Jaguar XJ (X350). Manual — part 17

Control modules may only be used on the vehicle to which they were originally fitted. Do not

attempt to use or test a control module on any other vehicle.

Functional Test

On completion of a maintenance procedure, a thorough test should be carried out, to make sure that

the relevant vehicle systems are working correctly.

Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have

been removed, blank off any exposed openings using grease-proof paper and masking tape.

Immediately seal fuel, oil and hydraulic lines when separated, using plastic caps or plugs, to prevent

loss of fluid and the entry of dirt. Close the open ends of oilways, exposed by component removal,

with tapered hardwood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a separate container for each component and its associated parts.

Before dismantling a component, clean it thoroughly with a recommended cleaning agent; check that

the agent will not damage any of the materials within the component. Clean the bench and obtain

marking materials, labels, containers and locking wire before dismantling a component.

Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake,

fuel or hydraulic systems are being worked on. A particle of dirt or a fragment of cloth could cause a

dangerous malfunction if trapped in these systems. Clean all tapped holes, crevices, oilways and fluid

passages with compressed air. Do not permit compressed air to enter an open wound. Always use

eye protection when using compressed air.

Make sure that any O-rings used for sealing are correctly refitted or renewed if disturbed. Mark

mating parts to make sure that they are replaced as dismantled. Whenever possible use marking

materials which avoid the possibilities of causing distortion or the initiation of cracks, which could

occur if a center punch or scriber were used. Wire together mating parts where necessary to prevent

accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and

to parts requiring further inspection before being passed for reassembly. Place labelled parts and

other parts for rebuild in separate containers. Do not discard a part which is due for renewal until it

has been compared with the new part, to make sure that the correct part has been obtained.

Inspection

Before inspecting a component for wear or performing a dimensional check, make sure that it is

absolutely clean; a slight smear of grease can conceal an incipient failure. When a component is to be

checked dimensionally against figures quoted for it, use the correct equipment (surface plates,

micrometers, dial gauges etc.) in serviceable condition. The use of makeshift equipment can be

dangerous. Reject a component if its dimensions are outside the limits quoted, or if damage is

Use of Control Modules

apparent. A part may be refitted if its critical dimension is exactly to the limit size and it is otherwise

satisfactory. Use Plastigauge 12 Type PG-1 for checking bearing surface clearance, e.g. big end

bearing shell to crank journal. Instructions for the use of Plastigauge and a scale giving bearing

clearances in steps of 0,0025 mm (0.0001 in) are supplied with the package.

On-Board Diagnostics (OBD)

This vehicle uses programmed electronic control systems to provide engine management and

emission regulation, automatic transmission operation and anti-lock braking control. These control

systems are integral with the On-Board Diagnostics (OBD) facility which is used in conjunction with

either the Jaguar approved diagnostic system or the more restricted scan tools.

The OBD information in this manual provides diagnostic and rectification procedures for emission

related electrical and mechanical systems. The information is intended to facilitate fault diagnosis

and the subsequent rectification of the vehicle without recourse to the Jaguar approved diagnostic

system.

The manual covers the following OBD topics:

•

General Information

•

Engine Management System

•

Automatic Transmission

•

Anti-lock Braking System

Each section comprises one or more of the following sub-sections as required.

The Description and Operation sub-section includes:

•

A general illustration and parts list to help the identification of the particular system or

component.

•

A brief description of the system operating characteristics and monitoring procedure

accompanied by a component illustration.

•

Additional information, where appropriate, is provided in the form of component

calibrations, characteristics and cross sectional views.

•

A localized circuit diagram is included to provide circuit identification, connectors, splices,

fuses, wire gauge and colors. See Circuit Diagrams.

The Diagnosis and Testing sub-section is dedicated to fault analysis and rectification, and includes:

•

Recommended special tools.

•

Symptom chart; a chart containing all relevant Diagnostic Trouble Codes (DTC), their possible

causes and an indication of the appropriate test.

•

Specific pinpoint test(s), designed so that fault diagnosis can be carried out in a logical and

efficient manner.

The Removal and Installation sub-section covers:

•

Removal procedure(s), formatted in the recommended sequence.

www.

•

Illustrated guide to the use of special tools.

•

Illustrations to support the relevant text.

•

Installation procedure as above and including special recommendations for processes,

lubricants and tightening torques.

Circuit Diagrams

To understand the relationship between the vehicle electrical system and the system circuit

diagrams, Refer to the Electrical Guide.

In the interest of clarity, single lines may represent multiple wires. Refer to the color code (1st alpha)

followed by the wire reference (numeric/alpha/numeric) to trace origin and destination.

e.g. BW 647B002. BW (black with white trace) 647 (wire reference) B002 (stage from origin).

Glossary of Terms

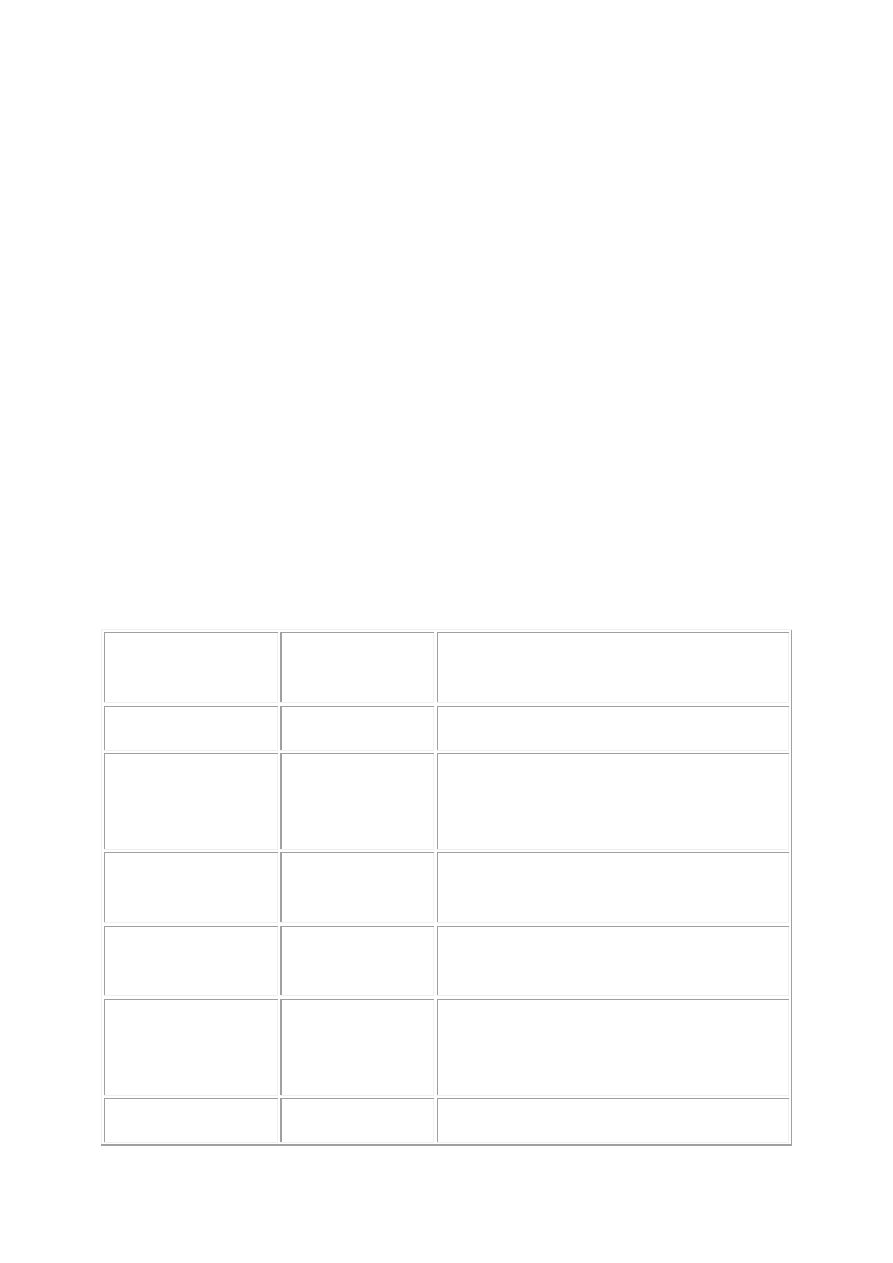

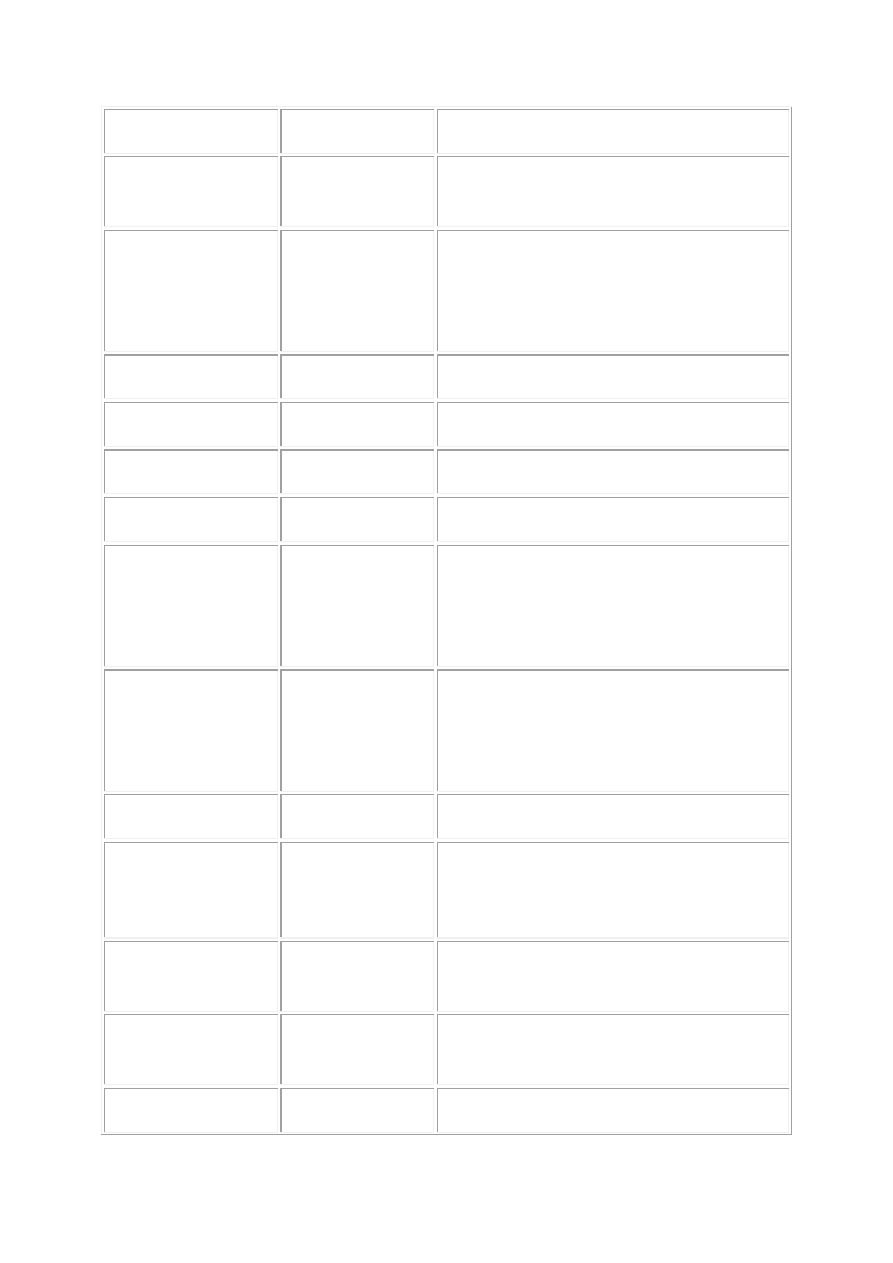

This glossary of terms is intended to cover mainly emissions-related (to SAE J 1930) terminology, and

other abbreviations that may be used in this manual.

The required term may be looked-up in the left-hand column, and subsequent columns give the

standard acronym, unit or abbreviation, and definition.

Term(s)

Acronym / Unit

/ Abbreviation

Definition

Accelerator Pedal

AP

Accelerator Pedal

Position Sensor

APP

Is a multitrack sensor which inputs the

drivers demand into the engine control

module (ECM)

After Bottom Dead

Center

ABDC

Event occurring after BDC

After Top Dead

Center

ATDC

Event occurring after TDC

Airbag /

Supplementary

Restraint System

Airbag, SRS

Airbag restraint system for driver and

front seat passenger

Air Cleaner

ACL

Air Conditioning

A/C

Air Conditioning

Control Module

A/CCM

Module controlling air conditioning,

heating and ventilation

Air Conditioning

Signal

ACS

Air conditioning compressor clutch

operation is signalled to the ECM which

induces idle speed corrections to

compensate for engine load changes

Alternating current

ac

Air Fuel Ratio

AFR

Nominally 14.7 parts air to one part fuel

Ampere

A

SI unit of current

Ampere hour

Ah

ABS Control

Module

ABS CM

System which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and diverting fluid

pressure away from it (them)

ABS / Traction

Control Control

Module

ABS/TCCM

System which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and diverting fluid

pressure away from it (them)

Atmosphere

atm

Unit of pressure (1.01325 bar)

Barometric

Absolute Pressure

Sensor

BARO Sensor

Sensor measuring the pressure of

surrounding air at any given

temperature and altitude

Battery positive

voltage

B+

The positive voltage from a battery or

any circuit connected directly to it

Before Bottom

Dead Center

BBDC

Event occurring before BDC

Before Top Dead

BTDC

Event (usually ignition) occurring before

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст