Suzuki Grand Vitara JB416 / JB420. Manual — part 97

1D-56 Engine Mechanical: For M16A Engine with VVT

Crankshaft Inspection

S5JB0A1416037

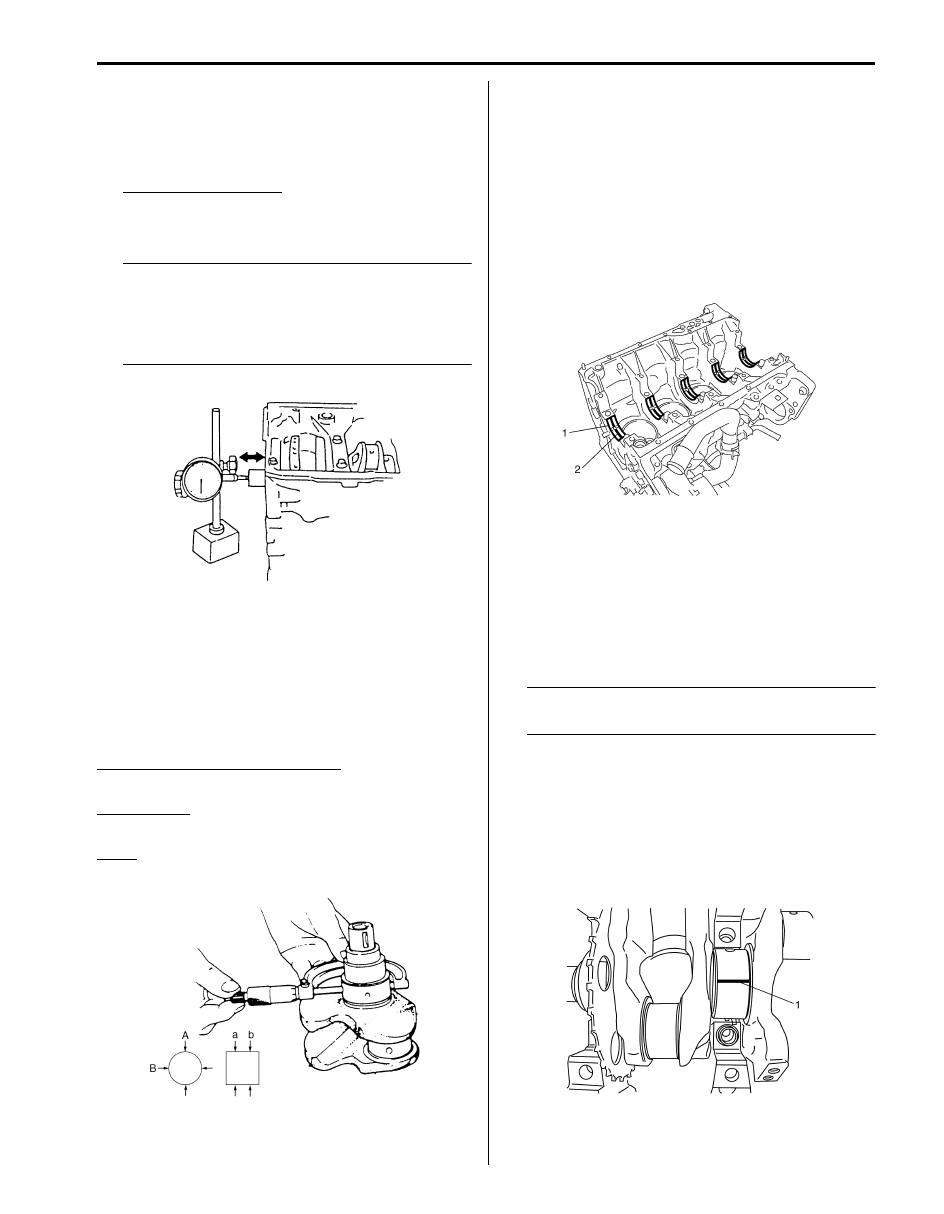

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder

block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

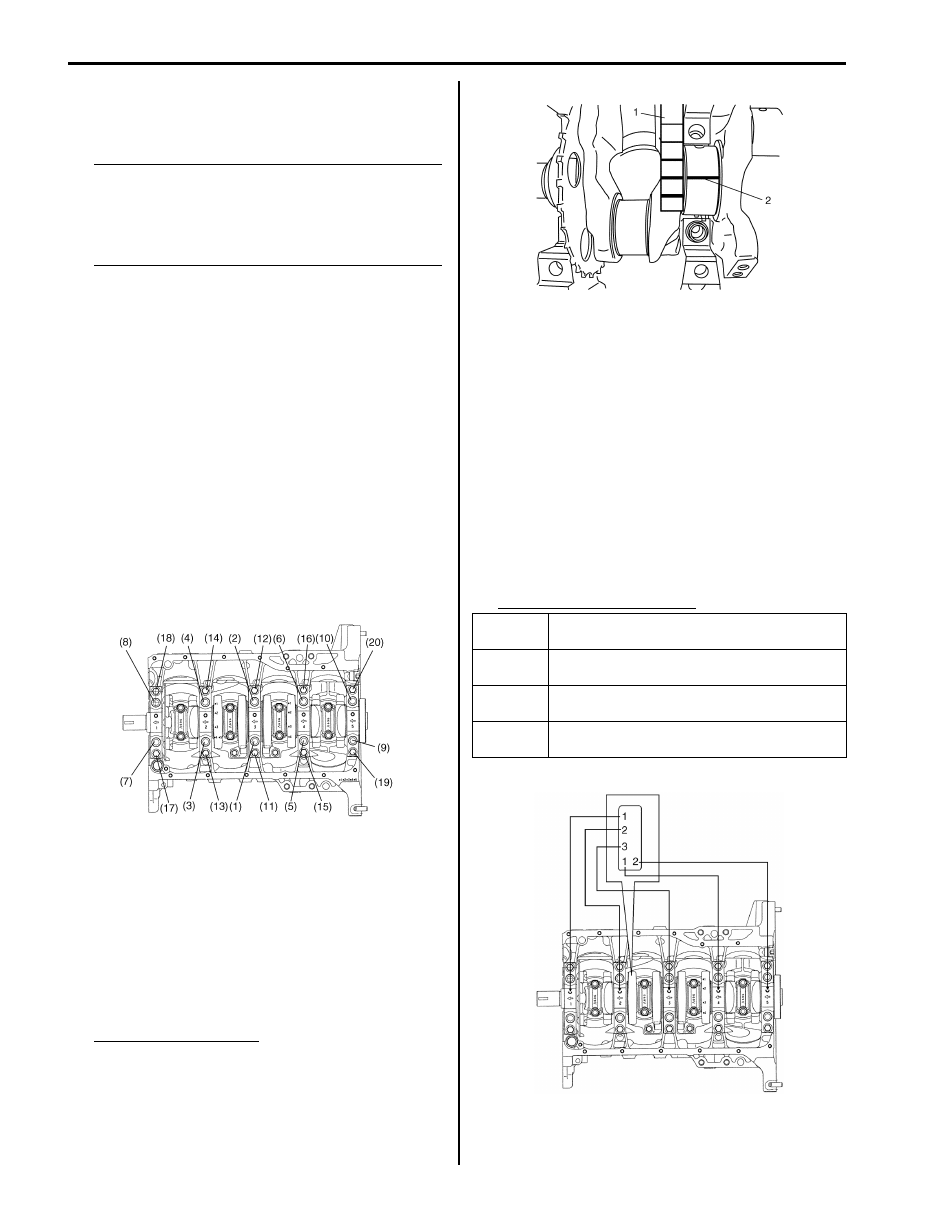

2) Tighten main bearing cap No.1 bolts (1) – (10) and

main bearing cap No.2 bolts (11) – (20) gradually as

follows.

NOTE

If main bearing cap No.1 bolt is reused, make

sure to check main bearing cap No.1 bolt for

deformation referring to “Main Bearing Cap

No.1 Bolt” under “Main Bearings Inspection:

For M16A Engine with VVT”.

a) Tighten bolts (1) – (10) to 30 N

⋅m (3.0 kgf-m,

22.0 lb-ft) according to numerical order in the

figure.

b) In the same manner as in Step a), tighten them

to 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them

to 60

°.

d) Tighten bolts (11) – (20) to 25 N

⋅m (2.5 kgf-m,

18.0 lb-ft) according to numerical order in the

figure.

Tightening torque

Main bearing cap No.1 bolt ((1) – (10)): 30

N

⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0 kgf-m,

36.5 lb-ft) and then retighten by turning

through 60

°

Main bearing cap No.2 bolt ((11) – (20)): 25

N·m (2.5 kgf-m, 18.0 lb-ft)

I2RH0B140135-01

I2RH0B140136-01

I2RH0B140137-01

Engine Mechanical: For M16A Engine with VVT 1D-57

3) Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If its limit is exceeded, replace thrust bearing with

new standard one or oversize one to obtain standard

thrust play.

Crankshaft thrust play

Standard: 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Limit: 0.35 mm (0.0138 in.)

NOTE

After checking the thrust play, make sure that

thread deformation of each bearing cap No.1

bolt referring to “Main Bearing Cap No.1

Bolt” in “Main Bearings Inspection: For M16A

Engine with VVT”.

Out-of-Round and Taper (Uneven Wear) of Journals

An unevenly worn crankshaft journal shows up as a

difference in diameter at a cross section or along its

length (or both). This difference, if any, is determined by

taking micrometer readings. If any one of journals is

badly damaged or if amount of uneven wear in the sense

exceeds its limit, regrind or replace crankshaft.

Crankshaft out-of-round and taper

Limit: 0.01 mm (0.0004 in.)

Out-of-round

A – B

Taper

a – b

Main Bearings Inspection

S5JB0A1416038

General Information

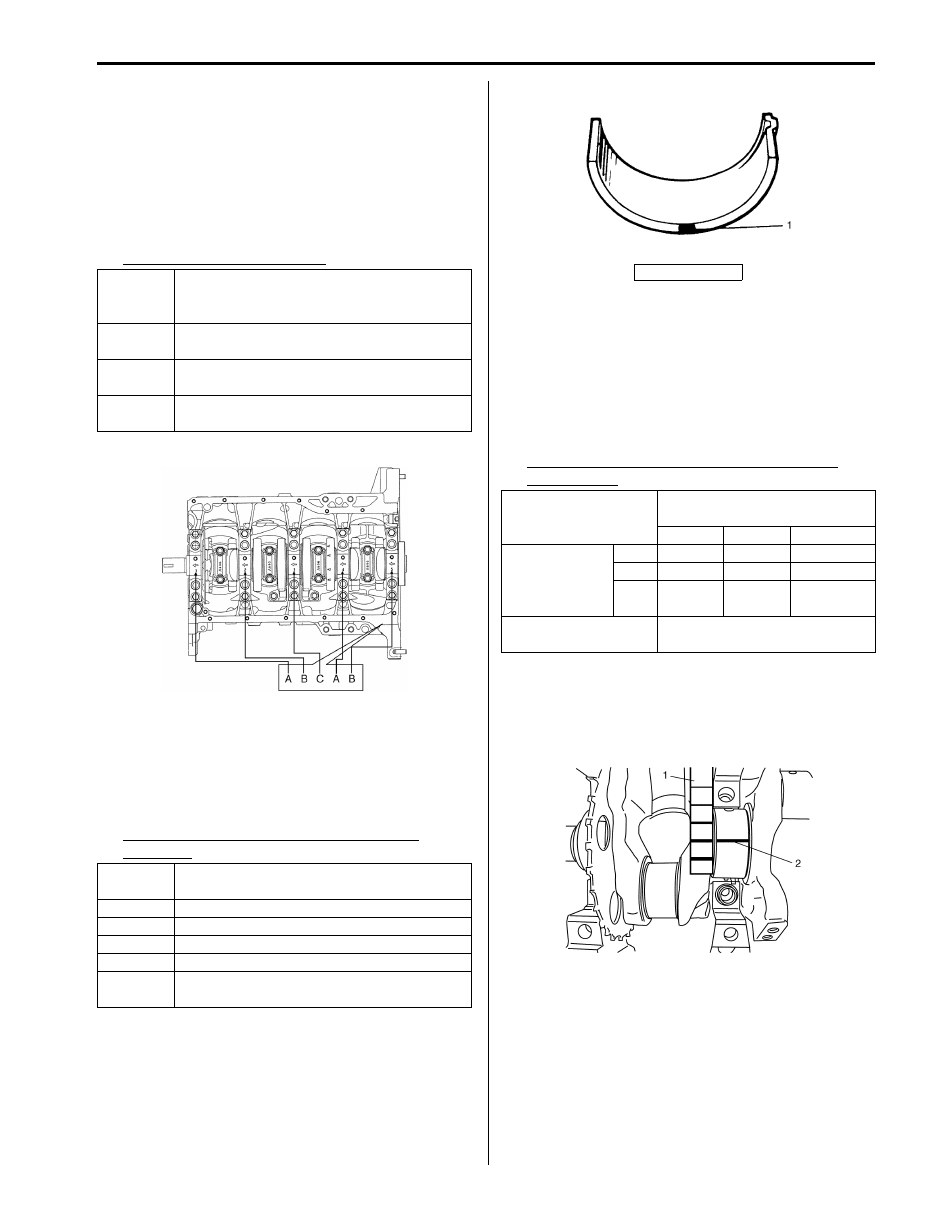

• Service main bearings are available in standard size

and 0.25 mm (0.0098 in.) undersize, and each of them

has 5 kinds of bearings differing in tolerance.

• Upper half of bearing (1) has oil groove (2) as shown

in the figure.

Install this half with oil groove to cylinder block.

• Lower half of bearing does not have an oil groove.

Visual Inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is found, replace both upper and

lower halves. Never replace either half without replacing

the other half.

Main Bearing Clearance

NOTE

Do not rotate crankshaft while gauging

plastic is installed.

Check clearance by using gauging plastic according to

the following procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) the full width of

bearing (parallel to crankshaft) on journal, avoiding

oil hole.

I2RH01140183-01

I2RH0B140138-01

I2RH0B140139-01

I2RH0B140140-01

1D-58 Engine Mechanical: For M16A Engine with VVT

4) Tighten main bearing cap No.1 bolts (1) – (10) and

main bearing cap No.2 bolts (11) – (20) gradually as

follows.

NOTE

If main bearing cap No.1 bolt is reused, make

sure to check main bearing cap No.1 bolt for

deformation referring to “Main Bearing Cap

No.1 Bolt” under “Main Bearings Inspection:

For M16A Engine with VVT”.

a) Tighten bolts (1) – (10) to 30 N

⋅m (3.0 kgf-m,

22.0 lb-ft) according to numerical order in the

figure.

b) In the same manner as in Step a), tighten them

to 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them

to 60

°.

d) Tighten bolts (11) – (20) to 25 N

⋅m (2.5 kgf-m,

18.0 lb-ft) according to numerical order in the

figure.

Tightening torque

Main bearing cap No.1 bolt ((1) – (10)): 30

Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0 kgf-m,

36.5 lb-ft) and then retighten by turning

through 60

°

Main bearing cap No.2 bolt ((11) – (20)): 25

N·m (2.5 kgf-m, 18.0 lb-ft)

5) Remove bearing caps and using scale (1) on

gauging plastic envelop (2), measure gauging plastic

width at its widest point. If clearance exceeds its

limit, replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to regrind

crankshaft journal for use of 0.25 mm undersize

bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard: 0.021 – 0.041 mm (0.0008 – 0.0016 in.)

Limit: 0.054 mm (0.0021 in.)

Selection of Main Bearings

Standard bearing

If bearing is in malcondition, or bearing clearance is out

of specification, select a new standard bearing according

to the following procedure and install it.

1) First check journal diameter. As shown in the figure,

crank web No.2 has stamped numbers.

Three kinds of numbers (“1”, “2” and “3”) represent

the following journal diameters.

Stamped numbers on crank web No.2 represent

journal diameters marked with an arrow in the figure

respectively. For example, stamped number “1”

indicates that corresponding journal diameter is

51.9940 – 52.0000 mm (2.0471 – 2.0472 in.).

Crankshaft journal diameter

2) Next, check bearing cap bore diameter without

bearing. On mating surface of cylinder block, five

alphabets are stamped as shown in the figure.

I2RH0B140137-01

Stamped

numbers

Journal diameter

1

51.9940 – 52.0000 mm

(2.0471 – 2.0472 in.)

2

51.9880 – 51.9939 mm

(2.0468 – 2.0470 in.)

3

51.9820 – 51.9879 mm

(2.0465 – 2.0467 in.)

I2RH0B140141-01

I2RH0B140142-02

Engine Mechanical: For M16A Engine with VVT 1D-59

Three kinds of alphabets (“A”, “B” and “C”) or

numbers (“1”, “2” and “3”) represent the following

cap bore diameters.

Stamped alphabets or numbers on cylinder block

represent bearing cap bore diameter marked with an

arrow in the figure respectively.

For example, stamped “A” or “1” indicates that

corresponding bearing cap bore diameter is 56.0000

– 56.0060 mm (2.2048 – 2.2049 in.).

Crankshaft bearing cap bore

3) There are 5 kinds of standard bearings differing in

thickness. To distinguish them, they are painted in

the following colors at the position as indicated in the

figure.

Each color indicated the following thickness at the

center of bearing.

Standard size of crankshaft main bearing

thickness

4) From number stamped on crank web No.2 and

alphabets stamped on cylinder block, determine new

standard bearing to be installed to journal, by

referring to the table shown.

For example, if number stamped on crank web No.2

is “1” and alphabet stamped on cylinder block is “B”,

install a new standard bearing painted in “Brown” to

its journal.

New standard size crankshaft main bearing

specification

5) Using scale (1) on gauging plastic (2), check bearing

clearance with newly selected standard bearing.

If clearance still exceeds its limit, use next thicker

bearing and recheck clearance.

6) When replacing crankshaft or cylinder block due to

any reason, select new standard bearings to be

installed by referring to number stamped on new

crankshaft or alphabets stamped on new cylinder

block.

Stamped

alphabet

(number)

Bearing cap bore diameter (without

bearing)

A (1)

56.0000 – 56.0060 mm

(2.2048 – 2.2049 in.)

B (2)

56.0061 – 56.0120 mm

(2.2050 – 2.2051 in.)

C (3)

56.0121 – 56.0180 mm

(2.2052 – 2.2054 in.)

Color

painted

Bearing thickness

Purple

1.992 – 1.996 mm (0.07843 – 0.07858 in.)

Brown

1.995 – 1.999 mm (0.07855 – 0.07870 in.)

Green

1.998 – 2.002 mm (0.07867 – 0.07882 in.)

Black

2.001 – 2.005 mm (0.07878 – 0.07893 in.)

Colorless

(no paint)

2.004 – 2.008 mm (0.07890 – 0.07906 in.)

I2RH0B140143-02

1. Paint

Number stamped on crank

web No.2 (Journal diameter)

1

2

3

Alphabet

stamped on

cylinder block

(Cap bore dia.)

A (1) Purple

Brown

Green

B (2) Brown

Green

Black

C (3) Green

Black

Colorless

New standard bearing to be

installed

I2RH01140191-01

I2RH0B140141-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст