Hummer H1 (2002+). Manual — part 62

____________________________________________

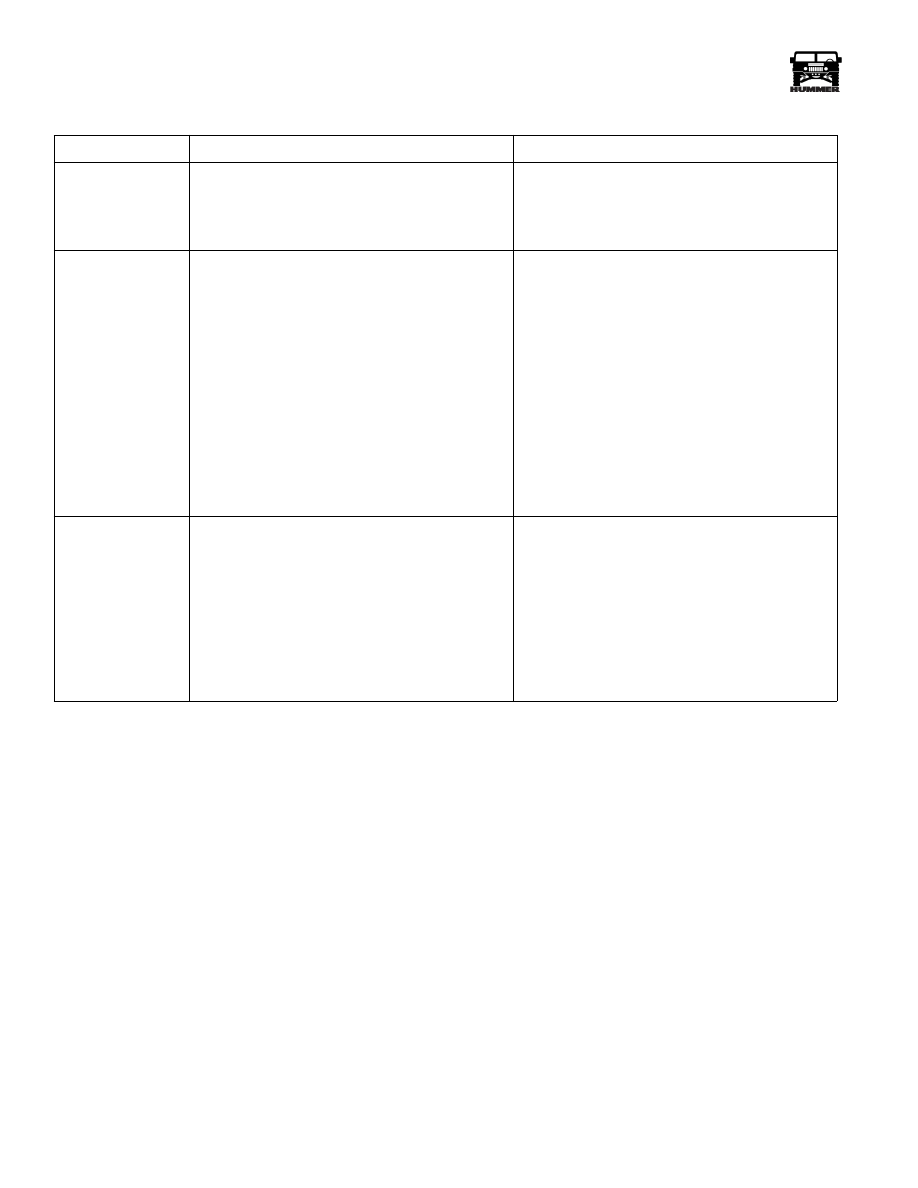

Transmission/Transfer Case 5-47

®

05745159

No Torque

(Drive) In Sec-

ond

1.

Worn or damaged intermediate sprag clutch.

1.

Replace transmission.

No Overrun

Braking In:

1.

Rear band or servo fault.

1.

Replace transmission.

2.

Main or output shaft damage.

2.

Replace transmission.

First (1)

3.

Lo roller or sprag clutch fault.

3.

Replace transmission.

-OR-

Second (2)

1.

Front band worn, wrong apply pin, or servo

problem.

1.

Replace transmission.

2.

Direct clutch housing fault.

2.

Replace transmission.

3.

Overrun clutch fault.

3.

Replace transmission.

4.

Rear gear set problem.

4.

Replace transmission.

Second and

Third Gear

Only In D

Range

1.

Shift solenoid A in off position:

• open voltage feed wire

• bad PCM ground

• solenoid seized

1.

Repair solenoid feed or PCM ground wire as

needed. Replace solenoid if stuck closed.

2.

1-2 shift valve fault.

2.

Replace valve body if 1-2 valve is scored or

spring has collapsed.

Converter

Clutch will Not

Release or Will

Not Apply

1.

PCM, or pulse width solenoid wiring fault

(short, open, ground).

1.

Locate and repair wiring problem as needed.

2.

Fluid contamination.

2.

Drain-change fluid and filter. flush cooler and

lines. Replace converter.

3.

Converter clutch solenoid fault.

3.

Test with scan tool and replace if inoperative.

4.

Fault with converter clutch, enable, or limit

valves.

4.

Remove oil pump and inspect valves (or pump

body) if damaged. Smooth minor burrs, nicks

with crocus cloth.

5.

PCM fault.

5.

Test with scan tool and replace if fault is

discovered.

6.

Converter clutch failure.

6.

Replace converter.

7.

Brake switch inoperative.

7.

Replace switch if open or shorted.

8.

Turbine shaft seal leak.

8.

Replace transmission.

Converter

Clutch Slips or

Soft Apply

1.

Low fluid level.

1.

Top off and check for leaks.

2.

Fluid contaminated or wrong fluid.

2.

Drain and change fluid and filter. Flush cooler

and lines.

3.

Turbine shaft seal leak.

3.

Replace seals.

4.

Oil pump bushing worn.

4.

Replace bushing.

5.

Low fluid pressure.

5.

Test pressure and replace transmission if

necessary.

6.

Converter clutch (pulse width) solenoid fault.

6.

Check solenoid wiring. If OK, replace

solenoid.

TRANSMISSION DIAGNOSIS GUIDE (Cont’d)

Problem

Potential Cause

Correction

5-48

Transmission/Transfer Case

_____________________________________________

®

Converter

Clutch Apply

Timing Incor-

rect

1.

Incorrect sensor input signal to PCM caused

by inoperative sensor.

1.

Test operation of all sensors with scan tool.

Replace failed sensors as needed.

2.

PCM problem.

2.

Test with scan tool. Repair wires or module as

required.

Harsh Shifts

(All Drive

Ranges)

1.

Pressure control solenoid stuck in off (de-

energized) position.

1.

Replace solenoid.

2.

Accumulator fault:

• piston spring broken

• piston seal damage

• piston spring missing

• cover bolts loose

• gasket damaged

2.

Overhaul accumulator.

3.

Valve body check ball missing or misposi-

tioned.

3.

Reposition check balls. Replace transmission

if any check balls are missing.

4.

Incorrect PCM calibration.

4.

Replace PCM.

Harsh Engage-

ment In Drive

and Reverse

1.

High idle speed.

2.

Line pressure too high:

• pressure control solenoid failed

• reverse/boost, or pressure regulator valve stuck

• accumulator spring or seal failure

• shift sensor failure

• missing valve body check ball

1.

Adjust idle or check PCM with scan tool on

turbo diesel.

2.

Test pressure control solenoid and sensors

with scan tool and replace as needed. Repair

accumulator spring, or pressure regulator

valves as needed.

TRANSMISSION DIAGNOSIS GUIDE (Cont’d)

Problem

Potential Cause

Correction

____________________________________________

Transmission/Transfer Case 5-49

®

05745159

DTC P0218 Transmission Fluid Over temperature

Circuit Description

The flow of transmission fluid starts in the transmission pan. It

is then drawn through the filter and transmission case into the

oil pump assembly. The oil pump assembly pressurizes the

fluid, which becomes the main supply line of fluid. This fluid

is directed to various components and hydraulic circuits within

the transmission. The pressure regulator valve receives this

fluid and directs it to the converter clutch shift valve. The con-

verter clutch shift valve directs hot fluid leaving the torque

converter or regulated converter feed fluid, through the cooler

line to the transmission oil cooler. The transmission oil cooler

is located above the radiator. The cooled fluid (center lube) is

returned to the transmission through the return cooler line and

into center lube port of the transmission. The Automatic Trans-

mission Fluid Temperature (TFT) Sensor, detects the fluid

temperature in the transmission pan.

If the Powertrain Control Module (PCM) detects a high TFT

for a long period of time, then DTC P0218 sets. DTC P0218 is

a type D DTC.

Conditions for Setting the DTC

• No TFT Sensor DTCs P0712 or P0713

• The TFT is greater than 130°C (266°F)

• All conditions are met for 410 seconds

Action Taken When the DTC Sets

• The PCM does not illuminate the Malfunction Indicator

Lamp (MIL).

• The PCM freezes shift adapts from being updated.

• DTC P0218 is stored in the PCM history.

Conditions for Clearing the DTC

• A scan tool can clear the DTC from the PCM history.

The PCM clears the DTC from the PCM history if the

vehicle completes 40 warm-up cycles without a failure

reported.

• The PCM cancels the DTC default actions when the

fault no longer exists and the ignition is off long enough

in order to power down the PCM.

Diagnostic Aids

• Inspect the cooling system fluid level and condition.

• Verify the customer’s driving habits, such as trailer tow-

ing, etc. .

• The scan tool Trans. Fluid Temp. (TFT) should rise

steadily during warm-up cycles then stabilize.

• DTC P0218 may set approximately 600 seconds after

DTC P0711 has set. Follow the diagnostic table for the

DTC P0711. Repairing the condition that set DTC

P0711 will likely eliminate DTC P0218.

• First diagnose and clear any engine DTCs or APP codes

that are present. Then inspect for any transmission

DTCs that may have reset.

Test Description

The numbers below refer to the step numbers on the diagnostic

table.

3. DTC P0711 may also set a DTC P0218. Go to the DTC

P0711 table for diagnosis.

4. This step inspects for air restrictions and loss of transmission

fluid flow, causing an extremely high TFT.

3-1-01

5-50

Transmission/Transfer Case

_____________________________________________

®

.

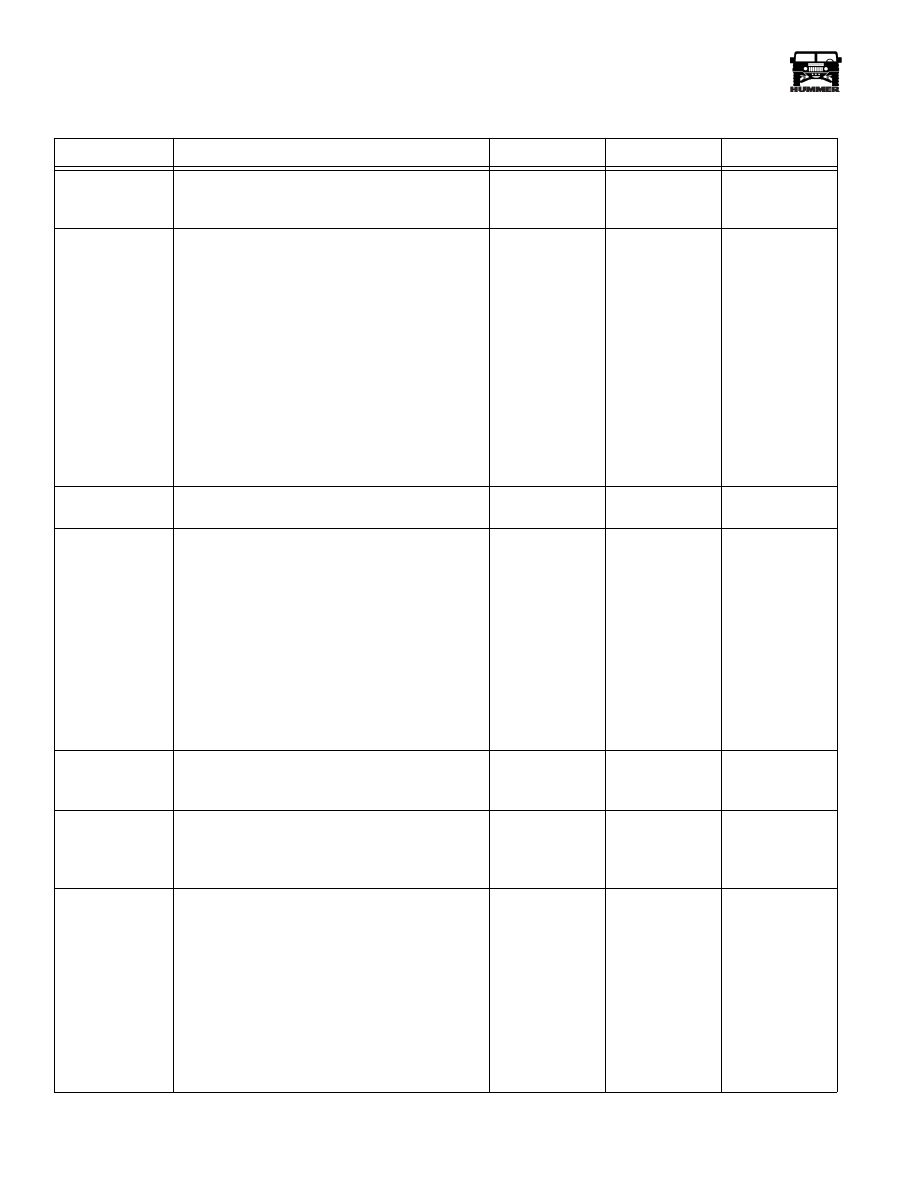

DTC P0218 Transmission Fluid Overtemperature

Step

Action

Value(s)

Yes

No

1

Was the Powertrain On-Board Diagnostic (OBD)

System Check performed?

Go to step 2

Go to Power-

train OBD Sys-

tem Check

2

Install the scan tool.

WIth the engine off, turn the ignition switch to the

run positon.

Impotant:

Before clearing the DTCs, use the

scan tool to record teh Freeze Frame and Failure

Records for reference. Using the Clear Info func-

tion erases the stored Failure Records from the

PCM.

Record the DTC Failure Records then clear the

DTC.

Perform the Transmission Fluid Checking Proce-

dure.

Was the Transmission Fluid Checking Proceedure

performed?

Go to step 3

Go to transmis-

sion fluid check-

ing procedure

3

Is DTC P0711 also set?

Go to diagnostic

aids

Go to step 4

4

Inspect the cooling system for the following con-

ditions:

• Air flow restrictions

• Air flow blockage

Inspect the transmission cooling system for the

following conditions:

• Air flow restrictions

• Air flow blockage

• Damaged cooler lines or hoses

• Low A/T fluid cooler flow. Refer to A/T cooler

flow test.

Was the condition found?

Go to step 7

Go to step 5

5

Perform the line pressure check procedure. Refer

to 4L80-E Line Pressure Check Procedure.

Was the condition found?

Go to step 7

Go to step 6

6

Inspect the torque converter stator for damage.

Refer to Torque Converter Clutch Diagnosis.

Was the condition found?

Go to step 7

Go to system

diagnosis table

“Transmission

Overheating”

7

In order to verify your repair, perform the follow-

ing procedure:

1.

Select DTC.

2.

Select Clear Info.

3.

Operate the vehicle under the following con-

ditons.

• Turn the ignition switch to the RUN position.

• The TFT must be less than 129°C (264°F) for at

least 5 seconds.

4.

Select Specific DTC. Enter P0218.

5.

Has the test run and passed?

System OK

Begin the diag-

nosis again. Go

to step 1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст