Suzuki Grand Vitara JB416 / JB420. Manual — part 272

6C-22 Power Assisted Steering System:

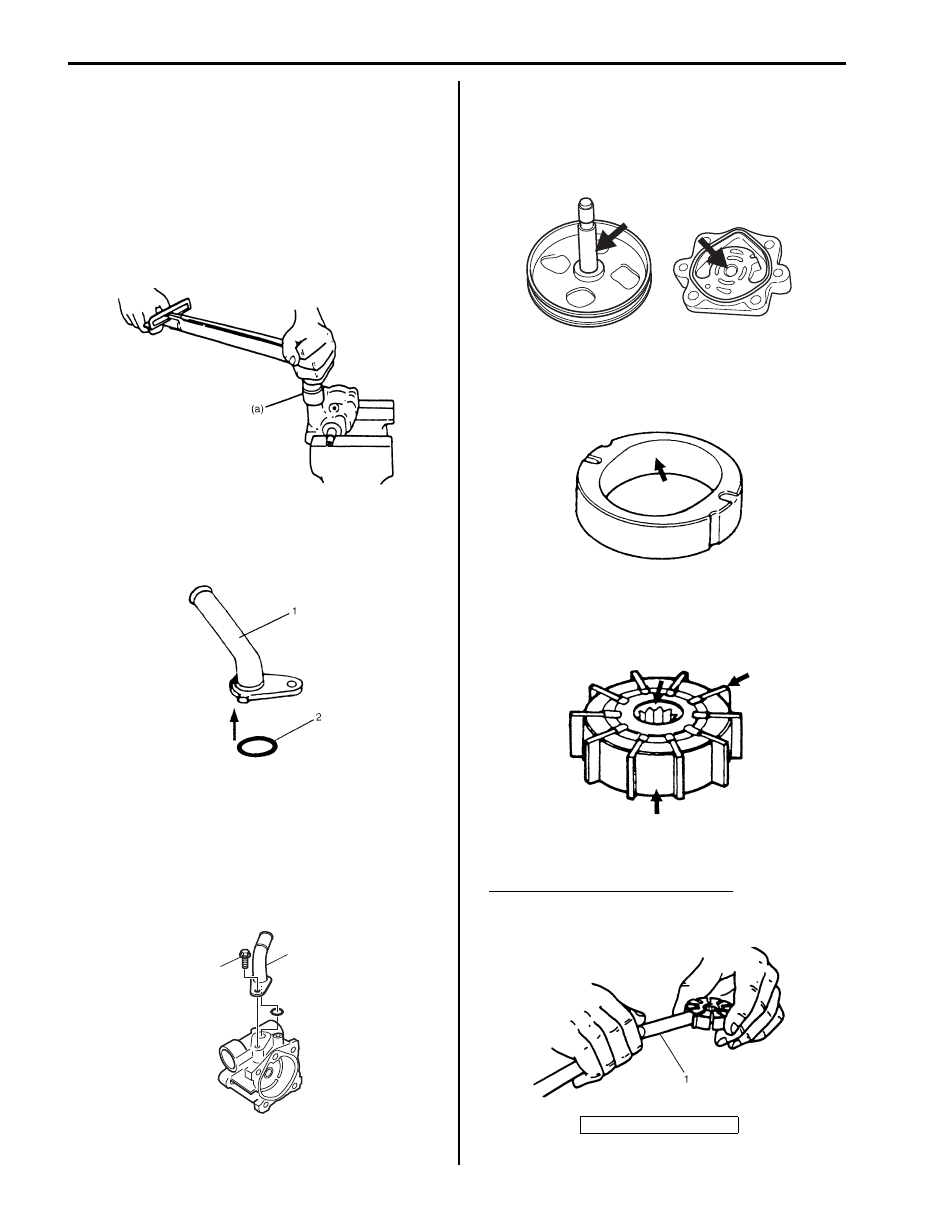

18) Apply power steering fluid to relief valve (flow control

valve).

19) Install relief valve (flow control valve) to pump body.

20) Install flow control spring.

21) Apply power steering fluid to O-rings of plug.

22) Install O-rings to plug.

23) Tighten plug to specified torque.

Tightening torque

Plug (a): 60 N·m (6.0 kgf-m, 43.5 lb-ft)

24) Apply power steering fluid to O-ring (2) of suction

connector (1).

25) Install O-ring (2) to suction connector (1).

26) Install suction connector (1) to pump body as shown

in the figure.

Tighten suction connector (1) bolts to specified

torque.

Tightening torque

Suction connector bolt for M16 engine model

(a): 12 N·m (1.2 kgf-m, 9.0 lb-ft)

P/S Pump Inspection for M16 Engine Model

S5JB0A6306014

Pump Body, Cover, Side Plate and Shaft

Check sliding surfaces of each part for wear and

damage. If any defect is found, replace pump assembly.

Cam Ring

Check vane sliding surface of cam ring for wear and

damage. If any defect is found, replace pump assembly.

Rotor and Vane

• Check sliding surfaces of rotor and vane for wear and

damage.

• Check clearance between rotor and vane. Replace

pump assembly if any defect is found.

Clearance between rotor and vane

Standard: 0.015 mm (0.0006 in.)

Limit: 0.027 mm (0.0011 in.)

IYSQ01630051-01

IYSQ01630052-01

1

(a)

I5JB0A630038-02

1. Thickness gauge

I5JB0A630051-01

IYSQ01630055-01

IYSQ01630056-01

IYSQ01630057-01

Power Assisted Steering System: 6C-23

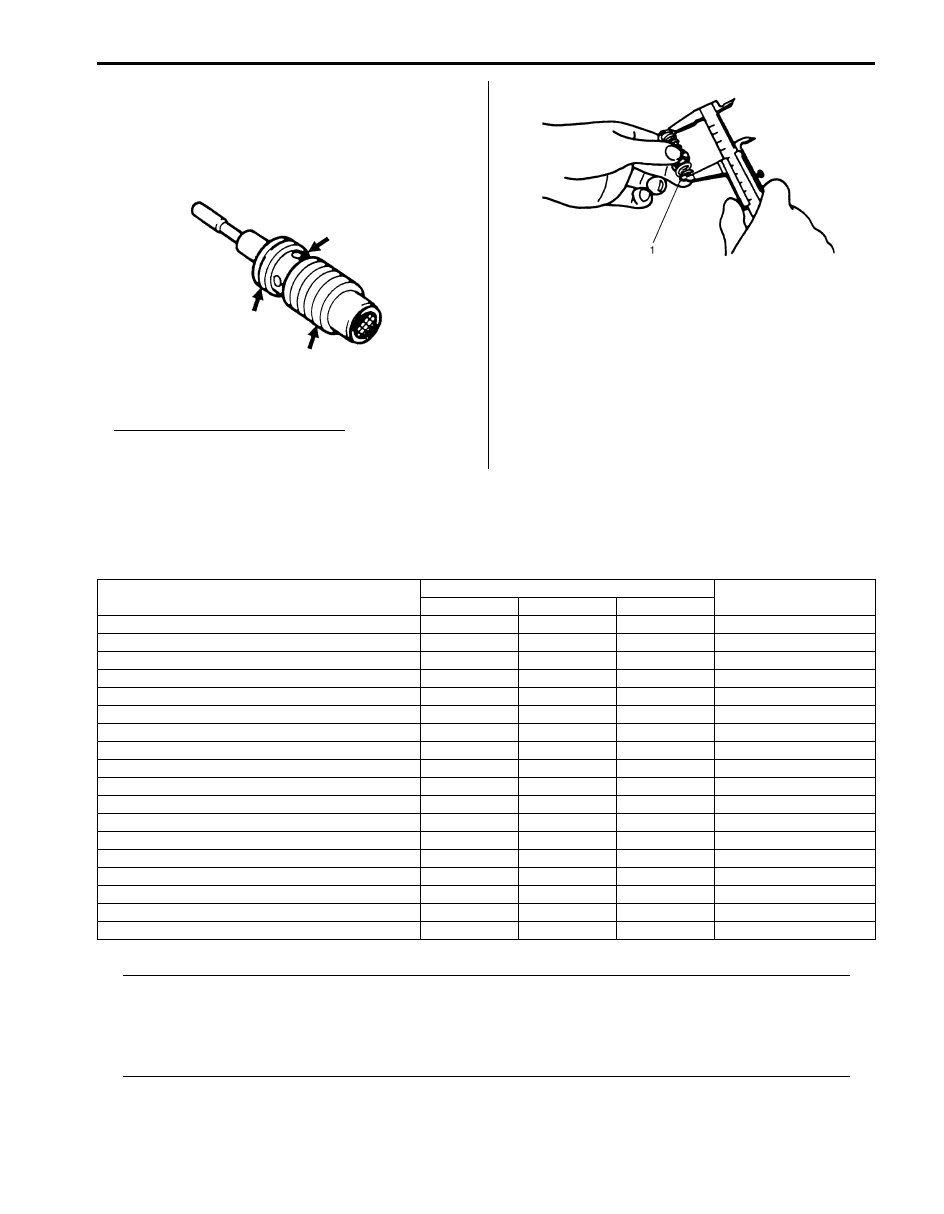

Relief Valve (Flow Control Valve) and Its Spring

• Check fluid passage of relief valve and orifice of

connector for obstruction (clogged).

• Check sliding surface of relief valve for wear and

damage.

• Check free length of relief valve spring (1). Replace if

any defective is found.

Free length of relief valve spring

Standard: 22.0 mm (0.866 in.)

Limit: 19.0 mm (0.748 in.)

P/S Pump Inspection for J20 Engine Model

S5JB0A6306026

Check P/S pump as follows.

• Damage of pump body.

• Oil leakage from pump body.

• Wear and damage of pulley.

• Abnormal noise when pulley is turned by hand.

If abnormality is found, replace P/S pump with new one.

Specifications

Tightening Torque Specifications

S5JB0A6307001

NOTE

The specified tightening torque is also described in the following.

“P/S Gear Case Assembly Components”

“P/S Hose / Pipe Components”

“P/S Pump Components for M16 Engine Model”

“P/S Pump Assembly Components for J20 Engine Model”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

IYSQ01630058-01

IYSQ01630059-01

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

P/S belt tension pulley bolt

25

2.5

18.5

P/S belt tension pulley nut

25

2.5

18.5

Tie-rod end nut

43

4.3

31.0

Wheel nut

100

10.0

72.5

Tie-rod end lock nut

65

6.5

47.0

Steering lower shaft bolt

25

2.5

18.5

Gear case high pressure pipe union bolt

35

3.5

25.5

Gear case cylinder pipe flare nut

25

2.5

18.0

Gear case mounting bolt

105

10.5

76

Gear case low pressure pipe union bolt

40

4.0

29.0

Stabilizer bar mount bracket mount bolt

60

6.0

43.0

Tie-rod ball nut

90

9.0

65.0

P/S pump mounting bolt

25

2.5

18.0

High pressure pipe union bolt

60

6.0

43.5

P/S pump cover bolt

28

2.8

20.5

Pressure switch for M16 engine model

28

2.8

20.5

Plug

60

6.0 43.5

Suction connector bolt for M16 engine model

12

1.2

9.0

6C-24 Power Assisted Steering System:

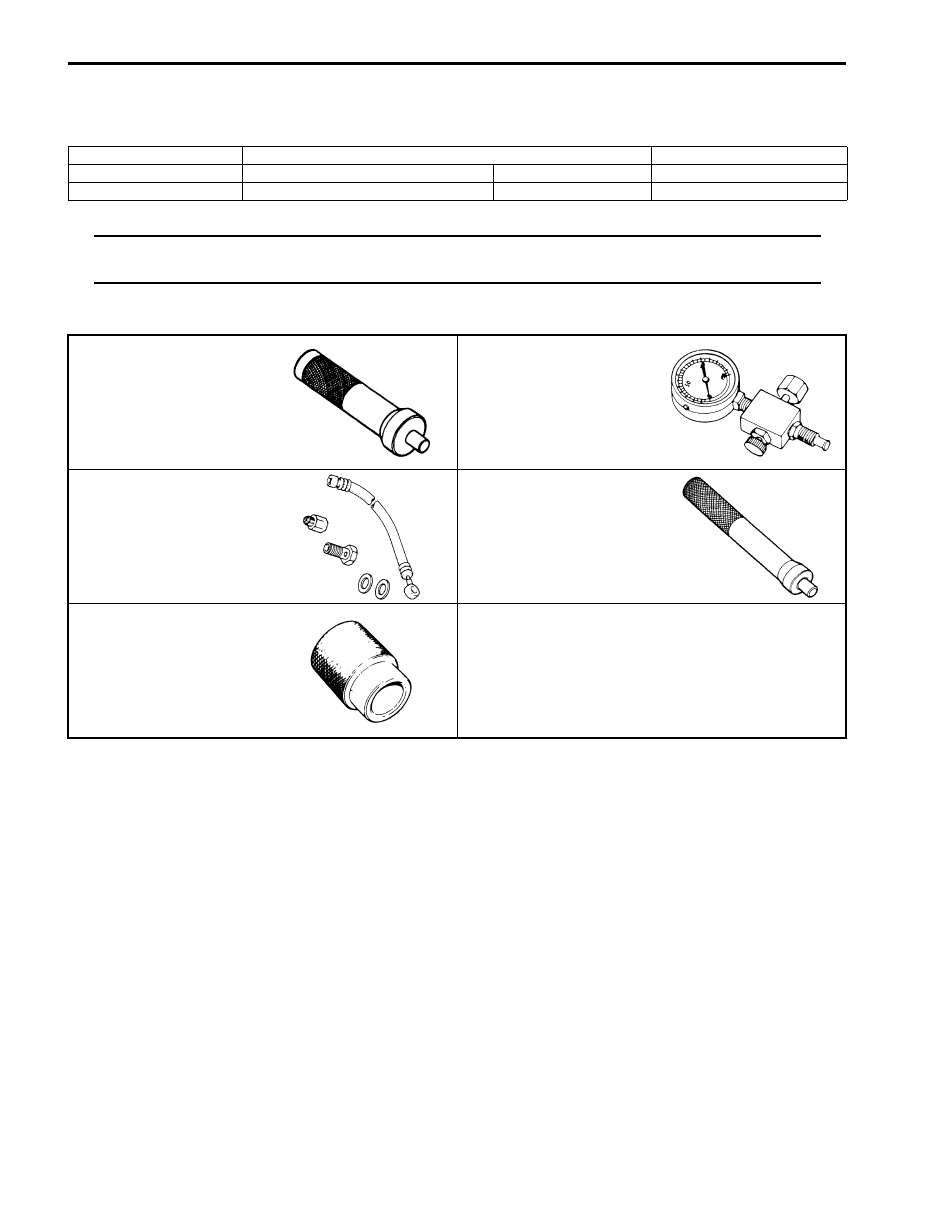

Special Tools and Equipment

Recommended Service Material

S5JB0A6308001

NOTE

Required service material is also described in the following.

“P/S Gear Case Assembly Components”

Special Tool

S5JB0A6308002

Material

SUZUKI recommended product or Specification

Note

Grease

SUZUKI Super Grease A

P/No.: 99000–25010

Thread lock cement

Thread Lock Cement 1305

P/No.: 99000–32100

09913–75821

09915–77412

Bearing installer attachment

Oil pressure gauge

09915–77420

09943–88211

Oil pressure gauge

attachment and hose set

Pinion bearing installer

09945–55410

Bushing installer

)

Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions . . . . . . . . . . . . .7-1

Precautions. . . . . . . . . . . . . . . . 7-1

Precautions for HVAC. . . . . . . . . . ... 7-1

Heater and Ventilation. . . . . . . . 7A-1

General Description . . . . . . . . . . . .7A-1

Heater and Ventilation Construction . . . . ... 7A-1

Body Ventilation Construction. . . . . . . . 7A-2

On-Board Diagnostic System Description (for

Vehicle without A/C). . . . . . . . . . .. 7A-2

HVAC Control System Description (for

Vehicle without A/C). . . . . . . . . . .. 7A-2

Schematic and Routing Diagram. . . . . . 7A-3

Heater and Ventilation Wiring Circuit Diagram . 7A-3

Electronic Control Input / Output Diagram (for

Vehicle without A/C). . . . . . . . . . .. 7A-3

Component Location . . . . . . . . . . ...7A-4

Electronic Components Location for Heater

(for Vehicle without A/C) . . . . . . . . ... 7A-4

Diagnostic Information and Procedures. . . 7A-5

Heater and Ventilation System Check . . . . 7A-5

Visual Inspection. . . . . . . . . . . . . 7A-7

DTC Check . . . . . . . . . . . . . . . 7A-7

DTC Clearance . . . . . . . . . . . . ... 7A-7

DTC Table. . . . . . . . . . . . . . ... 7A-7

Fail-Safe Table. . . . . . . . . . . . . 7A-7

Scan Tool Data . . . . . . . . . . . . ... 7A-7

Heater and Ventilation Symptom Diagnosis. . 7A-8

Repair Instructions . . . . . . . . . . . ..7A-9

Blower Unit and Heater Unit Components . . .. 7A-9

HVAC Unit Removal and Installation (for

Vehicle without A/C). . . . . . . . . . .. 7A-9

HVAC Air Filter Removal and Installation (for

Vehicle without A/C). . . . . . . . . . .. 7A-9

HVAC Air Filter Inspection (for Vehicle without

A/C). . . . . . . . . . . . . . . . ... 7A-9

Blower Motor Removal and Installation. . . ... 7A-9

Blower Motor Inspection . . . . . . . . . . 7A-9

Blower Motor Controller Removal and

Installation. . . . . . . . . . . . . ...7A-10

Blower Motor Controller Inspection . . . . ...7A-10

Blower Motor Relay Inspection . . . . . . .7A-10

Heater Core Removal and Installation . . . .. 7A-11

HVAC Control Module Removal and

Installation . . . . . . . . . . . . . ...7A-11

HVAC Control Module and Its Circuits

Inspection (for Vehicle without A/C) . . . . 7A-11

Air Flow Control Actuator Removal and

Installation . . . . . . . . . . . . . ...7A-11

Air Flow Control Actuator Inspection. . . . .7A-11

Temperature Control Actuator Removal and

Installation . . . . . . . . . . . . . ...7A-12

Temperature Control Actuator Inspection . . .7A-12

Air Intake Control Actuator Removal and

Installation . . . . . . . . . . . . . ...7A-13

Air Intake Control Actuator Inspection. . . ...7A-13

Actuator Linkage Inspection. . . . . . . ..7A-13

Center Ventilation Louver Removal and

Installation . . . . . . . . . . . . . ...7A-14

Side Ventilation Louver Removal and

Installation . . . . . . . . . . . . . ...7A-14

Rear Duct Components. . . . . . . . . .7A-15

Rear Duct Removal and Installation. . . . ..7A-15

Air Conditioning System. . . . . . . 7B-1

Precautions. . . . . . . . . . . . . . ...7B-1

134a (R-134a) . . . . . . . . . . . . ...7B-1

Precautions on Servicing Refrigerant Line. . ..7B-2

Precautions on Refrigerant Recovery . . . . .7B-3

Precautions on Refrigerant Charge. . . . . .7B-3

Precautions on Replenishing Compressor Oil . 7B-3

Precautions on Servicing Compressor

Assembly. . . . . . . . . . . . . . ...7B-4

General Description . . . . . . . . . . . .7B-4

AUTO A/C System Description . . . . . . ...7B-4

HVAC Control System Description. . . . . ..7B-4

HVAC Control Module Operation Description . .7B-5

A/C Refrigerant Type Description . . . . . ...7B-5

Sub-Cool A/C System Description . . . . . ..7B-6

A/C Evaporator Temperature Sensor

Description . . . . . . . . . . . . . . 7B-7

On-Board Diagnostic System Description. . ...7B-7

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст