Jaguar XJ (X350). Manual — part 45

1. Position the vehicle on a flat and level surface.

2. Check and adjust the tire pressures.

3. Measure the distance from the bottom of the wheel rim through the wheel centre to the lip of the wheel

arch.

4. NOTE:

If the suspension ride height is incorrect adjust as necessary.

Check that the suspension ride height is to the correct tolerance.

Specifications

5.

CAUTION: Make sure that the damper thread is dirt free and lubricated before loosening the lock nut and

adjustment nut. Failure to follow this instruction may result in damage to the vehicle.

NOTE:

Its is possible to gain access to adjust the front spring and damper assemblies whilst still installed to the vehicle. Access is

restricted to the rear spring and damper assembly adjustment nuts. The rear spring and damper assemblies may need to be

removed from the vehicle to make the necessary adjustments.

NOTE:

One full turn of the adjustment nut will adjust the height at the road wheel by approximatly 2.25 mm (0.09 inch) at the road

wheel.

NOTE:

Moving the adjustment nut towards the upper spring mount platform will raise the ride height.

Using the special tools, adjust the spring and damper assembly.

Loosen the spring and damper locking nut.

Adjust the spring seat position.

6. Using the special tools, tighten the lock nut.

7. Carry out a road test.

Suspension System

8. Repeat steps 1 to 4 and check that the suspension ride height is to the correct specification.

Specifications

9. If the suspension ride height is not to the correct specification repeat steps 5 to 8 until the correct

specification is reached.

Diagnosis and testing

Suspension System

Inspection and Verification

WARNING: Before carrying out a road test, make sure the vehicle is safe to do so. Failure to

follow this instruction may result in personal injury.

1 . Gather as much information from the driver as possible and verify the customer concern by

carrying out a road test, as closely as possible reproducing the conditions under which the fault

occurs.

If the customer complaint is of vibration.

Noise, Vibration and Harshness (NVH)

2 . Visually inspect for obvious signs of mechanical damage.

Mechanical

•

Tire pressures

•

Damaged tires

•

Wheel bearing(s)

•

Loose or damaged front or rear suspension components

•

Loose, damaged or missing suspension fastener(s)

•

Damaged or leaking air suspension components

•

Worn or damaged suspension bushing(s)

•

Loose, worn or damaged steering system components

•

Damaged axle components

3 . If an obvious cause for an observed or reported condition is found, correct the cause (if possible)

before proceeding to the symptom chart.

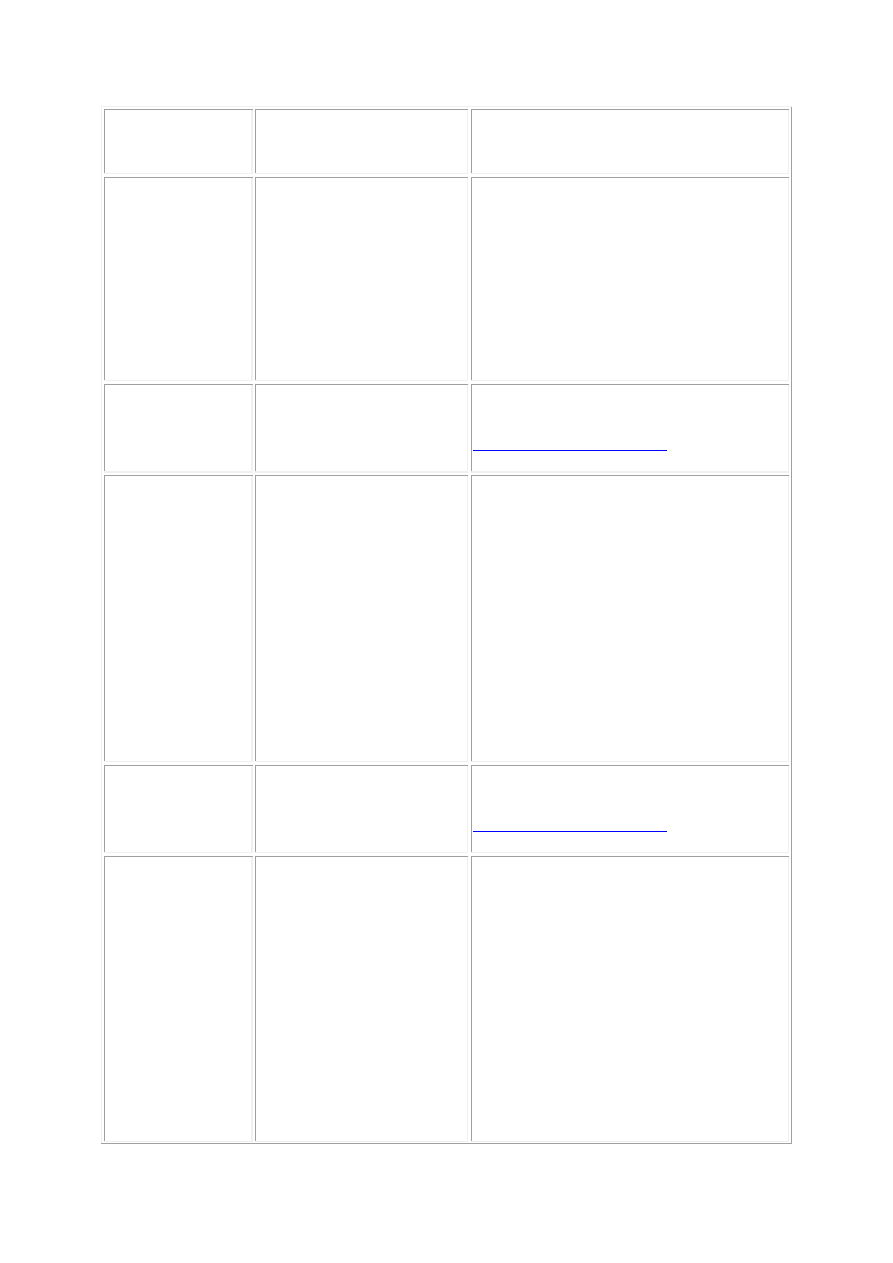

Symptom chart

Symptom

Possible causes

Action

Crabbing

•

Incorrect rear thrust

angle

•

Front or rear

Check the rear alignment.

Rear Toe Adjustment (57.65.08)

Check the

front and rear suspension for signs of damage

www.

suspension

components

or wear.

Drift/Pull/Wander

•

Tire pressures

•

Uneven tire wear

•

Damaged steering

components

•

Wheel alignment

•

Brake drag

•

Unevenly loaded or

overloaded vehicle

Check and adjust the tire pressures (see visual

inspection). Check for uneven tire wear,

investigate the cause and rectify as

necesssary. Check the steering for

wear/damage. Check and adjust the wheel

alignment as necessary. Check for binding

brakes, rectify as necessary. Advise the driver

of the load issues.

Front bottoming or

riding low

•

Damaged suspension

components

•

Air spring fault

Check the suspension components for

damage. Check the dynamic suspension.

Vehicle Dynamic Suspension

Uneven tire wear

•

Incorrect tire pressure

(rapid center rib or

inner and outer edge

wear)

•

Incorrect front or rear

toe (rapid inner or

outer edge wear)

•

Incorrect camber

(rapid inner or outer

edge wear)

•

Tires out of balance

(tires cupped or

dished)

Check and adjust the tire pressures (see visual

inspection). Check and adjust the wheel

alignment as necessary. Balance the tires as

necessary.

Harsh ride

•

Damaged suspension

components

•

Air spring fault

Check the suspension components for

damage. Check the dynamic suspension.

Vehicle Dynamic Suspension

Shimmy or wheel

tramp

•

Wheels/tires

•

Loose wheel nut(s)

•

Loose front suspension

fasteners

•

Front wheel bearing(s)

fault

•

Worn or damaged

suspension

component bushing

•

Loose, worn or

damaged ball joint(s)

•

Loose, worn or

damaged steering

components

Check the wheels and tires for condition and

balance. Check and tighten the wheel nuts

and suspension fasteners to specification.

Check the front wheel bearings, suspension

bushings, ball joints and steering components

for wear or damage. Check and adjust the

wheel alignment as necessary.

•

Front wheel alignment

Poor returnability of

the steering (self-

centering)

•

Steering column

•

Ball joints

•

Steering components

Check the steering column universal joints,

etc. Check the ball joints and other steering

components.

Sway or roll

•

Loose front or rear

stabilizer bar

•

Worn lower

suspension arm

stabilizer bar

insulators

•

Air spring fault

Check the stabilizer bar security and condition.

Rectify as necessary. Check the air springs.

Vehicle Dynamic Suspension

Vehicle leans to one

side

•

Front or rear

suspension

components

•

Air spring fault

Check the front and rear suspension. Check

the air springs.

Vehicle Dynamic Suspension

Component tests

Ball Joint Inspection

NOTE:

The front suspension is shown in the following procedures. The inspection of the rear

suspension upper ball joint is similar.

1 . Raise and support the vehicle.

2 . Prior to carrying out any inspection of the ball joints, inspect the front wheel bearings.

Wheel Bearing Inspection

3 .

CAUTION: The safety stand beneath the suspension lower lower arm must only support the

weight of the suspension and not the full weight of the vehicle. Failure to follow this instruction

may result in damage to the components.

Position a safety stand beneath the front suspension lower arm or rear suspension lower arm to be

tested.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст