Hummer H1 (2002+). Manual — part 83

___________________________________________

Transmission/Transfer Case 5-131

®

05745159

Transmission Cooler Flushing Procedure

Equipment Needed

• J–35944-A cooler flushing tool with included adapters

and J–35944-22 or J–35944-CSE* flushing solution.

• Measuring Cup

• Funnel

• Water Supply (hot water recommended)

• Water Hose (at least 5/8” I.D.)

• Shop Air Supply (with water/oil filters, regulator and

pressure gauge)

• Air Chuck (with clip if available)

• Oil Drain Container

• Five Gallon Pail With Lid

• Eye Protection

• Rubber Gloves

* Do not substitute with solutions that contain alcohol or gly-

col. Use of solutions that contain alcohol or glycol may dam-

age J–35944-A, oil cooler or transmission components.

Preparation

1.

After the repaired or replacement transmission is installed

in the vehicle, do not reconnect the oil cooler pipes.

2.

Remove the fill cap on J–35944-A and fill with 20-21 oz.

(0.6L) of flushing solution. Do not overfill.

3.

Install the fill cap on J–35944-A and pressurize the flusher

can using the shop air supply 80-100 psi (550-700 kPa).

4.

Connect the J–35944-A discharge hose to the oil cooler

return pipe.

5.

Clip the discharge hose onto the oil drain container.

6.

Attach J–35944-A to the undercarriage of the vehicle with

the hook provided and connect the hose from J–35944-A

to the other (feed) oil cooler pipe.

7.

With the water valve on J–35944-A in the “OFF” position,

connect the water hose from the water supply to J–35944-

A.

8.

Turn “ON” the water supply at the water faucet.

Initial Flush

1.

Turn the water valve on J–35944-A to the “ON” position

and allow the water to flow through the oil cooler and

pipes for 10 seconds to remove any remaining transmis-

sion fluid. If water does not flow through the oil cooler and

pipes, the cause of the blockage must be diagnosed and the

plugged component must be repaired or replaced. Con-

tinue with the cooler flushing and flow check procedure

once the blockage is corrected.

2.

Turn the water valve on J–35944-A to the “OFF” position

and clip the discharge hose onto the five gallon pail with a

lid.

3.

Turn the water valve on J–35944-A to the “ON” position

and depress the trigger to mix cooler flushing solution into

the water flow. Use the clip provided on the handle to hold

the trigger down. The discharge will foam vigorously

when the solution is introduced into the water stream.

4.

Flush the oil cooler and pipes with water and solution for

two minutes. During this flush, attach the air supply to the

air valve located on J–35944-A for 3-5 seconds at the end

of every 15-20 second interval to create a surging action.

5.

Release the trigger and turn the water valve on J–35944-A

to the “OFF” position.

Back Flush

1.

Disconnect both hoses from the oil cooler pipes and then

connect them to the opposite oil cooler pipe. This will

allow the oil cooler and pipes to be back flushed.

2.

Repeat steps 3 and 4 of the “INITIAL FLUSH” procedure.

3.

Release the trigger of J–35944-A and allow water only to

rinse the oil cooler and pipes for one minute.

4.

Turn the water valve on J–35944-A to the “OFF” position

and turn “OFF” the water supply at the faucet.

5.

Attach the air supply to the air valve on J–35944-A and

blow out the water from the oil cooler and pipes. Continue

until no water comes out of the discharge hose.

Flow Check

1.

Disconnect both hoses from the oil cooler pipes. Connect

the oil cooler feed pipe to the transmission and the return

pipe to the discharge hose. Clip the discharge hose onto

the oil drain container.

2.

Confirm the transmission is filled with automatic

transmission fluid.

3.

Start the engine with the transmission in “PARK” range

and run until automatic transmission fluid begins to flow

into the oil drain container. Turn off engine, empty oil

drain container and fill transmission with automatic

transmission fluid. Start the engine with the transmission

in “PARK” range and run for 30 seconds. A minimum of

two quarts (1.9 L) must be discharged during this 30

second run time.

If fluid flow is equal to or greater than 2 qt. in 30 seconds,

go to step 4.

If fluid flow is less than 2 qt. in 30 seconds, perform the

following diagnosis:

• Disconnect the oil cooler feed line at the radiator. Con-

nect the discharge hose to the oil cooler feed line. Clip

the discharge hose onto the empty oil drain container.

Start the engine with the transmission in “PARK” range

and run for 30 seconds. A minimum of two quarts (1.9

L) must be discharged during this 30 second run time.

Do the following according to the flow rate:

Insufficient feed flow:

• Inspect the transmission for leaks or blockage.

Sufficient feed flow:

• Inspect the oil cooler return pipe and the oil cooler for

blockages or leaks.

5-132

Transmission/Transfer Case

___________________________________________

®

4.

Remove the discharge hose, reconnect the cooler feed and

return pipes to the transmission and refill the unit to the

proper level. Inspect the transmission oil cooler pipe

connections at the radiator and transmission for leaks.

Cleanup

1.

Disconnect the water supply hose from J–35944-A and

bleed any remaining air pressure from the can. Remove the

fill cap from J–35944-A and return any unused flushing

solution to its container. Rinse J-35944-A with water. Do

not store J–35944-A with flushing solution in it.

2.

After every third use, clean J–35944-A as described in the

instructions included with the tool.

3.

Dispose of any waste water/solution/transmission fluid in

accordance with local regulations.

Transmission Fluid And Filter Replacement

1.

Support transmission/transfer case assembly with jack

positioned under transfer case.

2.

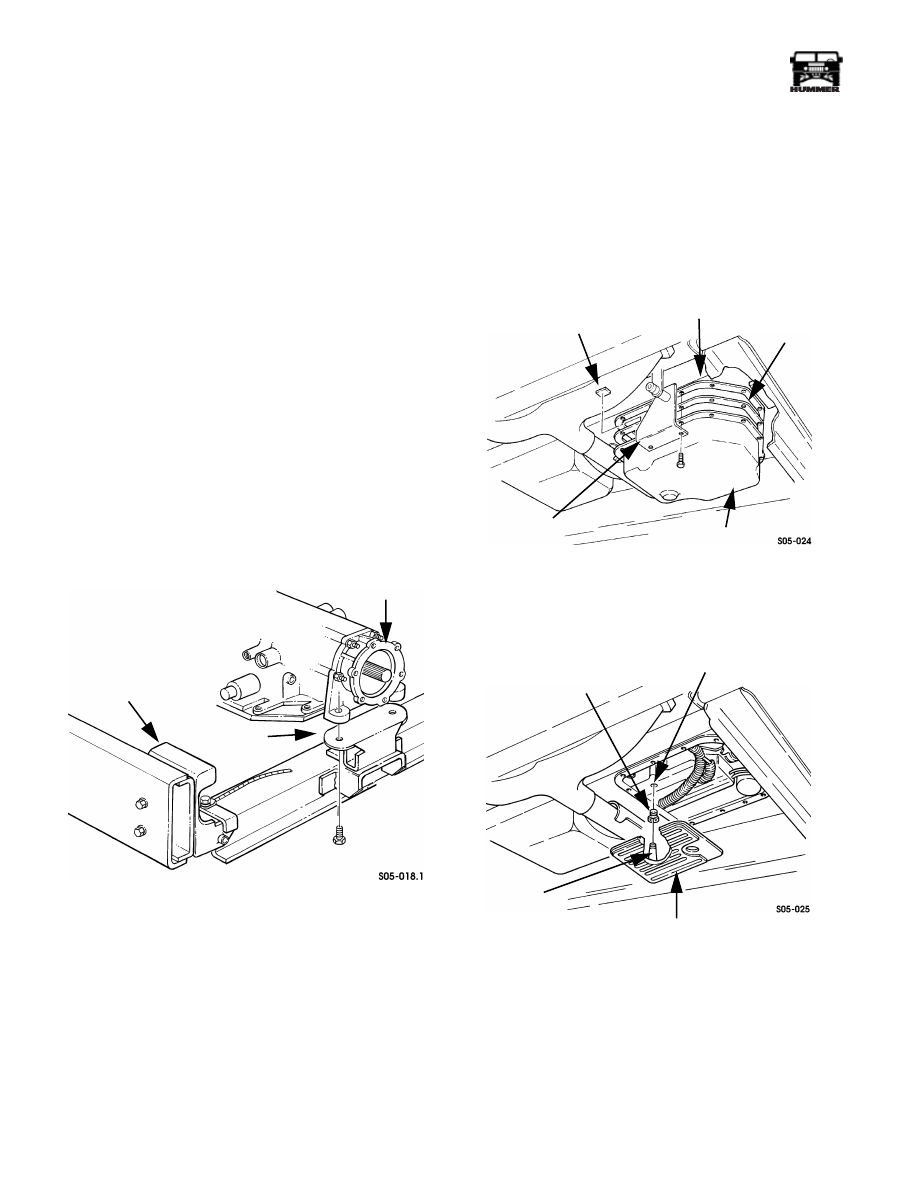

Remove bolts attaching rear mount to transmission

(Figure 5-28).

3.

Remove bolts attaching crossmember to frame brackets

and remove crossmember.

Figure 5-28: Transmission-to-Crossmember

Mounting

4.

Loosen transmission oil pan bolts and allow fluid to drain.

5.

Move shift rod bracket aside and remove pan gasket, and

oil pan (Figure 5-29). Pan gasket is reusable.

6.

Remove oil filter from valve body (Figure 5-30).

7.

Inspect filter seal (Figure 5-30). Undamaged seal is re-

usable.

8.

Remove magnet from oil pan. Then clean pan and magnet.

9.

Install seal in valve body.

10. Insert filter pipe in case with twisting motion. Align filter

with valve body and work into place (Figure 5-30).

11. Position magnet in oil pan.

12. Install gasket on oil pan and install pan on transmission.

Tighten pan bolts to 18 lb-ft (24 N•m) torque.

13. Install rear crossmember and transmission mount.

14. Remove support jack.

15. Refill transmission with Dexron III fluid.

Figure 5-29: Oil Pan Removal/Installation

Figure 5-30: Oil Filter Removal/Installation

REAR

MOUNT

FRAME

BRACKET

ADAPTER

PAN

GASKET

TRANSMISSION

OIL PAN

MAGNET

SHIFT ROD

BRACKET

OIL PAN

SEAL

VALVE BODY

INLET PORT

OIL FILTER

FILTER

PIPE

___________________________________________

Transmission/Transfer Case 5-133

®

05745159

COOLER LINE AND BYPASS VALVE SERVICE

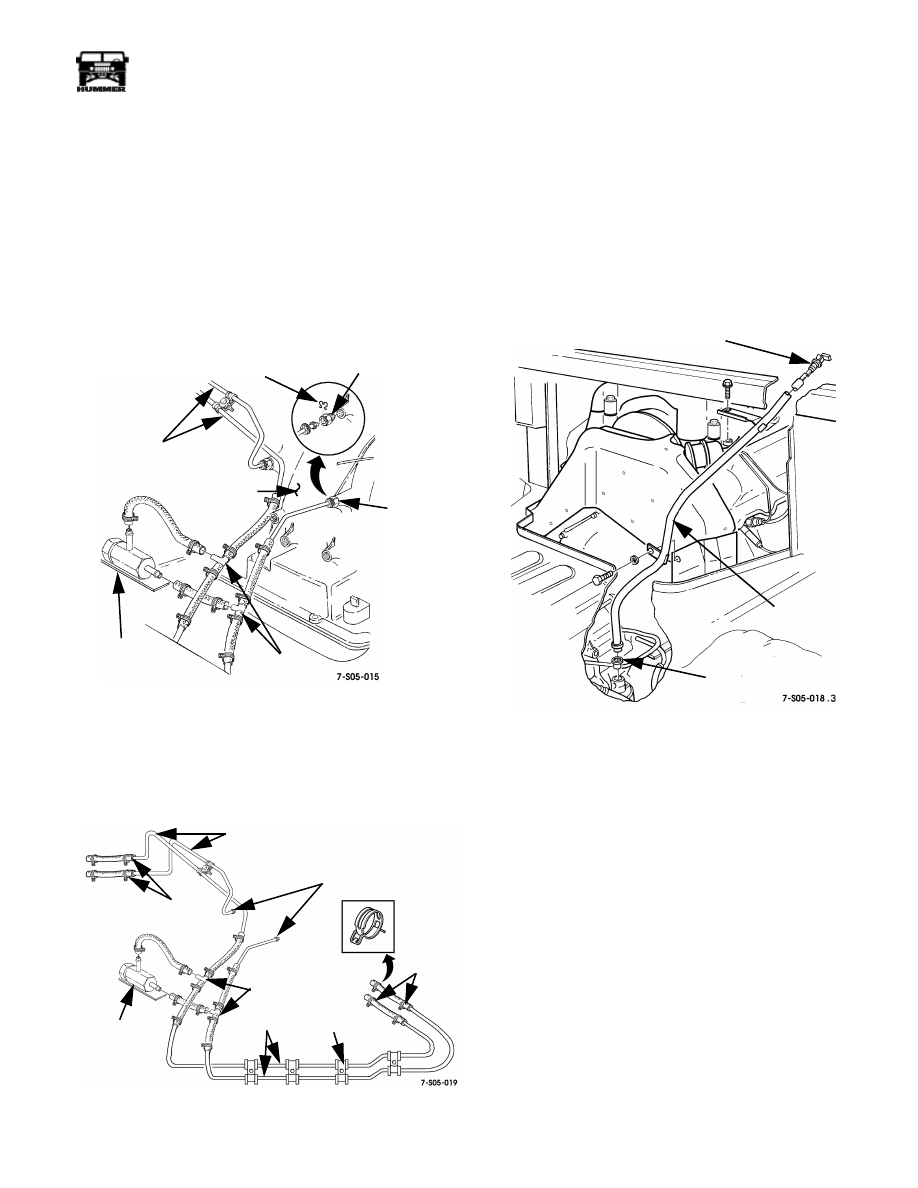

The transmission and transfer case oil cooler lines are replace-

able parts.

The lines consist of metal tubing interconnected by sections of

rubber hose (Figure 5-31). Each of the tube or hose sections

can be replaced separately. It is not necessary to replace com-

plete assemblies.

On Hummers, the cooler lines are fastened to the trans

mission with quick connect fittings. The flared end of the line

fits tightly into the adapter and is secured to the adapter with a

clip. The clip is then secured with a nylon retainer.

Figure 5-31: Bypass Valve Connections

A bypass valve is used in all Hummer vehicles (Figure 5-32).

The valve limits pressure buildup in the oil cooler and

lines.The bypass valve is attached to the passenger side cross-

member-to-frame bracket bolt. The cooler lines are attached to

body/chassis components with clamps (Figure 5-31).

Figure 5-32: Transmission/Transfer Case Oil Cooler

Line Connection

FILL TUBE REPLACEMENT

1. Remove dipstick from fill tube (Figure 5-33).

2. Remove console and engine cover.

3. Remove bolts attaching fill tube bracket to heat shield and

intake manifold (Figure 5-33).

4. Work fill tube out of transmission.

5. Remove fill tube seal from transmission. Discard if

damaged.

Figure 5-33: Fill Tube Attachment

6. Install fill tube seal in transmission.

7. Push fill tube into transmission.

8. Secure fill tube to the heat shield and intake manifold.

Tighten intake manifoldbolt to 31 lb-ft (42 N•m).

9. Install dipstick in fill tube.

10. Install engine cover and console.

11. Start engine and top off transmission fluid level if

required.

COOLER LINES

(TO TRANSFER CASE)

TRANSMISSION

BYPASS

VALVE

TEE

FITTINGS

NYLON

RETAINER CLIP

ADAPTER

QUICK

CONNECT

FITTING

TO

TRANSFER

CASE

TO

TRANSMISSION

METAL TUBE

TO

COOLER

BYPASS

VALVE

TEE

METAL

TUBE

CHASSIS

CLAMP

FILL TUBE

FILL TUBE SEAL

DIPSTICK

Section 5 Transmission/Trans er Case

5-134

Transmission/Transfer Case

___________________________________________

®

VENT LINE SERVICE

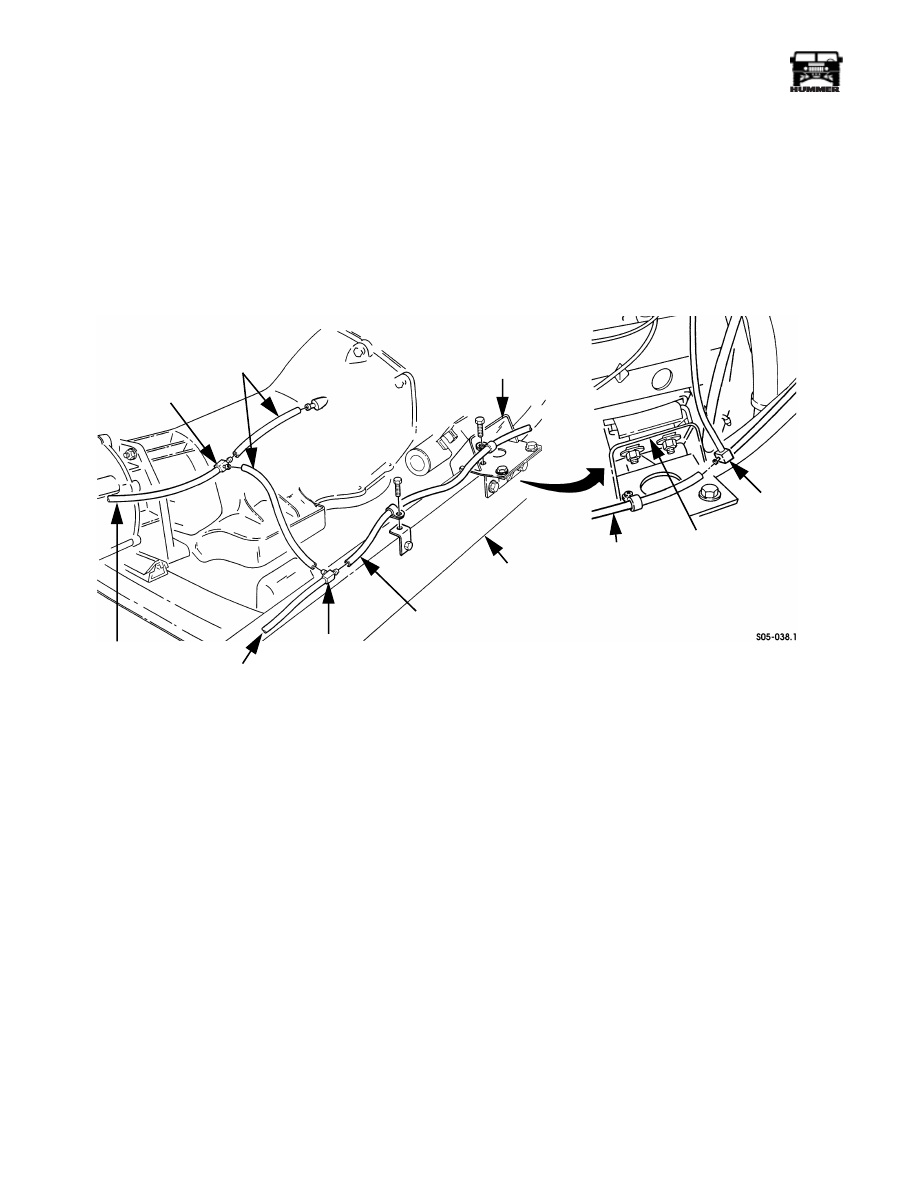

The transmission, transfer case, front and rear hubs, and winch

are all connected to a common vent line system (Figure 5-34).

The main vent lines are plastic while lines from the hubs to the

tee connections consist of rubber hoses. Brass tee fittings are

used at each vent line junction.

The transmission and transfer case vent lines and fittings are all

serviceable parts.

Vent lines or fittings can be replaced individually. It is not nec-

essary to replace all of the lines if only one section is damaged.

In cases where plastic vent line is supplied in bulk quantity, the

required length can be cut to size with a fine tooth hacksaw

blade. Diagonal pliers or similar cutting implements are not

recommended.

If a plastic line proves difficult to install, a small amount of liq-

uid soap can be used as a lubricant. Do not use any other prod-

uct to ease line assembly and installation.

Figure 5-34: Transmission Vent Line

TRANSMISSION

VENT LINES

TEE FITTING

LINE FROM

TRANSFER CASE

TEE FITTING

LINE FROM

REAR HUBS

FRAME RAIL

VENT LINE

TEE FITTING

ENGINE

MOUNTING

BRACKET

ENGINE

MOUNTING

BRACKET

LINE TO FRONT

HUBS AND WINCH

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст