Jaguar XJ (X350). Manual — part 263

-> No

REPAIR the short circuit. For additional information, refer to the wiring diagrams. Clear the DTC, test

the system for normal operation by driving the vehicle to a speed greater than 20 Kph (12.5 mph) for

more than 3 seconds.

G531322t76 : CHECK THE YAW RATE SENSOR AND ACCELEROMETER CAN -

CIRCUIT FOR HIGH RESISTANCE

1. Key off. 2. Disconnect the ABS module connector, EC030. 3. Key on, engine off. 4. Measure the

resistance between:

IP023, harness side EC030, harness side

Pin 01

Pin 19

•

Is the resistance less than 10 ohms?

-> Yes

GO to Pinpoint Test

G531322t77

.

-> No

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. Clear the

DTC, test the system for normal operation by driving the vehicle to a speed greater than 20 Kph (12.5

mph) for more than 3 seconds.

G531322t77 : CHECK THE YAW RATE SENSOR AND ACCELEROMETER CAN +

CIRCUIT FOR HIGH RESISTANCE

1. Measure the resistance between:

IP023, harness side EC030, harness side

Pin 02

Pin 18

•

Is the resistance less than 10 ohms?

-> Yes

GO to Pinpoint Test

G531322t78

.

-> No

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. Clear the

DTC, test the system for normal operation by driving the vehicle to a speed greater than 20 Kph (12.5

mph) for more than 3 seconds.

G531322t78 : CHECK THE YAW RATE SENSOR AND ACCELEROMETER CAN +

AND - CIRCUITS FOR SHORT CIRCUIT TO EACH OTHER

1. Measure the resistance between:

IP023, harness side IP023, harness side

Pin 02

Pin 01

•

Is the resistance greater than 10 Kohms?

-> Yes

An intermittent fault may be present in the wiring harness. Visually check for chaffed wires or other

physical damage to the harness.

-> No

REPAIR the short circuit. For additional information, refer to the wiring diagrams. Clear the DTC, test

the system for normal operation by driving the vehicle to a speed greater than 20 Kph (12.5 mph) for

more than 3 seconds.

www.

Removal and installation

Anti-Lock Brake System (ABS) Module

(70.60.02)

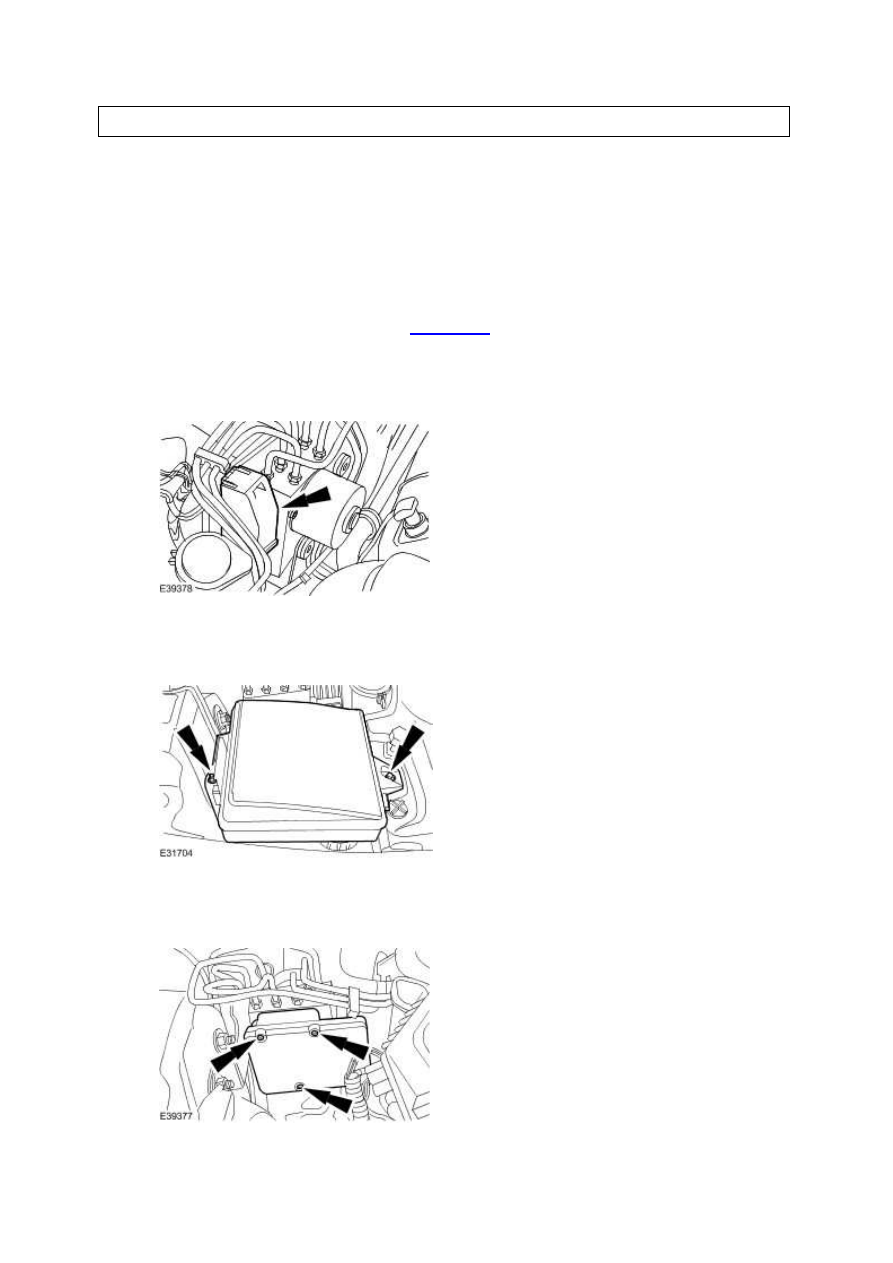

Removal

1 . Disconnect the battery ground cable.

2 . Disconnect the hydraulic control unit electrical connector.

3 . Detach the engine compartment battery junction box.

4 . Remove the ABS module.

Installation

1 . To install, reverse the removal procedure.

Brake Master Cylinder Pressure

Transducer

Removal

1

.

WARNING: Brake fluid contains polyglycol ethers and polyglycols. Avoid contact

with the eyes. Wash hands thoroughly after handling, as prolonged contact may cause

irritation and dermatitis. If brake fluid contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention. If taken internally do not induce vomiting,

seek immediate medical attention. Failure to follow these instructions may result in

personal injury.

Disconnect the battery ground cable.

2 . Disconnect the brake master cylinder primary pressure transducer electrical connector.

3

.

CAUTION: If brake fluid is spilt on the paintwork, the effected area must be

immediately washed down with cold water.

Remove the brake master cylinder primary pressure transducer.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст