Hummer H1 (1992-1998). Manual — part 56

2-41. ENGINE ASSEMBLY FROM SUBASSEMBLIES

(Cont’d)

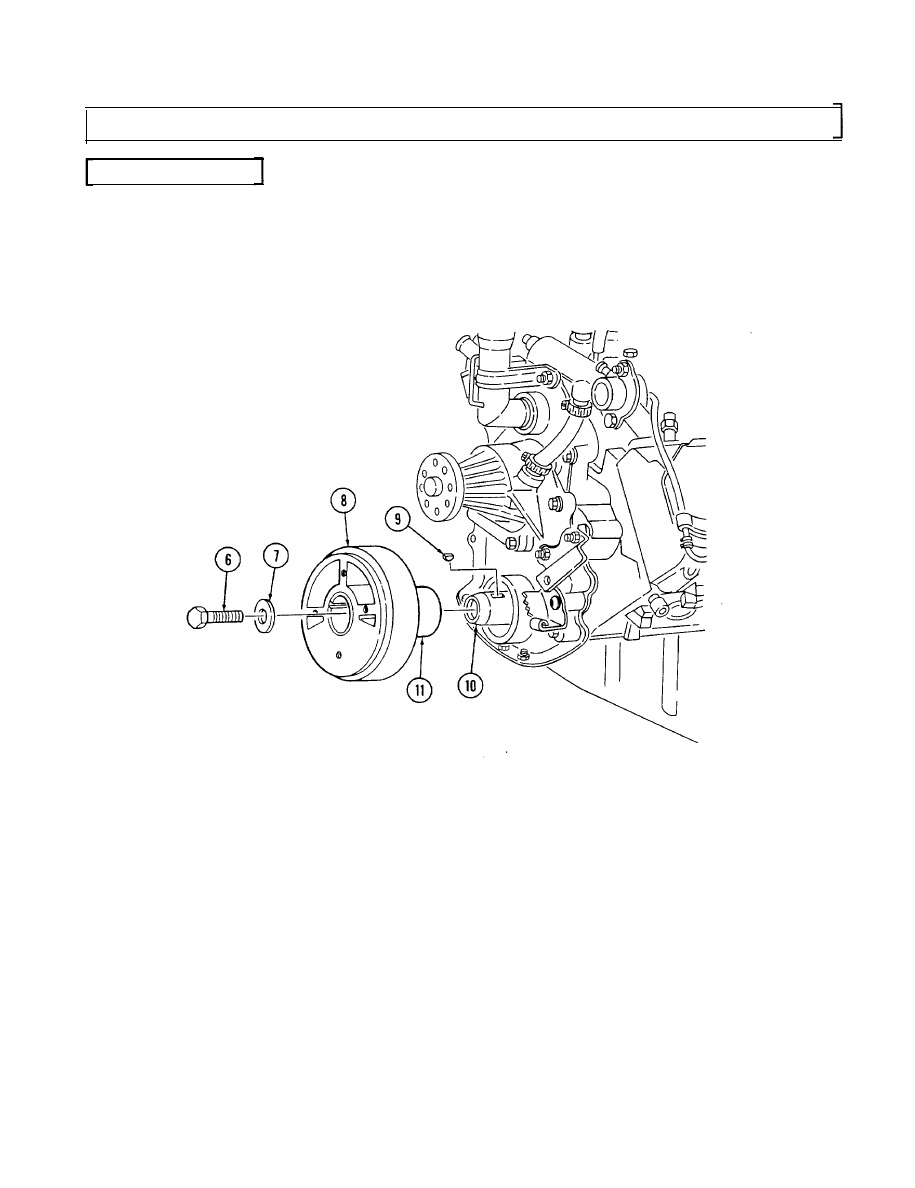

z. Torsional Damper

1. Install woodruff key (9) in crankshaft (10).

2. Apply lubricating oil to seal surface (11) on torsional damper (8).

3. Install torsional damper (8) on crankshaft (10) far enough to install washer (7) and capscrew (6).

4, Hold flywheel stationary with pry bar and tighten capscrew (6) to 140-162 lb-ft (190-220 N•m).

2-185

2-186

Change 1

2 - 4 1 . ENGINE ASSEMBLY FROM SUBASSEMBLIES (Cont’d)

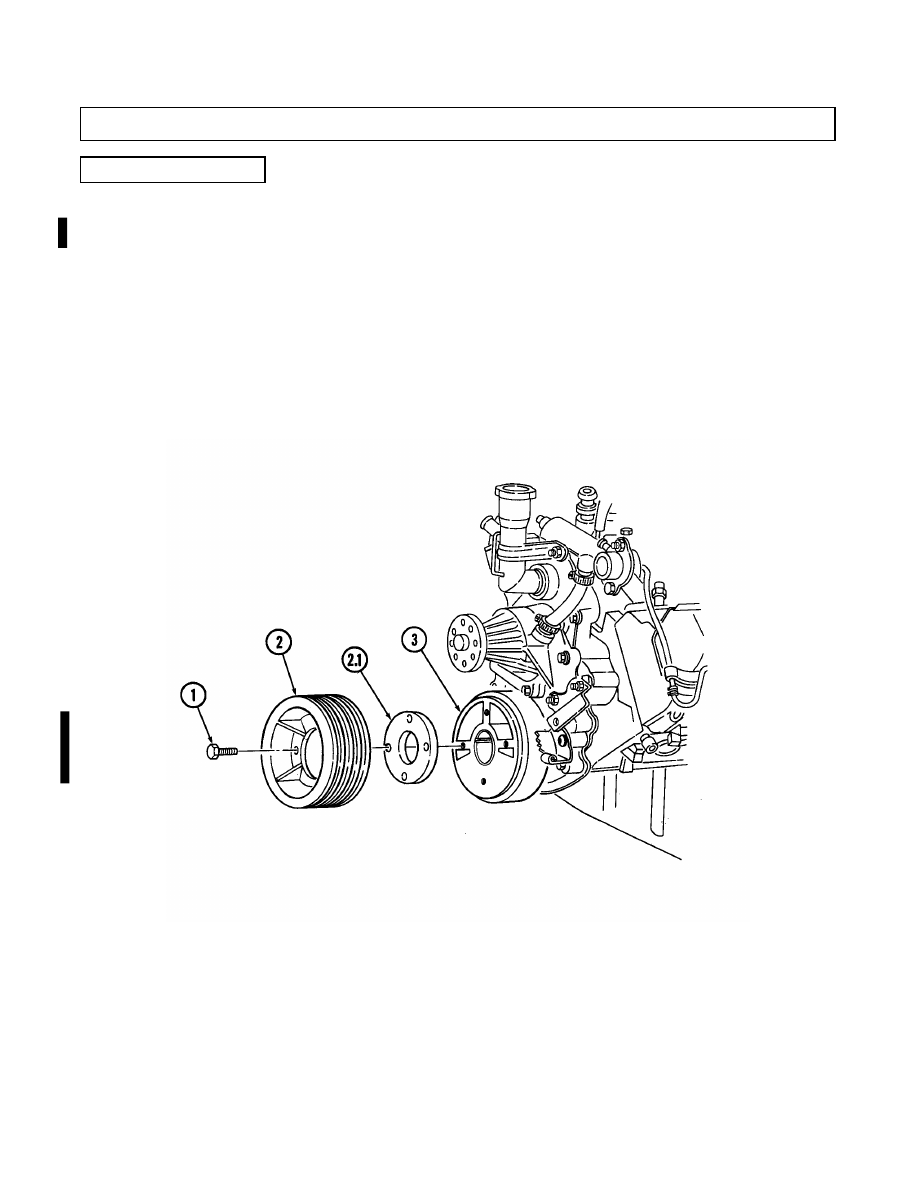

aa. Crankshaft Pulley

1.

Apply sealing compound to four capscrews (1).

2.

Install crankshaft pulley (2) and spacer (2.1) (if removed) on torsional damper (3) with four

capscrews (1).

3.

Hold flywheel stationary with pry bar and tighten capscrews (1) to 48 lb-ft (65 N

•

m).

2-41. ENGINE ASSEMBLY FROM SUBASSEMBLIES (Cont’d)

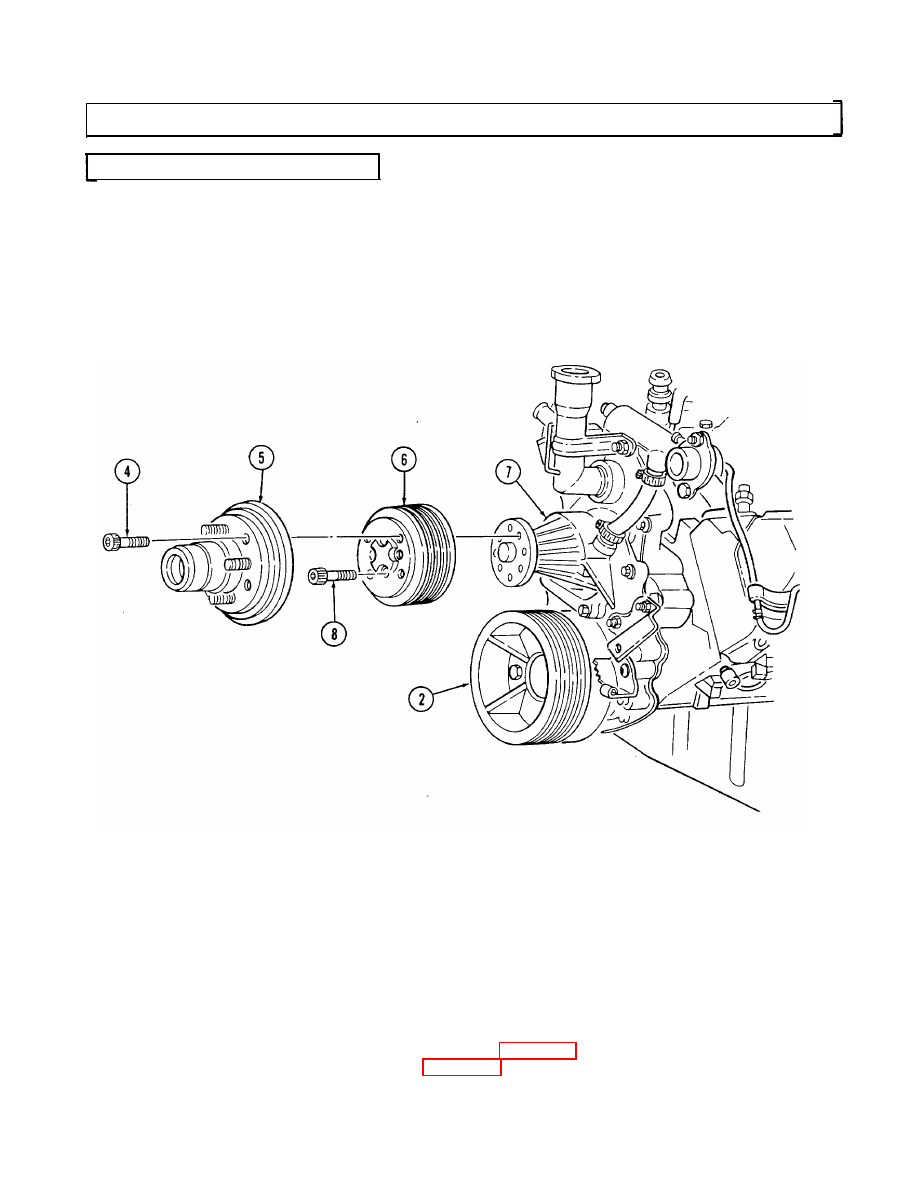

bb. Fan Drive and Water Pump Pulley

1. Apply sealing compound to four socket head screws (8).

2. Install water pump pulley (6) on water pump (7) with four socket head screws (8).

3. position pry bar between water pump pulley (6) and crankshaft pulley (2) and apply pressure t

O

prevent rotation. Using 6 mm hex head driver, tighten socket head screws (8) to 20 lb-ft (27 N•m).

4. Apply sealing compound to four socket head screws (4).

5. Install fan drive (5) on water pump pulley (6) with four socket head screws (4). Repeat step 3. Using

5/16-in. hex head driver, tighten socket head screws (4) to 45 lb-ft (61 N•m).

FOLLOW-ON TASKS:

●

Remove engine from repair stand (para. 2-14).

●

Perform engine run-in (para. 2-43).

2-187

Section VI. FINAL INSPECTION

2-42. GENERAL

Following any major repair to the engine, the engine must be run-in, and tests made prior to release for

issue to user. Paragraph 2-43 contains instructions for engine run-in.

2-43. ENGINE RUN-IN

This task covers:

Out of Chassis Run-In

INITIAL SETUP

Test Equipment

Manual References

Dynamometer

N O T E

This procedure should be performed in a well-ventilated

work area.

If engine dynamometer is available, follow manufacturer’s

instructions for its use. If dynamometer is not available, refer

to TM 9-2320-280-34 for In Chassis Run-In.

1. Connect engine to dynamometer,

CAUTION

l

Operating an engine without sufficient lubricating oil will cause

damage to engine.

●

If any leaks or abnormal noise is noted, stop engine immediately

and correct as necessary. Any abnormalities must be corrected

before proceeding to the next test interval.

●

Oil pressure should be 40-50 psi (276-345 kPa) under load and

10 psi (69 kPa) minimum at idle. If oil pressure does not meet

specifications, stop engine immediately and correct as necessary.

●

Oil temperature must not exceed 260°F ( 127°C) and coolant

temperature must not exceed 230°F (110°C). If coolant

temperature or oil temperature exceed limits, stop engine

immediately and correct as necessary.

2. Start engine and run-in according to schedule in table 2-1.

2-188

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст