Jaguar XJ (X350). Manual — part 312

Description and operation

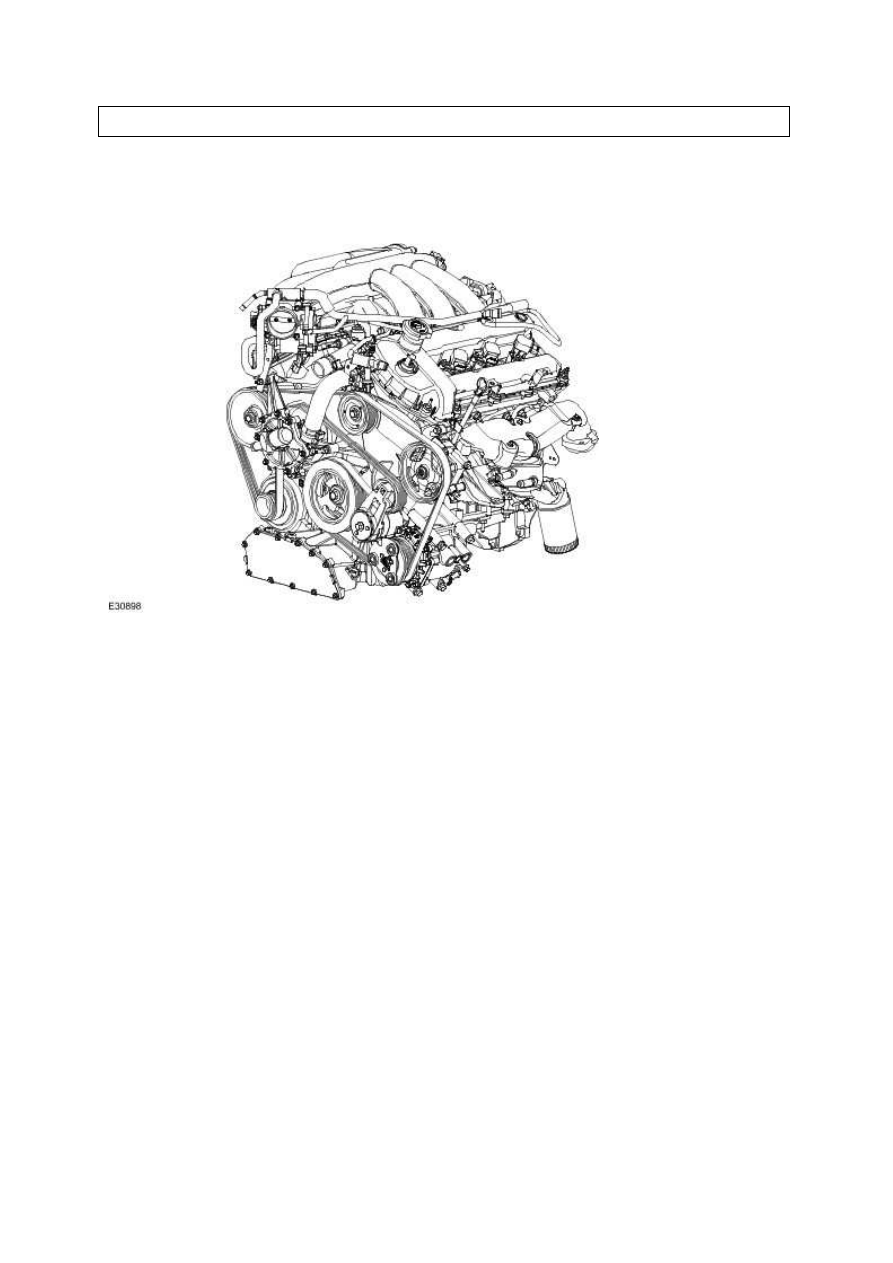

Engine

The 3.0 litre 24 valve V6 engine has four overhead camshafts and are driven by two timing chains.

The engine incorporates electronic engine management with distributorless ignition system,

sequential electronic fuel injection. It also has two catalytic converters in the exhaust system which

includes two oxygen sensors and two catalytic monitor sensors.

Viewed from the driving position, the right-hand cylinder bank is numbered 1 to 3, from the front of

the vehicle and the left-hand cylinder bank are numbered 4 to 6, from the front of the vehicle.

The engine includes the following:

•

Compression ratio of 10.5:1.

•

3 Stage variable geometry intake manifold.

•

Lightweight valve gear.

•

Unique camshaft lift and duration.

•

Twin knock sensor engine management control.

•

Fully variable camshaft timing (VCT) system.

Variable Intake System (V.I.S).

The variable intake system consists of a three stage upper intake manifold assembly, two position

electronically driven gate valves and an engine management powertrain control system.

The engine control module (ECM) switches the intake manifold tuning valves between fully open and

fully closed at calibrated engine speeds.

The intake manifold efficiency is therefore increased which will also increase the engine torque and

engine performance.

Variable Camshaft Timing (VCT)

Oil is supplied to the front of each VCT actuator via the spider bracket assembly which contains the

VCT actuator solenoid, supply oil galleries and timing chain guide. Oil pressure advances and retards

the camshaft timing which is controlled by the engine management system via a solenoid valve

mounted on top of the oil feed spider assembly. Camshaft timing, dependant on engine speed, load

and oil temperature can be optimized over the adjustment range of 30 degrees.

Engine Lubrication System

The engine lubrication system is of the force-feed type in which oil is supplied under full pressure to

the:

•

crankshaft main bearings.

•

crankshaft thrust main bearing.

•

connecting rod bearings.

•

valve shims.

•

camshaft bearings.

•

variable camshaft timing.

All other parts are lubricated by gravity flow or splash of the oil.

Oil Pump

The rotary oil pump develops the oil pressure:

•

The oil pump is located at the front of the crankshaft.

•

The oil pump is driven by the crankshaft.

•

A full flow oil filter is externally mounted on the oil filter housing.

If the filter element should become blocked a spring-loaded bypass valve will open and allow an

uninterrupted flow of oil to the engine.

www.

Diagnosis and testing

Engine

For additional information, refer to<<303-00>>.

Removal

Engine (12.41.01)

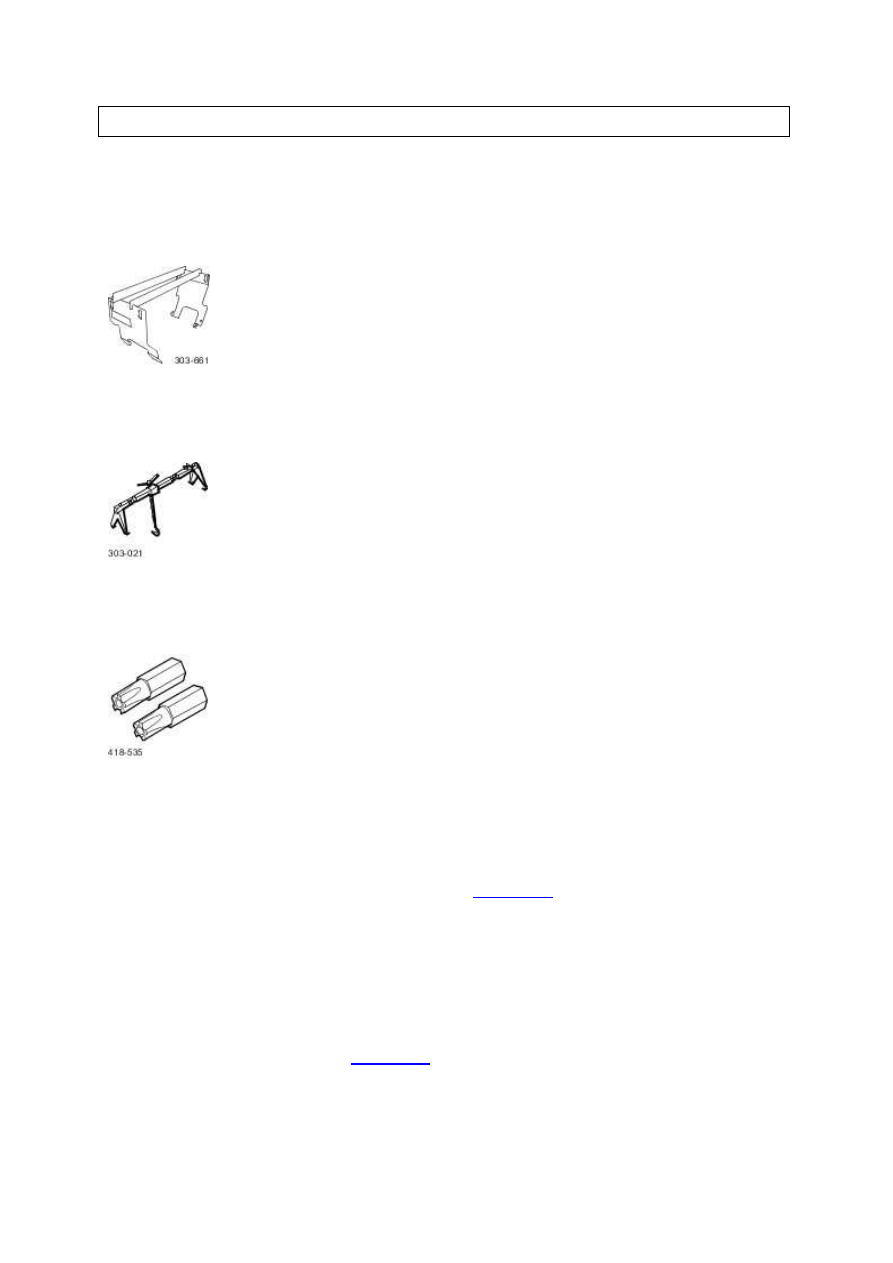

Special Service Tools

Engine Lifting Bracket

303-661

Engine Support Bracket

303-021

5 point security torx bit

418-535

Removal

1 . Remove the automatic transmission assembly. <<307-01>>

2 . Lower the vehicle.

3 . Remove the hood assembly. <<501-03>>

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст