Hummer H1 (2002+). Manual — part 195

________________________________________________________

Electrical System 12-7

®

05745159

CIRCUIT MAINTENANCE AND REPAIR

All electrical connections must be kept clean and tight. Loose

or corroded connections may cause a discharged battery, weak

starting, dim lights, or possible electrical system damage.

Wires must be replaced or repaired if insulation becomes

burned, cracked, or deteriorated. When replacing a wire, it is

important that the same gauge size wire be used. Refer to wir-

ing diagram for proper wire gauge sizes. Never replace a wire

with one of a smaller size or replace a fusible link wire with a

wire of a larger size. It should also be noted that fusible link

wire utilizes a special insulation covering. When replacing a

fusible link wire, the replacement wire should be the type in

accordance with SAE J156. Further, fusible link wire should

never be shortened or spliced. If a repair is necessary, entire

fusible link wire must be replaced with one of the proper gauge

size, length and insulation type.

Any wire repair must maintain the waterproof integrity of the

vehicle. Any splice located below the 30 in. (76 cm.) fording

level or in a high splash area must be waterproof and heavy

duty adhesive wall shrink tubing should be used as a minimum

in these areas.

Each harness or wire must be held securely in position to pre-

vent damage to insulation caused by vibrating and chafing.

NOTE:

Before performing any wire repair, disconnect battery

ground cable.

Ground Point legend

G1 - Engine ground-Intake Manifold

G2 - Ground Buss Exterior Fuse Box

G3 - Body Ground

G4 - Instrument Panel Ground Buss Interior

G5 - Frame Ground

Wiring Repair

Wiring harness and wires - All wires are of a specific insula-

tion color indicated on the wiring diagrams. Insulation color

helps to identify circuits and make correct connections. Insula-

tion colors and their abbreviations are as follows:

BK - Black

PK - Pink

BR - Brown

PP - Purple

DB - Dark Blue

RD - Red

DG - Dark Green

GY - Gray

TN - Tan

LB - Light Blue

WH - White

LG - Light Green

YL - Yellow

OR - Orange

Wire repair is very important for the continued, reliable opera-

tion of the vehicle. This repair must be done as described in the

following procedure:

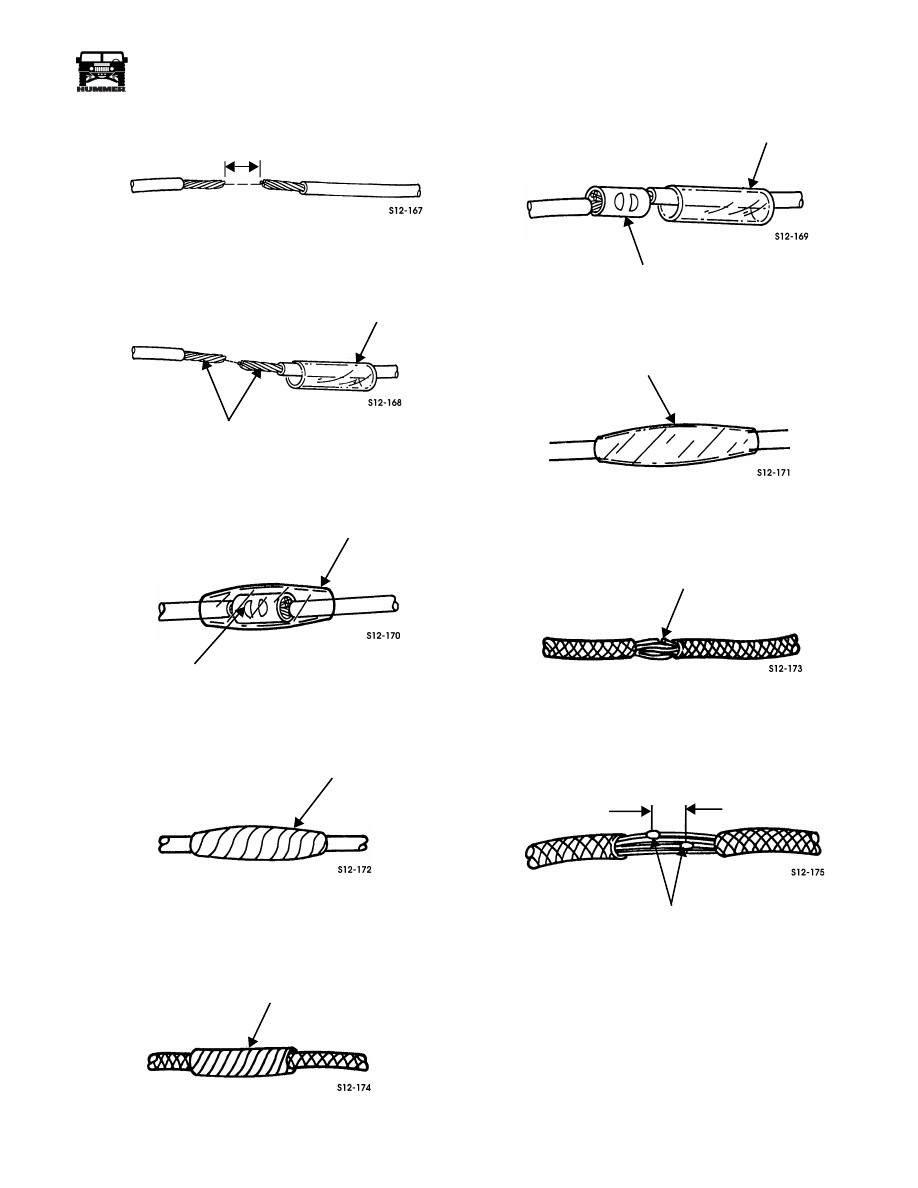

Single Wire Repair (Exposed)

1.

Remove damaged area, removing as little wire as possi-

ble (Figure 12-8).

NOTE:

Care should be exercised in stripping the wire insula-

tion to avoid cutting wire conductor strands.

2.

Strip wire ends to the appropriate length required by the

splice clip (Figure 12-9).

NOTE:

Heat shrink tubing is available in various diameters.

Typically the heat shrink tubing will shrink to approximately

one-half of its original diameter, therefore the tubing diameter

selected for the repair should not be greater than twice the wire

insulation diameter to ensure a proper seal.

3.

Slide heat shrink tubing over one of the wire ends

(Figure 12-10).

NOTE:

Splice clips are available for different wire gauge

sizes. Therefore, it is important to select the appropriate size

for the wire gauge being repaired.

4.

Slide both ends of wire into splice clip and crimp splice

clip to wire ends (Figure 12-11).

5.

Pull wires, by hand, in opposite directions to test the crimp

of the splice clip.

6.

Center heat shrink tubing over splice clip (Figure 12-12).

7.

Using a heat gun or equivalent heat source, apply heat to

heat shrink tubing until tubing conforms to splice clip and

wire insulation (Figure 12-13).

8.

After the splice cools, apply two layers of vinyl adhesive

electrical tape to complete the repair (Figure 12-14).

Single Wire Repair (In a Harness)

1.

Remove harness covering in the affected area

(Figure 12-15).

2.

Repair damaged wire using the exposed single wire repair

procedures. (Go to Step 1.)

3.

After completing the wire repair, apply two layers of vinyl

adhesive electrical tape over the affected area to complete

the repair (Figure 12-16).

Multiple Wire Repair (In a Harness)

NOTE:

Since more than one splice is required in this case,

stagger the wire splices such that they are no closer than 3 in.

(7.6 cm) from each other.

Repair affected wires using the single wire repair (in a harness)

procedures.

4-1-00

12-8

Electrical System

_________________________________________________________

®

FUSIBLE LINK MAINTENANCE

The following procedure covers the replacement of fusible

links encountered through circuit diagnosis.

1.

Disconnect battery ground cable.

2.

Carefully remove old fusible link from termination

(alternator, power stud, starter).

3.

Locate original wiring harness splice between fusible link

and wiring harness (Figure 12-7).

4.

Cut fusible link splice on harness side. Do not splice into

original fusible link; this may be weakened and cause a

premature failure and repeat problem.

5.

Identify the original fuse link size and length of fuse link

cut from vehicle.

6.

Matching the wire size, cut a length of fusible link wire to

the total length cut from vehicle in Step 4. Be sure to

compensate for any harness wire removed with original

wire. This will avoid overtight wiring that may become

separated with normal operation.

NOTE:

Fusible link is a wire with special insulation. It is im-

portant that replacement material be fusible link wire and it

should be labeled as such. The replacement fusible link should

be between six and nine inches long.

7.

Install a new crimp on connector of the same type and size

as the original lug or connector. Seal connection with low

temperature heat shrink tubing.

8.

Place a piece of heat shrink tubing onto the wire and

install a butt connector onto the fusible link.

9.

Install the fusible link by connecting it to the wiring

harness with the butt connector and heat shrink tubing.

10. Connect terminal end to original location, alternator,

power stud, or starter. Reconnect battery ground cable and

check circuit(s) affected for proper operation.

Figure 12-7: Fusible Link

WIRING

HARNESS

BUTT CONNECTOR

HEAT SHRINK

TUBING

FUSIBLE

LINK

TERMINALS

BURNT SECTION

ORIGINAL

SPLICE

CUT HERE TO

REPLACE LINK

S12-022.3

4-1-00

________________________________________________________

Electrical System 12-9

®

05745159

Figure 12-8: Damaged Wire

Figure 12-9: Heat Shrink Tubing

Figure 12-10: Splice Clip

Figure 12-11: Electrical Tape

Figure 12-12: Electrical Tape

Figure 12-13: Splice Clip

Figure 12-14: Heat Shrink Tubing

Figure 12-15: Damaged Wire

Figure 12-16: Multiple Wire Splice

DAMAGED AREA

STRIPPED WIRE ENDS

HEAT SHRINK TUBING

HEAT SHRINK TUBING

SPLICE CLIP

ELECTRICAL TAPE

ELECTRICAL TAPE

HEAT SHRINK TUBING

SPLICE CLIP

HEAT SHRINK TUBING

DAMAGED WIRE

3.0 INCH

MINIMUM

SPLICE

4-1-00

12-10

Electrical System

_______________________________________________________

®

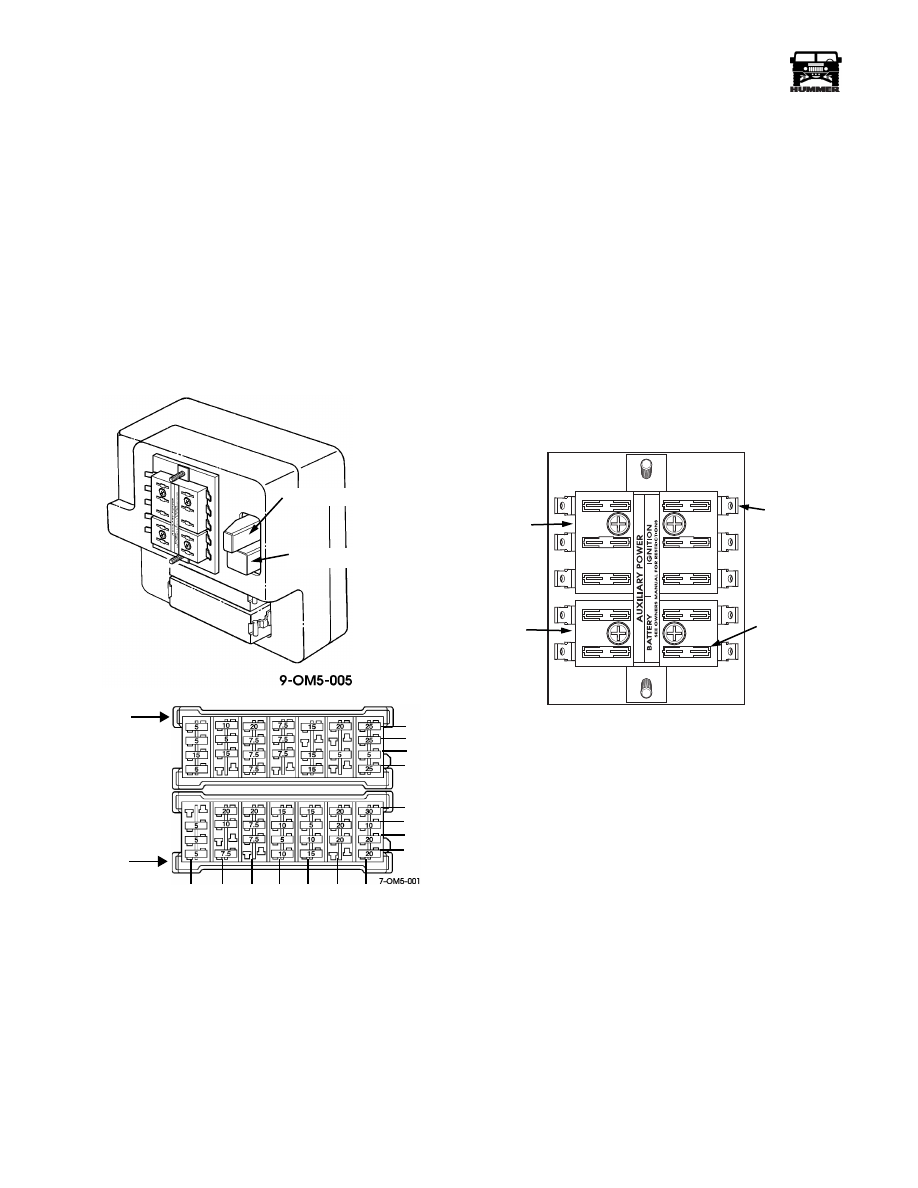

FUSE/RELAY LOCATION AND

IDENTIFICATION

Interior Fuse Box

The interior fuse box, is located under the instrument panel to

the left of the steering column. The fuse box is divided into two

mini-fuse junction blocks, relays, and a auxilliary power

point.The mini-fuse blocks may be accessed without removing

the main fuse box cover (Figure 12-17).

To access relays, the main fuse box cover must be removed.

Before removing any of the fuse box access covers, refer to the

illustrations and charts in this section for the location of specific

fuses, relays, and circuit breakers. Doing this will enable you to

go directly to the fuse or circuit breaker you want to inspect.

Figure 12-17: Interior Fuse Box and Mini Fuse Layout

Fuses and circuit breakers protect the vehicle's electrical sys-

tem from damage caused by overloading. An overloaded cir-

cuit breaker will switch the circuit on again, causing

intermittent operation. A blown fuse will permanently disable

the circuit until the fuse is replaced.

Whenever a fuse blows or a circuit breaker opens a circuit, all

electrical components using that circuit will not operate.

Therefore, during diagnosis of any of these electrical compo-

nents, check the appropriate fuses and circuit breakers for dam-

age (Figure 12-20).

In Line Fuses

Some fuses are placed in-line with the components they are

protecting, meaning they are not located in the fuse box but in

the actual wire suppling current to the device. The only inline

fuse used on the Hummer is in the power feed to the HVAC

high blower relay. This fuse is located on the passenger side of

the engine compartment inside a black plastic cover.

Auxiliary Power Point

An auxiliary power point is provided to ease installation of af-

termarket electrical accessories. The power point is divided

into 2 sections: Ignition and Battery. When a power supply is

needed, a fuse must be installed into one of the empty slots,

and a connection made to the adjacent terminal. The main sup-

ply circuits to both sections of the aux. power point are fused to

30 amps. Total amperage draw on either section should not ex-

ceed 30 amps.

Figure 12-18: Auxiliary Power Point

1

H

G

F

E

D

C

B

A

2

3

4

5

6

7

UPPER

LOWER

BLOCK

MINI-FUSE

MINI-FUSE

BLOCK

INTERIOR FUSE BOX

CTIS BUZZER

FLASHER

9-OM5-006

IGNITION

BATTERY

FUSE SLOT

TERMINAL

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст