Jaguar XJ (X350). Manual — part 135

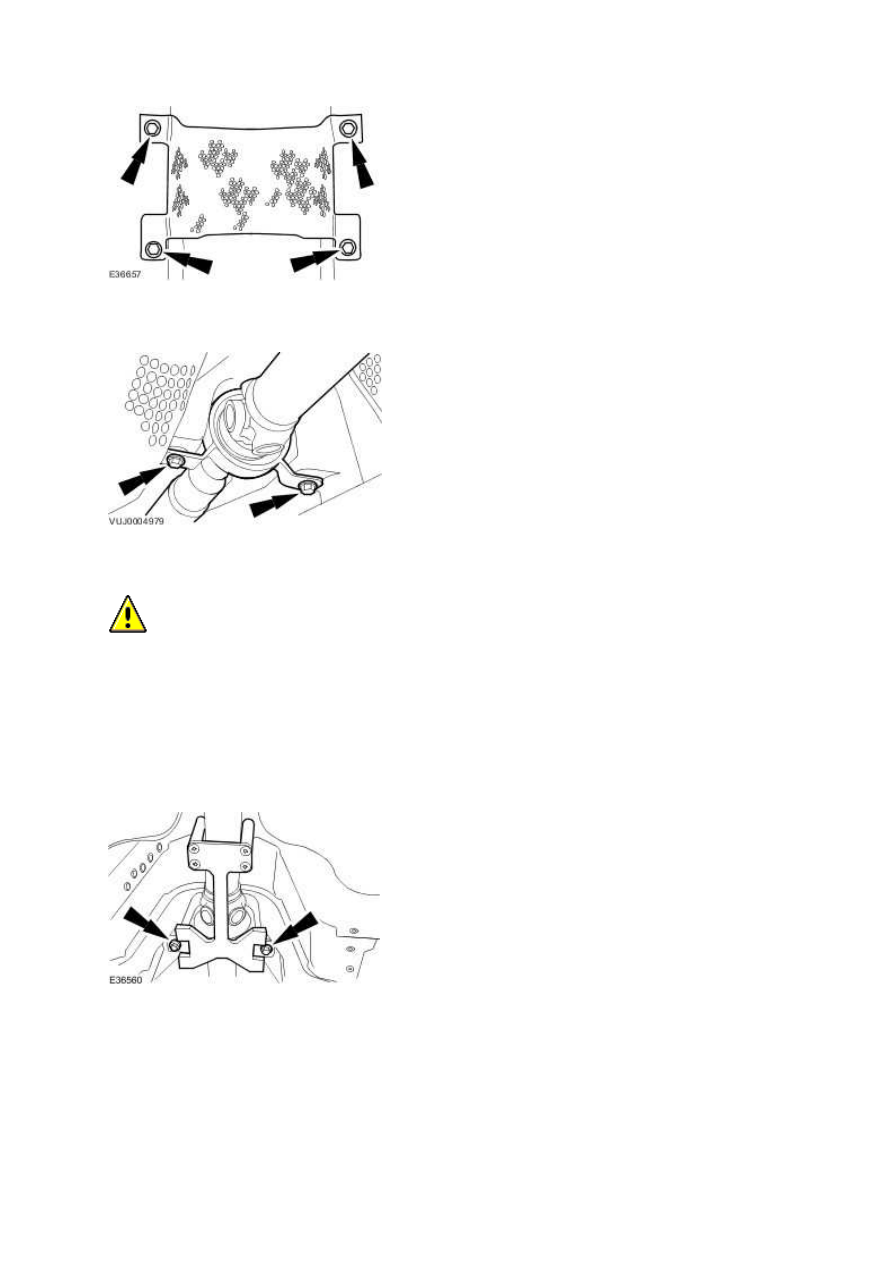

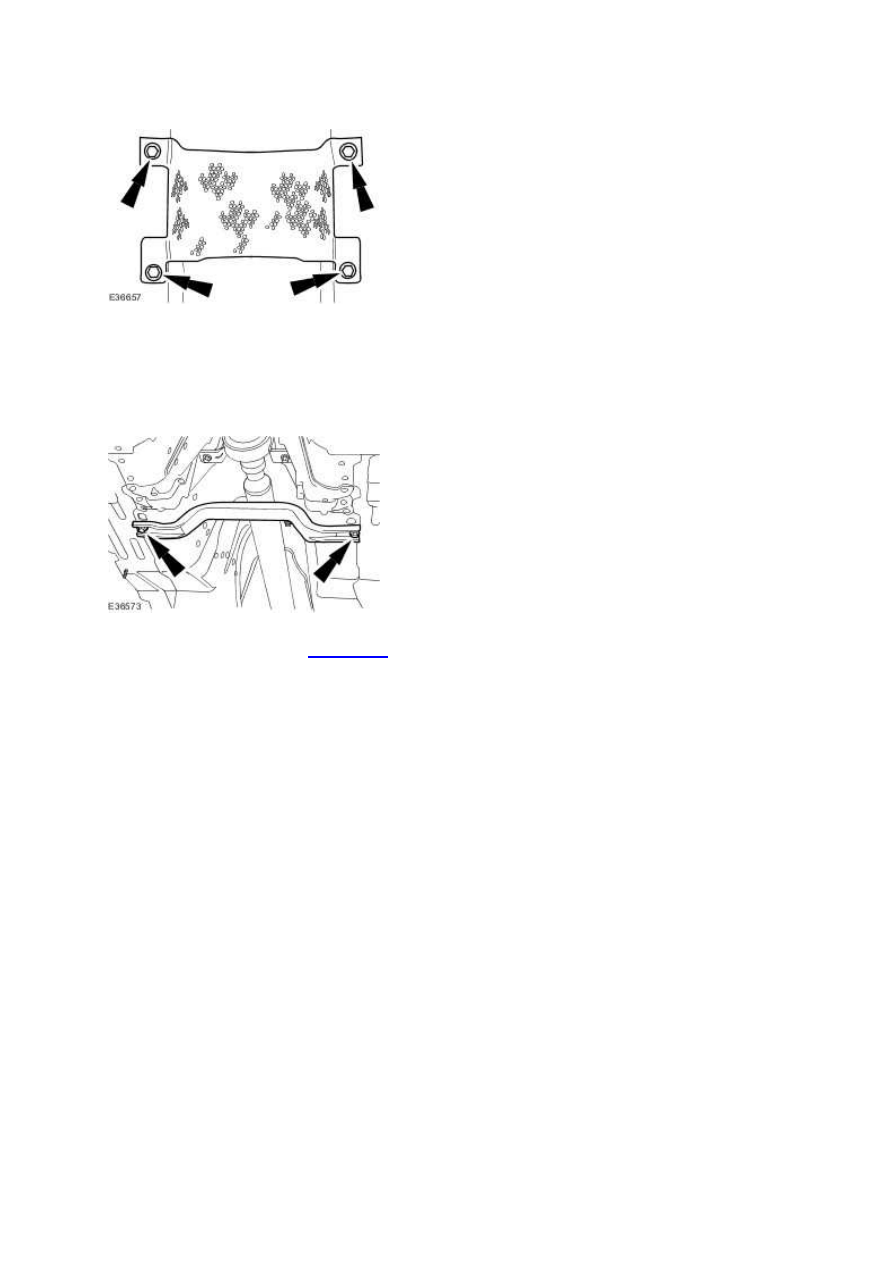

5. Loosen the driveshaft centre bearing retaining bolts two complete turns.

6.

CAUTION: Make sure the driveshaft centre bearing is correctly aligned to the driveshaft.

Failure to follow these instructions may result in damage to the vehicle.

Using the special tool, align the driveshaft centre bearing.

•

Tighten to 40 Nm.

7. Install the driveshaft heat shield retaining bolts.

•

Tighten to 7 Nm.

Description and operation

Driveline System

The driveline transfers engine torque to the drive wheels. Power is transmitted through the

transmission to the driveshaft and then to the rear drive axle which is connected to the rear drive

halfshaft.

For additional information, refer to

Halfshaft

(205-05 Rear Drive Halfshafts)

For additional information, refer to

Driveshaft

(205-01 Driveshaft)

For additional information, refer to

Axle Assembly

(205-02 Rear Drive Axle/Differential)

The engine angle is built into the engine mounts. If the engine angle is out of specification, the

engine mounts must be inspected for damage.

Driveline Vibration

Driveline vibration exhibits a higher frequency and lower amplitude than high-speed shake. Driveline

vibration is directly related to the speed of the vehicle and is usually noticed at various speed ranges.

Driveline vibration can be felt as a tremor in the floorpan or is heard as a rumble, hum, or boom.

Driveline vibration can exist in all drive modes, but may exhibit different symptoms depending upon

whether the vehicle is accelerating, decelerating, cruising, or coasting. Check the driveline angles if

the vibration is particularly noticeable during acceleration or deceleration, especially at lower

speeds. Check that the centre bearing washers between the body and bearing housing are 3mm

minimum and 8mm maximum thickness.

In order to diagnose vibrations in the driveshaft, refer to the Jaguar approved diagnostic system for

analysis/rectification.

Driveline Angle

Driveline angularity is the angular relationship between the engine crankshaft, the driveshaft, and

the rear drive axle pinion. Factors determining driveline angularity include ride height, rear springs

and engine mounts.

An incorrect driveline (pinion) angle can often be detected by the driving condition in which the

vibration occurs.

•

A vibration during coasting from 72 to 56 km/h (45 to 35 mph) is often caused by a high

pinion angle.

•

A vibration during acceleration from 56 to 72 km/h (35 to 45 mph) may indicate a low pinion

angle.

When these conditions exist, check the driveline angles.

If the tires and driveline angle are not the cause, carry out the Noise, Vibration and Harshness (NVH)

tests to determine whether the concern is caused by a condition in the driveline. For additional

information, refer to

Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness)

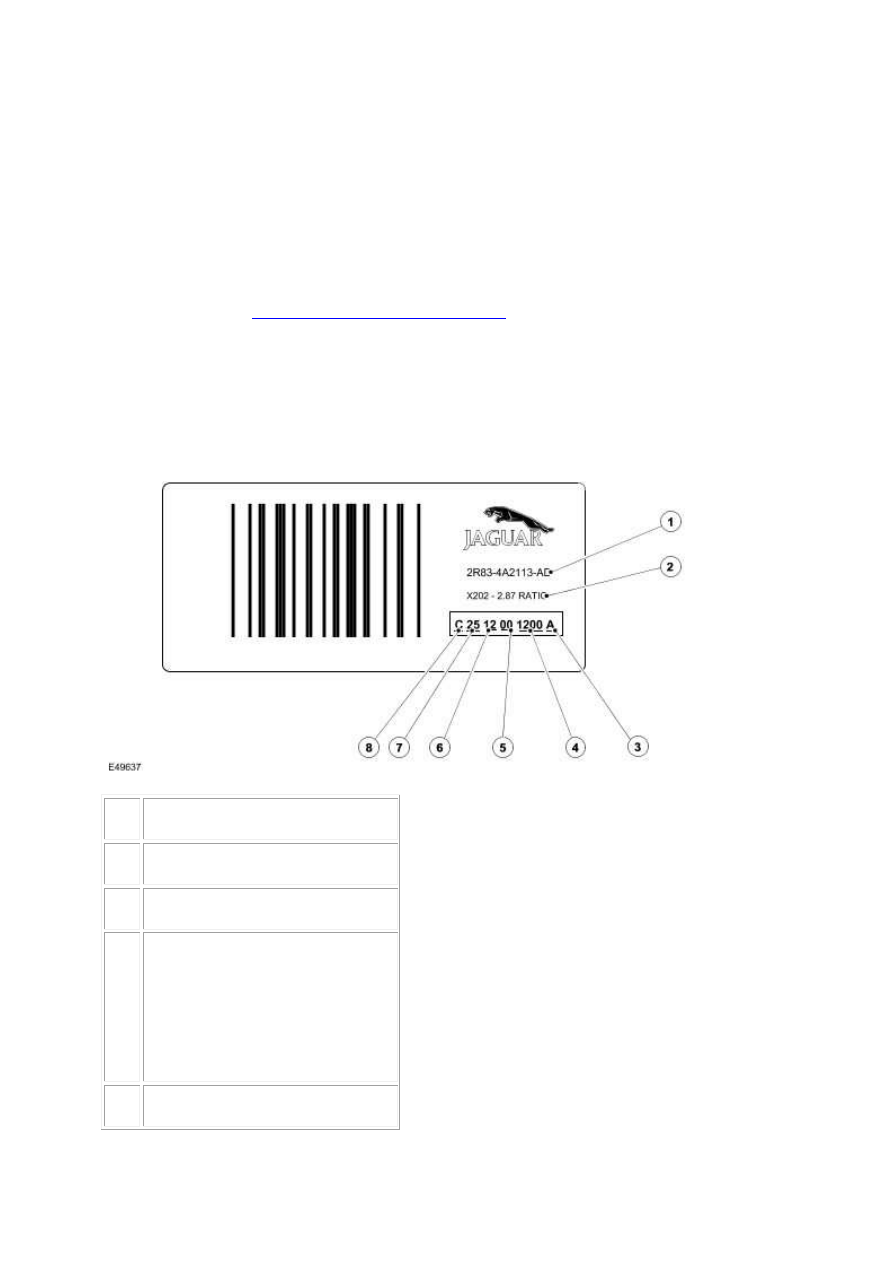

Rear Drive Axle Identification Tag

Item

Description

1

Part Number

2

Ratio and Vehicle Line

3

Rear Drive Axle Ratio

•

A and E = 2.87 Ratio

•

B and F = 3.07 Ratio

•

C and G = 3.31 Ratio

•

D = 2.69 Ratio

4

Time Built

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст