Hummer H1 (2002+). Manual — part 196

______________________________________________________

Electrical System 12-11

®

05745159

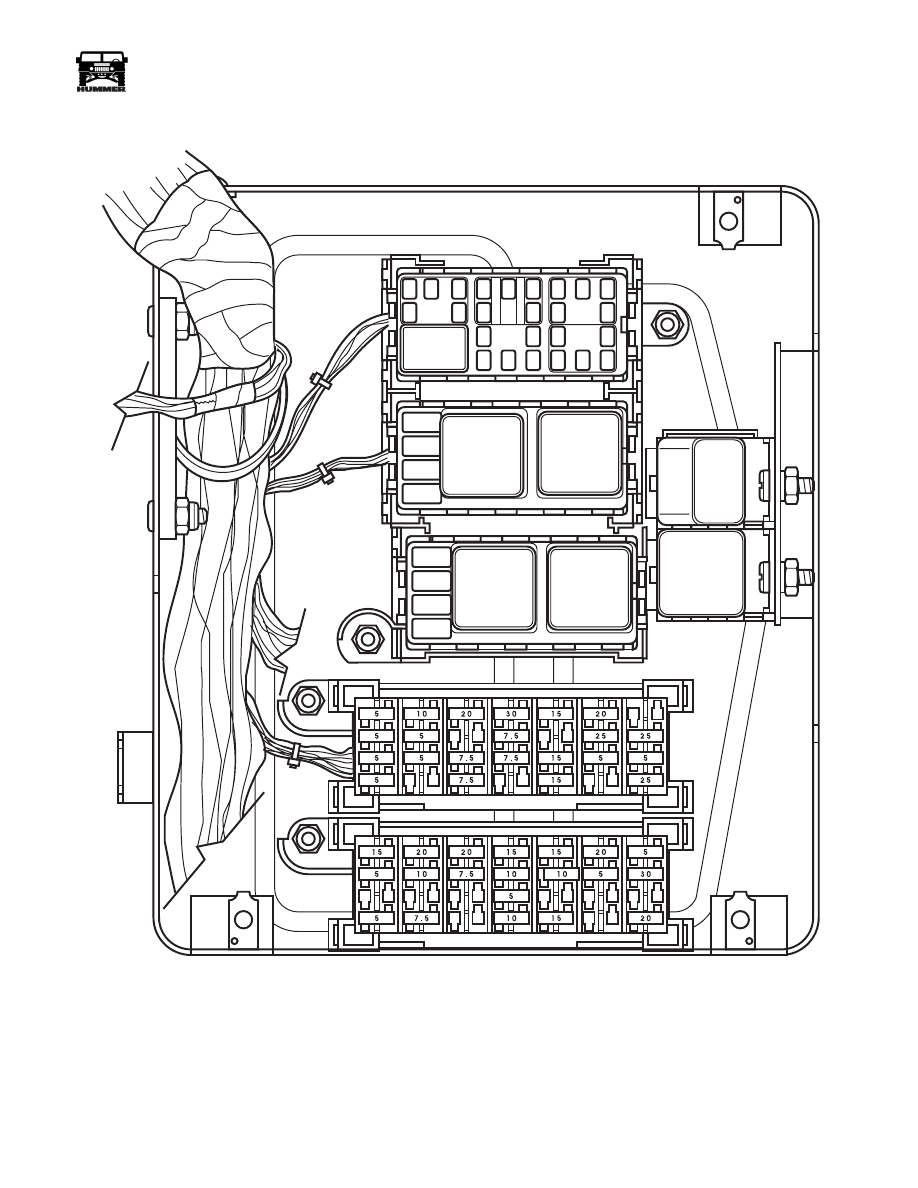

Figure 12-19: Relay Location (Interior Fuse Box)

9-S12-083

C

F

E

B

D

A

B

A

A

B

SIGNAL

FLASHER

CTIS

ALARM

MIRROR

CUTOUT

IGNITION

WIPER

POWER

WINDOW

REAR

WIPER

4-1-00

12-12

Electrical System

_______________________________________________________

®

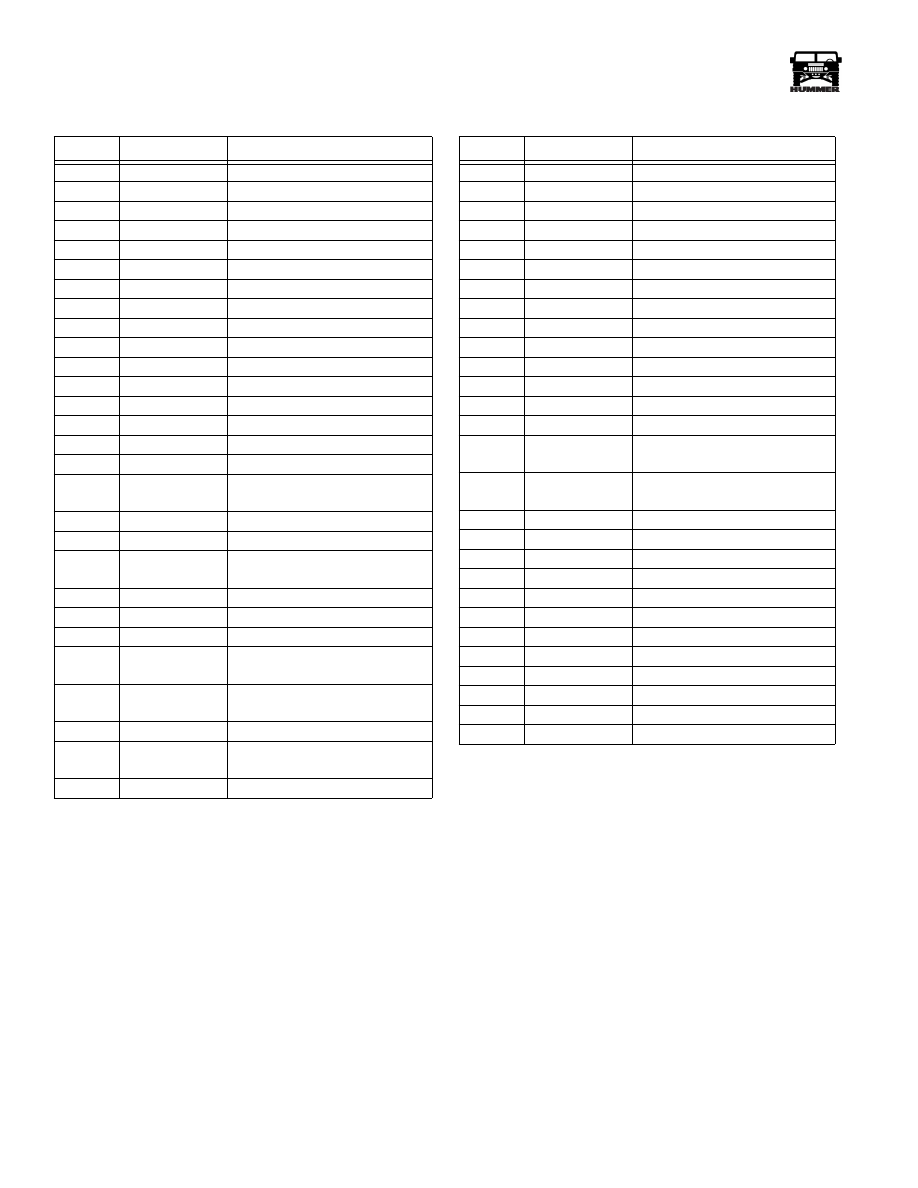

Upper Mini-Fuse Location

*May not be provided.

Lower Mini-Fuse Location

Figure 12-20: Mini Fuse Identification (Interior Fuse Box)

FUSE

AMPERAGE

CIRCUIT PROTECTED

1E

5

Spare Fuse

2E

–

Blank

3E

7.5

Spare Fuse

4E

–

Blank

5E

15

Spare Fuse

6E

–

Blank

7E

25

Spare Fuse

1F

5

Radio Lights

2F

5

Panel Lights Dimmer Module

3F

7.5

Front Parking/Running Lights

4F

7.5

Rear Parking/Running Lights

5F

15

Trailer Lights

6F

5

Underhood and Trouble Lights

7F

5

Light Circuit to Chime

1G

5

CTIS/Key Chime

2G

5

Power Windows

3G

30

Auxilliary Power Point (Igni-

tion)

4G

7.5

Radio Ignition

5G

–

Blank

6G

25

Rear Wiper/Washer (Slant

Back Only)

7G

25

Windshield Wiper/Washer

1H

5

DLC Power Terminal 16

2H

10

Radio Memory/Clock

3H

20

Power Door Locks/Power

Mirror/ Remote entry Battery

4H

30

Auxilliary Power Point (Bat-

tery)

5H

15

Dome/Courtesy Lights

6H

20

Auxiliary Power Outlet (con-

sole)

7H

25*

Trailer Brake Controller

FUSE

AMPERAGE

CIRCUIT PROTECTED

1A

5

Spare Fuse

2A

7.5

Spare Fuse

3A

–

Blank

4A

10

Spare Fuse

5A

15

Spare Fuse

6A

–

Blank

7A

20

Spare Fuse

1B

–

Blank

2B

–

Blank

3B

–

Blank

4B

5

Gauges/Indicator Lights/MIL

5B

Blank

6B

5

Transmission Brake Switch

7B

5

Remote entry igniton Feed

1C

5

Transmission Shifter Lock/

Heated Windshield

2C

10

A/C Clutch/Rear Defrost/

HVAC Ignition Feed Relay

3C

7.5

Backup Lights

4C

10

Turn Signals

5C

10

Cruise Control

6C

20

HVAC System

7C

30

HVAC Blower

1D

15

Radio Amplifier-Monsoon only

2D

20

PCM Battery/Fuel Lift Pump

3D

20

Cigar Lighters

4D

15

Stoplights

5D

15

Flashers

6D

–

Blank

7D

5

Compass Mirror Battery Feed

4-1-00

______________________________________________________

Electrical System 12-13

®

05745159

Exterior Fuse Box

Figure 12-21: Exterior Fuse Box

The exterior fuse box is located under the hood on the driver’s

side of the engine compartment. The exterior fuse box houses

mini and maxi fuses, circuit breakers, and relays which supply

power to many of the electrical components in the engine com-

partment. The exterior fuse box can be accessed by first

removing the left side cowl cover then removing the fuse box

cover itself. Fuse and relay locations are labled on the inside of

the cover. Spare mini fuses are located in the exterior fuse box

for convient replacement. A fuse puller is also provided to ease

fuse removal.

Figure 12-22: Mini-Fuse Identification

(Exterior Fuse Box)

Figure 12-23: Maxi-Fuse Identification (Exterior Fuse

Box)

Auxiliary Power Studs

The external fuse box provides 2 threaded studs for use as aux-

iliary power connections. Each stud is fused for up to 30 amps

with maxi-fuses located in the external fuse box. Both studs

provide battery power.

Figure 12-24: Auxiliary Power Studs

Ground Points

Two main grounding points are provided to ground vehicle

systems and add-on items. The main grounding stud is located

on the driver’s side of the engine compartment next to the exte-

rior fuse box. The second grounding point is located to the left

of the instrument panel on the interior of the vehicle.

NOTE: Never drill holes in the body to ground electrical

items, the corrosion resistance is compromised, and bad

grounding could result.

FUSE

AMPERAGE

CIRCUIT PROTECTED

1A

–

Blank

2A

10

PCM Ignition Feed

3A

20

Engine Ignition Feed

1B

–

Blank

2B

5

ABS Controller

3B

20

Engine Ignition Feed

1C

25

ABS Valve Relay

2C

30

Heated Windshield

3C

–

Blank

1D

20

Horn

2D

30

Heated Windshield

3D

–

Blank

9-OM5-004

ABS

VALVE

RELAY

HEATED

W/S

HEATED

W/S

RELAY

RELAY

CTIS

PUMP

RELAY

FUEL

PUMP

RELAY.

ABS

WNG.

RLY.

HORN

RELAY

A/C

RELAY

40A

20A CB

30A CB

30A CB

30A CB

30A

40A

40A

40A 30A

30A

#1

#2

#3

#4

#5

#6

#7

#8

#10

#9

25

20

30

30

5

10

20

20

BLANK

BLANK

BLANK

BLANK

5

EXTERIOR

FUSE BOX

FUSE

PULLER

MINI-FUSE LAYOUT

1

2

3

A

B

C

D

MAXI-FUSES

Fuse/

CB

Amperage

Circuit Protected

1

40A

Starter Circuit

2

20A CB

Parking Lights

3

30A CB

Headlights

4

30A CB

Rear Defrost

5

30A CB

Power Windows

6

30A

CTIS Compressor

7

40A

ABS/TT4 Hyd. Pump

8

40A

Ignition Switch Batt Feed

9

30A

Auxiliary power stud A

10

30A

Auxiliary power stud B

9-OM5-004

EXTERNAL FUSE BOX

POWER STUD “A”

POWER STUD “B”

PWR STD A

PWR STD B

MAXI-FUSES

4-1-00

12-14

Electrical System

_______________________________________________________

®

BATTERY CHARGING

General Information

A low charge or discharged battery can be recharged as long as

the cells are not shorted, sulfated, or damaged. Batteries can be

recharged quickly at 20 amp charge levels, or for longer peri-

ods at 10, 5, or 2 amps. A 5 amp charge is preferable.

The battery charger should be equipped with a polarity sensor

to avoid damage through incorrect hookup. Charger capacity

should range from 5 to 20 amps for slow and fast charge rates.

The time and amp rate of charge required will vary depending

on battery condition and temperature. Generally, it takes longer

to recharge a cold battery. State of charge will also affect

charging time as a partially discharged battery may only re-

quire one third the charge time of a fully discharged battery.

There are a number of safety precautions that must be observed

before charging a battery. The following precautions are neces-

sary to avoid personal injury:

Battery Charging Precautions

• Battery electrolyte contains sulfuric acid which can

cause severe burns. Avoid contact with electrolyte by

wearing protective gloves and a face shield. Flush skin

or eyes with water if contact occurs and seek medical

assistance immediately.

• Always wear eye and facial protection when connecting

charging equipment.

• Never attempt to charge a frozen battery. The case could

fracture at the first surge of current.

• Never charge a battery with a low electrolyte level. In-

ternal arcing and battery explosion could occur.

• Never exceed a 20 amp charge with a cold battery. Use a

lower (5-10 amp) rate until the battery warms up.

• Never use excessive charge rates. Reduce charge rate if

the battery becomes overly warm, or if a steady stream

of gas starts to exit the vents.

• Do not use high charge rates on a completely discharged

battery. Use low rates or a trickle charge only.

• Never allow sparks, or an open flame near a charging

battery. The charging process generates hydrogen gas

which is highly inflammable.

• Charge batteries in properly ventilated areas only. Do

not allow hydrogen gas to accumulate and concentrate

in poorly ventilated areas.

Charge Rate and Time

Charge rate will depend on battery temperature and degree of

discharge. Ideally, charging should not proceed until battery

temperature has reached 60°F (16°C). However, in cases where

a cold battery must be charged, start with a 5 amp rate and in-

crease it as battery temperature rises.

In the case of a fully discharged battery, a 24 hour trickle

charge of 1-2 amps is recommended. A 20 amp charge rate

should be used when a battery is only partially discharged.

Suggested charge times are outlined in the charge rate chart

(Figure 12-25). Note that the chart suggested times and rates

are for a battery at 70°F (21°C). Charge times will be greater if

battery temperature is below 55°F (13°C).

Figure 12-25: Charge Rate Chart

Battery Checking Procedures

Visual Inspection

Check for obvious damage, such as a cracked or broken case or

cover or overcharging of the electrical system that could permit

loss of electrolyte. If obvious damage is noted, replace the battery.

Load Test

Before proper testing, the battery must be in a fully charged

state to obtain an accurate test. Load testing requires the use of

battery side terminal adapters to ensure good connections. Do

not attempt to load test a side post battery by screwing bolts

into the terminals as connections.

NOTE: When load testing, batteries must be disconnected

from each other.

1.

Using a battery load tester, measure voltage across the battery

terminals. Normal battery voltage should be 12v or higher.

Recent cranking or load testing will lower the normal voltage.

If no cranking or load testing has been performed, and battery

voltage is below 12v, replace the battery.

2.

Connect battery load tester to the battery to be tested. If

battery has been recently charged, apply a 300 amp load

for 15 seconds to remove the surface charge. Skip this step

if the battery has not been charged.

3.

Wait 15 seconds for the battery to recover. Apply the

necessary load test for the battery being tested. The load

required should be listed on the battery label, if it is not,

use the cold crank amperage divided by 2. (300 cca/2=150

cca)This load should be applied for 30 seconds

4.

If the voltage does not drop below the minimum value, the

battery is good and should be returned to service. The

battery temperature must be estimated by feel and by the

temperature the battery has been exposed to for the

proceeding few hours. If the battery has been exposed to

temperatures below ambient, use the chart below to adjust

the minimum test voltage (Figure 12-26).

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст