Jaguar XJ (X350). Manual — part 1031

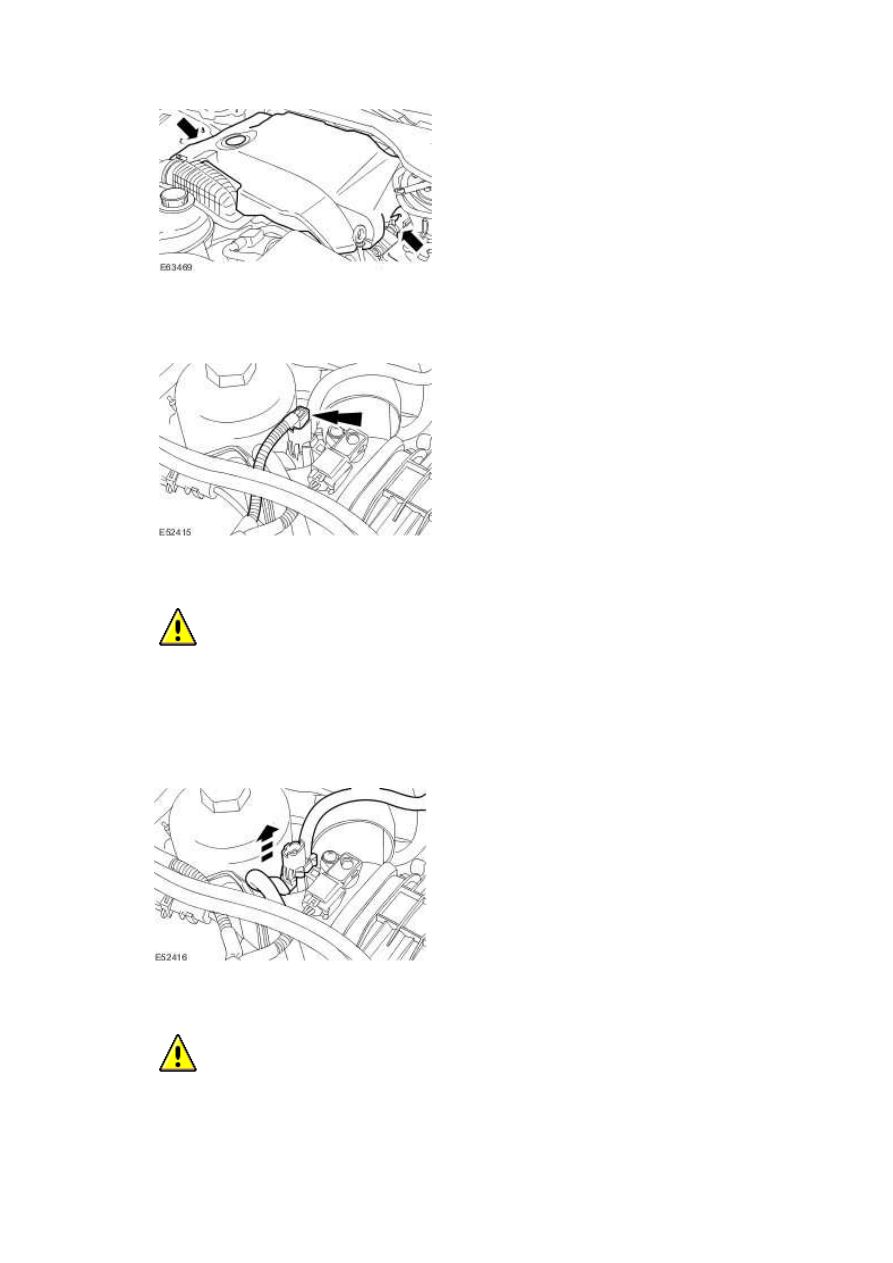

3 . Disconnect the fuel temperature sensor electrical connector.

4

.

CAUTION: Do not use excessive force when detaching the fuel return line from the

retaining bracket. Failure to follow this instruction may result in damage to the fuel return

line.

To gain access to the locking tangs, detach the fuel return line from the retaining bracket and

position to it one side.

5

.

CAUTION: Do not use excessive force when releasing the fuel temperature sensor

locking tangs. Failure to follow this instruction may result in damage to the fuel

temperature sensor.

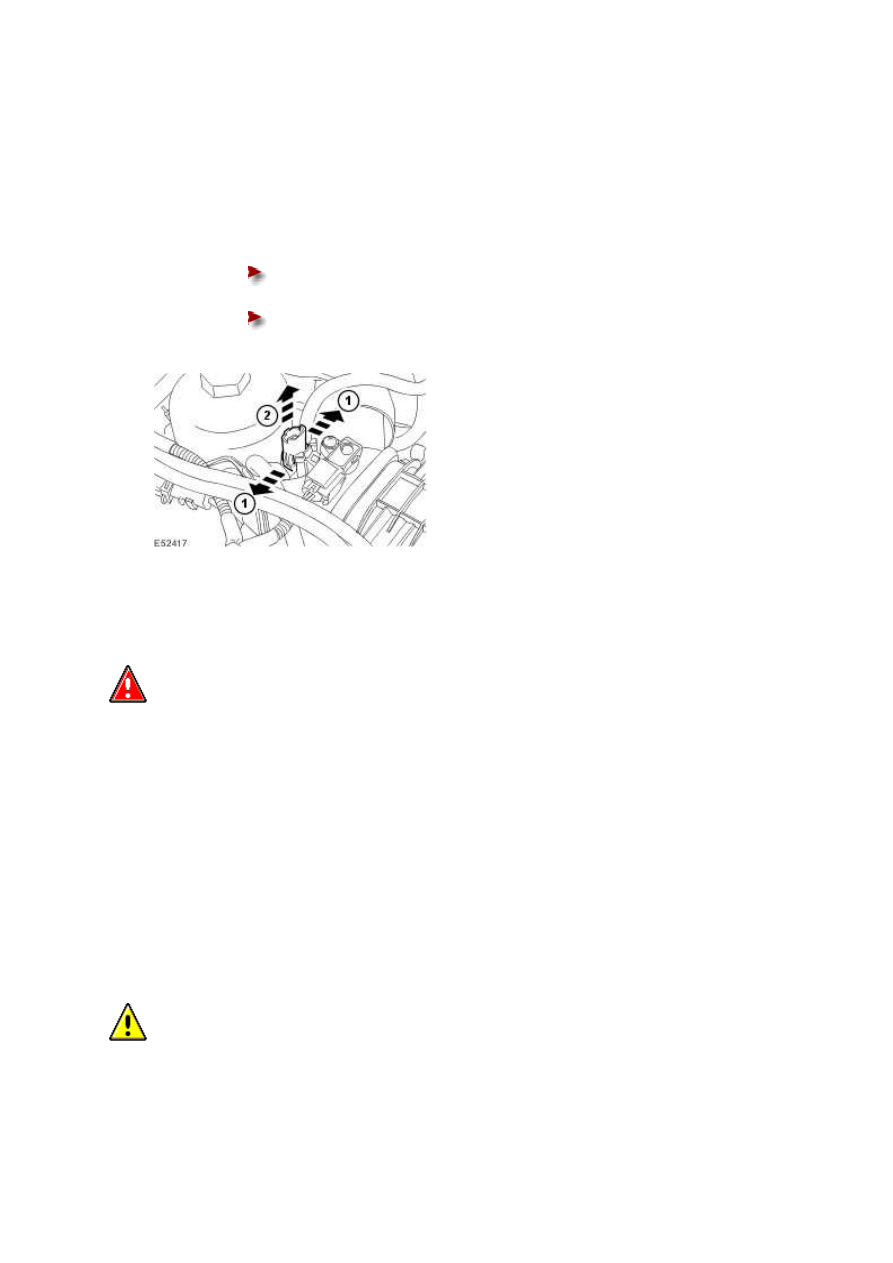

Remove the fuel temperature sensor.

1) Release the locking tangs.

2) Remove the fuel temperature sensor from the fuel return line.

Install a clean blanking caps to the fuel return line.

Discard the O-ring seal.

Installation

WARNING: Do not smoke or carry lighted tobacco or open flame of any type when working

on or near any fuel related components. Highly flammable mixtures are always present and may

ignite. Failure to follow these instructions may result in personal injury. This procedure involves

fuel handling. Be prepared for fuel spillage at all times and always observe fuel handling

precautions. Failure to follow these instructions may result in personal injury. Do not carry out any

repairs to the fuel injection system with the engine running. The fuel pressure within the system

can be as high as 1600 bar. Failure to follow this instruction may result in personal injury. Do not

carry out any repairs to the fuel injection system without checking that the fuel pressure has

dropped to zero. Failure to follow this instruction may result in personal injury. Wait at least one

minute after the engine stops before commencing any repair to the fuel injection system. Failure

to follow this instruction may result in personal injury. CAUTIONS:

CAUTION: Make sure the workshop area in which the vehicle is being worked on is as clean

and as dust free as possible. Foreign matter from work on clutches, brakes or from machining or

welding operations can contaminate the fuel system and may result in later malfunction. Always

carry out the cleaning process before carrying out any repairs to the fuel injection system

components. Failure to follow this instruction may result in foreign matter ingress to the fuel

www.

injection system. Diesel fuel injection equipment is manufactured to very precise tolerances and

fine clearances. It is therefore essential that absolute cleanliness is observed when working with

these components. Always install blanking caps to any open orifices or lines.

NOTE:

Install a new O-ring seal and fuel temperature sensor.

1 . NOTE:

Remove and discard the blanking caps from the fuel return line.

To install, reverse the removal procedure.

Intake Air Temperature (IAT) Sensor

(18.30.52)

Removal

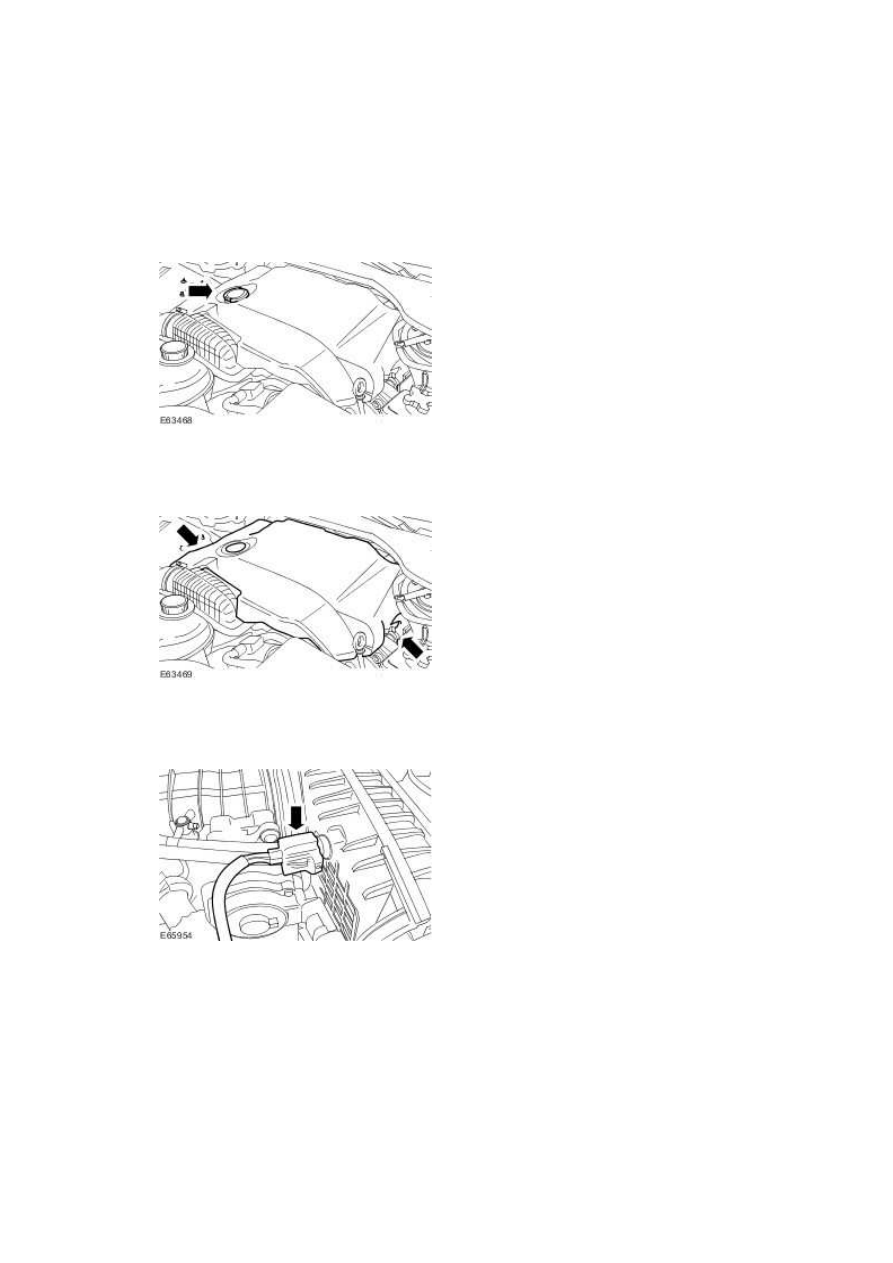

1 . Remove the oil filler cap.

2 . Remove the engine cover.

3 . Disconnect the intake air temperature (IAT) sensor electrical connector.

4 . Remove the IAT sensor.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст