Suzuki Grand Vitara JB416 / JB420. Manual — part 232

5A-62 Automatic Transmission/Transaxle:

DTC P1702: Internal Control Module Memory Check Sum Error

S5JB0A5104044

DTC Detecting Condition and Trouble Area

NOTE

DTC P1702 can never be cleared once it has been set.

1) Ignition switch OFF.

2) Replace TCM.

3) Repeat “A/T System Check”.

DTC P1703: CAN Invalid Data - TCM

S5JB0A5104045

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

4

Inspection solenoid valve

1) Inspection solenoid valve referring to “Solenoid Valves

Is check results satisfactory?

Intermittent trouble or

faulty TCM. Check for

intermittent trouble

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good TCM and

recheck.

Replace defective

solenoid valve referring

to “Solenoid Valves

(Shift Solenoid-A, Shift

Solenoid-B, TCC

Pressure Control

Solenoid and Pressure

Control Solenoid

Removal and

Installation”.

Step

Action

Yes

No

DTC Detecting Condition

Trouble Area

An internal TCM fault is detected by TCM

(1 driving cycle detection logic)

TCM

DTC Detecting Condition

Trouble Area

When abnormality on the gear shift control signal from ECM is

detected by TCM, TCM sets DTC P1703.

(1 driving cycle detection logic)

• Engine control system

• TCM

• ECM

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

DTC Check

Check DTC of ECM referring to “DTC Check in Section 1A”.

Is there any DTC(s)?

Go to applicable DTC

troubleshooting.

Substitute a known-

good TCM and recheck.

Automatic Transmission/Transaxle: 5A-63

DTC P1723: Range Select Switch Malfunction

S5JB0A5104056

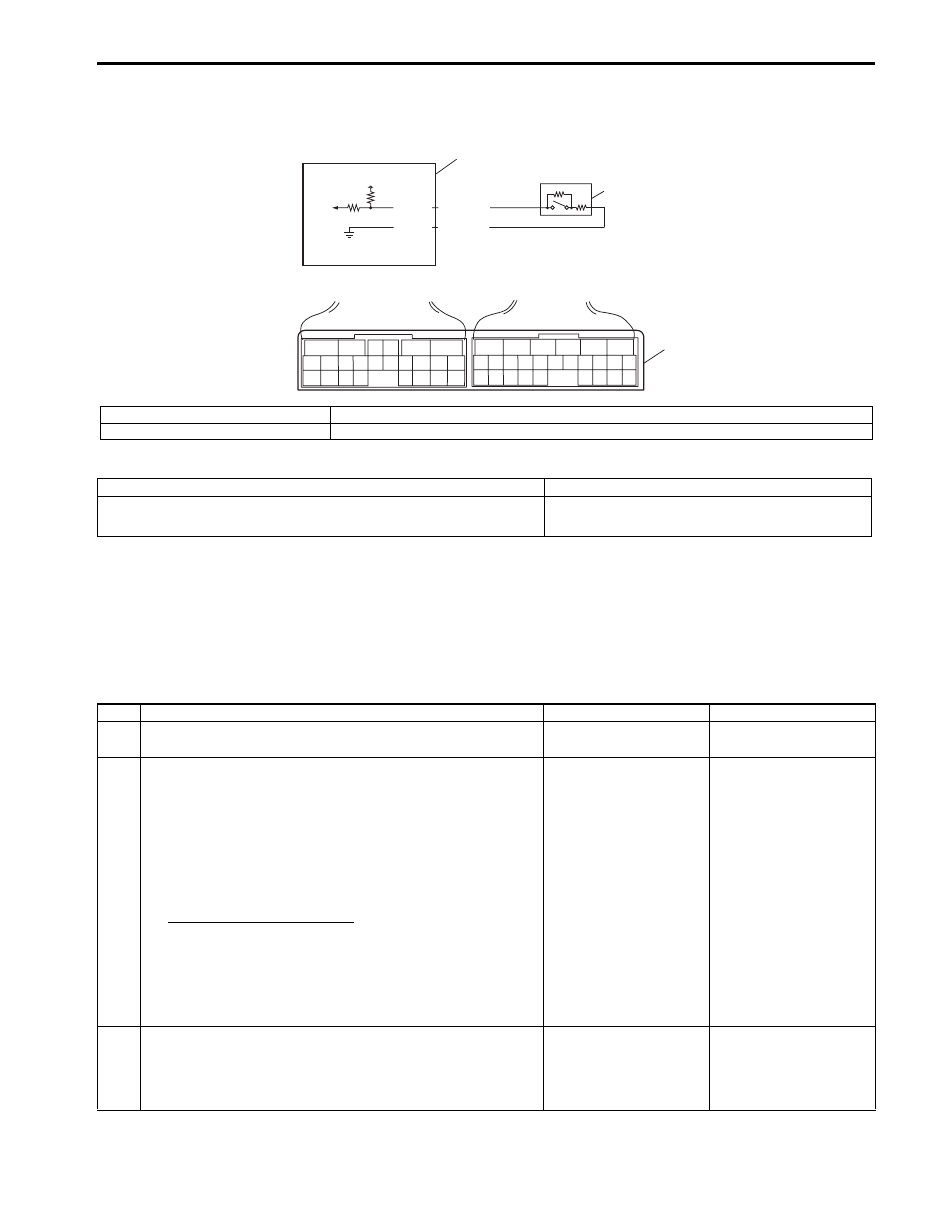

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine and run it for 20 sec. or more.

4) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting

5V

2

1

3

6

5

16 15 14 13 12 11

4 3

24 23

21

22

10 9

8

7

2

1

19

20

18 17

E92

17 16

26 25

15 14

6

5

3

4

2

13 12

23 22

24

11 10 9

21 20 19

8 7

18

1

E93

E92-20

E92-10

YEL/RED

YEL/BLK

I5JB0A510001-01

1. “3” position switch

3. Terminal arrangement of TCM connector (viewed from harness side)

2. TCM

DTC Detecting Condition

Trouble Area

“3” position switch signal is inputted out of specified value.

(1 driving cycle detection logic)

• “3” position switch or its circuit malfunction

• TCM

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Check “3” position switch circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to “3” position switch at

“E92-10” and “E92-20” terminals.

3) If OK, check resistance of switch circuit between

terminals “E92-10” and “E92-20” of disconnected

harness side TCM connector.

“3” position switch circuit

Shift selector lever to “P”, “N” or “D” range: 3.96 –

4.04 k

Ω

Shift selector lever to “R”, “3”, “2” or “L” range: 0.99

– 1.01 k

Ω

Is result as specified?

Intermittent trouble or

faulty TCM. Check for

intermittent trouble

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good TCM and

recheck.

Go to Step 3.

3

Check “3” position switch

Check “3” position switch referring to ““3” Position Switch

Inspection”.

Is result as specified?

Replace “3” position

switch.

“3” position switch

circuit is malfunction.

5A-64 Automatic Transmission/Transaxle:

DTC P1774: CAN Communication Bus Off

S5JB0A5104057

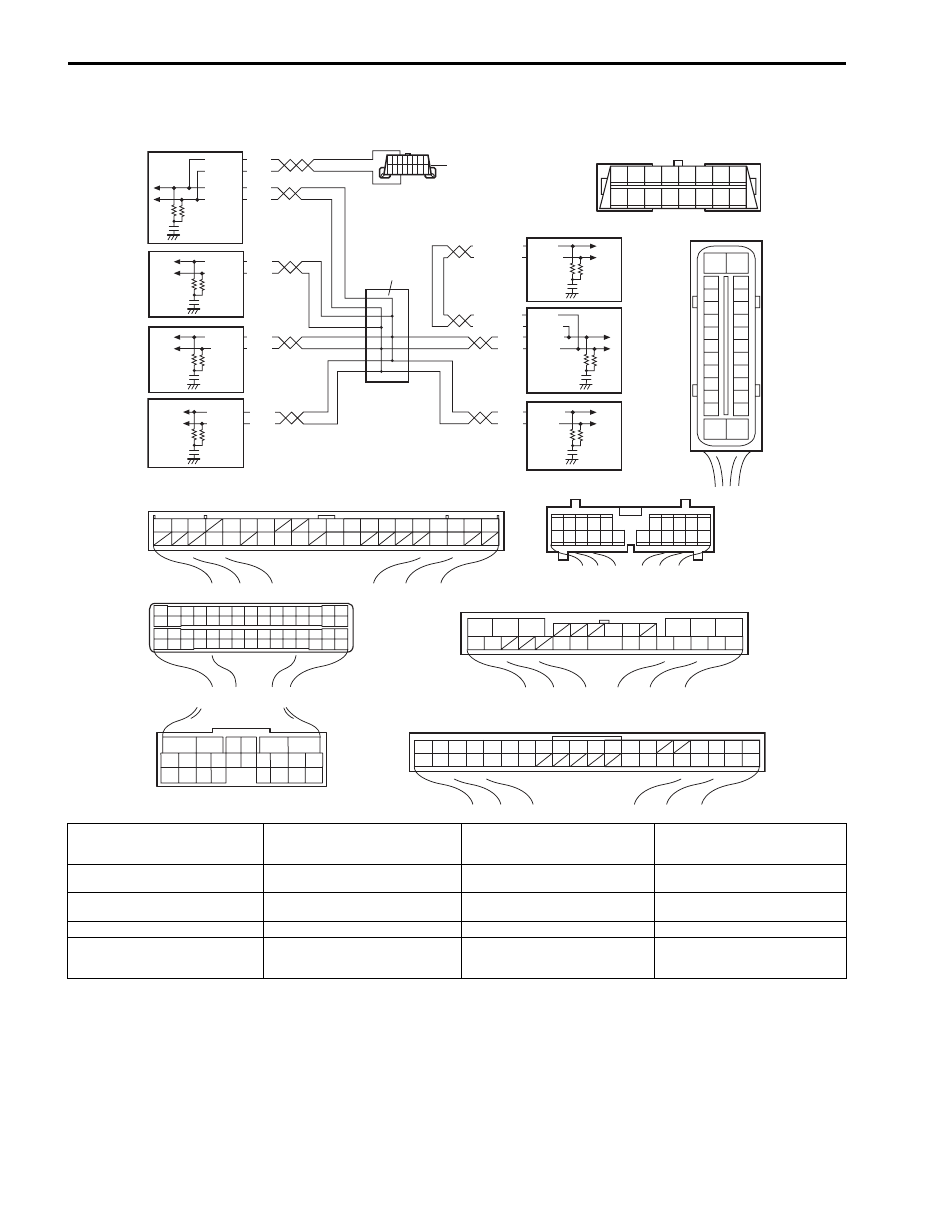

Wiring Diagram

WHT

RED

WHT

RED

G44-18

G44-19

G44

[A]

[B]

[C]

[H]

[G]

1

2

3

4

5

6

7

8

9

10

11

14

15

16

36

34 33 32

30 29

24 23

37

18

19

20

G28-8

G28-10

WHT/BLU

WHT/BLU

WHT/RED

WHT/RED E23-4

E23-19

WHT

RED E03-12

E03-10

E03-6

E03-8

WHT

RED

E92-17

E92-7

WHT

RED

E91-22

E91-23

WHT

RED

WHT

RED

G31-1

G31-3

G31-2

G31-4

6

5

16 15 14 13 12 11

4 3

24 23

21

22

10 9

8

7

2

1

19

20

18 17

E92

2 1

E23

3

4

18

19

5

6

7

10

11

17

20

47 46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

5453

59

60

58

26

27

28

15

30

56

48

32 31

34

35

36

37

40

42

3938

44

45

43

41

33

12

13

23

8

1

2

3

4

5

6

7

8

9

10

11

17

1615141312

2221201918

G28

[F]

G31

E91

1

2

3

4

7

8

9

10

11

14

15

16

36

34

35

24 23

21

22

28 27

25

26

37

39 38

40

18 17

13 12

19

20

1

2

3

10

11

12

16

17

18

15 14 13

19

20

21

25

26

5

6

[E]

[D]

E03

15

16

17

18

19

20

21

22

23

24

25

2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

8 7 6 5 4 3 2 1

9

10

11

12

13

14

15

16

1

2

3

4

9

5

6

7

8

I5JB0A510002-01

[A]: Keyless start control module

connector (if equipped) (viewed

from harness side)

[F]: Combination meter connector

(viewed from harness side)

3. TCM

8. Combination meter

[B]: ECM connector (viewed from

harness side)

[G]: 4WD control module connector

(viewed from harness side)

4. Keyless start control module (if

equipped)

9. Junction connector

[C]: TCM connector (viewed from

harness side)

[H]: BCM connector (viewed from

harness side)

5. DLC

[D]: DLC (viewed from harness side)

1. BCM

6. ECM

[E]: ABS hydraulic unit / control

module connector (viewed from

harness side)

2. 4WD control module

7. ABS hydraulic unit / control

module

Automatic Transmission/Transaxle: 5A-65

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure: ” and confirm

that the trouble has been corrected.

DTC Detecting Condition

Trouble Area

Transmission error that is inconsistent between transmission data

and transmission monitor (CAN bus monitor) data is detected more

than 7 times continuously.

(1 driving cycle detection logic)

• ECM

• TCM

• Combination meter

• BCM

• ABS hydraulic unit / control module

• 4WD control module

• Keyless start control module (if equipped)

• CAN communication line circuit

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC in TCM referring to “DTC Check”.

Is there DTC P1774?

Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3

CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control

modules for open, short and high resistance.

Is each CAN communication circuit in good condition?

Go to Step 4.

Repair circuit.

4

DTC check

1) Turn ignition switch to OFF position.

2) Disconnect each connector.

ECM

ABS hydraulic unit / control module

BCM

4WD control module

Keyless start control module (if equipped)

Combination meter

3) Recheck DTC in TCM referring to “DTC Check”.

Is there DTC P1774?

Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст