Suzuki Grand Vitara JB416 / JB420. Manual — part 267

6C-2 Power Assisted Steering System:

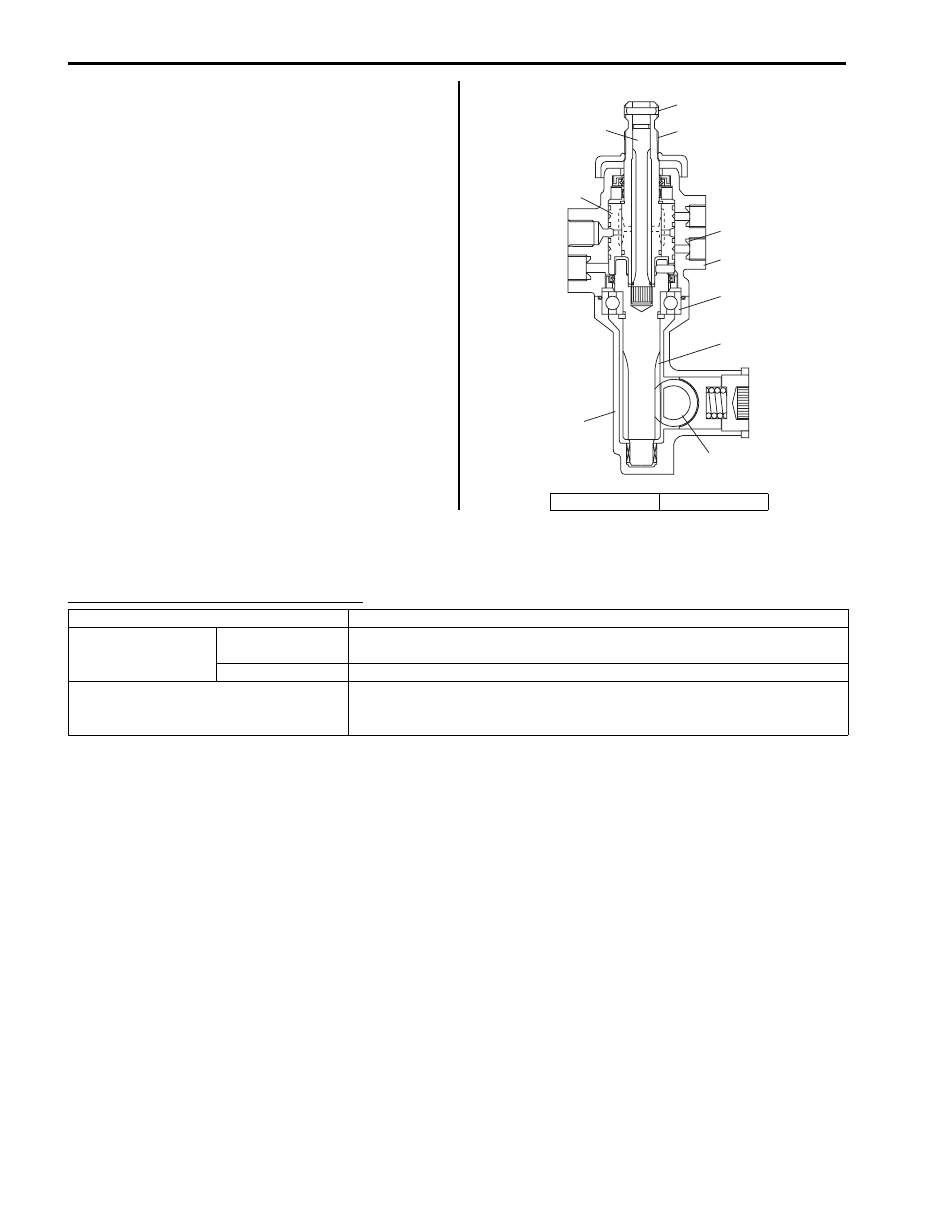

Steering Gear Case Construction

S5JB0A6301002

The steering gear case consists of two sections: one

including a cylinder and the other a valve. Main

components of the cylinder section are a gear case (7), a

rack (8) and a tube and those of the valve section are a

valve case (10), a sleeve (4) and a stub shaft (2). The

sleeve is linked with the pinion (6) through a pin (1) and

the valve and stub shaft are integrated into one unit.

Then the pinion and the stub shaft are linked to each

other by means of the torsion bar (3).

Thus, when the stub shaft moves, the valve changes its

position, thereby switching the hydraulic passage from

the pump to the cylinder to help steering operation.

When turning the steering wheel feels heavy due to P/S

fluid leakage or for some other reason (i.e., when in the

manual steering mode), the stub shaft and pinion are in

direct linkage and the force is output directly through the

pinion and rack.

P/S Pump Construction

S5JB0A6301003

The power steering pump is a vane type and is driven by the V-ribbed belt from the crankshaft.

Power steering (P/S) pump specifications

Flow Control Valve (Relief Valve)

As the discharge rate of the P/S pump increases in proportion to the pump revolution speed, a flow control valve is

added to control it so that the optimum amount of fluid for steering operation is supplied according to the engine speed

(driving condition).

5. Bearing

9. Ferrule

1

3

2

4

9

5

6

7

10

8

I5JB0A630002-01

Model

Vane type

Hydraulic pressure

control

Relieved

pressure

6370 kPa (63.7 kg/cm

2

, 906 psi) for M16 engine

6860 kPa (68.6 kg/cm

2

, 975 psi) for J20 engine

Control device

Flow control valve and relief valve

Power steering pressure switch

Switch turns on (closes) when the pressure is higher than 2500 –

3000 kPa (25 – 30 kg/cm

2

, 356 – 427 psi).

ECM uses this signal for idle speed control.

Power Assisted Steering System: 6C-3

Schematic and Routing Diagram

P/S Fluid Flow Diagram

S5JB0A6302001

Diagnostic Information and Procedures

P/S System Symptom Diagnosis

S5JB0A6304001

IYSQ01630002-01

1. Power steering pump

3. P/S fluid reservoir

5. Pinion

2. Valve section

4. Rack

6. Cylinder

Condition

Possible cause

Correction / Reference Item

Steering wheel feels

heavy (at low speed)

Fluid deteriorated, low viscosity,

different type of fluid mixed

Replace fluid.

Pipes or hoses deformed, air entering

through joint

Replace defective part.

Insufficient air purging from P/S circuit

Purge air.

P/S belt worn, lacking in tension

Adjust belt tension or replace belt as

necessary.

Tire inflation pressure excessively low

Inflate tire.

Front end alignment out of order

Check and adjust front end alignment.

Steering wheel installed improperly

(twisted)

Install steering wheel correctly.

Bind in tie-rod or tie-rod end ball joint

Replace defective part.

P/S pump hydraulic pressure fails to

increase

Check pressure and repair or replace defective

part.

P/S pump hydraulic pressure increases

but slowly

Check pressure and repair or replace defective

part.

Steering gear case malfunction

Replace gear case.

Steering wheel feels

heavy momentarily when

turning it to the left or

right

Air drawn in due to insufficient amount of

fluid

Add fluid and purge air.

Slipping P/S belt

Adjust belt tension or replace belt as

necessary.

P/S pump hydraulic pressure fails to

increase

Check pressure and repair or replace defective

part.

P/S pump hydraulic pressure increases

but slowly

Check pressure and repair or replace defective

part.

Steering gear case malfunction

Replace gear case.

6C-4 Power Assisted Steering System:

Steering Wheel Check

S5JB0A6304002

• Check steering wheel for looseness or rattle by trying

to move it in its shaft direction and lateral direction.

If found defective, repair or replace.

• Check steering wheel for play, holding car in straight

forward condition on the ground and with engine

stopped.

Steering wheel play “a”

: 0 – 30 mm (0 – 1.2 in.)

If steering wheel play is not within specification,

inspect as follows and replace if found defective.

– Tie-rod end ball stud for wear

– Lower ball joint for wear

– Steering shaft joint for wear

– Steering pinion or rack gear for wear or breakage

– Each part for looseness

Poor recovery from turns Deformed pipes or hoses

Replace defective part.

Steering column installed improperly

Install steering column correctly.

Front end alignment out of order

Check and adjust front end alignment.

Ball joints binding

Replace defective part.

P/S pump hydraulic pressure fails to

increase

Check pressure and repair or replace defective

part.

P/S pump hydraulic pressure increases

but slowly

Check pressure and repair or replace defective

part.

Steering gear case malfunction

Replace gear case.

Vehicle pulls to one side

during straight driving

Mismatched or uneven tire

Replace tire.

Low or uneven tire inflation pressure

Inflate tires to proper pressure or adjust right

and left tires inflation pressure.

Brake dragging in one wheel

Repair.

Front end alignment out of order

Check and adjust front end alignment.

Rear end alignment out of order

Check and adjust rear end alignment.

Malfunction of control valve in gear case Replace gear case.

Steering wheel play is

large and vehicle wanders

Refer to “Steering Symptom Diagnosis

in Section 6A”.

Fluid leakage

Loose joints of (hydraulic pressure)

pipes and hoses

Retighten.

Deformed or damaged pipes or hoses

Replace defective part.

Abnormal noise

Air drawn in due to insufficient amount of

fluid

Add fluid and purge air.

Air mixed into fluid from pipes or hoses Replace pipes or hoses.

Slipping (loose) P/S belt

Adjust belt tension.

Worn P/S belt

Replace belt.

Loose gear case fastening bolt

Retighten bolts.

Loose linkage or joints

Retighten.

Pipes or hoses in contact with part of

vehicle body

Install pipes and hoses correctly.

Vanes of P/S pump defective

Replace defective part.

Malfunction of control valve in gear case Replace gear case.

Bearing of P/S pump shaft defective

Replace bearing.

No idle up

Power steering pressure switch

defective

Replace power steering pressure switch.

Condition

Possible cause

Correction / Reference Item

I5JB0A630004-02

Power Assisted Steering System: 6C-5

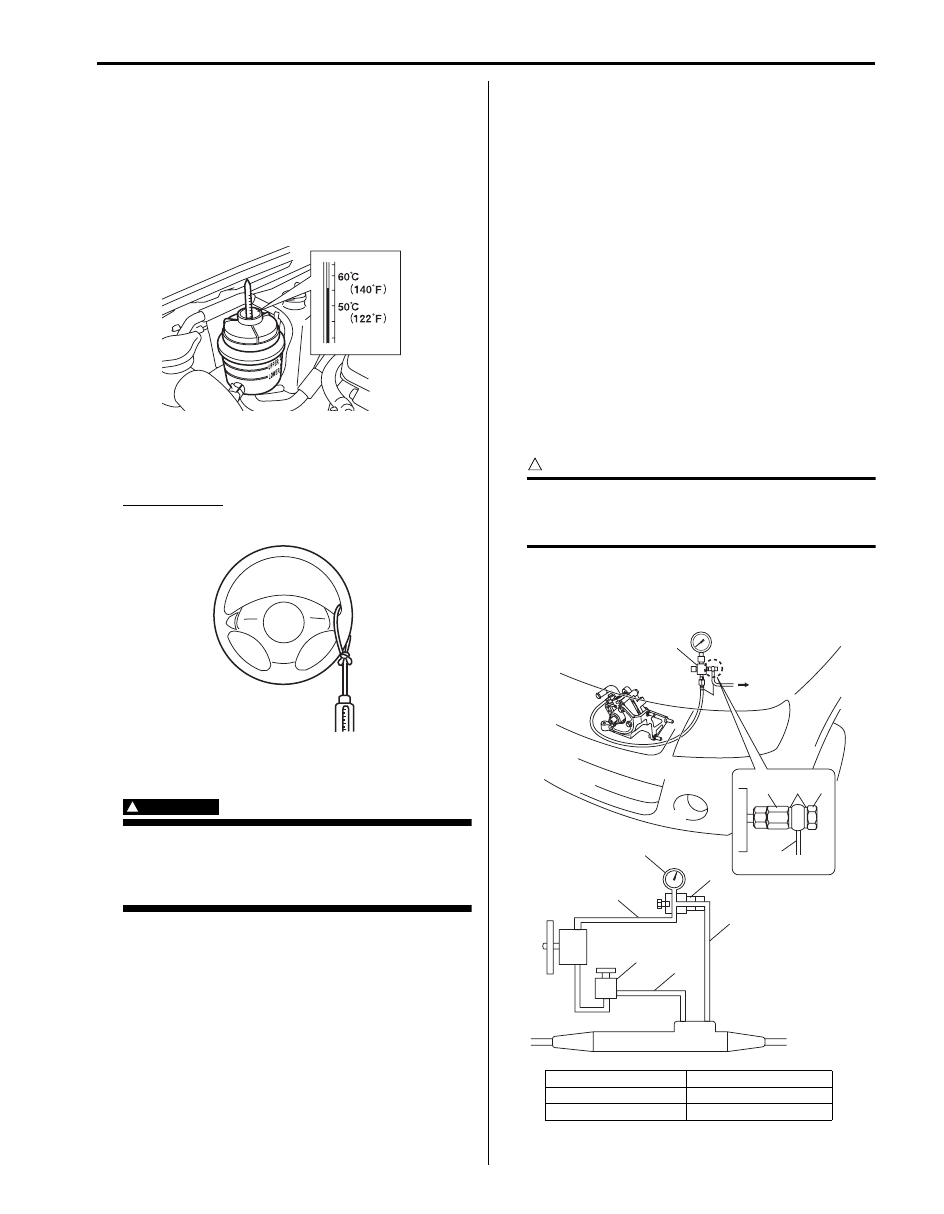

Steering Force Check

S5JB0A6304003

1) Place vehicle on level road and set steering wheel at

straight-ahead position.

2) Check that tire inflation pressure is as specified.

(Refer to tire placard.)

3) Start engine and keep it running till power steering

fluid is warmed to 50 to 60

°C (122 to 140 °F).

4) With engine idling, measure steering force by pulling

spring balancer hooked on steering wheel in

tangential direction.

Steering force

: Less than 30 N (3.0 kg, 6.6 lb)

Steering Wheel Recovery Check

S5JB0A6304006

WARNING

!

When performing a check, select a place

where there is no traffic or possibility of a

traffic accident and be very careful during

testing to avoid occurrence of an accident.

Check steering wheel for recovery as follows.

1) Rotate it to either right or left end.

2) Keep it at the end, and start the vehicle slowly.

3) Accelerate vehicle slowly.

If steering wheel begins to return at the vehicle speed

less than 10 km/h (6.3 mph), it is normal condition.

If the check result is abnormal, diagnose the fault part

referring to “Poor recovery from turns” in “P/S System

Symptom Diagnosis”.

Idle Up System Check

S5JB0A6304004

1) Warm up engine to normal operating temperature.

2) Turn A/C switch OFF, if equipped.

3) Turn steering wheel fully and check idle speed.

Engine idle speed drops a little momentarily when

steering wheel is turned fully but returns to its

specified level immediately.

If power steering pressure switch connector is

connected, check the same with that connector

disconnected.

Momentary drop of engine idle speed should be less

when it is connected than when disconnected.

Hydraulic Pressure in P/S Circuit Check

S5JB0A6304005

1) After cleaning joint of high pressure hose and P/S

pump thoroughly, disconnect hose from pump and

install special tool (oil pressure gauge, attachment

and hose).

CAUTION

!

Take care not to cause damage to A/C

condenser during service operation, if

equipped.

Special tool

(A): 09915–77412

(B): 09915–77420

I5JB0A630005-01

I5JB0A630057-01

1. P/S fluid reservoir

4. Union bolt

2. Attachment

5. High pressure side

3. Gasket

6. Low pressure side

(A)

(A)

(B)

(B)

5

1

6

(B)

2

5

4

3

I5JB0A630007-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст