Suzuki Grand Vitara JB416 / JB420. Manual — part 268

6C-6 Power Assisted Steering System:

2) Check each connection for fluid leakage and bleed

air. Refer to “P/S System Air Bleeding Procedure”.

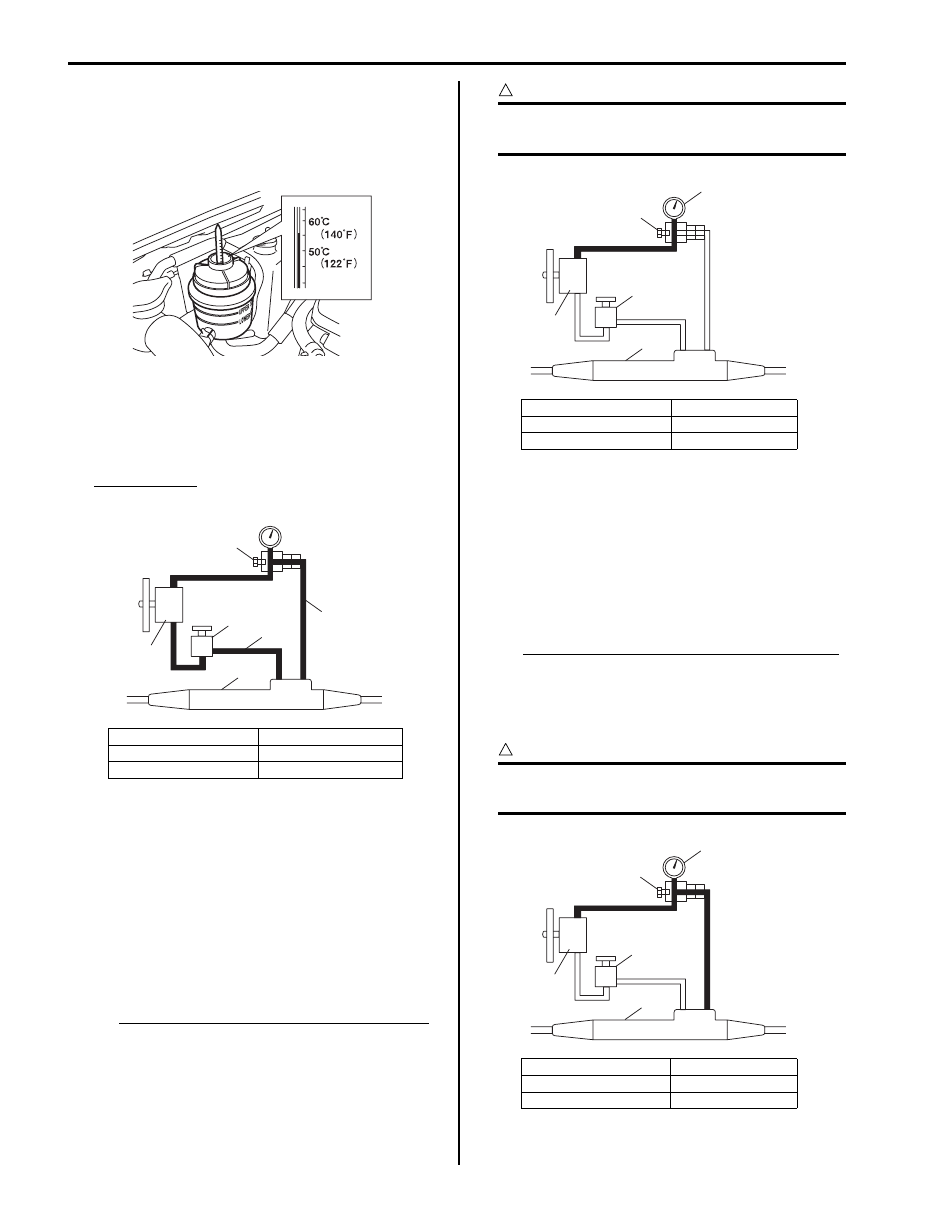

3) With engine idling, turn steering wheel and warm up

engine till temperature of fluid in tank rises to 50 – 60

°C (122 – 140 °F).

4) Check back pressure by measuring hydraulic

pressure with engine idling and hands off steering

wheel.

When back pressure is higher than specified values,

check control valve and piping for clogging.

Back pressure

Lower than 1000 kPa (10 kg/cm

2

, 142 psi)

5) Check relief pressure.

a) Increase engine speed to about 600 r/min. (rpm).

Close gauge valve gradually while watching

pressure increase indicated by gauge and take

reading of relief pressure (maximum hydraulic

pressure).

If it is higher than specified values, possible

cause is malfunction of relief valve.

If it is lower than specified values, possible

cause is either failure of P/S pump or settling of

relief valve spring.

Relief pressure when gauge value is closed

M16 Engine model: 6170 – 6870 kPa (61.7 –

68.7 kg/cm

2

, 877 – 977 psi)

J20 Engine model: 6560 – 7360 kPa (65.6 –

73.6 kg/cm

2

, 933 – 1047 psi)

CAUTION

!

Be sure not to close gauge valve for longer

than 10 seconds.

b) Open gauge valve fully and increase engine

speed to about 1500 r/min. (rpm). Then turn

steering wheel to the left or right fully and take

reading of relief pressure.

If it is higher than specified values, possible

cause is malfunction of relief valve.

If it is lower than specified values, possible

cause is failure in steering gear case. Replace

gear case.

Relief pressure when gauge value is opened

M16 Engine model: 6170 – 6870 kPa (61.7 –

68.7 kg/cm

2

, 877 – 977 psi)

J20 Engine model: 6560 – 7360 kPa (65.6 –

73.6 kg/cm

2

, 933 – 1047 psi)

CAUTION

!

Be sure not to hold steering wheel at fully

turned position for longer than 10 seconds.

1. P/S fluid reservoir

4. P/S gear case

2. Gauge valve (open)

5. High pressure side

3. P/S pump

6. Low pressure side

I5JB0A630005-01

2

3

5

1

6

4

I5JB0A630008-01

1. P/S fluid reservoir

4. P/S pump

2. Gauge valve (shut)

5. P/S gear case

3. Oil pressure gauge

1. P/S fluid reservoir

4. P/S pump

2. Gauge valve (open)

5. P/S gear case

3. Oil pressure gauge

2

4

1

3

5

I5JB0A630009-04

2

4

1

3

5

I5JB0A630010-01

Power Assisted Steering System: 6C-7

Repair Instructions

P/S Fluid Change

S5JB0A6306016

CAUTION

!

Do not use any fluid other than the specified

P/S fluid. Use of any fluid other than the

specified P/S fluid may cause juddering or

some other faulty condition to occur.

1) Lift up vehicle.

2) Remove front under cover.

3) When engine is cool, remove P/S gear low pressure

hose (1) from pipe and drain P/S fluid from low

pressure hose.

4) Install low pressure hose to pipe.

5) Fill specified P/S fluid and bleed air referring to “P/S

System Air Bleeding Procedure”.

P/S fluid specification

: Equivalent of DEXRON

®

-II

P/S fluid capacity

Reference: 0.7 – 0.8 liters (1.48/1.23 – 1.69/1.41

US/Imp.pt)

P/S Fluid Level Check

S5JB0A6306001

With engine stopped, check fluid level indicated on P/S

fluid reservoir, which should be between “UPPER” and

“LOWER” marks. If it is lower than “LOWER” mark, fill

fluid up to “UPPER” mark.

NOTE

• Be sure to use an specified power steering

fluid.

• Fluid level should be checked when fluid is

cool.

1

I5JB0A630011-01

I5JB0A630012-01

6C-8 Power Assisted Steering System:

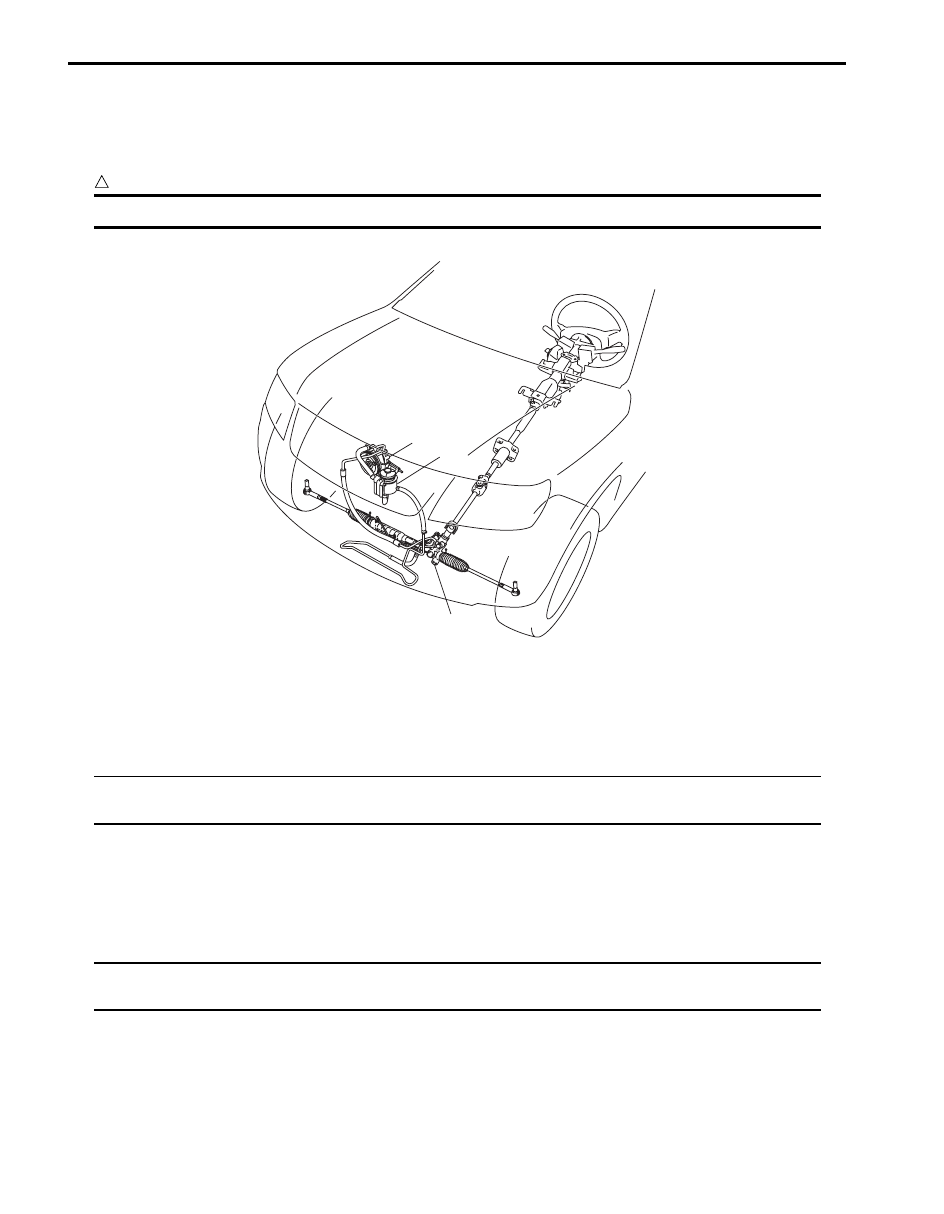

P/S Fluid Leakage Check

S5JB0A6306002

Start engine and turn steering wheel fully to the right and left so that maximum hydraulic pressure is provided.

Then visually check P/S gear case assembly (1), P/S pump (2) and P/S fluid reservoir (3) themselves and each joint of

their connecting pipes for leakage.

CAUTION

!

Never keep steering wheel turned fully for longer than 10 seconds.

P/S System Air Bleeding Procedure

S5JB0A6306003

1) Hoist the front end of vehicle and apply safety stands.

2) Fill P/S fluid reservoir with fluid up to specified level.

NOTE

Before starting engine, place transmission gear shift lever in “Neutral” (shift selector lever to “P”

range for A/T model), and set parking brake.

3) After running engine at idling speed for 3 to 5 seconds, stop it and add fluid to satisfy specification.

4) With engine stopped, turn steering wheel to the right and left as far as it stops, repeat it a few times and fill fluid to

specified level.

5) With engine running at idling speed, repeat stop-to-stop turn of steering wheel till all foams in P/S fluid reservoir

are gone.

NOTE

Make sure to bleed air completely. If air remains in fluid, P/S pump may make humming noise or

steering wheel may feel heavy.

6) Finally check to make sure that fluid is filled to specified level.

2

3

1

I5JB0A630001-01

Power Assisted Steering System: 6C-9

P/S Pump and A/C Compressor (If Equipped)

Drive Belt Inspection and Adjustment for M16

Engine Model

S5JB0A6306004

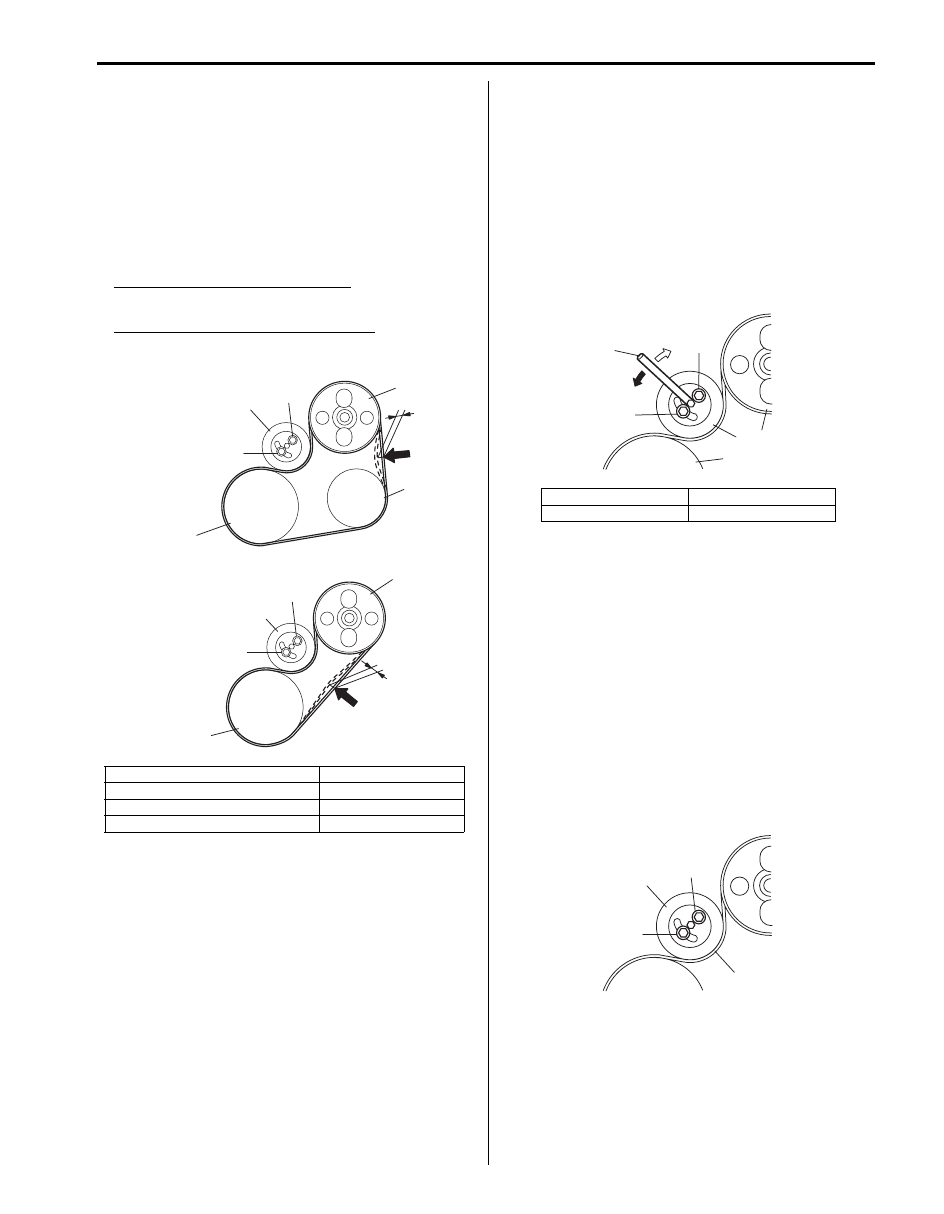

Inspection

• Check that belt is free from any damage and properly

fitted in pulley groove.

• Check belt tension by measuring how much it deflects

when pushed at intermediate point between pulleys

with about 10 kg (22 lb) force.

Deflection of P/S belt with A/C (a)

: 9 – 10 mm (0.35 – 0.39 in.)

Deflection of P/S belt without A/C (b)

: 4 – 9 mm (0.16 – 0.35 in.)

Adjustment

1) To adjust P/S belt tension, loosen tension pulley bolt

(2) and nut (1) and turn tension pulley (3) using

hexagon wrench (4).

2) Adjust belt tension to specification, and then tighten

tension pulley bolt (2) and nut (1) to specified torque.

Tightening torque

P/S belt tension pulley bolt (a): 25 N·m (2.5 kgf-

m, 18.5 lb-ft)

P/S belt tension pulley nut (b): 25 N·m (2.5 kgf-

m, 18.5 lb-ft)

P/S Pump and A/C Compressor (If Equipped)

Drive Belt Inspection and Adjustment for J20

Engine Model

S5JB0A6306017

Refer to “Water Pump and Generator Drive Belt On-

Vehicle Inspection (For J20 Engine) in Section 1J”.

P/S Pump and A/C Compressor (If Equipped)

Drive Belt Removal and Installation for M16

Engine Model

S5JB0A6306018

Removal

1) Remove tension pulley bolt (1) and nut (2).

2) Remove tension pulley (3) and P/S pump drive belt

(4).

Installation

Reverse removal procedure noting the following

instruction.

Adjust belt tension referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Inspection and

Adjustment for M16 Engine Model”.

1. P/S pump pulley

5. Tension pulley bolt

2. A/C compressor pulley (if equipped)

6. Tension pulley nut

3. Crankshaft pulley

[A]: with A/C

4. Tension pulley

[B]: without A/C

4

5

6

4

3

3

2

1

1

[A]

[B]

“a”

“b”

5

6

I5JB0A630013-01

5. Loose

7. P/S pump pulley

6. Tight

8. Crank shaft pulley

4

8

3

7

6

1, (b)

2, (a)

5

I5JB0A630014-01

3

4

1

2

I5JB0A630015-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст