Hummer H1 (2002+). Manual — part 268

_______________________________________________________

PCM/Tech 1 Scan Tool 5

®

05745159

PCM Programming (TDC Offset)

The PCM will automatically activate the TDC Offset program when the engine coolant is greater than 170°F (77°C). If the PCM is

not programmed with a TDC Offset, a P1214 will set. If the PCM and Fuel injection pump are replaced together, or the front cover

of the engine is replaced, the TDC offset will have to be “cleared” to allow the PCM to relearn the new value.

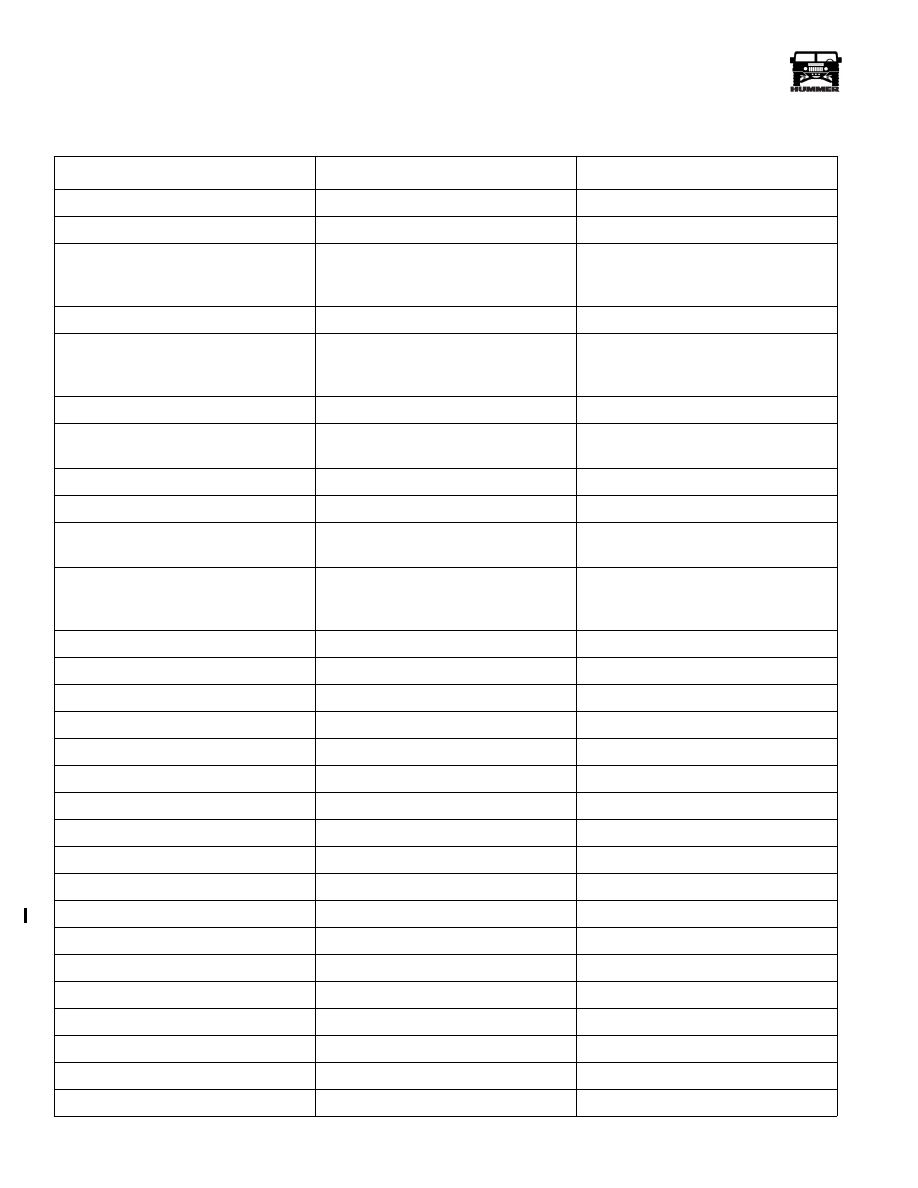

Table 3-1: Powertrain OBD System Check

Step

Action

Value(s)

Yes

No

1

1) Turn on the ignition leaving the engine OFF.

2) Observe the Malfunction Indicator Lamp (MIL).

Is the MIL on?

—

Go to Step 2

Go to “No Mal-

function Indica-

tor Lamp”

2

1) Turn OFF the ignition.

2) Install the scan tool.

3) Turn ON the ignition.

Does the scan tool display PCM data

—

Go to Step 3

Go to “No Scan

Tool Data”

3

Using the scan tool to command the MIL to turn OFF.

Does the MIL turn OFF?

—

Go to Step 4

Go to DTC

P1641 MIL Con-

trol Circuit

4

Check for DTCs using the scan tool.

Were any current, history, or MIL request DTCs set?

—

Go to Step 5

Go to Step 6

5

Using the scan tool, store the Freeze Frame Data and the

Failure Records Data.

Is the action complete?

—

Go the Applica-

ble DTC Table

—

6

Does the engine start and continue to run?

—

Go to step 7

Go to “Engine

Cranks but Does

Not Run”

7

1) Turn ON the ignition leaving the engine OFF.

2) Check the ECT.

3) Start the engine.

4) Allow the engine temperature to reach the specified

value.

5) While the engine is reaching the operating temperature,

check the ECT.

6) Compare the scan tool values of the sensors with the typ-

ical values shown in the Scan Tool Values.

Are the displayed values normal or within typical ranges?

90°C-95°C

—

—

8

Refer to indicated “Component(s) System” checks.

—

—

—

6

PCM/Tech 1 Scan Tool

______________________________________________________

®

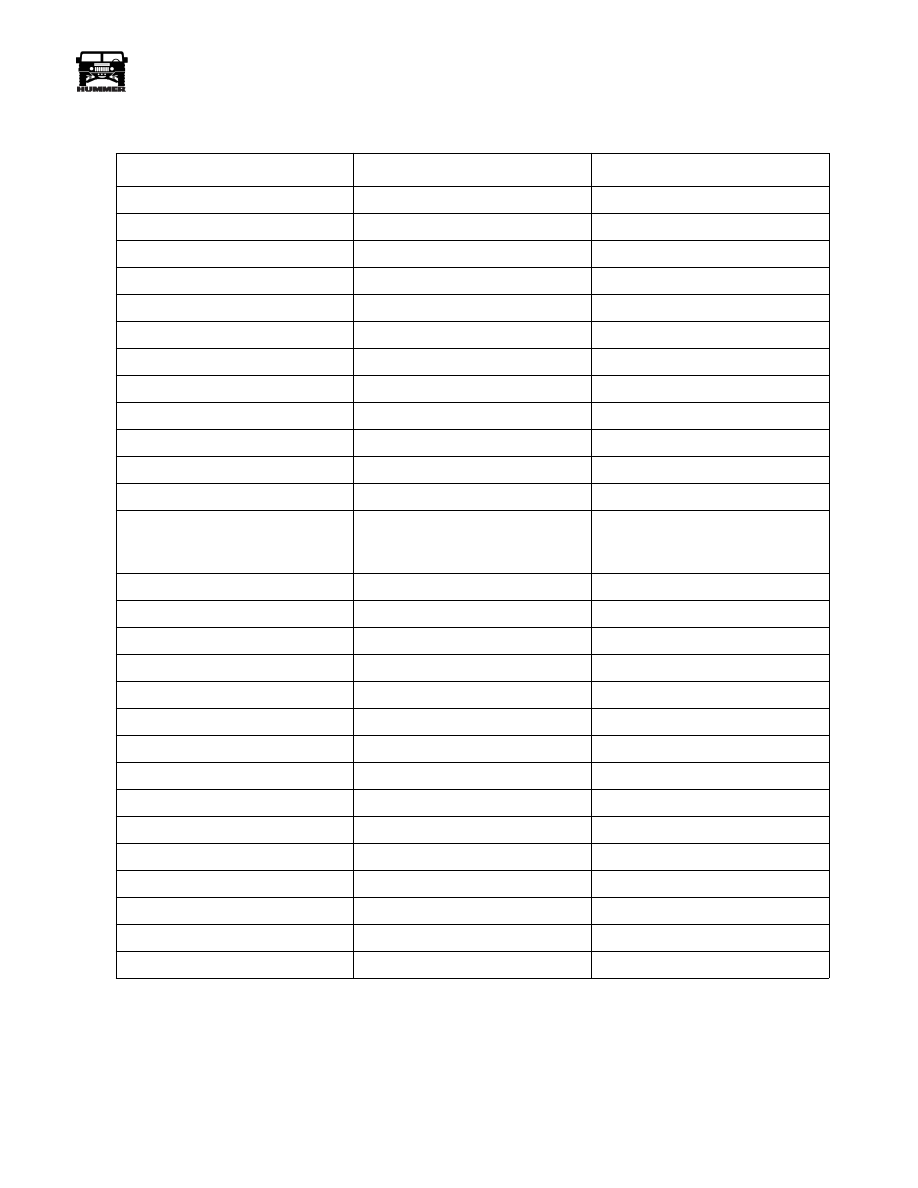

Typical Engine Data Values

Idle/Upper Radiator Hose Hot/Closed Throttle/Park or Neutral/ACC. “OFF”

Tech 1 Parameter

Units Displayed

Typical Data Value

Engine Speed

RPM

±100 RPM from desired

Desired Idle

RPM

PCM idle command

ECT

C°/F°

85°C - 105°C

(185°F - 221°F)

*varies with coolant temp.

Start Up ECT

C°/F°

varies (depends on start up ECT)

IAT

C°/F°

60°C - 80°C

(140°F - 177°F)

*varies with incoming air

ECT Sensor

volts

1.7-2.2 volts (varies with coolant temp.)

Baro

kPa/Volts

3-5 volts (varies with altitude and baro

pressure)

ESO Solenoid

on/off

on

Boost Solenoid

%

60 - 70%

Boost Pressure

kPa

60 - 103 kPa

*varies with altitude

Fuel Temp

C°/F°

60°C - 80°C

(140°F - 176°F)

*varies with fuel temp.

Fuel Rate

millimeters cubed

7 - 12 mm3

Glow Plug

volts

0 volts

Glow Plug System

disabled/enabled

disabled

Des. Inj Timing

Degrees

3.5 - 6.0°

Act. Inj. Timing

Degrees

3.5 - 6.0°

APP Angle

%

0%

APP 1

volts

.45 - .95 volts

APP 2

volts

4.0 - 4.5 volts

APP 3

volts

3.6 - 4.0 volts

Inj. Pump Sol. Closure Time

milliseconds

1.70 - 1.90 ms

TDC Offset

Degrees

-.25 to -.75

Ignition Volts

volts

12 - 14 volts

MPH kp/h

MPH kp/h

0 0

Cruise Switch

on/off

off

Cruise Active

on/off

off

Cruise Brake Sw.

open/closed

closed

Brake Switch

open/closed

open

Set Switch

on/off

off

4-01-00

_______________________________________________________

PCM/Tech 1 Scan Tool 7

®

05745159

Resume Switch

on/off

off

TR Switch

Park-Neutral, Reverse, Drive Ranges

Park

Crank Ref Missed

#

0 (missed)

Inj. Pump Cam Reference Missed

#

0 (missed)

Lift Pump

volts

12 - 15 volts

Lift Pump System

disabled/enabled

enabled

Engine Load

%

4 - 6%

Engine Torque

ft-lb

7 - 10 ft-lb

# of Current DTC’s

#

0

DTC Set This Ign.

yes/no

no

Ignition volts

volts

12 - 15 volts

TFT Sensor

volts

2.5 - 3.5 volts

TFT

C°/F°

50°C - 70°C

(122°F - 158°F)

*varies

Calc. A/C Load

ft-lb

0 ft-lb

A/C Request

on/off

off

Glow Plug “Wait” lamp

on/off

off

A/C Compressor

engaged/disengaged

disengaged

A/C Relay

yes/no

no

MIL Lamp

on/off

off

STS Lamp

on/off

off

4WDL Mode

enabled/disabled

disabled

Front Axle Switch

unlocked/locked

unlocked

A/B/C Range Sw.

on on on/off off off

off off

1-2 Sol. 2-3 Sol.

on off

on off

TCC Enabled

on/off

off

PC Solenoid

on/off

off

Device Control

yes/no

no

Engine Run Time

hours/minutes/seconds

varies

Typical Engine Data Values

Idle/Upper Radiator Hose Hot/Closed Throttle/Park or Neutral/ACC. “OFF”

Tech 1 Parameter

Units Displayed

Typical Data Value

8

PCM/Tech 1 Scan Tool

______________________________________________________

®

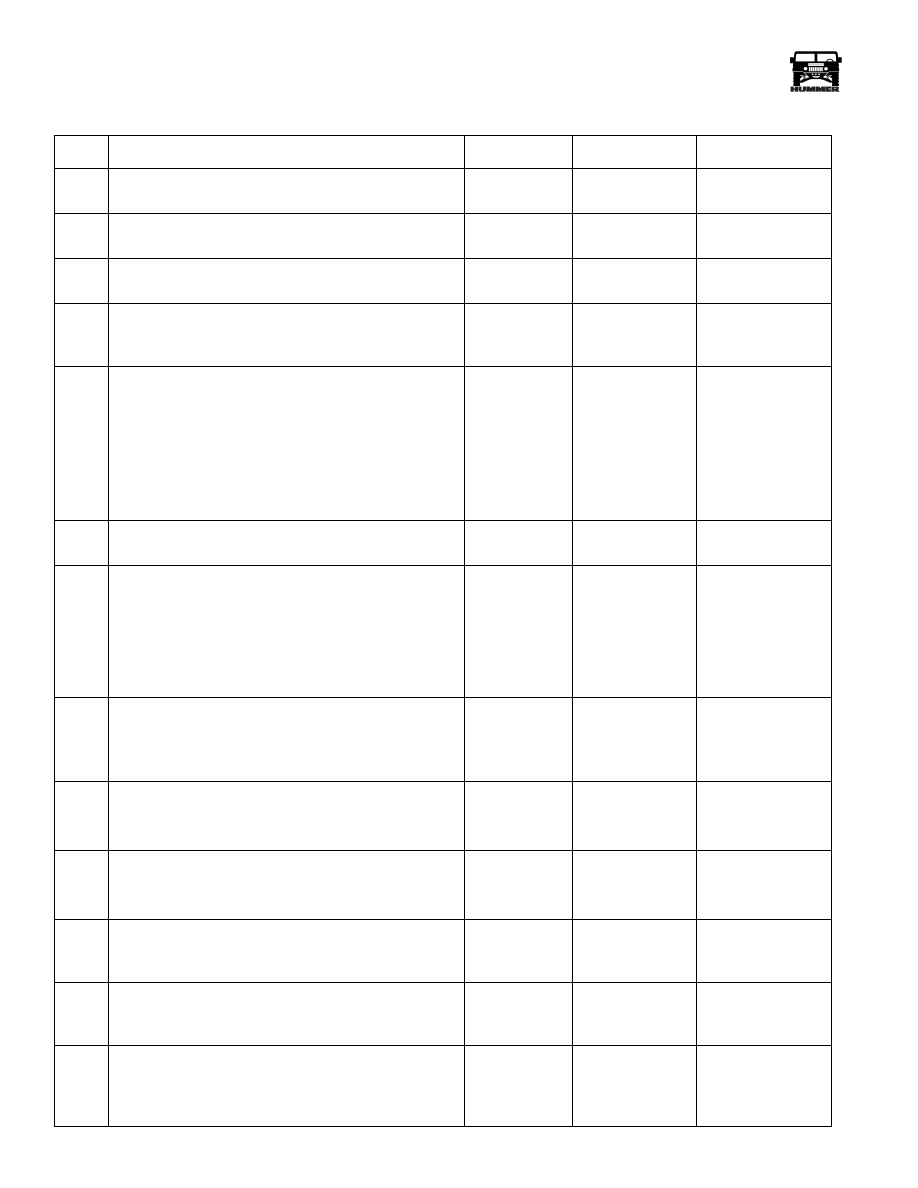

No Malfunction Indicator Lamp (MIL) “Check Engine”

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD System

Check

2

Attempt to start the engine.

Does the engine start?

—

Go to Step 3

Go to Step 6

3

Check the fuse number 4.

Is the fuse OK?

—

Go to Step 4

Go to Step 14

4

Turn the ignition “ON,” probe the ignition feed circuit at

the cluster connector with a test light to ground.

Is the test light “ON?”

—

Go to Step 5

Go to Step 11

5

1. Turn the ignition “OFF.”

2. Disconnect the black PCM connector.

3. Turn the ignition “ON.”

4. Connect a fused jumper to the MIL control circuit at

the PCM connector.

5. Observe the MIL.

Is the MIL “ON?”

—

Go to Step 9

Go to Step 10

6

Check the PCM ignition Feed and Battery Feed fuses.

Are both of the fuses OK?

—

Go to Step 7

Go to Step 13

7

1. Turn the ignition “OFF.”

2. Disconnect the PCM connectors.

3. Turn the ignition “ON.”

4. Probe the PCM harness ignition and battery feed cir-

cuits with a test light to ground.

Is the test light “ON” both circuit?

—

Go to Step 8

Go to Step 12

8

1. Check for a faulty PCM ground or a poor PCM ground

connection.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Go to Step 20

Go to Step 9

9

1. Check for a poor connection at the PCM.

2. If a poor connection is found, repair as necessary.

Was a problem found?

—

Go to Step 20

Go to Step 15

10

1. Check the MIL control circuit for an open.

2. If the MIL control circuit is open, repair as necessary.

Was a problem found?

—

Go to Step 20

Go to Step 16

11

Repair open in the ignition feed circuit to the cluster con-

nector.

Is the action complete?

—

Go to Step 20

—

12

Locate and repair open in the PCM battery feed circuit or

the PCM ignition feed circuit as necessary.

Is the action complete?

—

Go to Step 20

—

13

Locate and repair short to ground in the PCM Ignition

Feed circuit or the PCM Battery Feed circuit as neces-

sary.

Is the action complete?

—

Go to Step 20

—

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст