops below

the thermostat (7) opening temperature. The thermostat

(7) will remain open until coolant temperature falls below

the thermostat closing temperature. At that time the

thermostat (7) will close and begin a new cycle of

warming the coolant.

This repeated cycle of temperature control keeps the

engine at the optimal temperature for clean and efficient

performance.

1

Jiggle Pin

5

Water Pump

2

Cylinder Head

6

Cylinder Block

3

Overflow Bottle

7

Thermostat

4

Radiator

8

Thermostat Housing

4

5

6

7

8

1

3

2

4-6

THEORY OF OPERATION

4

Thermostat

Figure 4-4

The cooling system thermostat (1) is contained in the

thermostat housing located on the rear of the cylinder

head. The thermostat controls the flow of coolant through

the engine. The thermostat is in the closed position when

the engine is cold. When coolant temperature reaches

190° F (88° C) the thermostat begins to open, allowing

coolant to circulate. The thermostat opens fully when

coolant temperature reaches 205° F (96° C), allowing full

coolant system circulation. As engine load is varied, the

thermostat will vary its open or closed percentage to

maintain the engine in an optimum temperature range. A

jiggle pin is provided in the thermostat to aid in the

bleeding of the system when filling.

Water Pump

Figure 4-5

The engine is equipped with a belt-driven water pump (1)

driven from the crankshaft pulley. The water pump

circulates coolant throughout the entire cooling system.

The water pump is equipped with a “weep hole” for

indication of seal wear. The pump is serviceable as a unit

only.

TN0573

1

TN0747

1

THEORY OF OPERATION

4-7

4

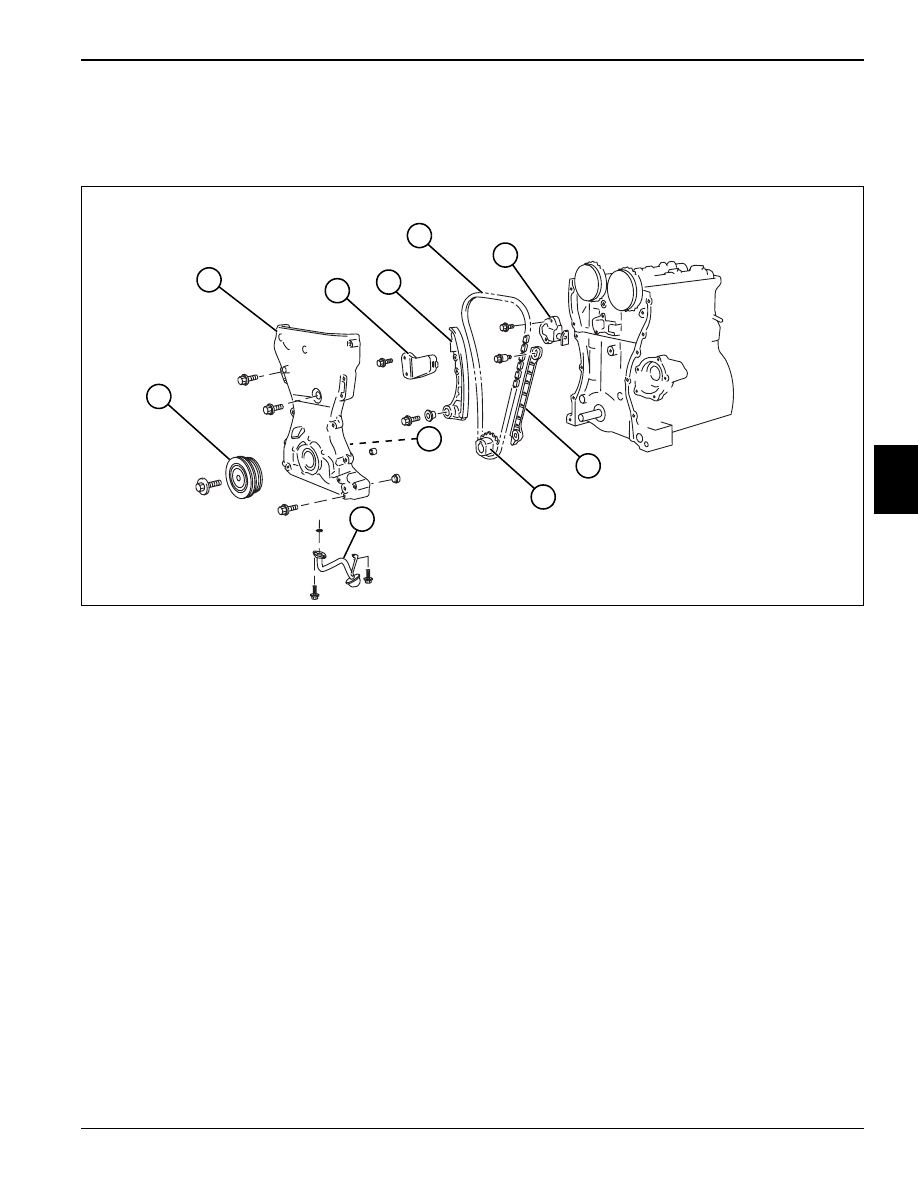

4.4 Front Cover, Timing Chain,

and Tensioner

Figure 4-6

Attached to the front of the engine is the one-piece cast

aluminum front cover. The front cover attaches the oil

pump pickup strainer and houses the oil pump and front

seal. Contained under the front cover is the timing chain,

chain guide, and chain tensioner setup.

1

Crankshaft Pulley

6

Tension Adjuster

2

Front Cover

7

Chain Guide

3

Tensioner Link

8

Crankshaft Sprocket

4

Tensioner

9

Oil Pump

5

Timing Chain

10

Pickup Strainer

TN0748

1

2

3

4

5

6

7

8

9

10

4-8

THEORY OF OPERATION

4

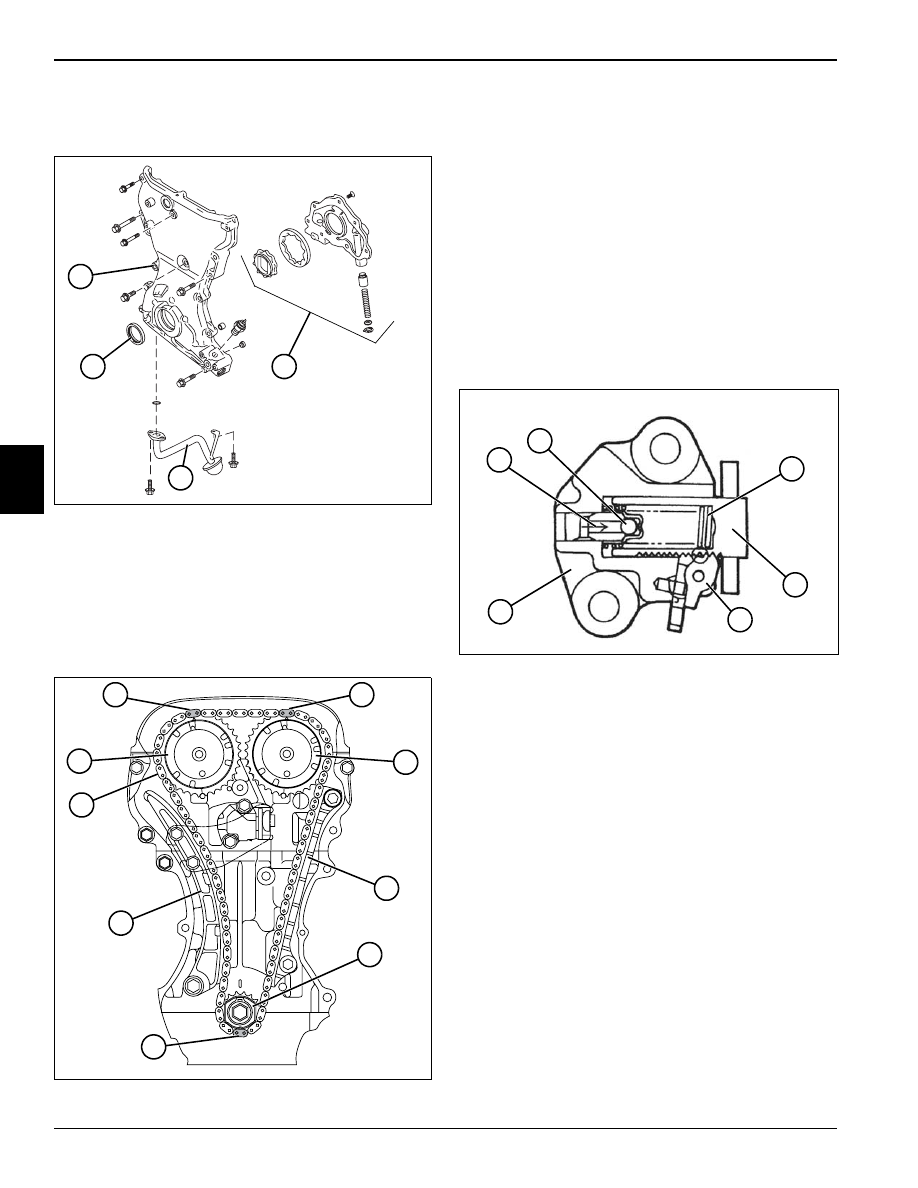

Front Cover

Figure 4-7

The front cover (1) houses the crankshaft-driven oil pump

(2) and front seal (3). Attached to the bottom of the cover

is the pickup strainer (4) for the oil pump.

Timing Chain

Figure 4-8

For the camshaft drive, a highly durable chain drive

system is used.

Through the timing chain (1), the crankshaft rotation is

transmitted from the crankshaft timing sprocket (7) to the

camshaft timing sprockets (2 and 5) installed on the end

of the intake and exhaust camshafts.

The timing chain has aligning links (3, 4, and 8) that are

used for aligning with the timing marks on the respective

camshaft sprockets and crankshaft sprocket.

A chain guide (6) and chain tensioner (9) system are

used to ensure quiet and accurate operation.

Tension Adjuster

Figure 4-9

The tension adjuster (6) has a plunger (4) inside, which

pushes against the tensioner link to give proper tension.

This plunger is operated by engine oil pressure (1) as

well as spring tension (3). The plunger is designed to

travel in only one way. Once the plunger has moved

outward, it will not come back due to the function of the

ratcheting mechanism (5).

There is a check ball (2) inside the plunger (4), which

keeps hydraulic pressure from dropping. With this

provision, the plunger can resist and absorb a kickback

force. During operation under low oil pressure, the ratchet

keeps the plunger from being pushed back, allowing

tension of the chain to be maintained. The result is quiet

operation without chain flapping.

TN0749

1

4

2

3

TN0502

1

2

3

4

5

6

7

8

9

TN0503

1

2

3

4

5

6

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст