Suzuki Grand Vitara JB416 / JB420. Manual — part 171

3B-37 Differential: Rear

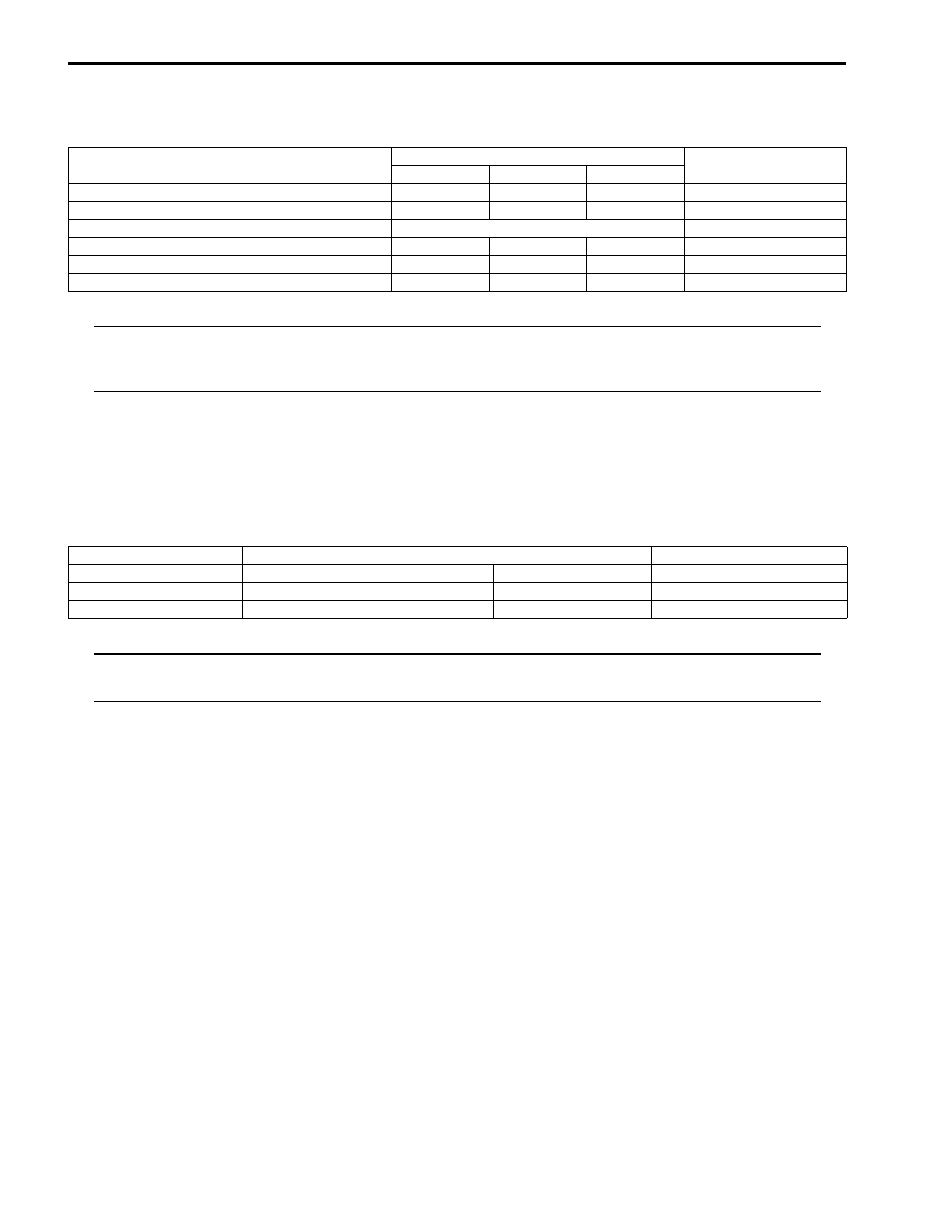

Specifications

Tightening Torque Specifications

S5JB0A3227001

NOTE

The specified tightening torque is also described in the following.

“Rear Differential Unit Components: Rear”

“Rear Differential Components: Rear”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S5JB0A3228001

NOTE

Required service material is also described in the following.

“Rear Differential Components: Rear”

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Rear differential front mounting bolt

120

12.0

87.0

Rear differential rear mounting bolt

120

12.0

87.0

Bevel gear bolt

Tighten 40 N

⋅m (4.0 kgf-m, 29.5 lb-ft) + 50° )

Rear cover bolt No.1

50

5.0

17.0

Rear cover bolt No.2

60

6.0

43.5

Retainer bolt

50

5.0

36.5

Material

SUZUKI recommended product or Specification

Note

Grease

SUZUKI Super Grease A

P/No.: 99000–25010

Sealant

SUZUKI Bond No.1217G

P/No.: 99000–31260

Thread lock cement

Thread Lock Cement Super 1322

P/No.: 99000–32110

Differential: Rear 3B-38

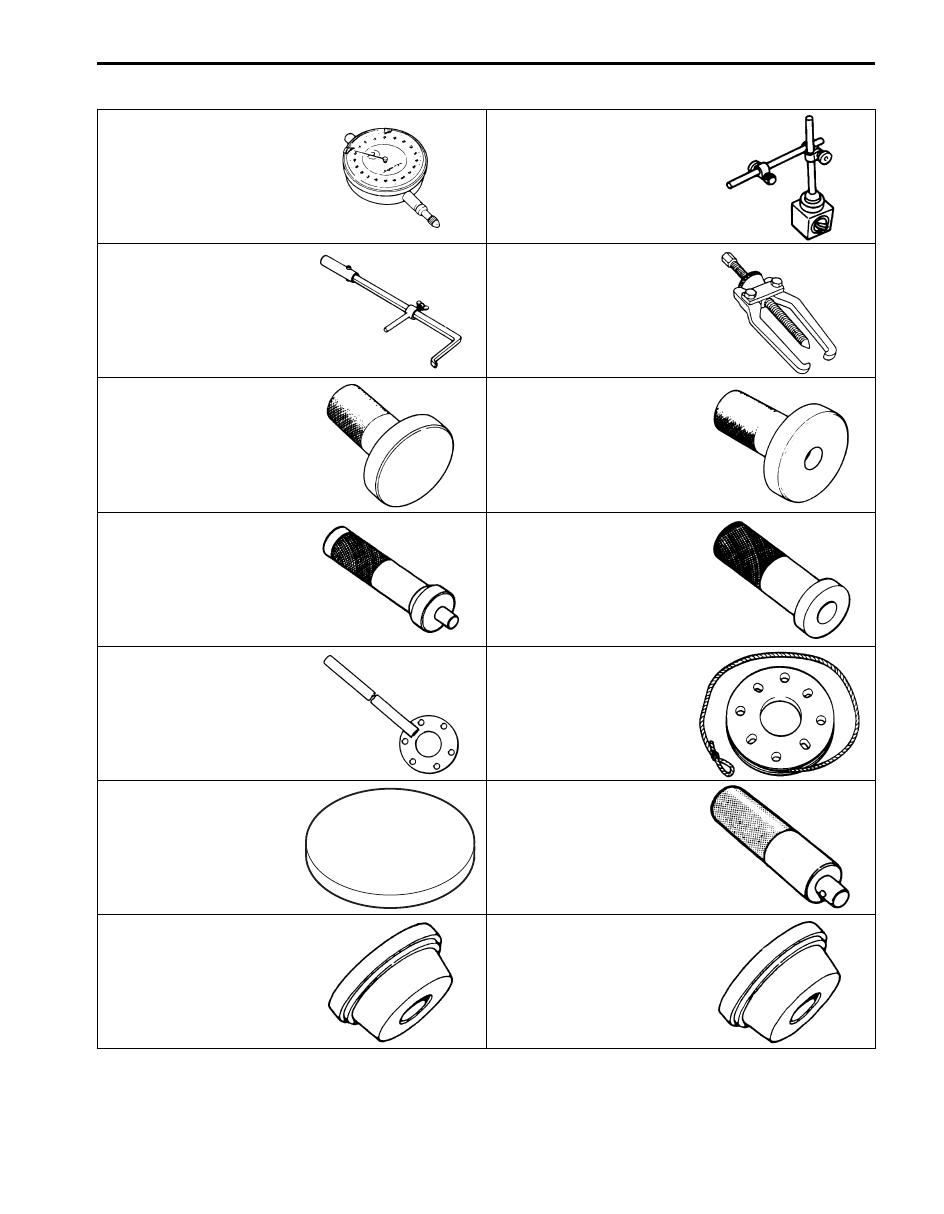

Special Tool

S5JB0A3228002

09900–20607

09900–20701

Dial gauge

Magnetic stand

09913–50121

09913–65135

Oil seal remover

Bearing puller

09913–75510

09913–75520

Bearing installer

Bearing installer

09913–75821

09913–85210

Bearing installer attachment

Bearing installer

09922–66021

09922–75222

Flange holder

Differential gear preload

adjuster

09922–76520

09924–74510

Bevel pinion gauge block

Bearing and oil seal handle

09924–84510–004

09924–84510–005

Bearing installer attachment

Bearing installer attachment

(D)

3B-39 Differential: Rear

09925–14520

09925–86010

Bearing and oil seal installer

(80 x 50 mm)

Bearing puller attachment

09925–88210

09926–78311

Bearing puller attachment

Differential bevel pinion

dummy

09926–78311–002

09926–78320

Pinion mounting dummy

Mounting dummy

09928–06510

09930–30104

Differential torque checking

tool

Sliding shaft

09940–53111

09941–64511

Differential side bearing

installer

Bearing and oil seal remover

(30 mm Min.)

09942–15511

09943–17912

Sliding hammer

Wheel hub remover

09951–16070

09951–16090

Shim adjuster attachment

Oil seal installer

09951–18210

09951–46010

Oil seal remover & installer

No. 2

Drive shaft oil seal installer

Transfer: Motor-Shift Type (Transfer with Shift Actuator) 3C-1

Driveline / Axle

Transfer

Motor-Shift Type (Transfer with Shift Actuator)

Precautions

Transfer Warning

S5JB0A3310002

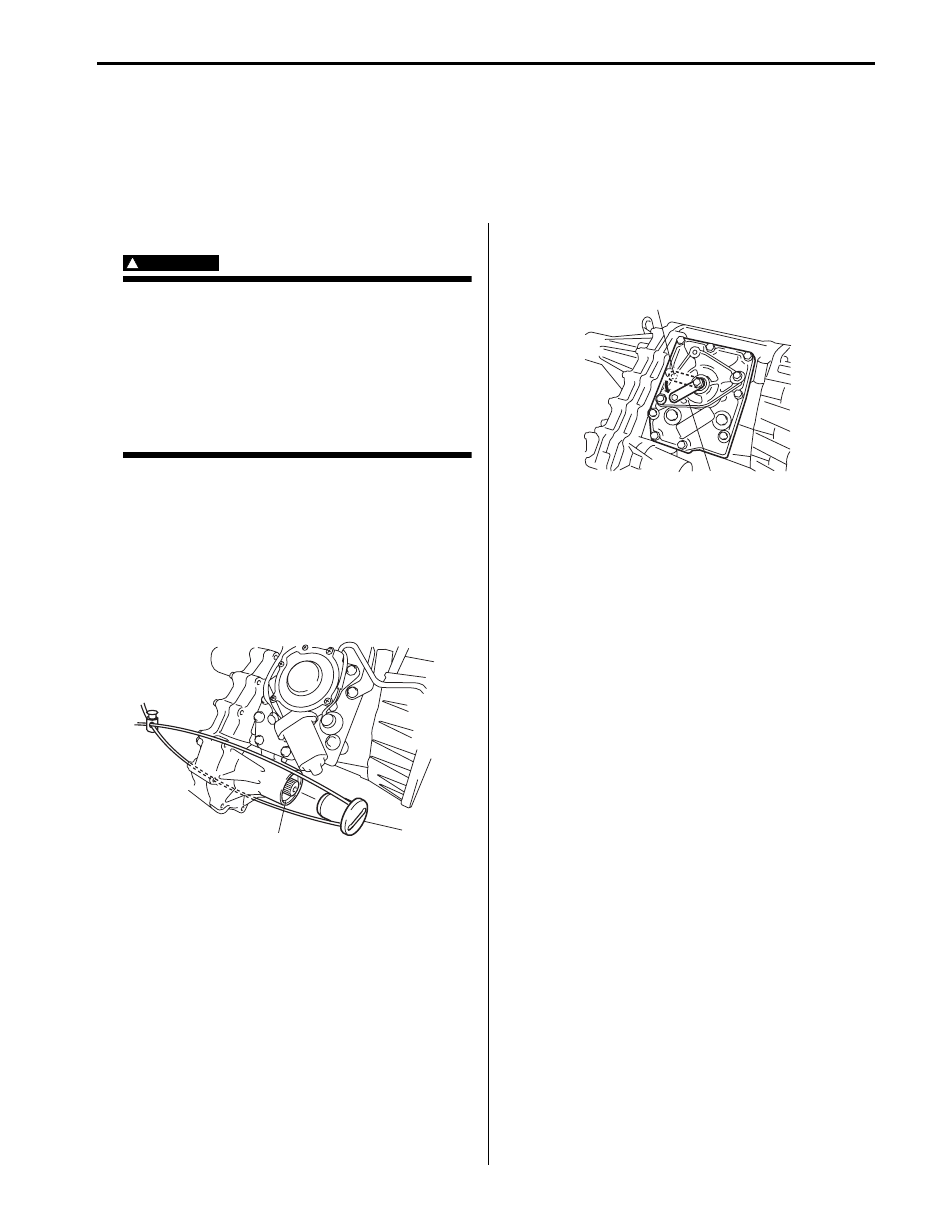

WARNING

!

This transfer has a center differential.

When testing with 2-wheel chassis

dynamometer or speedometer tester (which

tester roller is driven by vehicle wheels), be

sure to make the vehicle as rear wheel drive

or as front wheel drive temporarily as

follows.

Otherwise, front wheels drive rear wheels or

vise-versa and personal injury may result.

1) Remove front propeller shaft or rear propeller shaft

referring to “Propeller Shaft Removal and Installation

in Section 3D”.

2) Install special tool (cap) to flange yoke cover hole

(front or rear) of transfer (1) and fix it to transfer or

hook with string to prevent oil leakage from transfer.

Special tool

(A): 09928–36510

3) Pour specified oil into transfer up to lever plug hole if

front propeller shaft is removed.

4) Shift transfer to 4H-lock position as follows.

• M16 engine model:

Remove lever bolt (1) on transfer, push down

lever to 4H-lock position (2) and fix lever with bolt.

• J20 engine model:

Shift transfer to 4H-lock position by turning

transfer switch.

Precautions in Diagnosing Trouble

S5JB0A3310001

• Do not disconnect the following parts before

confirming diagnostic information (DTC, etc.) stored in

4WD control module memory. These actions will

erase memorized information in 4WD control module

memory.

– Disconnection of coupler from 4WD control module

– Disconnection of battery cable from battery

– Disconnection of ground wire harness of 4WD

control module

– Disconnect main fuse from fuse box

• Diagnostic information stored in 4WD control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• Be sure to read “Precautions for Electrical Circuit

Service:” before inspection and observe what is

written there.

(A)

1

I5JB0A331107-03

2

1

I5JB0A331108-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст