Jaguar XJ (X350). Manual — part 713

4

—

Turbocharger

5

Turbocharger retaining nuts

6

Exhaust manifold stud (note orientation of stud)

Variable Vane Turbocharger

The engine is fitted with twin variable vane Turbochargers, electronically controlled, one to each

bank. The turbochargers are fixed to the exhaust manifold by a three hole flange. The turbocharger

consists of two elements, a turbine and a compressor both installed on a single shaft.

The turbocharger bearings are supplied with oil from the engine.

The turbine uses the flow of the exhaust gas to drive the compressor. The compressor draws air

through the air cleaner and forces it into the intake manifold.

Principles of Operation - Variable vane turbocharger

The turbocharger is designed to improve engine induction and engine performance. The list below

details the concerns relating to turbocharger performance.

High engine speed produces excessive turbine speed and therefore creates excessive

turbocharger boost pressure.

Low engine speed does not produce sufficient turbine speed and therefore not enough

turbocharger boost pressure is achieved.

The turbocharger does not have a wastegate control valve. Instead, it has variable turbocharger

vanes which are located in the turbocharger turbine housing and these direct the air flow into the

turbocharger turbine. The turbocharger vanes act as the control for the turbocharger boost pressure.

The turbocharger produces its full turbocharger boost pressure over the entire engine speed range,

not just at high engine speed. This is achieved through the adjustment of the vanes and the resulting

change in the flow of the exhaust gas.

The speed of the exhaust gas flow within the turbocharger is increased independent of engine speed

by varying the intake cross section in front of the turbocharger turbine. This is achieved by adjusting

the angle of the vanes controlling the air flow into the turbocharger turbine and this then drives the

turbocharger turbine faster. The higher turbocharger speed produces a high turbocharger boost

pressure at all engine speeds.

The engine control module (ECM) controls the turbocharger vanes by means of an electronic vane

adjustment solenoid attached to the turbocharger.

Regulation at Low Engine Speed

At low engine speeds the ECM operates the vane adjustment solenoid. The vane adjustment solenoid

moves the adjusting ring so that the vanes are set at a shallow angle. The shallow intake cross section

this creates for the stream of exhaust gas allows the turbocharger boost pressure to build up rapidly

and easily at low engine speeds.

Regulation at Moderate Engine Speed

As the engine speed increases and the quantity of exhaust gas increases, the vane adjustment

solenoid moves the adjusting ring so that the vanes are set at a steeper angle. The steeper angle

opens the intake cross section effectively reducing the gas flow, and turbine speed, while

maintaining constant turbocharger boost pressure.

Regulation at Maximum Engine Speed

As the engine speed increases the intake cross section in front of the turbocharger turbine is

continuously enlarged. The turbine speed and hence the quantity of the air supplied to the engine, is

adjusted to suit the engine speed. This means that the turbocharger boost pressure remains

optimized over all engine speeds.

The maximum position of the turbocharger vanes (maximum opening cross section) is also an

emergency position, in the event of an electrical concern. This lowers the chance of engine damage

due to excessive boost in the event of a turbocharger control concern.

www.

Diagnosis and testing

Turbocharger

Principle of operation

The turbochargers used on the 2.7L diesel engine are variable geometry units, which means that the

amount of boost generated can be varied according to the engine load, not just the engine speed.

The vane angles are varied by solenoids mounted on the turbochargers.

The solenoid operation is governed by the engine control module in response to engine load and

conditions, ensuring the correct boost pressure for the prevailing conditions.

For information on the operation of the system,

Turbocharger

Overview

There are changes to the engine management system (EMS) for 2006 my, the most obvious of which

will be the change to 7-digit diagnostic trouble codes (DTCs) from the familiar 5-digit.

Refer to the DTC index in this section for guidance on how to use these codes with the Jaguar

approved diagnostic system or a scan tool.

Inspection and Verification

WARNING: The following tests may involve working in close proximity to hot components.

Make sure adequate protection is used. Failure to follow this instruction may result in personal

injury.

WARNING: The turbochargers can continue to rotate after the engine has stopped. Do not

attempt to check the turbochargers until one minute has elapsed since the engine was switched

off. Failure to follow this instruction may result in personal injury.

NOTE:

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If diagnostic trouble codes (DTCs) are recorded and the symptom is not present when

performing the pinpoint tests, an intermittent concern may be the cause. Always check for loose

connections and corroded terminals.

NOTE:

This section contains references to Parameter Identifiers (PIDs). Where the Jaguar approved

diagnostic system is not available, a scantool may be used to access these PIDs, all of which give

information, and some of which can be used to both read information and to activate

components. The format of the information may vary, depending on the tool used.

1 . Verify the customer concern.

2 . Visually inspect for obvious signs of mechanical or electrical damage.

Mechanical

Electrical

Intake air system

Hose(s)/hose connections

Turbocharger(s)

General engine condition.

Circuit(s)

Turbocharger actuator(s)

Engine control module (ECM)

Electrical connections and harnesses to the turbocharger(s)

3 . If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4 . If the cause is not visually evident use the Jaguar approved diagnostic system or a scan tool to

retrieve the fault codes before proceeding to the DTC index, or the symptom chart if no DTCs are set.

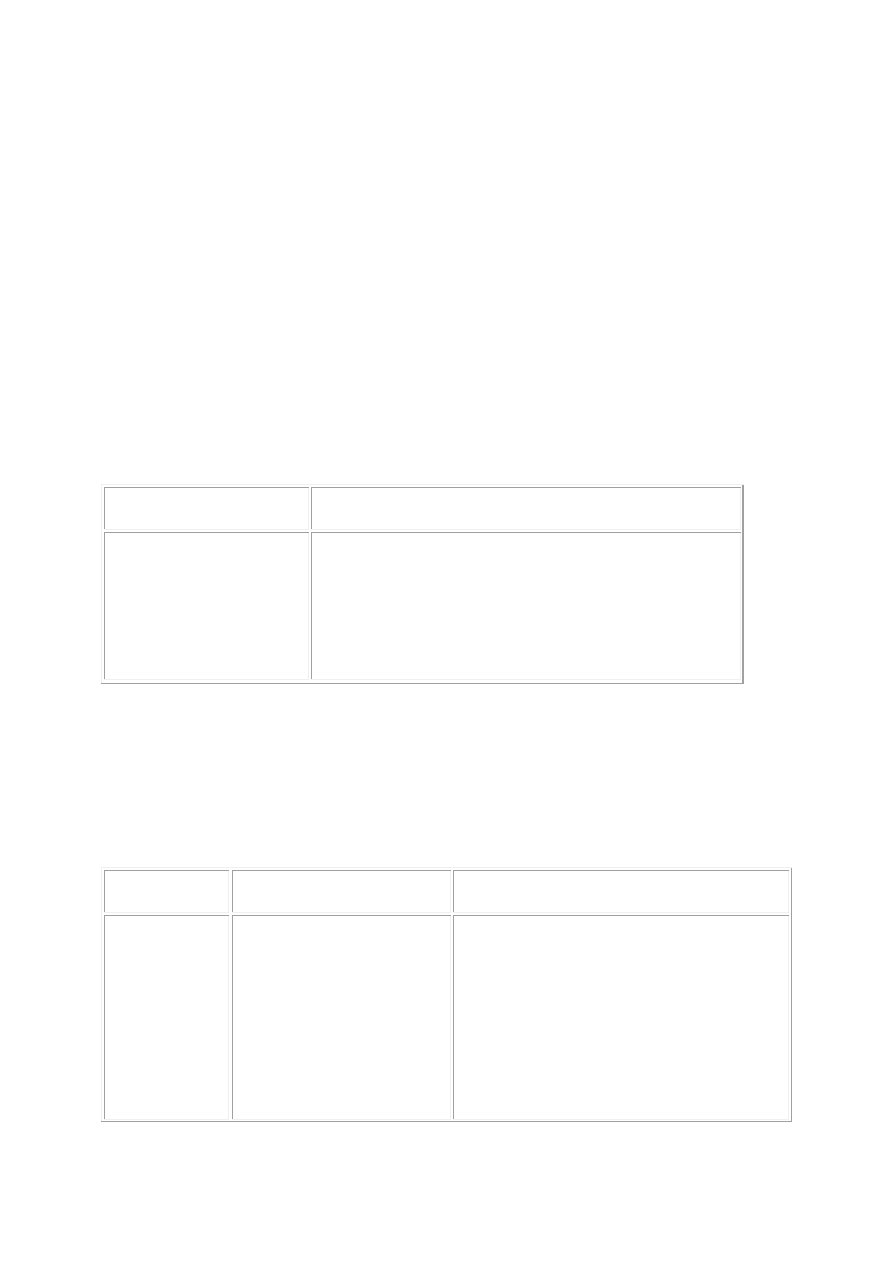

Symptom chart

Symptom

Possible source

Action

Poor

performance

Low/Contaminated fuel

Restricted air intake system

General engine condition

ECM failure

Check the fuel level and condition,

Fuel Charging and Controls Check the air intake

for restriction,

Intake Air Distribution and Filtering Check the

engine condition, compressions, etc,

Engine - 2.7L Diesel Check for DTCs. Refer to the

warranty policy and procedures manual if an

ECM is suspect.

NOTE:

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст