Hummer H1 (2002+). Manual — part 260

____________________________________________________________

Accessories 13-33

®

05745159

Diagnostics

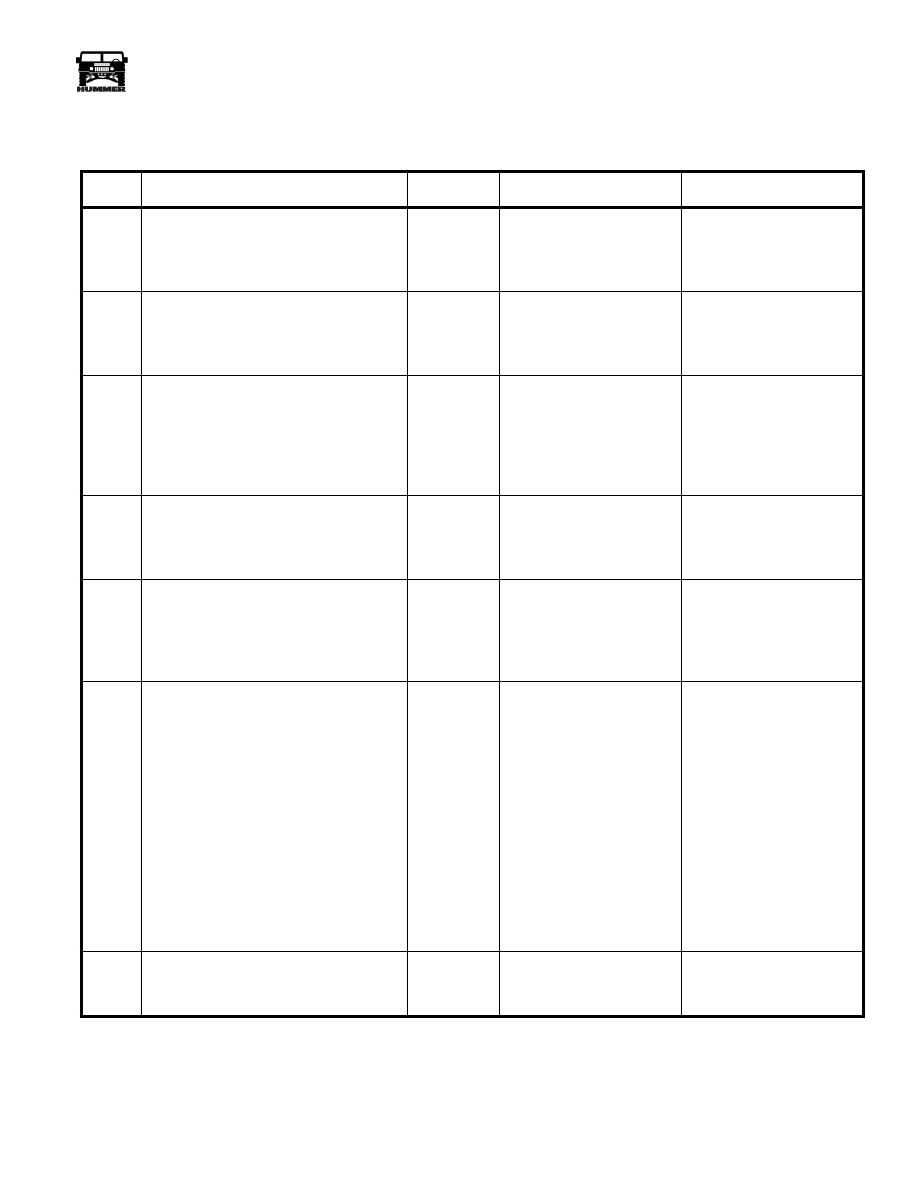

Table 1: Off Road Light Package Inoperative

STEP

ACTION

VALUE(S)

YES

NO

1

Turn high beam headlights on. Using a

DVOM, check for approximate battery

voltage at the white supply wire to the

dash switch. Is voltage present?

Approxi-

mate battery

+ voltage.

Go to step 2.

Replace/repair circuit

breaker/circuit of high

beam headlight circuit (CB

3-30A).

2

Turn high beam headlights and HID light

switch to the “ON” position. Check for

approximate battery voltage at terminal

86 of relay. Is voltage present?

Approxi-

mate battery

+ voltage.

Go to step 3.

Replace/repair switch/cir-

cuit between switch and

relay terminal 86 (blue

wire).

3

Check for approximate battery voltage at

terminal 87 of relay. Is voltage present?

Approxi-

mate battery

+ voltage.

Go to step 4.

Repair relay ground cir-

cuit (terminal 85), relay

power supply circuit with

30 amp in-line fuse (termi-

nal 30). If OK, replace

relay.

4

Check red wires at the ballast connectors

for voltage. Is voltage present?

Approxi-

mate battery

+ voltage.

Go to step 5.

Repair wiring between ter-

minal 87 and ballasts.

5

Using a DVOM, check resistance of the

ground circuit (black wire) between the

ballast connector and the ground stud at

the exterior fuse box. Is the resistance

less than.2

W

?

< .2

W

.

Go to step 6.

Repair ground circuit/con-

nections.

6

WARNING: Do not attempt to take

voltage readings at the light connec-

tors. Extreme high voltage (approxi-

mately 1250 volts) may be present

which could cause personal injury

or damage to equipment.

Turn HID light switch to the “OFF” posi-

tion before disconnecting light connec-

tors. If one light operates and one does

not, disconnect light connectors and con-

nect right light to left ballast and left light

to right ballast. Does the inoperative light

now shine and the other one not?,

Light “ON”

Replace the ballast con-

nected to the presently

inoperative light.

Replace the original inop-

erative light.

7

For additional diagnostic information

call KC HiLites customer service at 1-

800-528-0950.

13-34

Accessories

_____________________________________________________________

®

AIR RESTRICTION GAUGE

Removal

1.

Disconnect the hose from the air restriction gauge and the

hose barb in the air cleaner and remove the hose

(Figure 13-71).

2.

Remove two screws securing the gauge and bezel to the

mounting bracket and remove the gauge and bezel.

3.

Remove the hose barb from the air cleaner housing.

4.

Using a 1/8” drill bit, drill out two rivets securing the

mounting bracket to the A-frame and remove the

mounting bracket.

Figure 13-71: Air Filter Restriction Gauge Mounting

Installation

1.

Position the mounting bracket on the A-frame and secure

with two 1/8” pop rivets.

2.

Install the air restriction gauge from the engine side and

the bezel from the street side of the bracket and secure

with two screws through the bezel into the gauge.

3.

Use pipe thread sealant (Loctite 592) and install the brass

hose barb in the air cleaner housing.

4.

Install the hose from the gauge to the hose barb in the air

cleaner housing.

GAUGE

BRACKET

HOSE

BARB

A-FRAME

____________________________________________________________

Accessories 13-35

®

05745159

DUAL OIL FILTER

Removal

1.

Remove oil filters from oil filter adapter.

2.

Remove bolt, gasket and two small o-rings securing

adapter to engine block and remove adapter.

3.

Remove large o-ring, plug and two connectors from

adapter.

Installation

1.

Use pipe thread sealant (Loctite 592) on the threads of the

pipe plug and install the pipe plug in the oil filter adapter.

Remove any sealant that might have gotten into the oil

passage during the pipe plug installation (Figure 13-72).

2.

Install two oil filter connectors in the oil filter adapter and

tighten to 25 lb ft (34 Nm).

3.

Install the large o-ring in the groove on the oil filter

adapter.

4.

Install two small o-rings in the grooves in the oil filter

bolt.

5.

Install the oil filter adapter gasket onto the oil filter bolt

with the smooth side facing the bolt head.

6.

Lubricate all the o-rings and the oil filter gasket with clean

engine oil, insert the oil filter bolt through the oil filter

adapter and mount the adapter to the engine block.

Position the adapter for easy removal and replacement of

the oil filters and tighten the oil filter bolt to 50 lb ft (68

Nm).

7.

Lubricate the rubber sealing surface on both oil filters and

install the filters on the oil filter adapter. Tighten the oil

filters until the sealing surface contacts the adapter then

3/4 turn tighter.

8.

Refill the engine with fresh oil if previously drained, or

top up the oil level if not previously drained and run the

engine until warm while checking for leaks. Your oil

capacity should increase by approximately one quart

(2.8 ml).

Figure 13-72: Dual Oil Filter Assembly

BOLT

GASKET

O- RING

ADAPTER

PLUG

O- RING

CONNECTOR

OIL

FILTER

13-36

Accessories

_____________________________________________________________

®

DELCO COMPACT DISC CHANGER

REPLACEMENT

Removal

1.

Remove four screws retaining the CD changer bezel to the

console and remove bezel (See Figure 13-73).

2.

Remove four screws retaining the CD changer mounting

brackets to the console.

3.

Pull the CD changer out far enough to remove the wire

harness connector from the changer and cut the tie strap

securing the cable to the console harness (See Figure

13-74).

4.

If CD changer wire harness is to be replaced, radio must

be removed to gain access to harness connection at the

radio (Figure 13-75).

Figure 13-73: CD Changer Installation

Installation

1.

Connect wire harness connector to the side of the CD

changer and insert the changer into the console and the

front support bracket. Secure CD harness to the console

harness with a tie strap.

2.

Install four screws in the changer mount brackets and tighten.

3.

Install changer bezel with four screws and tighten.

Radio Removal

1.

Insert both radio removal keys in the holes in the face of

the radio to disengage locking clips from the mounting

sleeve.

2.

Pull radio out of mounting sleeve far enough to expose

wire connections and disconnect audio harness connector,

antenna cable and CD harness connector if equipped.

3.

Straighten locking tabs and pull mounting sleeve out of

face plate.

Radio Installation

1.

Install mounting sleeve through face plate and support

plate and bend locking tabs to secure.

2.

Connect harness connectors and antenna cable to radio.

3.

Insert radio into mounting sleeve, align rear mount pin

with upper support bracket and push in until locking clips

engage.

4.

Advise end user to reprogram theftlock.

Figure 13-74: CD Changer Harness Routing

Figure 13-75: Radio Removal

FRONT MOUNT BRACKET

BEZEL

CD CHANGER

CONSOLE

CD CHANGER

RADIO

CABLE

CD CHANGER

00-S12-009

LOCKING TAB

MOUNTING SLEEVE

RADIO REMOVAL KEYS

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст