Suzuki Grand Vitara JB416 / JB420. Manual — part 108

1D-100 Engine Mechanical: For J20 Engine

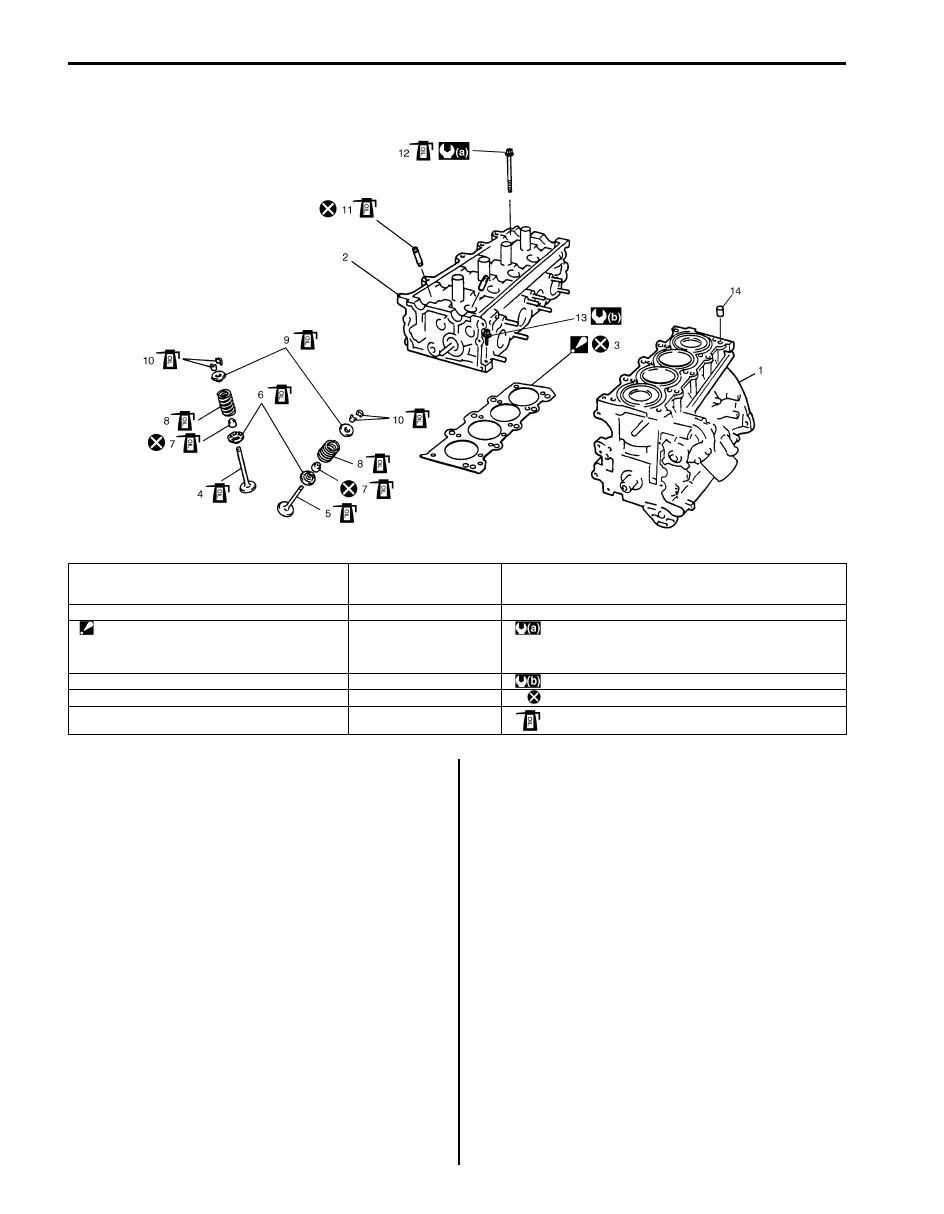

Valves and Cylinder Head Components

S5JB0A1426032

Valves and Cylinder Head Removal and

Installation

S5JB0A1426033

Removal

1) Remove engine assembly from vehicle referring to

“Engine Assembly Removal and Installation: For J20

Engine”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation: For J20 Engine in

Section 1E”.

3) Remove cylinder head cover referring to “Cylinder

Head Cover Removal and Installation: For J20

Engine”.

4) Remove timing chain cover. Refer to “Timing Chain

Cover Removal and Installation: For J20 Engine” for

removal.

5) Remove 2nd timing chain and 1st timing chain. Refer

to “2nd Timing Chain and Chain Tensioner Removal

and Installation: For J20 Engine” and “1st Timing

Chain and Chain Tensioner Removal and

Installation: For J20 Engine” for removal.

6) Remove camshafts, tappets and shims. Refer to

“Camshafts, Tappet and Shim Removal and

Installation: For J20 Engine” for removal.

I5JB0A142039-01

1. Cylinder block

7. Valve stem seal

13. Cylinder head bolt (M6)

: Be sure to tighten cylinder head bolt (M8) after securing

cylinder head bolt (M10).

2. Cylinder head

8. Valve spring

14. Knock pin

3. Cylinder head gasket

: Identification number provided on gasket comes

to crankshaft pully side, facing up.

9. Valve spring retainer

: Tighten 52 N

⋅m (5.2 kgf-m, 38.0 lb-ft), 82 N⋅m (8.2 kgf-m, 59.5

lb-ft), 0 N

⋅m (0 kgf-m, 0 lb-ft), 52 N⋅m (5.2 kgf-m, 38.0 lb-ft)

and 103 N

⋅m (10.3 kgf-m, 74.5 lb-ft) by the specified

procedure.

4. Intake valve

10. Valve cotter

: 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

5. Exhaust valve

11. Valve guide

: Do not reuse.

6. Valve spring seat

12. Cylinder head bolt (M10)

: Apply engine oil to sliding surface of each part.

Engine Mechanical: For J20 Engine 1D-101

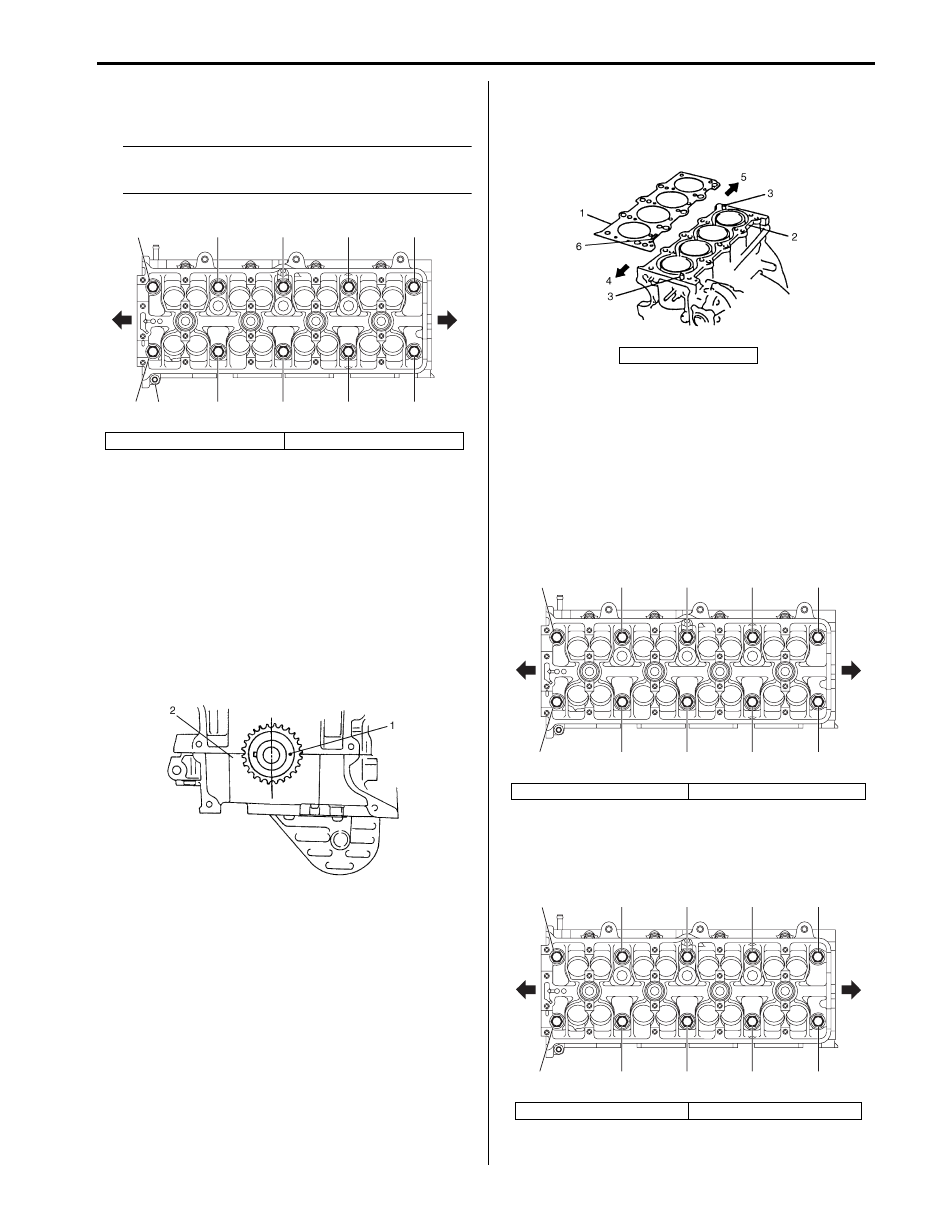

7) Loosen cylinder head bolts (M10) in such order as

numbered in figure and remove them.

NOTE

Don’t forget to remove cylinder head bolt

(M6) (3) as shown in figure.

8) Check all around cylinder head for any other parts

required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove cylinder head with intake manifold, exhaust

manifold and water outlet cap. Use lifting device, if

necessary.

Installation

1) Match match mark (1) on crank timing sprocket and

mating surface (2) of cylinder block and lower

crankcase.

2) Clean mating surface of cylinder head and cylinder

block (2). Remove oil, old gasket and dust from

mating surface.

3) Install knock pins (3) to cylinder block.

4) Install new cylinder head gasket (1) to cylinder block.

Identification number (6) provided on gasket comes

to crankshaft pulley side (4), facing up (toward

cylinder head side).

5) Install cylinder head to cylinder block.

Apply engine oil to cylinder head bolts and tighten

them gradually as follows.

a) Tighten cylinder head bolts (M10) to 52 N

⋅m (5.2

kgf-m, 38.0 lb-ft) according to numerical order in

figure.

b) In the same manner as in step a), retighten

cylinder head bolts (M10) to 82 N

⋅m (8.2 kgf-m,

59.5 lb-ft).

c) Loosen cylinder head bolts (M10) until tightening

torque is reduced to 0 according to numerical

order in figure.

1. Crankshaft pulley side

2. Flywheel side

“5”

“4”

“8”

“10”

“6”

“2”

3, “1”

“9”

“11”

“7”

“3”

1

2

I5JB0A142040-02

I2RH01140118-01

5. Flywheel side

1. Crankshaft pulley side

2. Flywheel side

1. Crankshaft pulley side

2. Flywheel side

I5JB0A142041-01

“7”

“9”

“4”

“2”

“6”

“8”

“5”

“1”

“3”

“10”

1

2

I5JB0A142042-01

“4”

“3”

“7”

“9”

“5”

“1”

“8”

“10”

“6”

“2”

1

2

I5JB0A142043-01

1D-102 Engine Mechanical: For J20 Engine

d) Tighten cylinder head bolts (M10) to 52 N

⋅m (5.2

kgf-m, 38.0 lb-ft) according to numerical order in

figure.

e) In the same manner as in step b), retighten

cylinder head bolts (M10) to 103 N

⋅m (10.3 kgf-

m, 74.5 lb-ft).

f) Tighten cylinder head bolt (M6) to specified

torque.

Tightening torque

Cylinder head bolt (M10) (a): Tighten 52 N

⋅m

(5.2 kgf-m, 38.0 lb-ft), 82 N

⋅m (8.2 kgf-m, 59.5

lb-ft), 0 N

⋅m (0 kgf-m, 0 lb-ft), 52 N⋅m (5.2 kgf-

m, 38.0 lb-ft) and 103 N

⋅m (10.3 kgf-m, 74.5 lb-

ft) by the specified procedure.

Cylinder head bolt (M6) (b): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

6) Install camshafts and tappets and shims. Refer to

“Camshafts, Tappet and Shim Removal and

Installation: For J20 Engine” for installation.

7) Install 1st timing chain. Refer to “1st Timing Chain

and Chain Tensioner Removal and Installation: For

J20 Engine” for installation.

8) Install 2nd timing chain. Refer to “2nd Timing Chain

and Chain Tensioner Removal and Installation: For

J20 Engine” for installation.

9) Install timing chain cover. Refer to “Timing Chain

Cover Removal and Installation: For J20 Engine” for

installation.

10) Check intake and exhaust valve lashes referring to

“Valve Lash (Clearance) Inspection: For J20

Engine”.

11) Install cylinder head cover referring to “Cylinder

Head Cover Removal and Installation: For J20

Engine”.

12) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation: For J20 Engine in

Section 1E”.

13) Install engine assembly to vehicle referring to

“Engine Assembly Removal and Installation: For J20

Engine”.

Valves and Cylinder Head Disassembly and

Assembly

S5JB0A1426034

Disassembly

1) When servicing cylinder head, remove intake

manifold, injectors, exhaust manifold and water

outlet cap from cylinder head.

2) Using special tools, compress valve springs and

then remove valve cotters (1) also by using special

tool.

Special tool

(A): 09916–14510

(B): 09916–16510

(C): 09919–28610

(D): 09916–84511

1. Crankshaft pulley side

2. Flywheel side

“7”, (a)

“9”, (a) 3, “11”, (b) “4”, (a)

“2”, (a)

“6”, (a)

“8”, (a)

“5”, (a)

“1”, (a)

“3”, (a)

“10”, (a)

I5JB0A142044-02

I5JB0A142045-01

Engine Mechanical: For J20 Engine 1D-103

3) Release special tool, and remove spring retainers

and valve springs.

4) Remove valve from combustion chamber side.

5) Remove valve stem seal (1) from valve guide, and

then valve spring seat (2).

NOTE

Do not reuse seal once disassembled. Be

sure to use new seal when assembling.

6) Using special tool (Valve guide remover), drive valve

guide out from combustion chamber side to valve

spring side.

Special tool

(A): 09916–46020

NOTE

Do not reuse valve guide once disassembled.

Be sure to use new valve guide (oversize)

when assembling.

7) Place disassembled parts except valve stem seal

and valve guide in order so that they can be installed

in their original positions.

Assembly

1) Before installing valve guide into cylinder head, ream

guide hole with special tool (11 mm reamer) so as to

remove burrs and make it truly round.

Special tool

(A): 09916–34542

(B): 09916–38210

2) Install valve guide to cylinder head.

Heat cylinder head uniformly at a temperature of 80

to 100

°C (176 to 212 °F) so that head will not be

distorted, and drive new valve guide into hole with

special tools.

Drive in new valve guide until special tool (Valve

guide installer) contacts cylinder head.

After installing, make sure that valve guide protrudes

by 13.0 mm (0.51 in.) from cylinder head.

Special tool

(A): 09916–57350

(B): 09916–57340

NOTE

• Do not reuse valve guide once

disassembled. Install new valve guide

(Oversize).

• Intake and exhaust valve guides are

identical.

Valve guide oversize

0.03 mm (0.0012 in.)

Valve guide protrusion “a” (In and Ex)

13.0 mm (0.51 in.)

I2RH01140125-01

I2RH01140126-01

I2RH01140127-01

I2RH01140128-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст