Hummer H1 (2002+). Manual — part 93

___________________________________________

Transmission/Transfer Case 5-171

®

05745159

Figure 5-133: Shift Sector Installation

Figure 5-134: Input Gear/Low range Planetary

Installation

8.

Assemble differential as follows:

a.

Lubricate differential cases, gears, thrust washers

with Dexron III.

b.

Install mainshaft gear in front case.

c.

Install sprocket gear.

d.

Install thrust washer on each front case pinion pin.

e.

Install long and short pinions in sets as shown.

f.

Install thrust washer at top of each pinion.

g.

Align and install rear case on front case. Be sure case

alignment paint or scribe marks are matched as

shown.

h.

Install and tighten differential case bolts evenly.

Figure 5-135: Input Gear Snap Ring Installation

Figure 5-136: Front Retainer Seal Installation

FRONT

CASE

SHIFT

SECTOR

INPUT GEAR

BEARING

INPUT GEAR/

PLANETARY

ASSEMBLY

INPUT

GEAR

SHAFT

INPUT GEAR

BEARING

SNAP RING

FRONT

RETAINER

TOOL

J–33831

5-172

Transmission/Transfer Case

___________________________________________

®

Figure 5-137: Front Retainer Installation

Figure 5-138: Assembling Low Range Fork and Hub

Figure 5-139: Engaging Low Range Fork Pin

in Shift Sector

9.

Check condition of tone wheel on mainshaft. Replace

wheel if teeth are chipped, cracked, or broken.

10. Coat needle bearing surface of mainshaft with petroleum

jelly. Then install first spacer, 53 needle bearings, and

remaining spacer. Use extra petroleum jelly to hold needle

bearings in place (Figure 5-143).

11. Install differential on mainshaft. Verify that needle roller

bearings were not displaced before proceeding

(Figure 5-144).

12. Install differential snap ring (Figure 5-145).

13. Install intermediate clutch shaft. Be sure shaft is fully

seated (Figure 5-146).

14. Install clutch shaft thrust ring and snap ring (Figure 5-147).

Figure 5-140: Installing Mainshaft Gear In Front

Case

INPUT

GEAR

FRONT

RETAINER

HUB

PADS

LOW

RANGE

FORK

LOWER

SLOT

SHIFT

SECTOR

LOW

RANGE

FORK

MAINSHAFT

GEAR

DIFFERENTIAL

FRONT CASE

___________________________________________

Transmission/Transfer Case 5-173

®

05745159

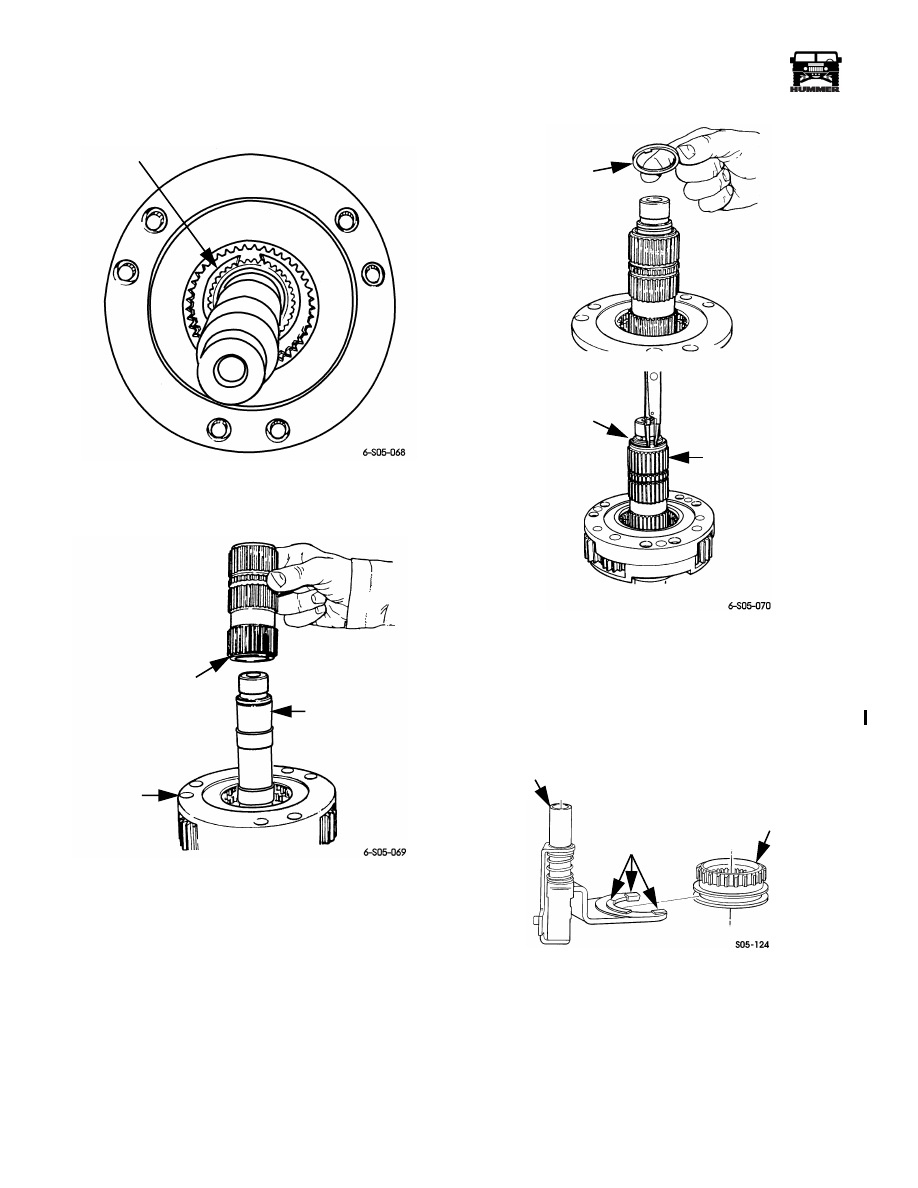

Figure 5-141: Differential Pinion and Sprocket Gear

Installation

Figure 5-142: Assembling Differential Front/Rear

Cases

Figure 5-143: Mainshaft Bearing Roller Installation

Figure 5-144: Installing Differential On Mainshaft

15. Install mode sleeve in mode fork. Replace fork pads if

worn or cracked. Do not reuse worn pads (Figure 5-148).

16. Install assembled mode fork and sleeve on mainshaft.

Then seat sleeve in differential (Figure 5-149).

17. Install assembled mainshaft, differential, mode fork, and

sleeve. Be sure mainshaft is seated in input gear pilot

bearing and that mode fork pin is seated in upper slot of

shift sector as shown (Figure 5-152).

THRUST

WASHERS (6)

SHORT

PINION (3)

THRUST

WASHERS (6)

SPROCKET

GEAR

MAINSHAFT

GEAR

FRONT

CASE

LONG

PINION (3)

CASE

ALIGNMENT

MARKS

FRONT

CASE

REAR

CASE

BEARING

SPACERS

NEEDLE ROLLER

BEARINGS

(HOLD IN PLACE

WITH PETROLEUM

JELLY)

DIFFERENTIAL

MAINSHAFT

5-174

Transmission/Transfer Case

___________________________________________

®

Figure 5-145: Differential Snap Ring Installation

Figure 5-146: Intermediate Clutch Shaft Installation

Figure 5-147: Intermediate Clutch Shaft Thrust Ring

and Snap Ring Installation

18. Install shift rail. Install rail through mode fork, range fork,

and into case bore and install lock pin (Figure 5-153).

Figure 5-148: Installing Mode Sleeve in Mode Fork

DIFFERENTIAL

SNAP RING

DIFFERENTIAL

MAINSHAFT

INTERMEDIATE

CLUTCH SHAFT

CLUTCH SHAFT

THRUST RING

INTERMEDIATE

CLUTCH SHAFT

CLUTCH SHAFT

SNAP RING

MODE FORK

ASSEMBLY

FORK

PADS

MODE

SLEEVE

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст