Hummer H1 (2002+). Manual — part 47

___________________________________________________________

Cooling System 4-3

®

05745159

quicker. At high temperatures, fluid viscosity decreases and

more fluid circulates through the cooler maintaining an even

operating temperature and a constant pressure in the cooler

(see Section 1 for service procedures).

A separate smaller oil cooler, mounted to the fan shroud, is

used to cool the power steering fluid.

Two fluid returns are used: one from the hydro-boost and one

from the power steering gear. Fluid flow through the hydro-

boost is never completely restricted during braking. The hydro-

boost incorporates a fluid return to release the hydraulic pres-

sures used when applying the brakes (see Section 8 for service

procedures).

ENGINE COOLING SYSTEM DIAGNOSIS AND

TROUBLESHOOTING

WARNING: Do not release surge tank cap when en-

gine is hot. Steam and/or coolant may cause serious in-

jury.

Loss of Coolant

1.

Pressurize system and check for leaks at all cooling sys-

tem hoses.

a.

Tighten loose clamps, fasteners, or fittings.

b.

Replace leaking hoses.

2.

Pressurize coolant system and check for leaks at water

pump or around cylinder heads. If any leakage is present,

replace cylinder head gaskets, cylinder heads, or water

pump.

3.

Check cylinder block for cracks. Replace if cylinder block

is cracked.

4.

Check expansion plugs and block heater for leaks.

5.

Check radiator and surge tank.

6.

Remove surge tank cap. With engine running, check for

excessive bubbles in surge tank that may indicate leaking

head gaskets or cracked cylinder heads. If bubbles are

present, remove cylinder heads and check for defective

head gaskets, cracked cylinder heads, or cracked cylinder

block. Replace cylinder heads if damaged. Replace engine

if cylinder block is cracked.

Engine Coolant Temperature Gauge Above

255°F (124°C), Engine Overheats

1.

Inspect for low coolant. Verify low coolant sensor is oper-

ating properly. (Refer to Electrical Troubleshooting, Sec-

tion 12).

2.

Inspect the drivebelt and pulleys for damage.

a. Replace any damaged parts.

b. Check belt tension. Replace if necessary.

WARNING: Use caution when testing thermostat. Hot

engine coolant will cause burns.

NOTE

: Off-road driving in extremely dusty conditions may

result in debris entrapment between the radiator and oil cooler.

Trapped debris may increase coolant temperature.

3.

Check for clogged or blocked radiator system. Clean and

flush as required. Cleaning requires the separation of the

oil cooler from the radiator and both units must be

thoroughly flushed with water and compressed air.

4.

Check thermostat for proper operation. Remove

thermostat and place thermostat in container of water

known to be 190°F (88°C). Observe valve. If valve does

not open, replace thermostat.

5.

Check radiator for bent fins. Straighten fins or replace

radiator if damaged beyond repair.

6.

Check operation of temperature gauge. Refer to Electrical

Troubleshooting (Section 12).

7.

Inspect fan blades for damage. Replace fan if damaged.

8.

Check fan clutch operation.

a.

Check for excessive bearing play. Using fingers only,

press tip of fan blade toward and away from engine.

Tip of blade total movement should not exceed 0.20

in. (5.1 mm). If movement is more, replace fan drive.

b.

With engine off and ambient temperature of 50°F (10°

C) or higher, fan should turn evenly with noticeable

drag. If fan turns hard, very easily, or with uneven

resistance, replace fan drive.

c.

Fan noise is sometimes evident under the following

normal conditions:

• When the drive is engaged for maximum cooling.

• During the first 15 seconds to one minute after start-

up, until the drive can redistribute the silicone fluid

back to its normal disengage operating condition

(after overnight settling).

Fan noise or an excessive roar will generally occur

continuously under all engine high speed conditions

(2400 RPM and up) if the drive assembly is locked-up

due to an internal failure. If the fan cannot be rotated

by hand or there is a rough, grating feel as the fan is

turned, replace the fan drive.

9.

Check for leaking or defective water pump. Replace

leaking or defective water pump.

WARNING: Do not release surge tank cap when engine

is hot. Steam and/or coolant may cause serious injury.

Fan Runs Continuously (Noisy)

1.

Check that all fan bolts are present and tightened to 45 lb-

ft (61 N•m).

2.

Perform steps 8a and 8b on preceding page.

3.

Check for fan cut off (disengagement).

4.

Observe fan drive disengagement after 1 to 1-1/2 minutes.

If fan speed does not drop and coolant temperature

remains below 190° F (88° C), replace fan drive.

4-4

Cooling System

____________________________________________________________

®

RADIATOR AND FAN SHROUD ASSEMBLY

SERVICE

Removal

1.

Remove hood (Section 10).

2.

Drain cooling system.

3.

Remove oil cooler (Section 1).

4.

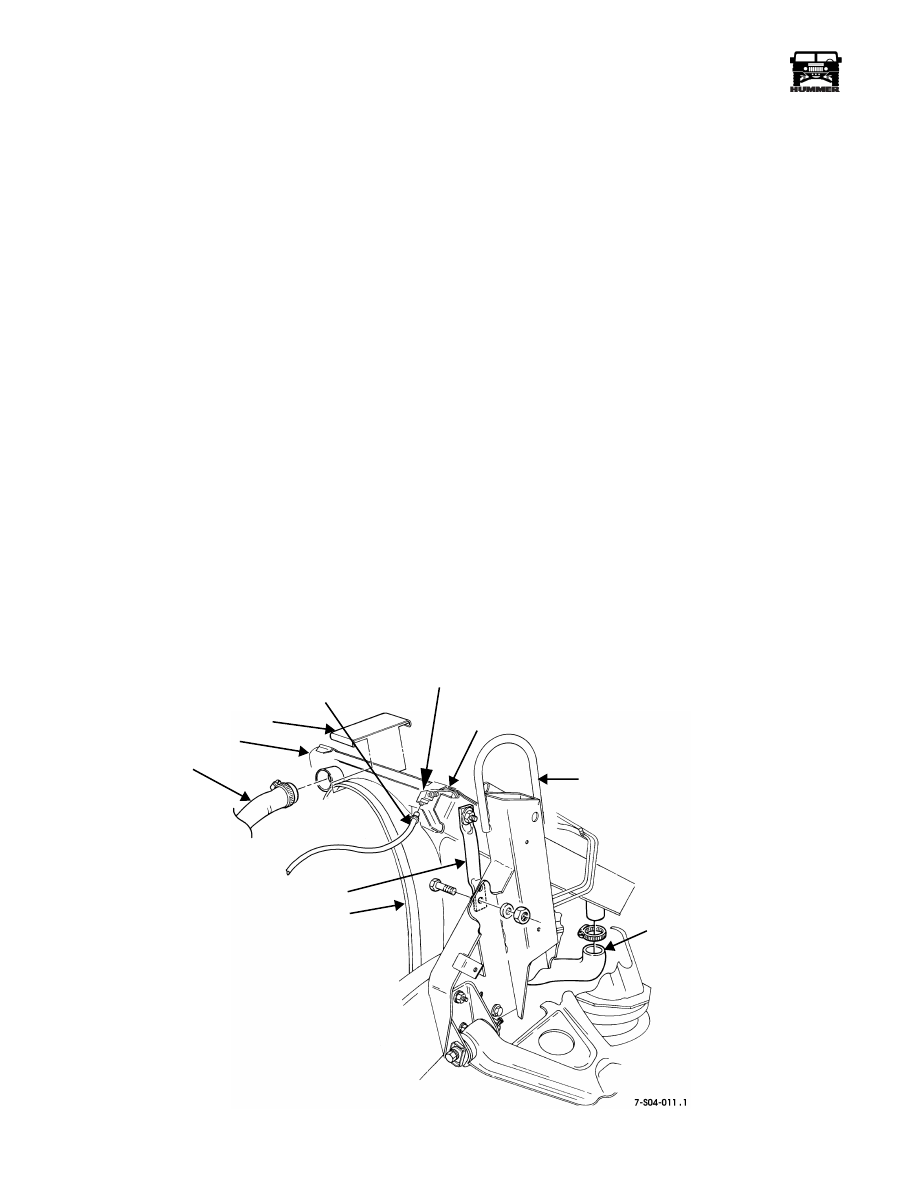

Disconnect upper hose from radiator (Figure 4-4).

5.

If equipped with air conditioner, discharge system and

remove condenser (Section 11).

6.

Remove power steering cooler mounting bolts and

position cooler aside.

7.

Disconnect ambient temperature switch, if equipped

(Section 11).

8.

Disconnect surge tank-to-radiator vent hose from adapter.

9.

Disconnect lower radiator hose from radiator.

10. Remove strap securing fan shroud to radiator.

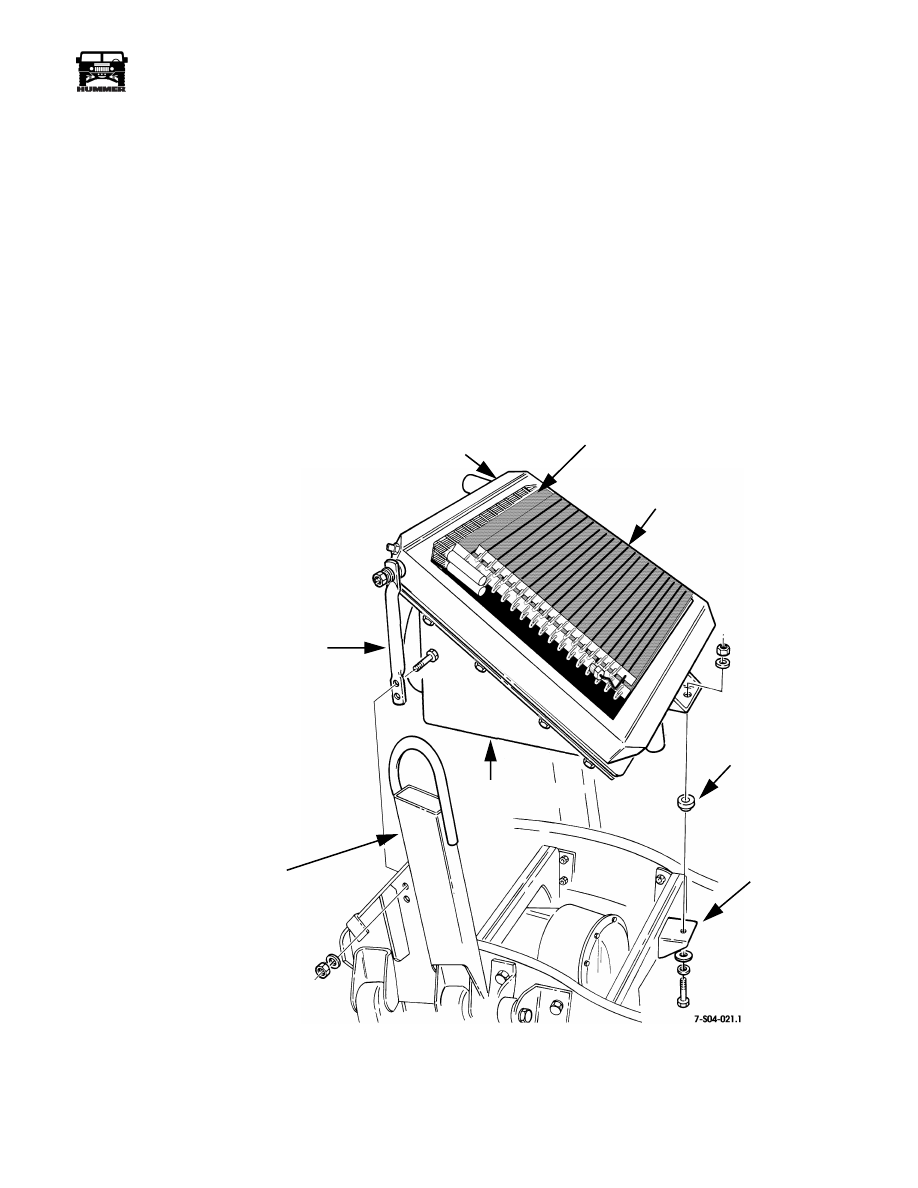

11. Remove lower mount from radiator and frame bracket

(Figure 4-5).

12. Detach rear support brackets from airlift brackets

(Figure 4-4).

13. Remove battery tray, and left splash shield. (Sections 10

and 12).

14. Remove the radiator from vehicle (Figure 4-5).

15. Remove retaining strips, and fan shroud from radiator.

16. Remove rear support brackets and insulators from

radiator.

Cleaning and Inspection

NOTE:

Clean all components, examine for wear or damage,

and replace if necessary.

1.

Remove debris embedded in radiator fins using water and

compressed air (Figure 4-5).

2.

Inspect radiator for breaks, punctures, cracks, or splits.

3.

Inspect adapters and fan shroud (Figure 4-4).

Installation

CAUTION:

To avoid equipment damage, upper edge of fan

shroud must align with radiator top tank seam to ensure

proper engine cooling.

NOTE:

Ensure fan shroud edge aligns with tank seam on radi-

ator.

1.

Secure fan shroud to radiator with retaining strips, lock-

washers, and bolts. Tighten bolts to 6 lb-ft (8 N•m)

(Figure 4-5).

2.

Secure rear support brackets and insulators to radiator

with washers and locknuts. Tighten locknuts to 26 lb-ft

(35 N•m).

3.

Align radiator with frame bracket, and rear support

brackets with airlift brackets (Figures 4-5 and 4-6).

4.

Fasten rear support brackets to air lift brackets with bolts,

washers, and locknuts. Do not tighten locknuts

(Figure 4-4).

Figure 4-4: Radiator and Fan Shroud Assembly Mounting

RADIATOR

UPPER RADIATOR HOSE

REAR SUPPORT BRACKET

LOWER RADIATOR HOSE

AIRLIFT BRACKET

ADAPTER

SURGE TANK-TO-RADIATOR VENT HOSE

FAN SHROUD

STRAP

HOSE FITTING WITH BLEED VALVE

___________________________________________________________

Cooling System 4-5

®

05745159

5.

Attach lower mount and radiator to frame bracket with

washers, and locknut. Do not tighten (Figure 4-5).

6.

Align fan shroud by sliding the radiator/shroud

assembly to maintain 1 1/2 ± 1/8 in. (38.1 ± 3 mm) from

edge of shroud ring and rear edge of fan. Measure at the

2, 4, 8, and 10 o’clock positions. The distance between

the top of the fan blade and fan shroud must not be less

than 1/4 in. (6 mm) at any position (Figure 4-6).

7.

Tighten rear support bracket locknuts to 26 lb-ft (35 N•m).

Tighten frame bracket bolt to 30 lb-ft (41 N•m)

(Figures 4-4 and 4-5).

8.

Install left splash shield and battery tray (Section 12).

9.

Install strap on radiator and shroud (Figure 4-4).

10. Connect upper and lower radiator hoses to radiator.

11. Use bolts to attach power steering cooler to brackets.

12. Connect ambient temperature switch, if equipped

(Section 11).

13. If equipped with air conditioner, install condenser and

charge system (Section 11).

14. Connect surge tank-to-radiator vent hose to adapter.

15. Fill cooling system (Section 4).

16. Install oil cooler (Section 1).

17. Start engine and check cooling system for leaks.

18. Install hood (Section 10).

Figure 4-5: Radiator and Fan Shroud Assembly Breakdown

RADIATOR

LOWER

MOUNT

FRAME

BRACKET

FAN SHROUD

REAR SUPPORT BRACKET

OIL COOLERS

CONDENSER

RIGHT SIDE

AIR LIFT BRACKET

4-6

Cooling System

____________________________________________________________

®

ENGINE COOLING SYSTEM SERVICE

Depressurizing/Draining

WARNING: To avoid injury, do not remove surge tank

filler cap before depressurizing cooling system when

engine temperature is above 190°F (88°C).

1.

If engine is hot, place a thick cloth over surge tank filler

cap. Turn counterclockwise to first stop to release internal

pressure (Figure 4-8).

2.

After pressure has vented, remove cap.

3.

Open drain valve and drain system (Figure 4-7).

4.

Close drain valve.

Replenishing

NOTE:

Ensure surge tank coolant level is 3/4 full before se-

curing filler cap.

1.

Ensure drain valve is closed and heater control valve is

open (Figure 4-7).

2.

Fill system with proper antifreeze solution (Table 4-1).

3.

Install filler cap on surge tank (Figure 4-8).

4.

Start engine and run at fast idle (1500 rpm) until engine

temperature reaches 190° F (88° C). Stop engine.

5.

Depressurize system.

6.

Fill with proper antifreeze solution until surge tank is 3/4

full (Table 4-1).

7.

Install filler cap on surge tank (Figure 4-8).

8.

Start engine and run at fast idle (1500 RPM) until engine

temperature reaches 190° F (88° C). Stop engine.

9.

Depressurize system. Use tester to ensure proper coolant

protection is provided.

10. Install filler cap on surge tank.

11. Start engine and check cooling system for leaks.

Figure 4-6: Fan Shroud Clearance Check Points

Figure 4-7: Drain Valve

Figure 4-8: Surge Tank and Filler Cap Location

10 O’CLOCK

2 O’CLOCK

8 O’CLOCK

4 O’CLOCK

FAN

SHROUD

POSITION

POSITION

POSITION

POSITION

DRAIN VALVE

SURGE TANK

FILLER CAP

SURGE

TANK

Expected Ambient

Temperature

Antifreeze/

Water Mixture

120° to -32° F

(49° to -36° C)

50% antifreeze/

50% water

Table 4-1: Antifreeze Preparation Guide

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст