Jaguar XJ (X350). Manual — part 827

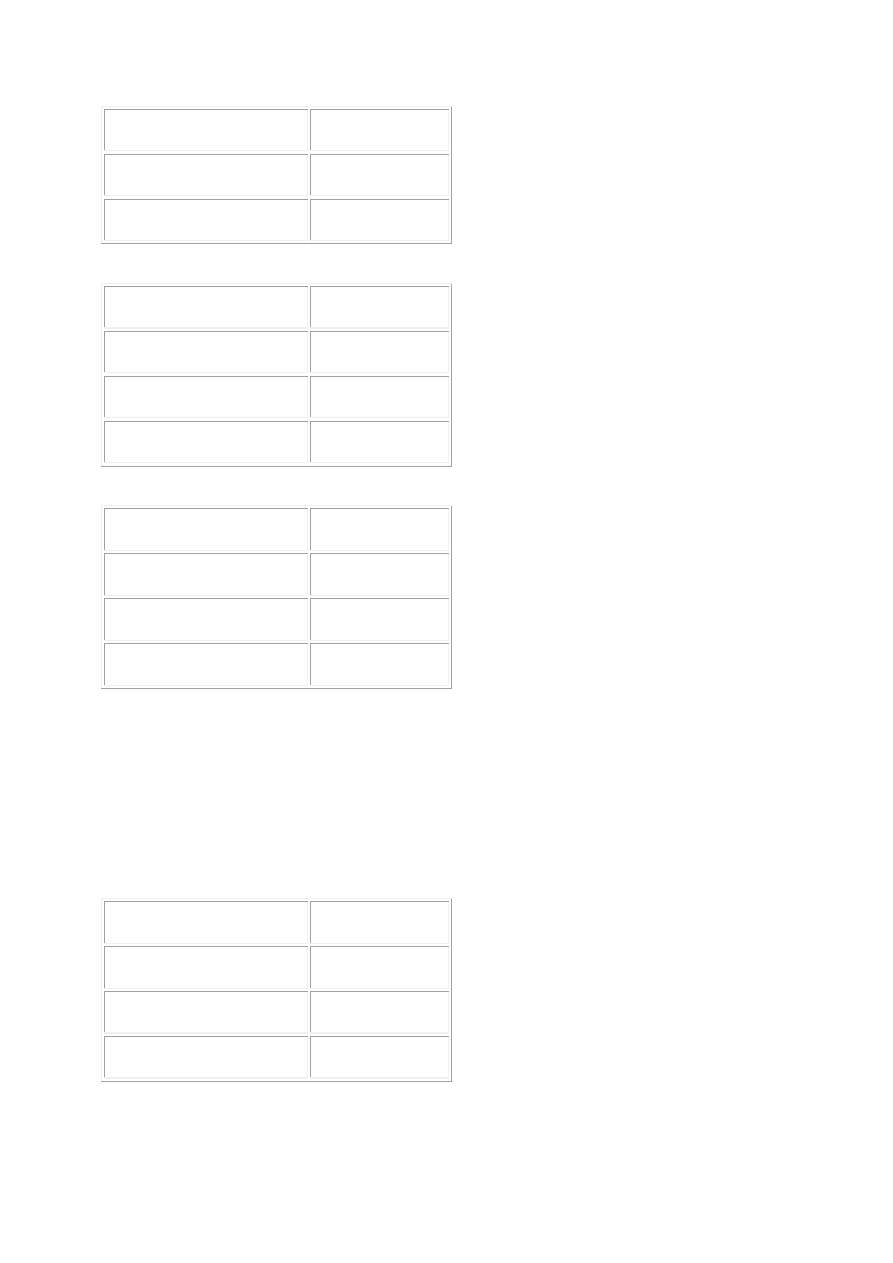

GEAR

3

ENGINE SPEED

1937 rpm

VEHICLE SPEED (GUIDE ONLY) 44.8 kph (27.8 mph)

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

2152 rpm

VEHICLE SPEED (GUIDE ONLY) 57.6 kph (35.8 mph)

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

2250 rpm

VEHICLE SPEED (GUIDE ONLY) 64.0 kph (39.8 mph)

"Green" ECM drive cycle chart. Site 5

NOTE:

The vehicle speed is for guidance only. DO NOT use the vehicle speed as the target to set

adaptions.

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

3500 rpm

VEHICLE SPEED (GUIDE ONLY) 89.0 kph (55.3 mph)

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

3287 rpm

VEHICLE SPEED (GUIDE ONLY) 80.0 kph (50.0 mph)

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

2891 rpm

VEHICLE SPEED (GUIDE ONLY) 80.0 kph (50.0 mph)

Monitor condition

Parameters

GEAR

3

ENGINE SPEED

2592 rpm

VEHICLE SPEED (GUIDE ONLY) 80.0 kph (50.0 mph)

Bring the vehicle to rest, allow to idle for one minute.

WARNING: The following tests may involve parts which are hot.

If sufficient adaptations have occurred, the canister purge valve should now be operating. This can be

verified manually by either touching or listening to the valve. By touching the canister purge valve, it

should be possible to feel the valve switching. Listening to the canister purge valve is best done using

a workshop stethoscope, through which it should be possible to hear the valve operating.

Diagnostic Trouble Code (DTC) Index/Symptom Chart

1 . Where the Jaguar approved diagnostic system is available, complete the S93 report before

clearing any or all fault codes from the vehicle.

www.

If a DTC cannot be cleared, then there is a permanent fault present that flags again as soon as it

is cleared. (The exception to this is P1260, which will only clear following an ignition OFF/ON

cycle after rectification).

2 . If the cause is not visually evident and the Jaguar approved diagnostic system is not available, use

a fault code reader to retrieve the fault codes before proceeding to the Diagnostic Trouble Code

(DTC) Index Chart, or the Symptom Chart if no DTCs are set.

3 . Using the Jaguar approved diagnostic system where available, and a scan tool where not, check

the freeze frame data for information on the conditions applicable when the fault was flagged. The

format of this will vary, depending on the tool used, but can provide information useful to the

technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint

tests, use the adaptor kit, part number 3548-1358-00.

NOTE:

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM)

accurate to 3 decimal places, and with an up-to-date calibration certificate. When testing

resistance, always take the resistance of the DMM leads into account.

NOTE:

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

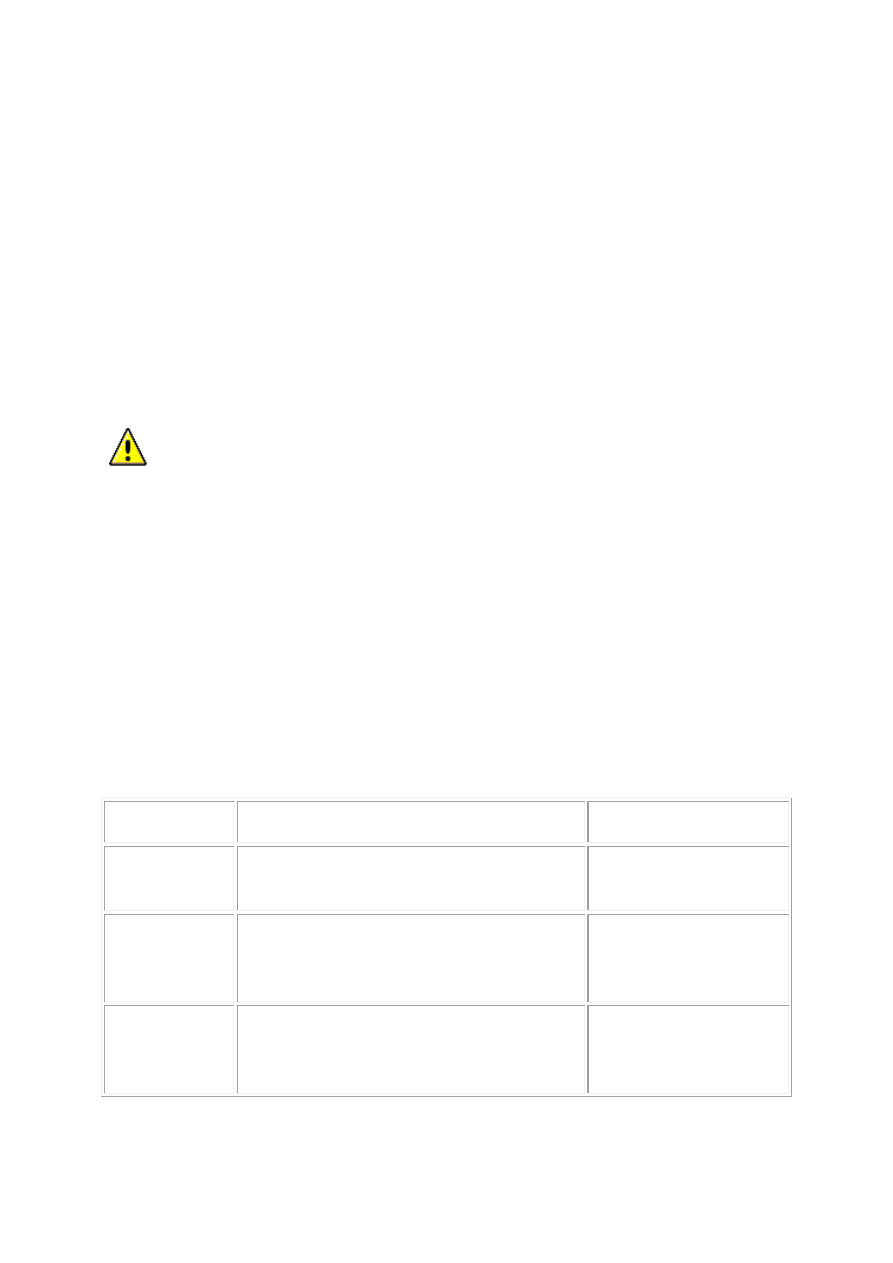

Symptom

Possible Source

Action

Difficulty in filling

Restriction in the vapor line between the fuel

tank and the carbon canister

outlet/atmospheric port

Refer to Action for DTC

P0446

Fuel smell

Adaptations incomplete

Purge valve inoperative

Carry out adaptations

procedure, check purge

valve operation

Message center

display (see

below)

Fuel filler cap missing/not tightened after

refuelling

Check fuel filler cap, refer to

Action for DTC P0455,

NOTE:

Warning Light

Message

Default Mode

DTC

Check engine

(after two trips)

None

ECM default. (Canister purge

inhibited, adaptive fuel metering

inhibited).

P0441, P0442, P0443, P0444,

P0445, P0446, P0447, P0448,

P0455, P0456

Check engine

(after two trips)

None

None

P0450, P0452, P0453

Red

Check fuel

filler cap

ECM default. (Canister purge

inhibited, adaptive fuel metering

inhibited).

P0455

Diagnostic

Trouble

Code

Description

Possible Source

Action

P0441 (Euro

only)

Incorrect purge

flow

Evaporative canister

purge pipe

restricted, leaking,

disconnected

Evaporative canister

vent restricted

Evaporative canister

purge valve to

engine pipe(s)

restricted, leaking,

disconnected

Evaporative canister

purge valve failure

GO to Pinpoint Test G307413p1.

.

P0442

Leak detected. 40

thou

Fuel tank filler cap seal

defective

System leak (canister

damage, pipework

damage)

Canister close valve

leaking

Fuel tank leak

Check filler cap, system pipework,

fuel tank. GO to Pinpoint Test

G307413p2.

. For fuel tank information, <<310-

01>> Where K-Line or Vacutec

equipment is available, carry out the

appropriate test. See bulletin 05.1-

29, or Vacutec operating instructions

P0443

Canister purge

valve malfunction

Canister purge valve

failure

Carry out system pressure check (K-

Line or Vacutec equipment. See

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст