Suzuki Grand Vitara JB416 / JB420. Manual — part 297

7B-79 Air Conditioning System:

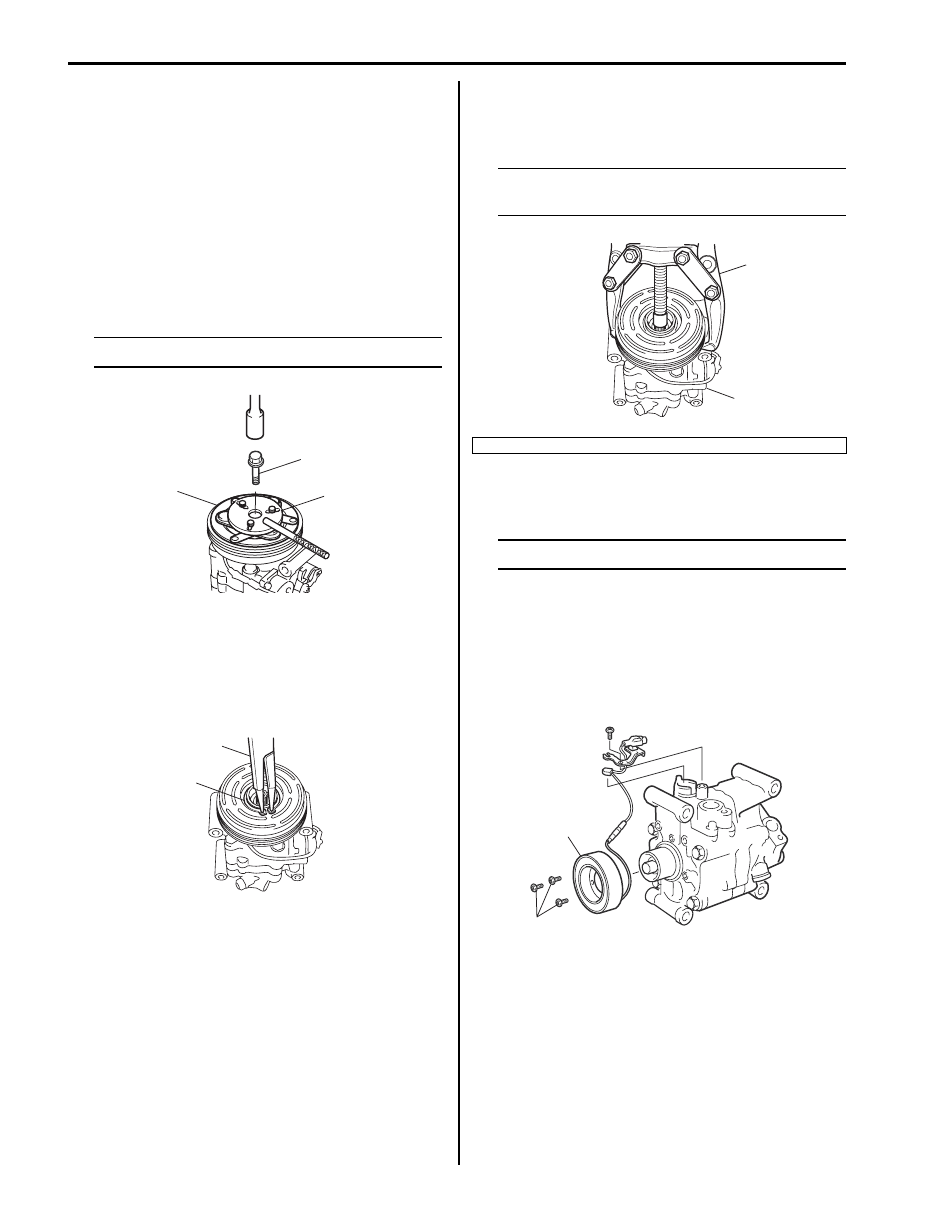

Magnet Clutch Removal and Installation for M16

Engine Model

S5JB0A7206048

Removal

1) Remove compressor from vehicle. Refer to

“Compressor Assembly Removal and Installation for

M16 Engine Model”.

2) Fix armature plate (1) with special tool (A) and

remove armature plate bolt (2).

Special tool

(A): 09991–06310

NOTE

Do not reuse armature plate bolt.

3) Remove armature plate.

4) Remove shims from shaft.

5) Using special tool (A), remove circlip (1).

Special tool

(A): 09900–06107

6) Remove magnet clutch lead wire clamp screw, and

remove magnet clutch read wire ground terminal.

7) Remove magnet clutch pulley with puller (1).

NOTE

Be careful not to damage pulley when

tapping magnet clutch.

8) Remove magnet clutch bolts, and then remove

magnet clutch coil.

NOTE

Do not reuse magnet clutch bolts.

Installation

1) Install magnet clutch coil (2), and then tighten new

magnet clutch coil bolts (1) as specified torque.

Tightening torque

Magnet clutch coil bolt (a): 4.9 N·m (0.49 kgf-m,

4.0 lb-ft)

1

2

(A)

I5JB0A720064-02

(A)

1

I5JB0A720065-01

2. Compressor

1

2

I5JB0A720066-01

2

1, (a)

I5JB0A720067-02

Air Conditioning System: 7B-80

2) Install clamp portion and ground terminal of lead

wire.

3) Install magnet clutch pulley (1).

a) Set magnet clutch squarely over clutch

installation boss.

b) Place special tool (A) onto clutch bearing.

Ensure that edge rests only on inner race of

bearing.

Special tool

(A): 09951–15510

c) Install snap ring (1) using special tool (B).

Special tool

(B): 09900–06107

CAUTION

!

Be careful not to scratch bearing seal.

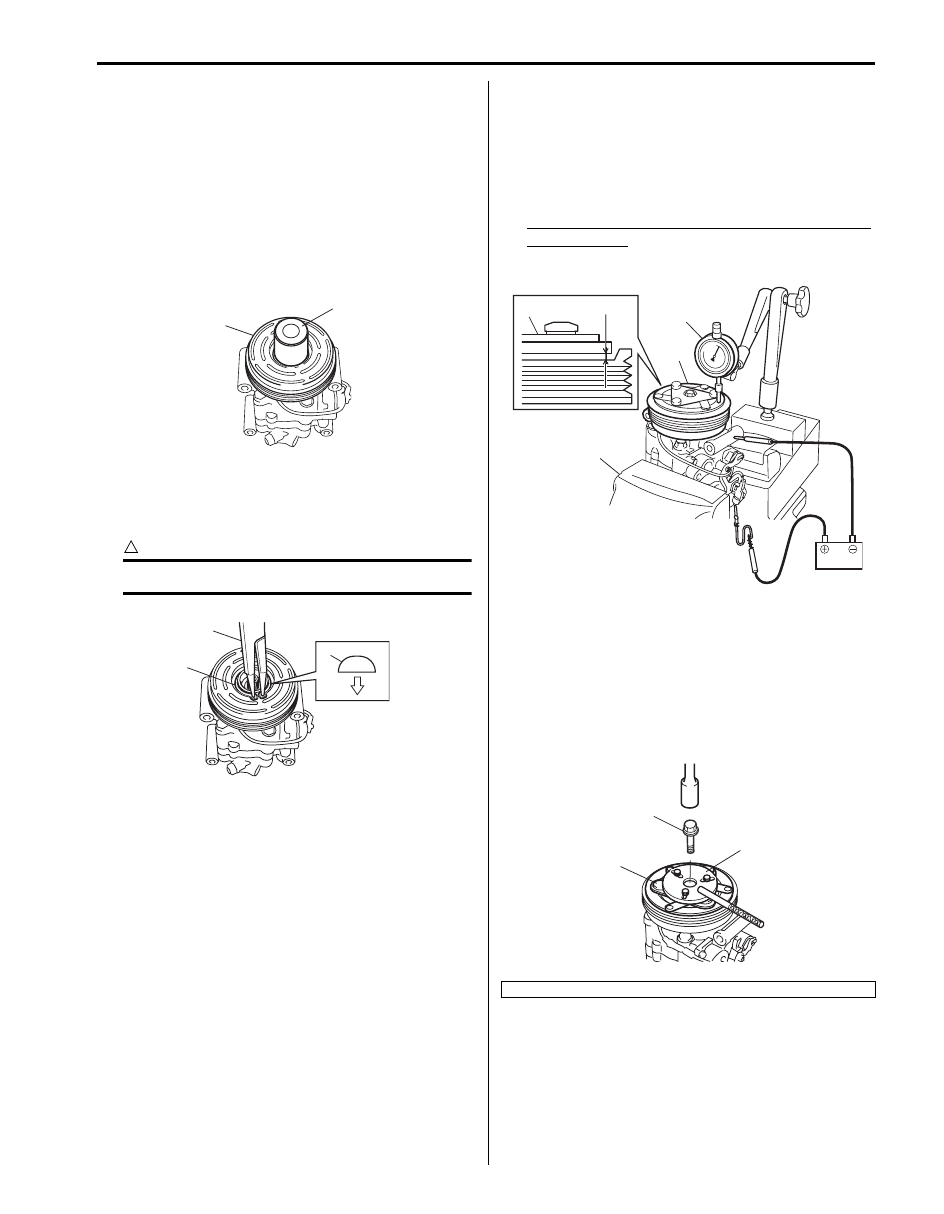

4) Inspect clearance between armature plate (1) and

magnet clutch pulley as follows.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on armature plate, and then

adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet

clutch coil lead wire.

d) Connect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are kept

in contact.)

e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are not

in contact.)

f) Read stroke of armature plate from dial gauge by

performing Step d) and e) repeatedly. (Stroke of

armature plate is clearance between armature

plate and magnet clutch pulley.)

If clearance is out of specification, adjust

clearance by changing number and/or thickness

of shim(s).

Standard clearance between armature plate and

magnet clutch

“a”: 0.3 – 0.5 mm (0.012 – 0.020 in.)

5) Tighten new armature plate bolt (1) as specified

torque.

Tightening torque

Armature plate bolt (a): 15 N·m (1.5 kgf-m, 11.0

lb-ft)

Special tool

(A): 09991–06310

1

(A)

I5JB0A720068-02

(B)

1

1

I5JB0A720087-02

2. Armature plate

1

2

1

3

“a”

I5JB0A720069-01

2

1

(A)

I5JB0A720070-02

7B-81 Air Conditioning System:

Magnet Clutch Removal and Installation for J20

Engine Model

S5JB0A7206049

Removal

1) Remove compressor from vehicle referring to

“Compressor Assembly Removal and Installation for

J20 Engine Model”.

2) Fix armature plate (1) with special tool (A) and

remove armature plate bolt.

Special tool

(A): 09991–06310

NOTE

Do not reuse armature plate bolt.

3) Remove armature plate.

4) Remove shim(s) from shaft.

5) Using special tool (A), remove snap ring (1).

Special tool

(A): 09900–06107

6) Remove magnet clutch pulley (1) with puller (2).

NOTE

Be careful not to damage pulley.

7) Remove snap ring (1) using special tool (B), and

then remove magnet clutch coil (1).

Special tool

(A): 09900–06107

Installation

1) Install magnet clutch coil (3).

NOTE

Protrusion (1) on underside of magnet clutch

coil and hole (2) on compressor body

assembly must match to stop movement of

magnet clutch coil and to locate lead wire

correctly.

1

(A)

2

I5JB0A720071-01

(A)

1

I5JB0A720072-01

1

2

I5JB0A720073-01

(A)

1

I5JB0A720074-02

2

1

3

I5JB0A720075-01

Air Conditioning System: 7B-82

2) Install new snap ring (1) using special tool (A).

Special tool

(B): 09900–06107

3) Install magnet clutch pulley.

a) Set magnet clutch horizontally over clutch

installation boss.

b) Place special tool (B) onto magnet clutch

bearing. Ensure that edge rests only inner rase

of bearing.

Special tool

(B): 09951–15510

c) Install new snap ring (1) using special tool (A).

Special tool

(A): 09900–06107

4) Install armature plate (1).

5) Using special tool (A), tighten new armature plate

bolt (2) to specified torque.

Tightening torque

Armature plate bolt (a): 21 N·m (2.1 kgf-m, 15.5

lb-ft)

Special tool

(A): 09991–06310

6) Adjust clearance between armature plate (1) and

magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise.

b) Set dial gauge on magnet clutch plate, and then

adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet

clutch coil lead wire.

d) Connect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley (2) are

kept in contact.)

e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley (2) are

not in contact.)

f) Read stroke of armature plate from dial gauge by

performing Step d) and e) repeatedly. (Stroke of

armature plate is clearance between armature

plate and magnet clutch pulley (2).)

Standard clearance between armature plate and

magnet clutch

“a”: 0.3 – 0.6 mm (0.012 – 0.024 in.)

7) Install compressor to vehicle referring to

“Compressor Assembly Removal and Installation for

J20 Engine Model”.

(A)

1

1

I5JB0A720088-04

(B)

I5JB0A720076-02

(A)

1

1

I5JB0A720077-01

1

2

2

1

“a”

I5JB0A720078-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст