Jaguar XJ (X350). Manual — part 369

Valve Clearance Check (12.29.47)

1. Remove the left-hand valve cover.

2. Remove the right-hand valve cover.

3.

CAUTION: Rotating the crankshaft in a counterclockwise direction may cause

engine damage. Crankshaft journals are directionally machined. Rotating the

crankshaft counterclockwise can raise burrs on bearing surfaces, reducing engine life.

CAUTION: Camshaft lobes must be 180 degrees away from each valve tappet or

the valve clearance will be incorrect.

Rotate the engine clockwise to position the camshaft lobe away from the shim surface.

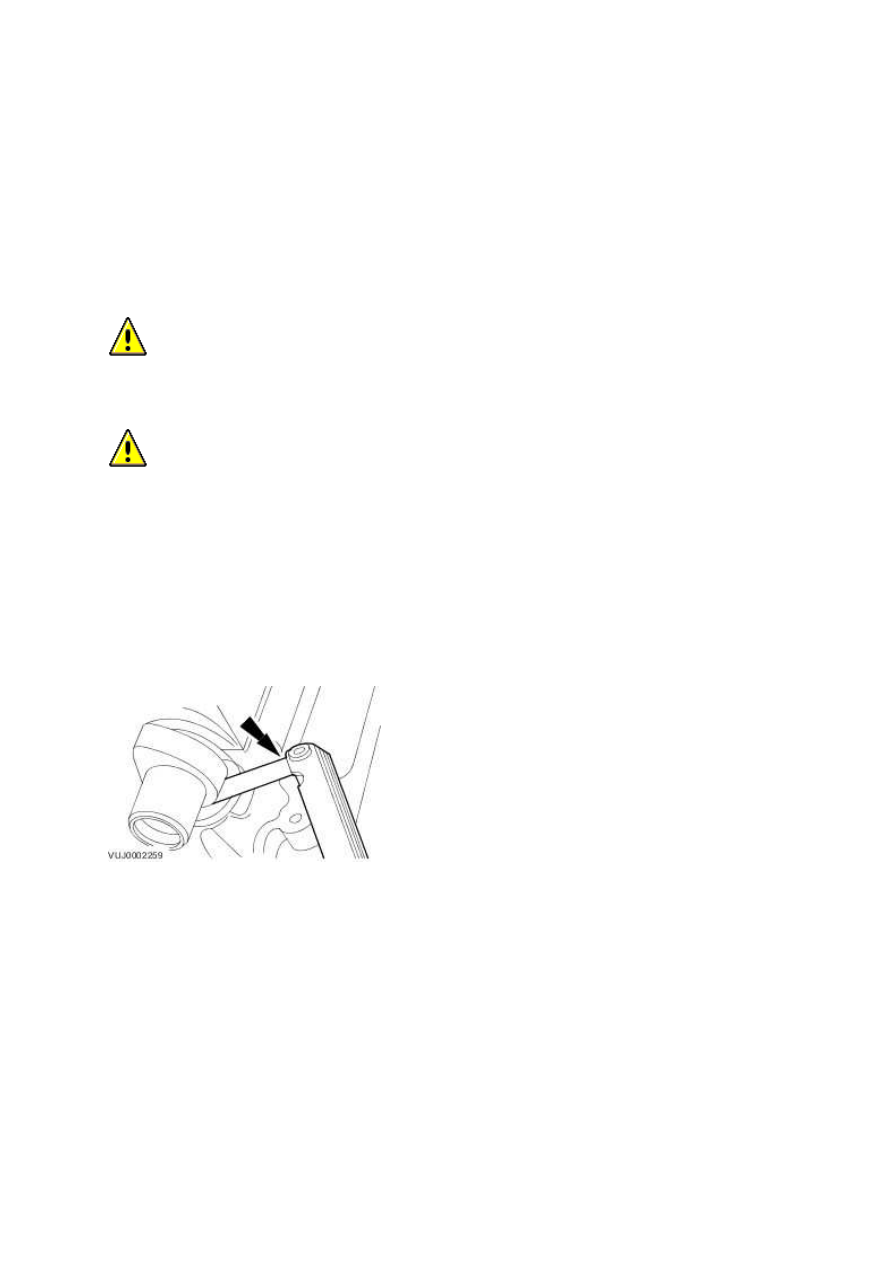

4. Using the feeler gauge set, measure the clearance between the camshaft and the shim

surface. Record and check the readings. Adjust the clearances as necessary.

Valve Clearance Check (12.29.47)

5. Install the right-hand valve cover.

6. Install the left-hand valve cover.

Description and operation

Engine

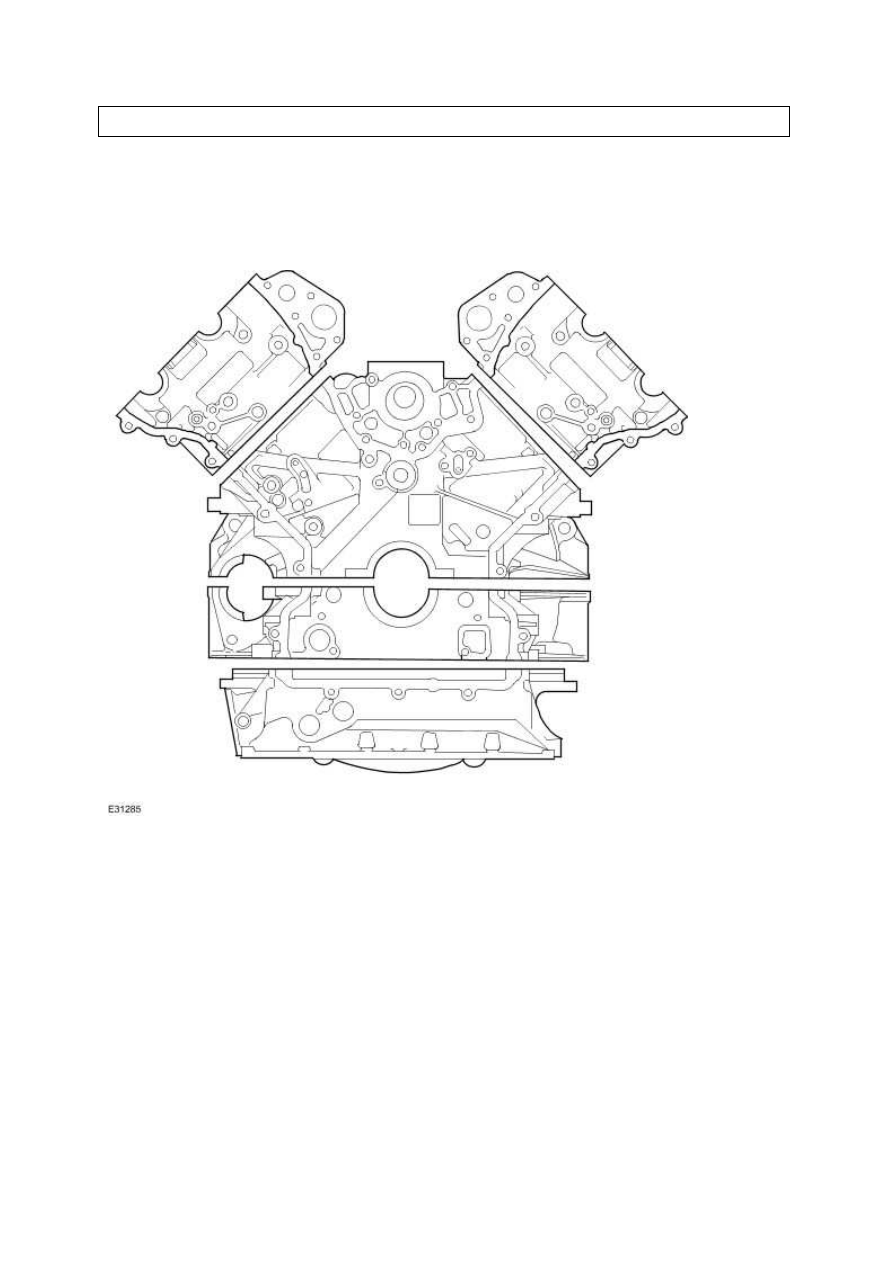

Cylinder Block

The 3.5L & 4.2L engine consists of an eight cylinder 90 degree 'Enclosed V' configuration liquid cooled

aluminium cylinder block with dry cast liners.

Viewed from the driving position, the right-hand cylinder bank is designated A-bank and the left-

hand cylinder bank as B-bank.

Cylinder Block Drain Plug

The coolant drain plug is located on the rear left side of the cylinder block.

On vehicles supplied with a cold climate package (i.e. vehicles operating in conditions regularly below

-30ºC) a cylinder block heater unit is fitted instead of the drain plug.

www.

Knock Sensors

Two knock sensors are fitted to the cylinder block on the inboard side of each cylinder bank. The

electrical connector of each sensor is secured to the left-hand engine cover bracket.

These piezo-electric sensors provide inputs to the engine control module (ECM) to indicate the

detection and location of detonation during combustion.

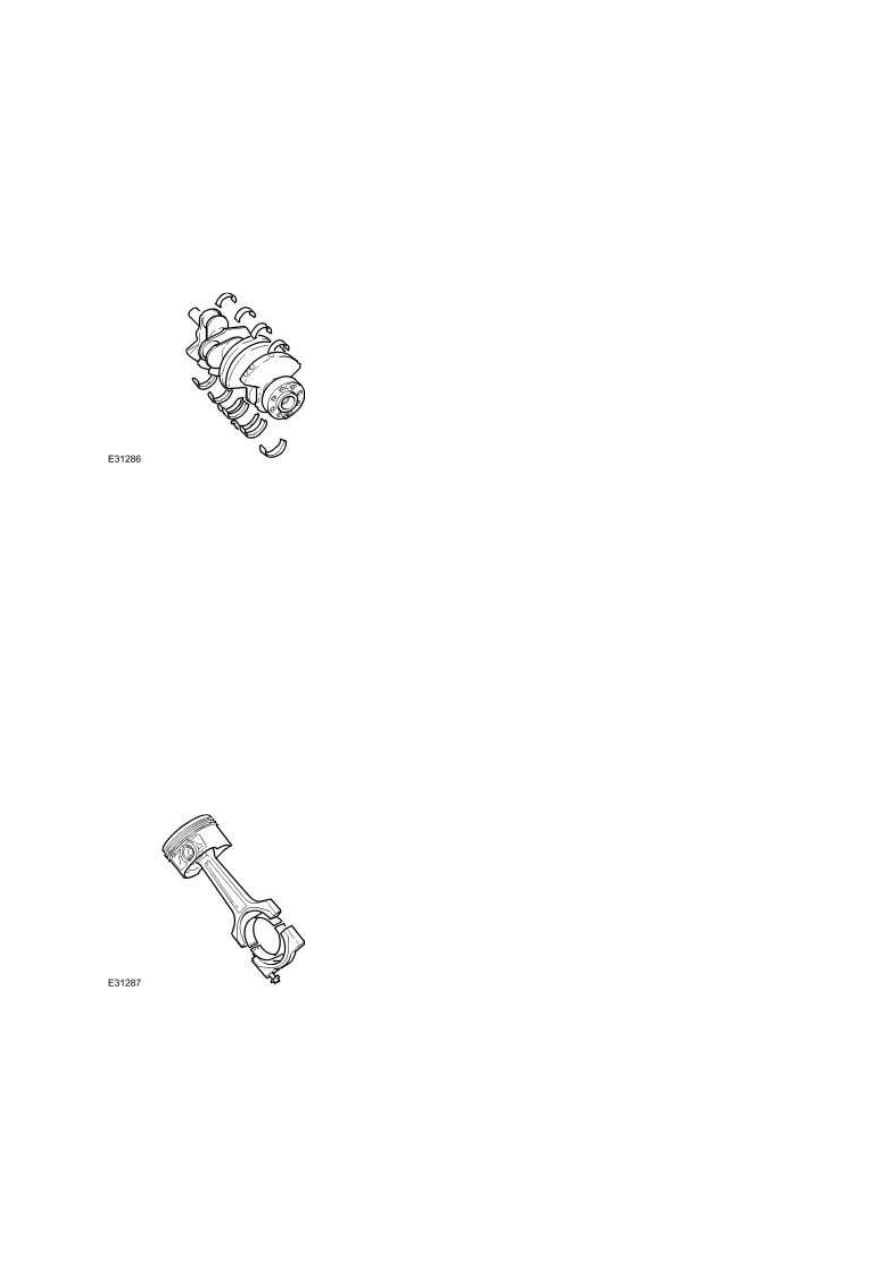

Crankshaft

The cast iron crankshaft has undercut and rolled fillets for improved strength and six counter-balance

weights make sure low levels of vibration from the four throw, five bearing configuration.

The main bearing shells are aluminium/tin split plain type. An oil groove in the top half of each

bearing transfers oil into the crankshaft oilway drillings for lubrication of the connecting rod

bearings. A lead/bronze thrust washer is fitted on each side of the top half of the center main

bearing.

The crankshaft rear oil seal is lipped and is a press fit in the interface of the bedplate to cylinder

block.

A torsional vibration crankshaft damper pulley is bolted to the front of the crankshaft.

Connecting Rods and Pistons

The connecting rods are manufactured from sinter-forged steel and have fracture-split bearing caps.

The opposing sides of each connecting rod being fractured at the bearing horizontal center line.

The cylinder position is etched on adjoining sides of the joint to identify matching connecting rods

and bearing caps. The connecting rod bearing shells are lead/bronze, split plain bearings.

The pistons are open ended skirt design with small recesses for valve clearance and flat upper

surfaces to reduce heat absorption. Three piston rings, two compression and one oil control, are

fitted to each piston. Each piston is fitted on a gudgeon pin which is in a lead/bronze bush fitted in

the connecting rod.

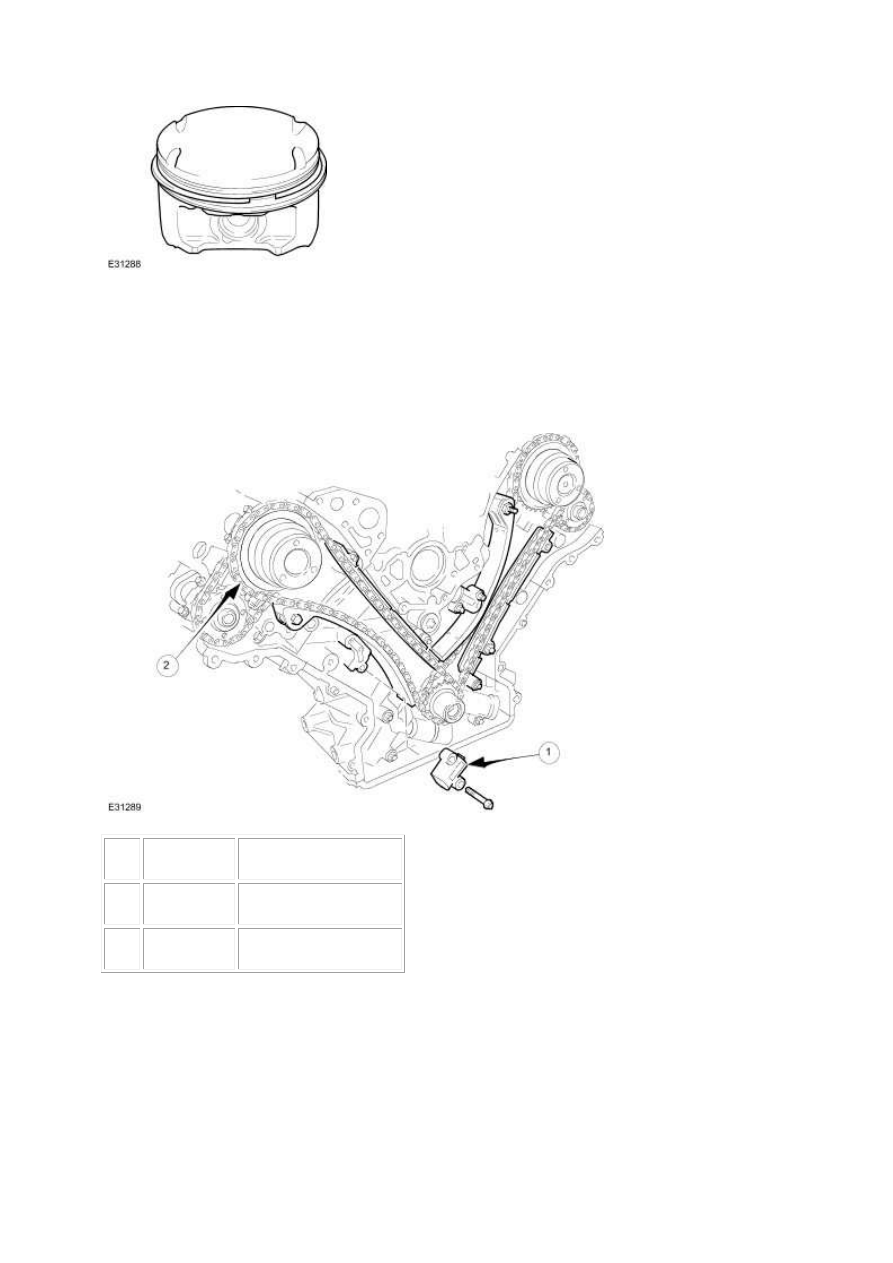

Timing Gear

Item

Part Number

Description

1

—

Primary chain tensioner

2

—

Primary chain

Multi link primary and single link secondary chains drive the camshafts of each cylinder bank. The

primary chains transmit the drive from sprocket on the crankshaft to a sprocket on each intake

camshaft. The secondary chains transmit the drive from a second, smaller sprocket on the intake

camshaft to a sprocket on the exhaust camshaft.

Each chain has a hydraulic tensioner operated by the engine lubricating system. A jet of oil from the

end of each tensioner lubricates the chains. The primary chain tensioners act on pivoting flexible

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст